EN 1034-6:2005

(Main)Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 6: Calender

Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 6: Calender

This European Standard applies to calenders intended for use in paper making and finishing and shall be

used together with EN 1034-1:2000. It deals with all significant hazards listed in clause 4. Related safety

requirements and/or measures are described in clause 5.

It does not cover hazards connected with lifting operations required for changing rolls, inserting reels into the

unwinding unit, removal of reels from the winding unit and heating systems for heating calender rolls..

This European Standard is not applicable to calenders that have been manufactured before the date of

publication of this standard.

Sicherheit von Maschinen - Sicherheitstechnische Anforderungen für Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 6: Kalander

Diese Europäische Norm gilt für Kalander der Papierherstellung und -ausrüstung und ist gemeinsam mit EN 1034-1:2000 anzuwenden. Es werden die in Abschnitt 4 aufgelisteten signifikanten Gefährdungen behandelt. Die entsprechenden Sicherheitsanforderungen und/oder Maßnahmen enthält Abschnitt 5.

Nicht behandelt werden die Gefährdungen der Hebeeinrichtungen, die zum Wechseln der Walzen, Einlegen der Rollen in die Abrollung und Entnehmen der Rollen aus der Aufrollung bestimmt sind, sowie Heizsysteme zum Erwärmen von Kalanderwalzen.

Diese Europäische Norm gilt nicht für Kalander, die hergestellt wurden, bevor CEN die Norm veröffentlichte.

Sécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 6: Calandres

La présente norme européenne s‘applique aux calandres destinées à la fabrication et à la finition du papier et doit être appliqué conjointement avec l'EN 1034-1:2000.

Elle traite tous les phénomènes dangereux significatifs, les situations dangereuses et les évènements dangereux qui s'appliquent aux défibreurs lorsqu'ils sont utilisés dans des conditions normales et conformément aux conditions prévisibles du fabricant (voir Article 4).

Les phénomènes dangereux liés aux dispositifs de levage, qui sont destinés au remplacement des cylindres, à la mise en place des bobines dans l’unité de déroulage et à la préhension des bobines de l'unité d’enroulage, ainsi qu’aux systèmes de chauffage destinés au réchauffement des cylindres de calandre ne sont pas traités dans la présente norme.

La présente norme européenne ne s’applique pas aux calandres qui ont été fabriquées avant sa publication par le CEN.

Varnost strojev – Varnostne zahteve za načrtovanje in konstrukcijo strojev in opreme za izdelavo papirja – 6. del: Kalander

General Information

- Status

- Withdrawn

- Publication Date

- 06-Dec-2005

- Withdrawal Date

- 01-Dec-2009

- Technical Committee

- CEN/TC 198 - Printing and paper machinery - Safety

- Drafting Committee

- CEN/TC 198/WG 2 - Paper Machinery

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Dec-2009

- Completion Date

- 02-Dec-2009

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

Control Union Certifications

Global certification for agriculture and sustainability.

Gozdarski inštitut Slovenije

Slovenian Forestry Institute. Forest management certification support, timber testing.

Sponsored listings

Frequently Asked Questions

EN 1034-6:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 6: Calender". This standard covers: This European Standard applies to calenders intended for use in paper making and finishing and shall be used together with EN 1034-1:2000. It deals with all significant hazards listed in clause 4. Related safety requirements and/or measures are described in clause 5. It does not cover hazards connected with lifting operations required for changing rolls, inserting reels into the unwinding unit, removal of reels from the winding unit and heating systems for heating calender rolls.. This European Standard is not applicable to calenders that have been manufactured before the date of publication of this standard.

This European Standard applies to calenders intended for use in paper making and finishing and shall be used together with EN 1034-1:2000. It deals with all significant hazards listed in clause 4. Related safety requirements and/or measures are described in clause 5. It does not cover hazards connected with lifting operations required for changing rolls, inserting reels into the unwinding unit, removal of reels from the winding unit and heating systems for heating calender rolls.. This European Standard is not applicable to calenders that have been manufactured before the date of publication of this standard.

EN 1034-6:2005 is classified under the following ICS (International Classification for Standards) categories: 85.100 - Equipment for the paper industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1034-6:2005 has the following relationships with other standards: It is inter standard links to EN 1034-6:2005+A1:2009; is excused to EN 1034-1:2000. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1034-6:2005 is associated with the following European legislation: EU Directives/Regulations: 98/37/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1034-6:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sicherheit von Maschinen - Sicherheitstechnische Anforderungen für Konstruktion und Bau von Maschinen der Papierherstellung und Ausrüstung - Teil 6: KalanderSécurité des machines - Prescriptions de sécurité pour la conception et la construction de machines de fabrication et de finition du papier - Partie 6: CalandresSafety of machinery - Safety requirements for the design and construction of paper making and finishing machines - Part 6: Calender85.100Oprema za papirno industrijoEquipment for the paper industry21.020Characteristics and design of machines, apparatus, equipment13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 1034-6:2005SIST EN 1034-6:2006en01-september-2006SIST EN 1034-6:2006SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1034-6December 2005ICS 85.100 English VersionSafety of machinery - Safety requirements for the design andconstruction of paper making and finishing machines - Part 6:CalenderSécurité des machines - Exigences techniques de sécuritépour la conception et la construction de machines defabrication et de finition du papier - Partie 6: CalandreSicherheit von Maschinen - SicherheitstechnischeAnforderungen für Konstruktion und Bau von Maschinender Papierherstellung und Ausrüstung - Teil 6: KalanderThis European Standard was approved by CEN on 4 November 2005.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1034-6:2005: ESIST EN 1034-6:2006

Relationship between this

European

Standard and the Essential Requirements

of EU Directive 98/37/EC.25

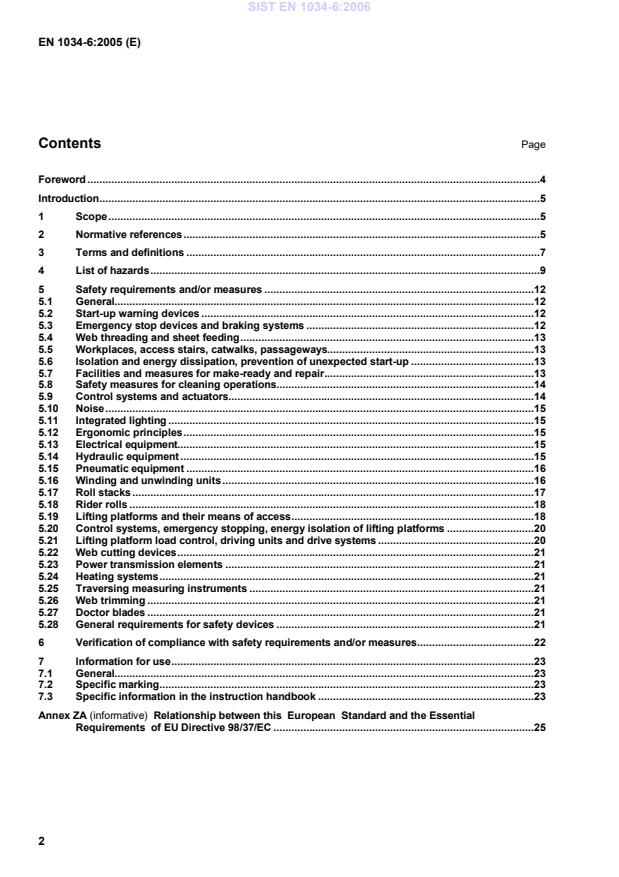

calender (example).9 Figure 3 — Example of an access to a lifting platform in upper position.19

Tables Table 1 — List of significant hazards.9 Table 2 — Methods used to verify safety requirements and/or measures.22

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are indicated in the scope of this European Standard.

For machines that have been designed and built according to the provisions of this type C standard, the following stipulation applies: When provisions of this type C standard are different from those which are stated in type A or B standards or from provisions made in EN 1034-1:2000, the provisions of this type C standard take precedence over the provisions of the other standards. 1 Scope This European Standard applies to calenders intended for use in paper making and finishing and shall be used together with EN 1034-1:2000. It deals with all significant hazards listed in clause 4. Related safety requirements and/or measures are described in clause 5.

It does not cover hazards connected with lifting operations required for changing rolls, inserting reels into the unwinding unit, removal of reels from the winding unit and heating systems for heating calender rolls. This European Standard is not applicable to calenders that have been manufactured before the date of publication of this standard. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

prEN 81-41:2004, Safety rules for the construction and installation of lifts — Special lifts for the transport of persons and goods — Part 41: Vertical lifting platforms intended for use by persons with impaired mobility EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs EN 349:1993, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 418:1992, Safety of machinery — Emergency stop equipment — Functional aspects — Principles for design EN 563:1994, Safety of machinery — Temperatures of touchable surfaces — Ergonomics data to establish temperature limit values for hot surfaces EN 894-1:1997, Safety of machinery — Ergonomic requirements for the design of displays and control actuators — Part 1: General principles for human interactions for displays and control actuators EN 894-2:1997, Safety of machinery — Ergonomic requirements for the design of displays and control actuators — Part 2: Displays

EN 954-1:1996, Safety of machinery — Safety related parts of control systems — Part 1: General principles for design EN 982:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Hydraulics EN 983:1996, Safety of machinery — Safety requirements for fluid power systems and their components —Pneumatics EN 999:1998, Safety of machinery — The positioning of protective equipment in respect of approach speeds of parts for the human body EN 1034-1:2000, Safety of machinery — Safety requirements for the design and construction of paper making and finishing machines - Part 1: Common requirements EN 1037:1995, Safety of machinery — Prevention of unexpected start-up EN 1050:1996, Safety of machinery — Principles for risk assessment EN 1088:1995, Safety of machinery — Interlocking devices associated with guards — Principles for design and selection EN 1127-1:1997, Explosive atmospheres — Explosion prevention and protection — Part 1: Basic concepts and methodology

EN 1760-1:1997, Safety of machinery — Pressure-sensitive safety devices — Part 1: General principles for the design and testing of pressure-sensitive mats and pressure-sensitive floors

EN 1760-2:2001, Safety of machinery — Pressure-sensitive safety devices — Part 2: General principles for the design and testing of pressure-sensitive edges and pressure-sensitive bars

EN 13023:2003, Noise measurement methods for printing, paper converting, paper making machines and auxiliary equipment — Accuracy categories 2 and 3 EN 60204-1:1997, Safety of machinery — Electrical equipment — Part 1: General requirements

(IEC 60204-1:1997)

EN 60024-11:2000, Safety of machinery — Electrical equipment — Part 11: High-voltage equipment for voltages above 1 000 V AC or 1 500 V DC, but not more than 36 kV (IEC 60204-11:2000) EN 61000-6-2:2001, Electromagnetic compatibility (EMC) — Part 6-2: Generic standard — Immunity —

Part 2: Industrial environment (IEC 61000-6-2:1999, modified) EN 61496-1:2004, Safety of machinery — Electro-sensitive protective equipment — Part 1: General requirements and tests (IEC 61496-1:2004, modified) prEN 61496-2:2005, Safety of machinery — Electro-sensitive protective equipment — Part 2: Particular requirements for equipment using active opto-electronic protective devices (AOPDs) (IEC 61496-2:2005) EN ISO 11957:1996, Acoustics — Determination of sound insulation performance of cabins — Laboratory and in situ measurements (ISO 11957:1996) EN ISO12100-1:2003, Safety of machinery — Basic concepts — General principles for design — Part 1: Basic terminology, methodology (ISO 12100-1:2003) SIST EN 1034-6:2006

machine using two or more adjacent rolls for glazing, smoothing, calibrating or embossing of paper, including the winding unit and unwinding unit if fitted, see 3.2 3.2

off-line calender

calender with winding and unwinding unit. An example is illustrated in Figure 1 3.3

on-line calender

calender integrated into a paper making or coating machine. An example is illustrated in Figure 2 3.4

sheet calender

calender used for glazing individual sheets of paper 3.5

lifting platform

lifting device integrated into a calender for people to carry out specific tasks, e.g. web threading, cleaning, maintenance. Often two lifting platforms are provided on the roll stack

NOTE: Safety devices are not shown.

Key 1 Unwinding unit 2 Lifting appliance 3 Roll stack

4 Lifting platform 5 Shell storage

6 Winding unit

Figure 1 — Off-line calender (example)

NOTE: Safety devices are not shown.

Key 1 Doctor

2 First nip 3 Doctor

4 Second nip

Figure 2 — On-line

calender (example) 4 List of hazards This clause contains all the significant hazards, as far as they are dealt with in this standard, which are identified by risk assessment in accordance with EN 1050 as significant for this type of machinery and which require action to eliminate or reduce the risk. When carrying out the risk assessment, the machine designer

has to check whether the list of hazards in Table 1 is complete and applicable with respect to the particular machine. Table 1 — List of significant hazards No. from Table A.1

of EN 1050:1996 Hazards EN 1034-6:2005 EN 1034-1: 2000 1 Mechanical hazards due to:

1.1 Crushing hazard 5.16.3; 5.16.4; 5.16.8; 5.16.9; 5.17.3; 5.19.3; 5.19.4; 5.19.5; 5.19.6; 5.19.8; 5.19.9; 5.25; 5.27.1 5.1; 5.3; 1.2 Shearing hazard 5.16.8; 5.19.5; 5.19.8; 5.25 5.1 1.3 Cutting or severing hazard 5.16.8; 5.22.1; 5.22.2; 5.26.2; 5.27.1; 5.27.2 5.11; 5.12

of EN 1050:1996 Hazards EN 1034-6:2005 EN 1034-1: 2000 1.4 Entanglement hazard 5.8; 5.16.7; 5.23, 5.26.1, 5.28.1; 5.28.2 5.2 1.5 Drawing-in or trapping hazard 5.4.5; 5.8.3; 5.16.3; 5.16.6; 5.17.1; 5.18; 5.23; 5.27.1; 5.28.1; 5.28.2 5.1; 5.4 1.6 Impact hazard 5.16; 5.19.6; 5.19.9; 5.23 5.1 1.8 Friction or abrasion hazard 5.7.1; 5.8; 5.23 5.1 1.9 High-pressure fluid injection or ejection hazard 5.14.1; 5.18.1 5.24 2. Electrical hazards due to:

2.1 Contact of persons with live parts 5.13 5.23 2.2 Contact of persons with parts that have become live under faulty conditions 5.13 5.23 2.4 Electrostatic phenomena 5.13 5.23 3 Thermal hazards, resulting in:

3.1 Burns by contact 5.8.4; 5.24, Clause 7 5.13; 5.17 4 Hazards generated by noise, resulting in:

4.1 Hearing loss and other physiological disorders

5.10, clause 7 5.15 4.2 Interference with speech communication, acoustic signals 5.10; clause 7 5.15 6 Hazards generated by radiation, particularly:

6.4 Ionizing radiation sources 5.25 5.20 6.5 Lasers 5.25 5.21 7 Hazards generated by materials and substances processed, used or exhausted by the machinery, for example:

7.1 Hazard resulting from the inhalation of asbestos 5.17.4; clause 7 5.16 7.2 Fire hazard 5.13 5.13; 5.18; 5.19; 5.23

8 Hazards generated by neglecting ergonomic principles in machinery design, for example by:

8.1 Unhealthy posture or excessive effort 5.4; 5.12; clause 7 5.22 8.2 Inadequate consideration of hand/arm or foot/leg anatomy 5.4; 5.12; clause 7 5.22 8.4 Inadequate local lighting 5.11 5.18 9 Combination of hazards 5.2.1; 5.2.2; 5.4; 5.6; 5.7; 5.8.1; 5.28; clause 7 5.6 SIST EN 1034-6:2006

of EN 1050:1996 Hazards EN 1034-6:2005 EN 1034-1: 2000 10 Unexpected start-up, unexpected overrun/overspeed:

10.1 Failure/disorder of the control system 5.2.3; 5.3.3; 5.3.4; 5.3.5; 5.6.2; 5.9.1; 5.9.2; 5.9.3; 5.9.4; 5.9.5; 5.13; 5.16.4; 5.16.5; 5.16.8; 5.17.1; 5.17.3; 5.20 5.14, 5.23 10.2 Restoration of energy supply after an interruption 5.6; 5.13; 5.14.2; 5.15.2; 5.20.6 5.8 10.3 External influences on electrical equipment 5.13 5.23 10.6 Errors made by the operator due to mismatch of machinery with human characteristics 5.9.1; 5.13; 5.20.2 5.14 11 Impossibility of stopping the machine in the

best possible conditions 5.3; 5.6; 5.14.2; 5.15.2; 5.20.1

14 Failure of the control circuit 5.2.3; 5.3.3; 5.3.4; 5.3.5; 5.6.2; 5.9.1; 5.9.2; 5.9.3; 5.9.4; 5.9.5; 5.13; 5.16.4; 5.16.5; 5.16.8; 5.17.1; 5.17.3; 5.20 5.14 15

Errors of fitting 5.7.3; 5.7.4; clause 7 clause 7 17 Unforeseen ejection of objects 5.16.1; 5.16.2; 5.19.7; 5.23 5.2 18 Loss of stability 5.9.2; 5.16.2; 5.21 clause 7 19 Slip, trip and fall of persons 5.5; 5.19.2; 5.19.4; 5.19.10 5.5 27 Mechanical hazards resulting from lifting processes

27.1 from load falls, collisions 5.16.1; 5.16.2; 5.16.5; 5.16.10; 5.19.7

27.6 from inadequate selection of lifting equipment 5.16.10; clause 7

27.9 from the effect of load on persons 5.19.7; clause 7

29 Hazards generated by neglecting ergonomic principles in lifting processes

29.1 Insufficient visibility from the driving position 5.16.1

34 Mechanical hazards and hazardous events due to:

34.1 Inadequate mechanical strength – inadequate working coefficients 5.20; 5.21.2; 5.21.3

34.3 Failing of controls in person carrier (function, priority) 5.20.3; 5.20.4; .5.21.1

34.4 Overspeed of person carrier 5.20.5

35 Falling of person from person carrier 5.19.2; 5.19.4

Falling or overturning of person carrier 5.21

of EN 1050:1996 Hazards EN 1034-6:2005 EN 1034-1: 2000 37 Human error, human behaviour 5.2.4; 5.3.6; 5.4.4 ; 5.6.3; 5.7.4; 5.8.4; 5.10.4; 5.16.10; 5.17.1; 5.17.2; 5.17.4; 5.19.1; 5.16.6; 5.20.3; 5.21.2; 5.27.2; 5.28.2; clause 7 clause 7

Emergency measures 5.3; 5.8.2; 5.20.1; 5.20.3; 5.20.4; clause 7 5.1.3; 5.7; 5.18; 5.19 5 Safety requirements and/or measures 5.1 General Calenders shall comply with the safety requirements and/or measures of this clause. In addition, the machinery shall be designed according to the principles of EN ISO 12100-2:2003 for hazards relevant but not significant, which are not dealt with by this European Standard (for example, sharp edges). 5.2 Start-up warning devices 5.2.1 For start-up warning devices on on-line calenders, 5.6.1 of EN 1034-1:2000 shall apply. 5.2.2 Start-up warning devices on off-line calenders shall comply with category B specified in 5.6.2 of

EN 1034-1:2000. 5.2.3 The control system of start-up warning devices shall comply with at least category 1 of

EN 954-1:1996 for

conventional control systems and category 2 of EN 954-1:1996 for electronic control systems. 5.2.4 The use of start-up warning devices shall be described in the instruction handbook. 5.3 Emergency stop devices and braking systems 5.3.1

Calenders shall be equipped with an emergency stop device. Emergency stop devices shall comply with the requirements of 5.7 of EN 1034-1:2000 and EN 418:1992 and shall act on all hazardous movements of the machine. This includes the movement of electric, hydraulic and pneumatic drives of calender rolls, unwinding, winding, threading, sheet feed devices and lifting platforms.

Actuators for emergency stopping are also required in areas that need to be accessed for cleaning. As a deviation from 5.7 of EN 1034-1:2000, in cases where it is not practicable to complete the whole stop procedure with a closed roll nip, it is permitted to open the nip even before standstill is attained if the safety devices are designed so that they prevent the drawing-in hazard with the nip both closed and open. Additional requirements for emergency stop devices of lifting platforms are contained in 5.20.1.

5.3.2

Calenders shall be provided with braking devices which operate on actuation of the emergency stop device. This requirement can be fulfilled, for example, by mechanical brakes or electric regenerative brakes. Braking devices shall operate in such a way that the stopping time of the machine does not exceed the shortest possible start-up time following emergency stopping. 5.3.3

The control system of emergency stop devices shall comply with at least category 3 of

EN 954-1.1996.

The emergency stop device shall be effective according to stop category 1 from 4.1.5 of

EN 418:1992. SIST EN 1034-6:2006

The control system of electric brakes shall comply with at least category 2 of EN 954-1:1996. Any fault in the brake control system shall lead to emergency stopping according to category 0 from 5.1.4 of

EN 418:1992. 5.3.5

The emergency stop control system of on-line calenders shall be integrated into the emergency stop control system of the paper/smoothing machine in such a way that the emergency stop devices of the other machine units also act on the calender and the calender emergency stop devices also act on the other machine units

It shall be ensured that all the safety-related parts of the linked emergency stop control system correspond to category 3 according to EN 954-1:1996.

5.3.6

The use and checking procedures of emergency stop devices shall be described in the instruction handbook. 5.4 Web threading and sheet feeding 5.4.1

For threading the paper web on off-line calenders with high roll stacks, for example super calenders, lifting platforms are required which satisfy the requirements of 5.19 to 5.21. 5.4.2

On-line calenders shall be provided with a threading device, for example, a rope threading device. 5.4.3

Sheet calenders require devices for feeding the paper sheets. 5.4.4

Safe working practices for threading the paper web and joining the web ends shall be described in the instruction handbook. 5.4.5 The wrapping points of the threading device according to 5.4.2 and the device according to 5.4.3 shall be safeguarded in accordance with 5.4.2 of EN 1034-1:2000. 5.5 Workplaces, access stairs, catwalks, passageways

The requirements laid down in 5.5 of EN 1034-1:2000 and in EN ISO 14122-1:2000, EN ISO 14122-2:2000 and EN ISO 14122-3:2000 shall be fulfilled. Additional requirements are specified in 5.19. 5.6 Isolation and energy dissipation, prevention of unexpected start-up 5.6.1

For isolation and energy dissipation of electric, pneumatic and hydraulic equipment from their respective power source, independent means shall be provided in accordance with 5.8 of EN 1034-1:2000 for the calendar and each lifting platform. The respective requirements from EN 1037:1996; EN 60204-1:1997 and, as far as applicable, EN 60204-11:2000 shall be fulfilled. Additional stipulations shall be observed for energy isolation of lifting platforms in accordance with 5.20.6. 5.6.2

The main control panel shall be equipped with independent means ensuring prevention of unexpected start-up of the calendar and or each lifting platform in accordance with 5.8.2 of EN 1034-1:2000 and 5.4 of EN IEC 60204-1:1997.

The associated controls shall be at least category 3 as specified in

EN 954-1:1996. 5.6.3

The use of the devices for energy isolation and prevention of unexpected start-up shall be described in the instruction handbook.

5.7 Facilities and measures for make-ready and repair 5.7.1

The requirements of 5.9 of EN 1034-1:2000 shall be fulfilled. Crawl speeds of calenders shall be as low as possible with a maximum of 0,25 m/s (15 m/min). Crawl speeds shall be indicated in the instruction handbook.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...