EN 14591-2:2007

(Main)Explosion prevention and protection in underground mines - Protective systems - Part 2: Passive water trough barriers

Explosion prevention and protection in underground mines - Protective systems - Part 2: Passive water trough barriers

This standard specifies the requirements for concentrated and distributed passive water trough barriers, and quick-deploy water trough barriers.

This standard specifies the requirements and test methods for water troughs which are used as components of the "water trough barrier" protective system for underground coal mines.

This standard does not apply to active water trough barriers.

Explosionsschutz in untertägigen Bergwerken - Schutzsysteme - Teil 2: Passive Wassertrogsperren

Diese Norm legt die Anforderungen an konzentrierte und aufgeteilte passive Wassertrogsperren und Wassertrog-Schnellsperren fest.

Diese Norm legt auch die Anforderungen und Prüfverfahren für Wassertröge fest, die als Komponenten des Schutzsystems "Wassertrogsperre" im Steinkohlenbergbau unter Tage Verwendung finden.

Diese Norm gilt nicht für aktive Wassertrogsperren.

Protection contre l'explosion dans les mines souterraines - Systèmes de protection - Partie 2: Arrêts-barrages passifs à bacs à l'eau

La présente norme définit les exigences relatives aux arrêts-barrages à eau passifs concentrés, répartis et rapides.

La présente norme définit également les exigences et les méthodes d’essais applicables aux bacs à eau utilisés dans les arrêts-barrages à eau dans les mines de charbon souterraines.

La présente norme ne s'applique pas aux arrêts-barrages à eau actifs.

Preprečevanje eksplozij in zaščita v podzemnih rudnikih - Zaščitni sistemi - 2.del: Pasivne vodne prepreke

General Information

- Status

- Published

- Publication Date

- 20-Mar-2007

- Withdrawal Date

- 29-Sep-2007

- Technical Committee

- CEN/TC 305 - Potentially explosive atmospheres - Explosion prevention and protection

- Drafting Committee

- CEN/TC 305/WG 5 - Equipment and protection systems for mining

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 17-Jul-2024

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 07-Mar-2023

- Effective Date

- 07-Mar-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

- Effective Date

- 22-Dec-2008

Overview

EN 14591-2:2007 - “Explosion prevention and protection in underground mines - Protective systems - Part 2: Passive water trough barriers” (CEN) defines requirements and test methods for passive water trough barriers used in underground coal mines. The standard covers concentrated, distributed, and quick‑deploy passive water trough barriers as components of an explosion‑mitigation system. It specifies construction, performance testing, marking, installation arrangements and user information; it does not apply to active water trough systems.

Key topics and technical requirements

- Scope and purpose: Water trough barriers are intended to extinguish explosion flames in roadways by dispersing water from destroyed troughs ahead of the flame front, preventing propagation and transition to detonation.

- Types covered: Concentrated and distributed barrier configurations, plus quick‑deploy (portable) trough barriers (Annex A).

- Construction requirements: Material, container shape, capacity and cover design; framework structures and additional fittings; water level indicators and marking.

- Testing and performance:

- Mechanical tests for strength and shape retention.

- Electrostatic property tests and assessment procedures.

- Heat reaction, water dispersion and full‑scale extinguishing efficiency tests (Annex B provides example procedures).

- Fire‑resistance tests and acceptance criteria.

- Tables specify acceptable container dimensions and water content for standard trough sizes.

- Installation and layout: Detailed guidance on arrangement of troughs within roadway cross‑sections, barrier configuration in workings, spacing and cordon examples (informative Annex D).

- Documentation and marking: Requirements for marking troughs and barriers and user instructions (Annexes C, E, F).

- Regulatory linkage: Informative Annex ZA relates the standard to EU Directive 94/9/EC (explosive atmospheres).

Practical applications and users

This standard is essential for:

- Mine safety engineers and safety managers designing explosion‑protection systems in underground coal mines.

- Equipment manufacturers and suppliers of water trough barriers for product design, type testing and CE/national standard compliance.

- Testing laboratories performing mechanical, electrostatic and full‑scale extinguishing tests.

- Regulators and certifying bodies assessing conformity with CEN requirements and relevant EU directives.

- Operational personnel responsible for installation, inspection, marking and quick deployment of passive barriers.

EN 14591-2:2007 provides prescriptive, testable criteria that improve safety by standardizing design, testing and installation of water trough barriers for explosion prevention in underground mining environments.

Related standards

- EN 14591 series (Part 1: 2‑bar explosion‑proof ventilation structure; Part 4: Automatic extinguishing systems for road headers)

- EN 13463-1 (non‑electrical equipment for potentially explosive atmospheres)

- EN ISO 4589-2, ISO 554 (referenced test/conditioning standards)

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

Bureau Veritas Chile

Bureau Veritas certification services in Chile.

Bureau Veritas Peru

Bureau Veritas certification services in Peru.

Sponsored listings

Frequently Asked Questions

EN 14591-2:2007 is a standard published by the European Committee for Standardization (CEN). Its full title is "Explosion prevention and protection in underground mines - Protective systems - Part 2: Passive water trough barriers". This standard covers: This standard specifies the requirements for concentrated and distributed passive water trough barriers, and quick-deploy water trough barriers. This standard specifies the requirements and test methods for water troughs which are used as components of the "water trough barrier" protective system for underground coal mines. This standard does not apply to active water trough barriers.

This standard specifies the requirements for concentrated and distributed passive water trough barriers, and quick-deploy water trough barriers. This standard specifies the requirements and test methods for water troughs which are used as components of the "water trough barrier" protective system for underground coal mines. This standard does not apply to active water trough barriers.

EN 14591-2:2007 is classified under the following ICS (International Classification for Standards) categories: 13.230 - Explosion protection; 73.100.99 - Other mining equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14591-2:2007 has the following relationships with other standards: It is inter standard links to prEN 14591-2, prEN 14591-3, EN ISO 80079-36:2016, EN ISO 4589-2:2017, EN 915:1996, EN 14591-2:2007/AC:2008; is excused to prEN 14591-2, prEN 14591-3. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14591-2:2007 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 94/9/EC; Standardization Mandates: M/BC/CEN/92/46. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14591-2:2007 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Explosionsschutz in untertägigen Bergwerken - Schutzsysteme - Teil 2: Passive WassertrogsperrenProtection contre l'explosion dans les mines souterraines - Systemes de protection - Partie 2: Arrets-barrages passifs a bacs a l'eauExplosion prevention and protection in underground mines - Protective systems - Part 2: Passive water trough barriers73.020Rudarstvo in kamnolomsko izkopavanjeMining and quarrying13.230Varstvo pred eksplozijoExplosion protectionICS:Ta slovenski standard je istoveten z:EN 14591-2:2007SIST EN 14591-2:2007en,fr,de01-julij-2007SIST EN 14591-2:2007SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14591-2March 2007ICS 13.230; 73.100.99 English VersionExplosion prevention and protection in underground mines -Protective systems - Part 2: Passive water trough barriersProtection contre l'explosion dans les mines souterraines -Systèmes de protection - Partie 2: Arrêts-barrages passifsà bacs à l'eauExplosionsschutz in untertägigen Bergwerken -Schutzsysteme - Teil 2: Passive WassertrogsperrenThis European Standard was approved by CEN on 4 February 2007.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2007 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14591-2:2007: ESIST EN 14591-2:2007

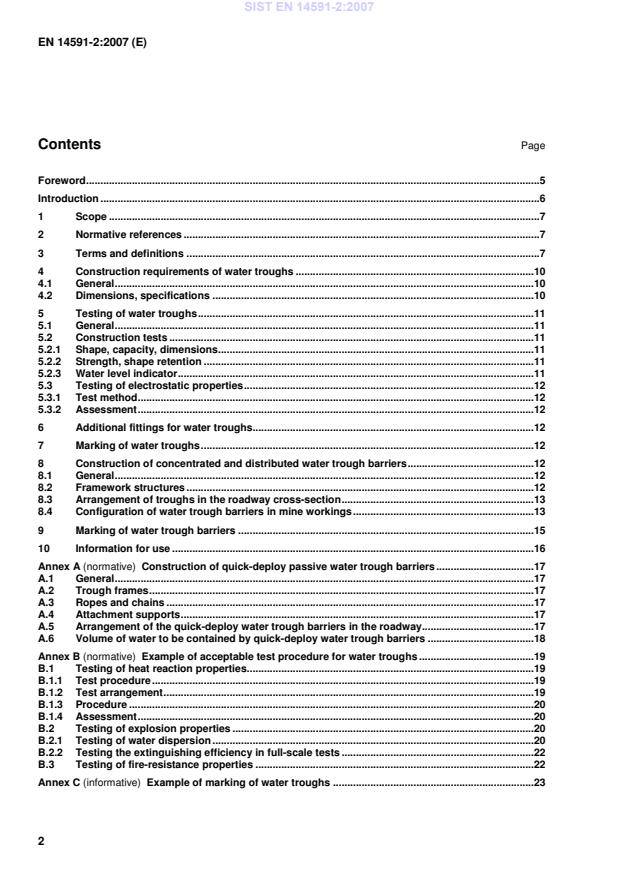

Construction of quick-deploy passive water trough barriers.17 A.1 General.17 A.2 Trough frames.17 A.3 Ropes and chains.17 A.4 Attachment supports.17 A.5 Arrangement of the quick-deploy water trough barriers in the roadway.17 A.6 Volume of water to be contained by quick-deploy water trough barriers.18 Annex B (normative)

Example of acceptable test procedure for water troughs.19 B.1 Testing of heat reaction properties.19 B.1.1 Test procedure.19 B.1.2 Test arrangement.19 B.1.3 Procedure.20 B.1.4 Assessment.20 B.2 Testing of explosion properties.20 B.2.1 Testing of water dispersion.20 B.2.2 Testing the extinguishing efficiency in full-scale tests.22 B.3 Testing of fire-resistance properties.22 Annex C (informative)

Example of marking of water troughs.23 SIST EN 14591-2:2007

Examples for configuration of water troughs.24 Annex E (informative)

Example for marking of water trough barriers.44 Annex F (normative)

Instructions for water trough barriers.45 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 94/9/EC.46 Bibliography.48

Figures Figure 1 — Trough group, plan view.9 Figure 2 — Water trough type A (side elevations).10 Figure 3 — Water trough type B (side elevations).10 Figure 4 — General rules for water trough barriers in mine workings.15 Figure A.1 — Quick-deploy water trough barrier (example).18 Figure B.1 — Test arrangement for determining heat reaction properties.19 Figure B.2 — Test arrangement for investigating water dispersion.21 Figure D.1 — Location of water troughs, sectional view.24 Figure D.2 — Arrangement of troughs in roadway cross-section – coverage.25 Figure D.3 — Arrangement of troughs in roadway cross-section – horizontal distances.26 Figure D.4 — Arrangement of troughs in the roadway cross-section – vertical distances.27 Figure D.5 — Arrangement of troughs in the roadway cross-section – vertical distances.27 Figure D.6 — Arrangement of troughs in the roadway cross-section – transverse and longitudinal position.28 Figure D.7 — Arrangement of troughs in the roadway cross-section – Obscurement by supports or fixtures.29 Figure D.8 — Arrangement of troughs in the roadway cross-section – Obscurement by supports or fixtures.30 Figure D.9 — Arrangement of troughs in the roadway cross-section – Obscurement by troughs.30 Figure D.10 — Arrangement of vertically-offset troughs in the roadway cross-section, distance < 1.2 m.31 Figure D.11 — Barrier cordon for a roadway intersection.32 Figure D.12 — Barrier cordon for shafts and insets.33 Figure D.13 — Barrier cordon for closely spaced roadway intersections.34 Figure D.14 — Barrier cordon for closely spaced junctions – Calculation examples for explosion-barrier setting distances.35 SIST EN 14591-2:2007

ISO 554, Standard atmospheres for conditioning and/or testing — Specifications 3 Terms and definitions For the purposes of this document, the following terms and definitions apply: 3.1 explosion barrier device intended effectively to suppress coal-dust and firedamp explosions and to limit their physical impact 3.2 water trough barrier explosion barrier in which the extinguishing medium, namely water, is contained in water troughs 3.3 water trough container to hold the extinguishing medium, namely water, together with matching cover 3.4 trough group any troughs located within a roadway section of no more than 3 m in length in the distributed barrier NOTE See Figure 1. A group can be composed of 1 to 3 rows of troughs. 3.5 roadway cross-section area bounded by the roadway floor and lagging or, where no lagging is installed, by the surrounding rock

Key 1 Trough group of one trough row 2 Trough group of two trough rows 3 Trough group of three trough rows Figure 1 — Trough group, plan view SIST EN 14591-2:2007

Figure 2 — Water trough type A (side elevations)

Figure 3 — Water trough type B (side elevations) SIST EN 14591-2:2007

Table 2 — Container dimensions and water content for 90 litre water troughs

Container dimensions mm Water trough type a b1 b2 h l1 l2 Capacity l Type A 25 ± 2 500 ± 2,5 > 415 275 ± 5 760 ± 5 > 675 90 ± 4,5 Type B 20 ± 2 500 ± 2,5 > 415 320 ± 5 760 ± 5 > 675 90 ± 4,5 The covers shall be designed to give a flush fit with the outer rim of the containers. 5 Testing of water troughs 5.1 General The test pieces for the tests described below comprise one or several water troughs which shall come from the same production run. The number of test pieces required is determined by the respective testing station. When issuing contracts for testing, each testing station shall be provided not only with descriptions and drawings of the equipment (e.g. containers, covers, floats and lid holders), but also with precise data on the composition of the material used. For an example of acceptable test procedures, see Annex B. NOTE Other test procedures are under consideration. 5.2 Construction tests 5.2.1 Shape, capacity, dimensions The specifications laid down in 4.2 shall be used as a basis for testing the shape, dimensions and capacity of the water troughs. 5.2.2 Strength, shape retention When a uniform static load is applied to a stack of water troughs, composed of five containers fitted one inside the other, by a force of 500 N (direction of force at right angles to the container bottoms), the containers shall not suffer damage or permanent deformation. During subsequent unstacking, the containers shall not be wedged together and shall not be damaged. 5.2.3 Water level indicator The minimum water level indicator shall be checked for correct operation and accuracy. The maximum margin of indicator error shall be ± 5 %. SIST EN 14591-2:2007

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...