EN 14180:2014

(Main)Sterilizers for medical purposes - Low temperature steam and formaldehyde sterilizers - Requirements and testing

Sterilizers for medical purposes - Low temperature steam and formaldehyde sterilizers - Requirements and testing

This European Standard specifies requirements and tests for LTSF sterilizers, which use a mixture of low temperature steam and formaldehyde as sterilizing agent, and which are working below ambient pressure only.

These sterilizers are primarily used for the sterilization of heat labile medical devices in health care facilities.

This European Standard specifies minimum requirements:

- for the performance and design of sterilizers to ensure that the process is capable of sterilizing medical devices;

- for the equipment and controls of these sterilizers necessary for the validation and routine control of the sterilization processes.

Sterilisatoren für medizinische Zwecke - Niedertemperatur-Dampf-Formaldehyd-Sterilisatoren - Anforderungen und Prüfung

Diese Europäische Norm legt Anforderungen und Prüfverfahren für NTDF-Sterilisatoren fest, in denen als Sterilisiermittel ein Gemisch von Niedertemperatur-Dampf und Formaldehyd angewendet wird und die nur unterhalb des Umgebungsdruckes arbeiten.

Diese Sterilisatoren werden in erster Linie in medizinischen Einrichtungen zur Sterilisation hitzeempfindlicher Medizinprodukte verwendet.

Diese Europäische Norm legt Mindest-Anforderungen zu folgenden Punkten fest,

für die Leistung und Konstruktion von Sterilisatoren zur Sicherstellung, dass das Verfahren in der Lage ist, Medizinprodukte zu sterilisieren;

an die Ausrüstung und Steuerung dieser Sterilisatoren, die für die Validierung und Routineüberwachung des Sterilisationsverfahrens erforderlich sind.

Stérilisateurs à usage médical - Stérilisateurs à la vapeur et au formaldéhyde à basse température - Exigences et essais

La présente Norme européenne spécifie les exigences et les essais relatifs aux stérilisateurs à la vapeur et au formaldéhyde à basse température, utilisant comme agent stérilisant un mélange à basse température de vapeur d'eau et de formaldéhyde et fonctionnant uniquement à une pression inférieure à la pression atmosphérique.

Ces stérilisateurs sont utilisés en priorité pour stériliser les dispositifs médicaux thermolabiles dans les centres de soins.

La présente Norme européenne spécifie les exigences minimales :

- de performances et de conception des stérilisateurs afin de garantir que le procédé permet de stériliser des dispositifs médicaux ;

- pour le matériel et les systèmes nécessaires aux opérations de validation et de contrôle de routine du procédé de stérilisation.

Sterilizatorji za uporabo v medicini - Sterilizatorji s paro z nizko temperaturo in s formaldehidom - Zahteve in preskušanje

Standard EN 14180 določa zahteve in preskuse za sterilizatorje s paro z nizko temperaturo in s formaldehidom kot sterilizacijskim sredstvom, ki delujejo samo pri nizkem zračnem tlaku. Ti sterilizatorji se primarno uporabljajo v zdravstvenih ustanovah za sterilizacijo medicinskih pripomočkov, občutljivih na vročino. Ta evropski standard določa minimalne zahteve: – za delovanje in načrtovanje sterilizatorjev za sterilizacijo medicinskih pripomočkov; – za opremo in kontrolnike teh sterilizatorjev, potrebnih za preverjanje in rutinski nadzor med postopkom sterilizacije.

General Information

- Status

- Withdrawn

- Publication Date

- 20-May-2014

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 102 - Sterilizers for medical purposes

- Drafting Committee

- CEN/TC 102/WG 6 - Gas sterilizers

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 02-Apr-2025

- Completion Date

- 11-Feb-2026

- Directive

- Not Harmonized93/42/EEC - Medical devices

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 14180:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sterilizers for medical purposes - Low temperature steam and formaldehyde sterilizers - Requirements and testing". This standard covers: This European Standard specifies requirements and tests for LTSF sterilizers, which use a mixture of low temperature steam and formaldehyde as sterilizing agent, and which are working below ambient pressure only. These sterilizers are primarily used for the sterilization of heat labile medical devices in health care facilities. This European Standard specifies minimum requirements: - for the performance and design of sterilizers to ensure that the process is capable of sterilizing medical devices; - for the equipment and controls of these sterilizers necessary for the validation and routine control of the sterilization processes.

This European Standard specifies requirements and tests for LTSF sterilizers, which use a mixture of low temperature steam and formaldehyde as sterilizing agent, and which are working below ambient pressure only. These sterilizers are primarily used for the sterilization of heat labile medical devices in health care facilities. This European Standard specifies minimum requirements: - for the performance and design of sterilizers to ensure that the process is capable of sterilizing medical devices; - for the equipment and controls of these sterilizers necessary for the validation and routine control of the sterilization processes.

EN 14180:2014 is classified under the following ICS (International Classification for Standards) categories: 11.080.10 - Sterilizing equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14180:2014 has the following relationships with other standards: It is inter standard links to EN 14180:2003+A2:2009, EN 14180:2025, EN 60751:2008, EN 60584-1:2013, EN 61010-1:2010, EN 61010-2-040:2005, EN 61326-1:2013, EN ISO 16396-1:2022, EN 764-7:2002, EN ISO 228-1:2003, EN ISO 11138-1:2006, EN ISO 15223-1:2021, EN ISO 11140-6:2022, EN ISO 14971:2012, EN 868-5:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14180:2014 is associated with the following European legislation: EU Directives/Regulations: 93/42/EEC; Standardization Mandates: M/023. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14180:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sterilizatorji za uporabo v medicini - Sterilizatorji s paro z nizko temperaturo in s formaldehidom - Zahteve in preskušanjeSterilisatoren für medizinische Zwecke - Niedertemperatur-Dampf-Formaldehyd-Sterilisatoren - Anforderungen und PrüfungStérilisateurs à usage médical - Stérilisateurs à la vapeur et au formaldéhyde à basse température - Exigences et essaisSterilizers for medical purposes - Low temperature steam and formaldehyde sterilizers - Requirements and testing11.080.10Sterilizacijska opremaSterilizing equipmentICS:Ta slovenski standard je istoveten z:EN 14180:2014SIST EN 14180:2014en,fr,de01-oktober-2014SIST EN 14180:2014SLOVENSKI

STANDARDSIST EN 14180:2003+A2:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14180

May 2014 ICS 11.080.10 Supersedes EN 14180:2003+A2:2009English Version

Sterilizers for medical purposes - Low temperature steam and formaldehyde sterilizers - Requirements and testing

Stérilisateurs à usage médical - Stérilisateurs à la vapeur et au formaldéhyde à basse température - Exigences et essais

Sterilisatoren für medizinische Zwecke - Niedertemperatur-Dampf-Formaldehyd-Sterilisatoren - Anforderungen und Prüfung This European Standard was approved by CEN on 10 April 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14180:2014 ESIST EN 14180:2014

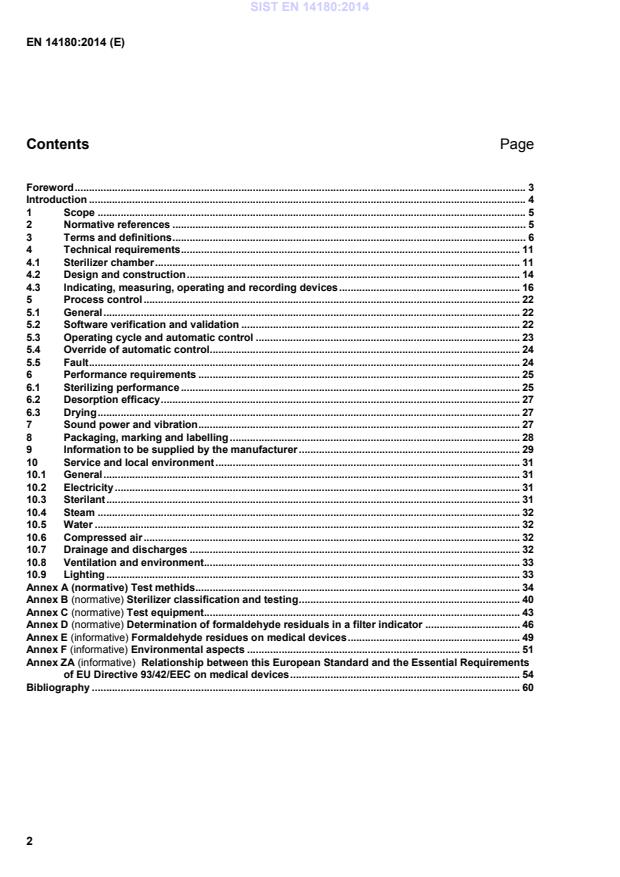

Foreword . 3 Introduction . 4 1 Scope . 5 2 Normative references . 5 3 Terms and definitions . 6 4 Technical requirements . 11 4.1 Sterilizer chamber . 11 4.2 Design and construction . 14 4.3 Indicating, measuring, operating and recording devices . 16 5 Process control . 22 5.1 General . 22 5.2 Software verification and validation . 22 5.3 Operating cycle and automatic control . 23 5.4 Override of automatic control . 24 5.5 Fault . 24 6 Performance requirements . 25 6.1 Sterilizing performance . 25 6.2 Desorption efficacy . 27 6.3 Drying . 27 7 Sound power and vibration . 27 8 Packaging, marking and labelling . 28 9 Information to be supplied by the manufacturer . 29 10 Service and local environment . 31 10.1 General . 31 10.2 Electricity . 31 10.3 Sterilant . 31 10.4 Steam . 32 10.5 Water . 32 10.6 Compressed air . 32 10.7 Drainage and discharges . 32 10.8 Ventilation and environment . 33 10.9 Lighting . 33 Annex A (normative) Test methids . 34 Annex B (normative) Sterilizer classification and testing . 40 Annex C (normative) Test equipment . 43 Annex D (normative) Determination of formaldehyde residuals in a filter indicator . 46 Annex E (informative) Formaldehyde residues on medical devices . 49 Annex F (informative) Environmental aspects . 51 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 93/42/EEC on medical devices . 54 Bibliography . 60

3.45 sterilizing agent physical or chemical entity, or combination of entities having sufficient microbicidal activity to achieve sterility under defined conditions [SOURCE: ISO/TS 11139:2006, 2.50] Note 1 to entry: The sterilizing agent is the condensate film, generated by condensation of the sterilant on the surface of the medical devices to be sterilized. 3.46 theoretical sterilant temperature temperature of the sterilant, calculated from the temperature versus vapour pressure relationship of the sterilant Note 1 to entry: This value is calculated from the beginning of the exposure time until the beginning of aeration. 3.47 unloading door door in a double-ended sterilizer through which the sterilization load is removed from the sterilizer chamber after a sterilization cycle Note 1 to entry: See also 3.18 loading door. 3.48 usable space specified space inside the sterilizer chamber, which is not restricted by fixed parts and which is available to accept the sterilization load 3.49 validation documented procedure for obtaining recording and interpreting the results required to establish that a process will consistently yield product complying with predetermined specifications [SOURCE: EN ISO 11139:2006, 3.35] 3.50 verification confirmation through provision of objective evidence that specified requirements have been fulfilled [SOURCE: EN 62304:2006, 2.55] 3.51 works test series of tests performed prior to delivery to demonstrate compliance of each piece of equipment with its specification 4 Technical requirements 4.1 Sterilizer chamber 4.1.1 Materials 4.1.1.1 The surfaces of the materials for the pressure vessel (including, for example, welds) that can come into contact with process chemicals shall be of materials which, under the designed operating conditions, are not impaired by these chemicals. They shall not release any substances known to be toxic in such quantities that can create a health or environmental hazard. SIST EN 14180:2014

Key a

pipe thread ISO 228-G1/2A Figure 1 — Example of the connection for test instruments 4.1.5.2 The sterilizer chamber shall be provided with a straight thermometry entry connection. An example is given in Figure 2. This connection shall be at a point of easy access. The connection shall be provided with a cap marked TT (Temperature Test) and sealed with a sterilant proof and mechanically resistant O-ring seal or flat seal. SIST EN 14180:2014

Key a

pipe thread ISO 228-G1A Figure 2 — Example of thermometry entry connection NOTE The test connections can be provided as accessories to be attached to a single entry port of the chamber. 4.2 Design and construction 4.2.1 Risk control and usability 4.2.1.1 Risk assessment and risk control for sterilizer design and software should be performed following the procedures and requirements given in EN ISO 14971:2012, Clauses 4, 5 and 6. Specific requirements and results should be established and documented. For products designed and placed on the market prior to publication of this edition of EN 14180 other standards may have been applied instead of EN ISO 14971. 4.2.1.2 Risk analysis shall address the specific sterilizer design and features. Measures taken for risk reduction shall consider aspects as user knowledge, experience, training, ergonomics and usability. NOTE EN ISO 12100 or EN 61508–1 can provide further helpful information. 4.2.2 Safety 4.2.2.1 Safety of the design shall be based on risk assessment. Technical solutions shall consider applicable standards. NOTE 1 For general design related to safety see EN 61010–1 and EN 61010–2–040. NOTE 2 Additional guidance is given in EN ISO 12100. NOTE 3 For guidance regarding specific design aspects, EN 60204–1 can apply. The guidance in EN 60204–1 can reduce testing. 4.2.2.2 If a powered chamber door is fitted, systems shall be provided to permit the removal of persons or objects entrapped by the moving door before the pressure, force and temperature specified in EN 61010-1:2010, 7.3.4, and 10.1 are exceeded. NOTE Reversing the direction of the door movement is a way to achieve this. 4.2.2.3 Sterilizers shall comply with EN 61326-1 regarding electromagnetic compatibility (EMC). SIST EN 14180:2014

bar and at maximum airflow. Means shall be provided between the filter and the sterilisation chamber to prevent fluid flow from the sterilizer chamber into the filter. SIST EN 14180:2014

1500 mm high, and the access shall not be obstructed. Fixings for these panels shall remain attached to either the panels or to the body of the sterilizer when panels are removed. The access for maintenance shall be positioned so that it will not compromise the safety of either the product or persons. NOTE Requirements for access are also specified in EN 61010–1:2010, 7.3.2 and 7.3.5. 4.2.8 Accessories If required for ergonomic reasons, loading equipment shall be available as a separate accessory to the sterilizer. If the equipment is intended to be connected to dedicated accessories, these combinations shall not cause any hazard or detrimental effect to the performance of the sterilizer. The mutual compatibility of both systems shall be verified (see 4.2.1 and 5.2). 4.2.9 Transport Where the weight, size or shape of the sterilizer or its various component parts prevents them from being moved by hand, the sterilizer, or each component part shall either be fitted with attachments for lifting gear, or be designed so that it can be fitted with such attachments, or be shaped in such a way that standard lifting gear can easily be attached. The sterilizer, it’s components and dedicated consumables (if applicable) shall be packed for transportation and storage in a way that their performance characteristics are maintained. When handled or transported, all parts of the sterilizer shall remain in their position and orientation so that the sterilizer remains stable and no moving part can cause a hazard. 4.3 Indicating, measuring, operating and recording devices 4.3.1 General 4.3.1.1 Indicating and operating devices shall be identified as to their function. They shall be readily accessible, clearly and durably marked with their function and designed to be easy to operate and read. 4.3.1.2 The devices shall be positioned and/or protected such that their performance is within the specified tolerances during the operation of the sterilizer. SIST EN 14180:2014

2 0,9 < 5 s when tested in flowing water according EN 60751:2008, 6.5.2. 4.3.2.6 Temperature control systems shall have a function which causes a fault to be indicated if a sensor fails. 4.3.3 Temperature indicating devices In addition to the requirements in 4.3.2.1, the temperature indicating devices shall: — be graduated in degrees Celsius; — have a scale, which includes 0 °C to 100 °C; — for analogue instruments be graduated in divisions not greater than 2 °C; — for digital instruments have a resolution of at least 0,1 °C. SIST EN 14180:2014

Key 1 chamber

Temperature indicating instrument Temperature recorder Temperature controller

Pressure indicating instrument Pressure recorder Pressure controller Figure 3 — Arrangements for temperature and pressure sensors 4.3.4 Pressure measuring and indicating devices 4.3.4.1 When used for control, monitoring or registration purposes, pressure measuring and indicating systems shall be protected against unauthorised operation by the use of an access device. 4.3.4.2 When used for process control, monitoring or registration purposes, absolute pressure measuring systems shall be used. 4.3.4.3 At least two independent sensors shall be used for the measurement of the chamber pressure, being dedicated to indication, control and registration. 4.3.4.4 The registration and monitoring/controlling devices shall be mutually independent as given by any of the arrangements shown in Figure 3. 4.3.4.5 When used for process control, monitoring or registration purposes, pressure measuring and indicating chain shall have maximum permissible errors of 1 % or less over the scale range, and be adjusted to ± 0,8 kPa (±0,008 bar) or less over the range from 0 kPa (0 bar) up to the sterilization pressure. 4.3.4.6 When used for process control, monitoring or registration purposes, pressure measuring systems shall have a function which causes a fault to be indicated if a sensor fails. 4.3.4.7 Pressure indicating devices shall: — be graduated in kilopascals or bars; — have a scale which includes the range 0 kPa (0 bar) to at least 10 % above the maximum process operating pressure when used for process control or monitoring purposes; SIST EN 14180:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...