EN 13012:2012

(Main)Petrol filling stations - Construction and performance of automatic nozzles for use on fuel dispensers

Petrol filling stations - Construction and performance of automatic nozzles for use on fuel dispensers

This European Standard specifies safety and environmental requirements for the construction and performance of nozzles to be fitted to metering pumps and dispensers installed at filling stations and which are used to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers, at flow rates up to 200 l min-1.

The requirements apply to automatic nozzles dispensing flammable liquid fuels at ambient temperatures from

-20 °C to +40 °C with the possibility for an extended temperature range.

This European Standard does not apply to equipment dispensing liquefied petroleum gas nor compressed natural gas.

This European Standard does not include any requirements for metering performance, such as may be specified under the Measuring Instruments Directive, nor those requirements specified under the Electromagnetic Compatibility Directive.

Vapour recovery efficiency rates are not considered within this European Standard.

NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG).

NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard.

Tankstellen - Anforderungen an Bau und Arbeitsweise von automatischen Zapfventilen für die Benutzung an Zapfsäulen

Diese Europäische Norm legt die sicherheitstechnischen Anforderungen und Umweltanforderungen an den Bau und die Arbeits¬weise von Zapfventilen fest, die an Zapfsäulen und druckversorgten Zapfsäulen an Tank-stellen installiert werden, für die Abgabe von flüssigen Kraftstoffen in Tanks von Kraftfahrzeugen, Booten und Leicht¬flug¬zeugen sowie in tragbare Behälter bei Durchflussraten bis zu 200 l min1.

Die Anforderungen gelten für automatische Zapfventile für die Abgabe von brennbaren flüssigen Kraft¬stoffen bei Umgebungstemperaturen von –20 °C bis 40 °C, wobei ein erweiterter Temperaturbereich möglich ist.

Diese Europäische Norm gilt nicht für Anlagen für die Abgabe von Flüssiggas oder verdichtetem Erdgas.

Diese Europäische Norm enthält keinerlei Anforderungen für Messausführungen, weder entsprechend der Mess¬geräte¬richtlinie noch entsprechend der EMV-Richtlinie.

Effizienzraten für Gasrückführung werden in dieser Europäischen Norm nicht behandelt.

ANMERKUNG 1 Diese Europäische Norm gilt nicht für Ausrüstung für Anwendungen mit Flüssiggas (LPG, en: liquified petroleum gas) oder Flüssigerdgas (LNG, en: liquefied natural gas) oder komprimiertem Erdgas (CNG, en: compressed natural gas).

ANMERKUNG 2 Diese Europäische Norm gilt nicht für Kraftstoffe, die nicht zur Explosionsgruppe IIA gehören.

Stations-service - Construction et performances des pistolets automatiques de remplissage utilisés sur les distributeurs de carburant

La présente Norme européenne spécifie les exigences relatives à la sécurité et à la protection de l'environnement pour la construction et les performances des pistolets de remplissage montés sur des ensembles de mesurage et de distribution installés dans des stations-service et utilisés pour distribuer des carburants liquides dans des réservoirs de véhicules à moteur, de bateaux, d'avions légers et dans des réservoirs portables, à des débits pouvant atteindre 200 l min-1.

Les exigences concernent les pistolets automatiques de remplissage distribuant des carburants liquides inflammables, à des températures comprises entre -20 °C et +40 °C avec la possibilité d’une gamme de température étendue.

La présente Norme européenne ne s'applique ni au matériel de distribution de gaz de pétrole liquéfié, ni au matériel de distribution de gaz naturel comprimé.

La présente Norme européenne ne comprend aucune exigence concernant les performances métrologiques telles que celles pouvant être spécifiées dans la directive concernant les instruments de mesure, pas plus que celles contenues dans la directive concernant la compatibilité électromagnétique.

Les taux d'efficacité de la récupération de vapeur ne sont pas abordés dans la présente norme Européenne.

NOTE 1 La présente Norme européenne ne s’applique pas aux équipements mettant en œuvre du gaz de pétrole liquéfié (GPL) ou du gaz naturel liquéfié (GNL) ou du gaz naturel compressé (GNC).

NOTE 2 Les carburants autres que ceux du Groupe d’Explosion IIA sont exclus de la présente Norme européenne.

Bencinski servisi - Izdelava in lastnosti točilnih ventilov, vgrajenih v napravah za točenje goriva

Ta evropski standard določa varnostne in okoljske zahteve za izdelavo in lastnosti točilnih ventilov, nameščenih na tlačne in sesalne naprave za točenje goriva, ki so postavljene na bencinskih servisih in se uporabljajo za točenje tekočih goriv v rezervoarje motornih vozil, čolnov in lahkih letal ter v premične rezervoarje s pretokom do 200 l/min. Zahteve se uporabljajo za točilne ventile za točenje vnetljivih tekočih goriv pri temperaturah okolja od -20 °C do +40 °C z možnostjo večjega temperaturnega razpona. Ta evropski standard se ne uporablja za opremo za točenje utekočinjenega naftnega plina ali stisnjenega zemeljskega plina. Ta evropski standard ne zajema zahtev za lastnosti merjenja, kakršne so lahko določene v direktivi o merilnih instrumentih, ali zahtev iz direktive o elektromagnetni združljivosti. Stopnje učinkovitosti rekuperacije hlapov niso zajete v tem evropskem standardu.

General Information

- Status

- Withdrawn

- Publication Date

- 26-Jun-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Sep-2021

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 16507:2014 - Railway applications - Ground based service - Diesel refuelling equipment - Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 13012:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Petrol filling stations - Construction and performance of automatic nozzles for use on fuel dispensers". This standard covers: This European Standard specifies safety and environmental requirements for the construction and performance of nozzles to be fitted to metering pumps and dispensers installed at filling stations and which are used to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers, at flow rates up to 200 l min-1. The requirements apply to automatic nozzles dispensing flammable liquid fuels at ambient temperatures from -20 °C to +40 °C with the possibility for an extended temperature range. This European Standard does not apply to equipment dispensing liquefied petroleum gas nor compressed natural gas. This European Standard does not include any requirements for metering performance, such as may be specified under the Measuring Instruments Directive, nor those requirements specified under the Electromagnetic Compatibility Directive. Vapour recovery efficiency rates are not considered within this European Standard. NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG). NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard.

This European Standard specifies safety and environmental requirements for the construction and performance of nozzles to be fitted to metering pumps and dispensers installed at filling stations and which are used to dispense liquid fuels into the tanks of motor vehicles, boats and light aircraft and into portable containers, at flow rates up to 200 l min-1. The requirements apply to automatic nozzles dispensing flammable liquid fuels at ambient temperatures from -20 °C to +40 °C with the possibility for an extended temperature range. This European Standard does not apply to equipment dispensing liquefied petroleum gas nor compressed natural gas. This European Standard does not include any requirements for metering performance, such as may be specified under the Measuring Instruments Directive, nor those requirements specified under the Electromagnetic Compatibility Directive. Vapour recovery efficiency rates are not considered within this European Standard. NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG). NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard.

EN 13012:2012 is classified under the following ICS (International Classification for Standards) categories: 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13012:2012 has the following relationships with other standards: It is inter standard links to EN 13012:2001, EN 13012:2021, EN IEC 60079-0:2018, ISO 9158:1988, ISO 9159:1988, EN 13617-2:2021, EN ISO 9013:2002/A1:2003, EN 2286:1989, EN ISO 6878:2004, EN 13463-1:2009, EN 976-1:1997, EN 572-7:2004, EN 1360:2013, EN ISO 228-1:2003, EN 16507:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13012:2012 is associated with the following European legislation: EU Directives/Regulations: 2014/34/EU, 94/9/EC; Standardization Mandates: M/079. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13012:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Tankstellen - Anforderungen an Bau und Arbeitsweise von automatischen Zapfventilen für die Benutzung an ZapfsäulenStations service - Construction et performances des pistolets automatiques de remplissage utilisés sur les distributeurs de carburantPetrol filling stations - Construction and performance of automatic nozzles for use on fuel dispenser75.200Petroleum products and natural gas handling equipmentICS:Ta slovenski standard je istoveten z:EN 13012:2012SIST EN 13012:2012en,fr,de01-september-2012SIST EN 13012:2012SLOVENSKI

STANDARDSIST EN 13012:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13012

June 2012 ICS 75.200 Supersedes EN 13012:2001English Version

Petrol filling stations - Construction and performance of automatic nozzles for use on fuel dispensers

Stations-service - Construction et performances des pistolets automatiques de remplissage utilisés sur les distributeurs de carburant

Tankstellen - Anforderungen an Bau und Arbeitsweise von automatischen Zapfventilen für die Benutzung an Zapfsäulen This European Standard was approved by CEN on 10 May 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13012:2012: ESIST EN 13012:2012

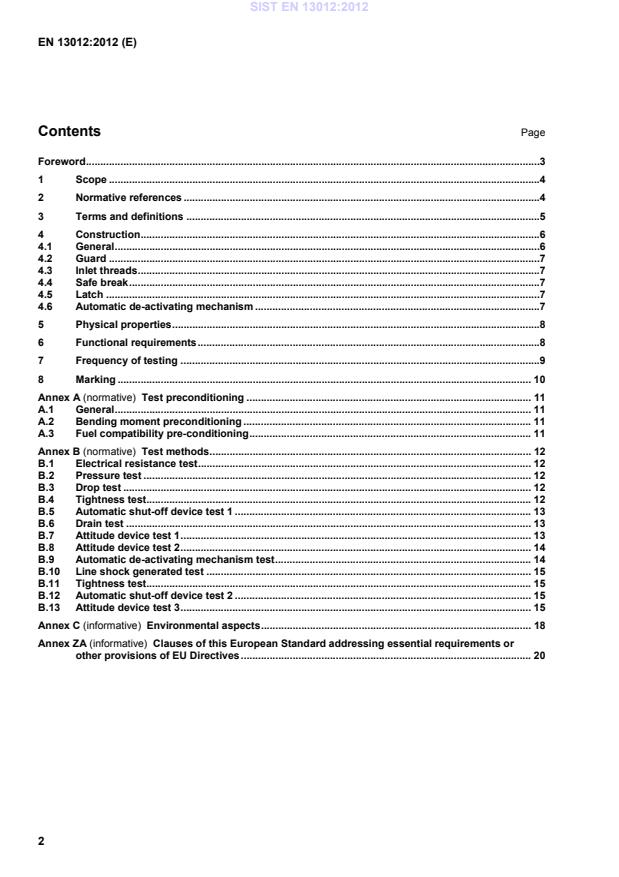

Test preconditioning . 11A.1 General . 11A.2 Bending moment preconditioning . 11A.3 Fuel compatibility pre-conditioning . 11Annex B (normative)

Test methods . 12B.1 Electrical resistance test . 12B.2 Pressure test . 12B.3 Drop test . 12B.4 Tightness test . 12B.5 Automatic shut-off device test 1 . 13B.6 Drain test . 13B.7 Attitude device test 1 . 13B.8 Attitude device test 2 . 14B.9 Automatic de-activating mechanism test . 14B.10 Line shock generated test . 15B.11 Tightness test . 15B.12 Automatic shut-off device test 2 . 15B.13 Attitude device test 3 . 15Annex C (informative)

Environmental aspects . 18Annex ZA (informative)

Clauses of this European Standard addressing essential requirements or other provisions of EU Directives . 20

–20 °C to +40 °C with the possibility for an extended temperature range. This European Standard does not apply to equipment dispensing liquefied petroleum gas nor compressed natural gas. This European Standard does not include any requirements for metering performance, such as may be specified under the Measuring Instruments Directive, nor those requirements specified under the Electromagnetic Compatibility Directive. Vapour recovery efficiency rates are not considered within this European Standard. NOTE 1 This European Standard does not apply to equipment for use with liquefied petroleum gas (LPG) or liquefied natural gas (LNG) or compressed natural gas (CNG). NOTE 2 Fuels other than of Explosion Group IIA are excluded from this European Standard. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 976–1:1997, Underground tanks of glass-reinforced plastics (GRP) — Horizontal cylindrical tanks for the non-pressure storage of liquid petroleum based fuels — Part 1: Requirements and test methods for single wall tanks EN 1360, Rubber and plastic hoses and hose assemblies for measured fuel dispensing systems — Specification EN 13463–1:2009, Non-electrical equipment for potentially explosive atmospheres — Part 1: Basic method and requirements EN 13617–2, Petrol filling stations — Part 2: Safety requirements for construction and performance of safe breaks for use on metering pumps and dispensers EN 60079-0, Explosive atmospheres — Part 0: Equipment — General requirements (IEC 60079-0) EN 60204–1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204–1:2005, modified) EN ISO 228–1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions, tolerances and designation (ISO 228-1) ISO 261, ISO general purpose metric screw threads — General plan ISO 965–2, ISO general purpose metric screw threads — Tolerances — Part 2: Limits of sizes for general purpose external and internal screw threads — Medium quality ISO 9158, Road vehicles — Nozzle spouts for unleaded gasoline SIST EN 13012:2012

Type II

maximum flow rate ≤ 80 l · min-1 > 80 l · min-1 ≤ 200 l · min-1 dimension of the spout According to ISO 9158 or ISO 9159 Not specified position of the sensor According to ISO 9158 or ISO 9159 ≤ 50 mm from plane of spout tip spout axis angle 0° + 2°

Female threads

Male threads

Maximum thread depth a mm Minimum thread length b mm ¾" 12,5 11,0 1" 15,5 14,0 1¼" 15,5 17,5 1½" 15,5 18,0 a The thread depth, measured from the outer fore-part to the metallic inner sealing face. b The stated minimum length does only apply if the female thread of the hose fitting includes an inner flat gasket. In case of using an outer flat gasket, the male threads may be shorter as stated.

4.4 Safe break Where a nozzle is provided with a safe break this shall fulfil the requirements according to EN 13617–2. 4.5 Latch Where a latch is provided and in use, it should be capable of being normally disarmed by the user. 4.6 Automatic de-activating mechanism If an automatic de-activating mechanism entirely in the nozzle exists, it shall fulfil the requirements according to Table 4. SIST EN 13012:2012

Test procedure Requirement

Electrical resistance of any point on the spout to hose coupling B.1 ≤ 100 k for each measurement Electrostatic properties – EN 13463-1:2009, 6.7 Ignitability of composite materials on nozzle body Ignition source C Effect time 20 s Surface flame impingement According to ISO 11925-3 The material tested shall not afterflame Bending moment Annex A Clause 6 Fuel compatibility Annex A Clause 6 Characteristics of nozzle body and/or cover to prevent dangerous, mechanically generated sparks (resistance to sparking) – EN 13463-1:2009, 6.4.4.2 6 Functional requirements The nozzle shall conform to the operational requirements given in Table 4 and Table 5 when tested according to the schedule given in Table 6. Where a test liquid is required it shall be an odourless kerosene except where noted otherwise. Table 4 — Operational requirements of nozzle (type tests) Test Test method Requirement Pressure test B.2 No quantifiable leakage or permanent deformation vi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...