EN 1401-1:2009

(Main)Plastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U) - Part 1: Specifications for pipes, fittings and the system

Plastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U) - Part 1: Specifications for pipes, fittings and the system

This Part of EN 1401 specifies the requirements for solid wall pipes, fittings and the system of unplasticized poly(vinyl chloride) (PVC U) piping systems in the field of non-pressure underground drainage and sewerage:

a) outside the building structure (application area code "U") and

b) both buried in ground within the building structure (application area code "D") and outside the building.

This is reflected in the marking of products by "U" and "UD".

It also specifies the test parameters for the test methods referred to in this European Standard.

This European Standard covers a range of nominal sizes, a range of pipes and fittings series and a range of stiffness classes and gives recommendations concerning colours.

NOTE 1 It is the responsibility of the purchaser or specifier to make the appropriate selection from these aspects, taking into account their particular requirements and any relevant national regulations and installation practices or codes.

In conjunction with prCEN/TS 1401-2 [1] and ENV 1401-3 [2] it is applicable to PVC U pipes and fittings, their joints and to joints with components of other plastics and non-plastics materials intended to be used for buried piping systems for non-pressure underground drainage and sewerage.

This European Standard is applicable to non foamed PVC U pipes without a socket as well as pipes with an integral socket.

The fittings can be manufactured by injection-moulding or be fabricated from pipes and/or mouldings.

Requirements and limiting values for application area code "D" are given in Table 4, Table 6, Table 13 and Table 15.

NOTE 2 Pipes, fittings and other components conforming to any of the plastics product standards listed in Annex C can be used with pipes and fittings conforming to this European Standard, provided they conform to the requirements for joint dimensions given in Clause 6 and to the requirements of Table 15.

Kunststoff-Rohrleitungssysteme für erdverlegte drucklose Abwasserkanäle und -leitungen - Weichmacherfreies Polyvinylchlorid (PVC-U) - Teil 1: Anforderungen an Rohre, Formstücke und das Rohrleitungssystem

Dieser Teil von EN 1401 legt die Anforderungen an Vollwand-Rohre, -Formstücke und das Rohrleitungssystem

aus weichmacherfreiem Polyvinylchlorid (PVC-U) für Abwasserkanäle und -leitungen fest, die in erdverlegten

Schwerkraftentwässerungssystemen

⎯ außerhalb der Gebäudestruktur (Anwendungskennzeichen „U“) sowie

⎯ innerhalb der Gebäudestruktur (Anwendungskennzeichen „D“) und außerhalb der Gebäudestruktur

eingesetzt werden.

Dies wird durch die Produktkennzeichnung „U“ bzw. „UD“ angezeigt.

In diesem Teil sind auch die Prüfparameter für die Prüfverfahren festgelegt, auf die in dieser Europäischen

Norm verwiesen wird.

Diese Europäische Norm enthält Festlegungen für Nennweiten, Rohrreihen für Rohre und Formstücke und

eine Reihe von Steifigkeitsklassen und gibt Empfehlungen für die Auswahl der Einfärbung von Rohrleitungsteilen.

ANMERKUNG 1 Der Anwender bzw. Auftraggeber ist unter Berücksichtigung der eigenen Anforderungen sowie der

geltenden nationalen Festlegungen und Verlegepraktiken für die entsprechende Auswahl dieser Kriterien verantwortlich.

Zusammen mit prCEN/TS 1401-2 [1] und ENV 1401-3 [2] gilt dieser Teil für Rohre und Formstücke aus

PVC-U, ihre Verbindungen untereinander sowie mit Rohrleitungsteilen aus anderen Kunststoffen oder Rohrwerkstoffen,

die für erdverlegte drucklose Abwasserkanäle und -leitungen vorgesehen sind.

Diese Europäische Norm gilt für Rohre aus ungeschäumtem PVC-U sowohl mit glatten Enden als auch mit

angeformter Muffe.

Die Formstücke können sowohl im Spritzguss als auch handgefertigt aus Rohren und/oder aus Spritzgussteilen

hergestellt sein.

Systèmes de canalisations en plastique pour les branchements et les collecteurs d'assainissement enterrés sans pression - Poly(chlorure de vinyle) non plastifié (PVC-U) - Partie 1 : Spécifications pour tubes, raccords et le système

La présente partie de l'EN 1401 spécifie les exigences pour les tubes, les raccords et le système à paroi

compacte fabriqués à partir de poly(chlorure de vinyle) non plastifié (PVC-U), destinés à être utilisés pour les

branchements et les collecteurs d'assainissement sans pression :

a) à l'extérieur de la structure du bâtiment (code de zone d'application « U ») ; et

b) aussi bien à l'extérieur du bâtiment qu'en enterré dans la structure du bâtiment (code de zone

d'application « D »).

Ceci est repéré au niveau du marquage des produits par « U » et « UD ».

Elle spécifie également les paramètres d'essai pour les méthodes d'essai référencées dans la présente

Norme européenne.

La présente Norme européenne couvre une gamme de dimensions nominales, une gamme de tubes et de

raccords ainsi qu’une gamme de classes de rigidité et donne des recommandations concernant les couleurs.

NOTE 1 Il est de la responsabilité de l'acheteur ou du prescripteur d'effectuer les sélections appropriées à partir de ces

données en tenant compte des exigences particulières, des éventuelles règles nationales concernées et des pratiques ou

codes de pose.

Conjointement aux prCEN/TS 1401-2 [1] et ENV 1401-3 [2], elle s'applique aux tubes et aux raccords en

PVC-U, à leurs assemblages ainsi qu'aux assemblages avec d'autres composants en d'autres matières,

plastiques ou non, destinés à être utilisés pour les systèmes de canalisations enterrées pour les

branchements et les collecteurs d'assainissement sans pression.

La présente Norme européenne est applicable aux tubes en PVC-U non expansé avec ou sans emboîtures.

Les raccords peuvent être fabriqués par moulage par injection ou façonnés à partir de tubes et/ou de

moulages.

Les exigences et les valeurs limites pour la zone d'application de code « D » sont données dans les

Tableaux 4, 6, 13 et 15.

Cevni sistemi iz polimernih materialov za odpadno vodo in kanalizacijo, ki delujejo po težnostnem principu in so položeni v zemljo - Nemehčan polivinilklorid (PVC-U) - 1. del: Specifikacije za cevi, fitinge in sistem

General Information

- Status

- Withdrawn

- Publication Date

- 03-Mar-2009

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 155 - Plastics piping systems and ducting systems

- Drafting Committee

- CEN/TC 155/WG 6 - Systems for soil and waste discharge - PVC-U

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Jul-2019

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 20-May-2015

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 1401-1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U) - Part 1: Specifications for pipes, fittings and the system". This standard covers: This Part of EN 1401 specifies the requirements for solid wall pipes, fittings and the system of unplasticized poly(vinyl chloride) (PVC U) piping systems in the field of non-pressure underground drainage and sewerage: a) outside the building structure (application area code "U") and b) both buried in ground within the building structure (application area code "D") and outside the building. This is reflected in the marking of products by "U" and "UD". It also specifies the test parameters for the test methods referred to in this European Standard. This European Standard covers a range of nominal sizes, a range of pipes and fittings series and a range of stiffness classes and gives recommendations concerning colours. NOTE 1 It is the responsibility of the purchaser or specifier to make the appropriate selection from these aspects, taking into account their particular requirements and any relevant national regulations and installation practices or codes. In conjunction with prCEN/TS 1401-2 [1] and ENV 1401-3 [2] it is applicable to PVC U pipes and fittings, their joints and to joints with components of other plastics and non-plastics materials intended to be used for buried piping systems for non-pressure underground drainage and sewerage. This European Standard is applicable to non foamed PVC U pipes without a socket as well as pipes with an integral socket. The fittings can be manufactured by injection-moulding or be fabricated from pipes and/or mouldings. Requirements and limiting values for application area code "D" are given in Table 4, Table 6, Table 13 and Table 15. NOTE 2 Pipes, fittings and other components conforming to any of the plastics product standards listed in Annex C can be used with pipes and fittings conforming to this European Standard, provided they conform to the requirements for joint dimensions given in Clause 6 and to the requirements of Table 15.

This Part of EN 1401 specifies the requirements for solid wall pipes, fittings and the system of unplasticized poly(vinyl chloride) (PVC U) piping systems in the field of non-pressure underground drainage and sewerage: a) outside the building structure (application area code "U") and b) both buried in ground within the building structure (application area code "D") and outside the building. This is reflected in the marking of products by "U" and "UD". It also specifies the test parameters for the test methods referred to in this European Standard. This European Standard covers a range of nominal sizes, a range of pipes and fittings series and a range of stiffness classes and gives recommendations concerning colours. NOTE 1 It is the responsibility of the purchaser or specifier to make the appropriate selection from these aspects, taking into account their particular requirements and any relevant national regulations and installation practices or codes. In conjunction with prCEN/TS 1401-2 [1] and ENV 1401-3 [2] it is applicable to PVC U pipes and fittings, their joints and to joints with components of other plastics and non-plastics materials intended to be used for buried piping systems for non-pressure underground drainage and sewerage. This European Standard is applicable to non foamed PVC U pipes without a socket as well as pipes with an integral socket. The fittings can be manufactured by injection-moulding or be fabricated from pipes and/or mouldings. Requirements and limiting values for application area code "D" are given in Table 4, Table 6, Table 13 and Table 15. NOTE 2 Pipes, fittings and other components conforming to any of the plastics product standards listed in Annex C can be used with pipes and fittings conforming to this European Standard, provided they conform to the requirements for joint dimensions given in Clause 6 and to the requirements of Table 15.

EN 1401-1:2009 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general; 23.040.05 - Pipeline and its parts for external sewage systems; 23.040.20 - Plastics pipes; 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1401-1:2009 has the following relationships with other standards: It is inter standard links to EN 1401-1:1998, EN 1401-1:2019, EN ISO 2507:2026, EN ISO 1043-1:2001, EN ISO 1167-1:2006, EN ISO 13257:2018, EN ISO 9969:2016, EN 10204:2004, EN ISO 580:2005, EN ISO 472:2001, EN ISO 1183-1:2025, EN ISO 9852:2017, EN ISO 13263:2017, EN ISO 3126:2005, EN ISO 2507-1:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1401-1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kunststoff-Rohrleitungssysteme für erdverlegte drucklose Abwasserkanäle und -leitungen - Weichmacherfreies Polyvinylchlorid (PVC-U) - Teil 1: Anforderungen an Rohre, Formstücke und das RohrleitungssystemSystemes de canalisations en plastique pour les branchements et les collecteurs d'assainissement enterrés sans pression - Poly(chlorure de vinyle) non plastifié (PVC-U) - Partie 1 : Spécifications pour tubes, raccords et le systemePlastics piping systems for non-pressure underground drainage and sewerage - Unplasticized poly(vinyl chloride) (PVC-U) - Part 1: Specifications for pipes, fittings and the system93.030Zunanji sistemi za odpadno vodoExternal sewage systems23.040.01Deli cevovodov in cevovodi na splošnoPipeline components and pipelines in generalICS:Ta slovenski standard je istoveten z:EN 1401-1:2009SIST EN 1401-1:2009en,fr,de01-junij-2009SIST EN 1401-1:2009SLOVENSKI

STANDARDSIST EN 1401-1:19991DGRPHãþD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1401-1March 2009ICS 93.030Supersedes EN 1401-1:1998

English VersionPlastics piping systems for non-pressure underground drainageand sewerage - Unplasticized poly(vinyl chloride) (PVC-U) - Part1: Specifications for pipes, fittings and the systemSystèmes de canalisations en plastique pour lesbranchements et les collecteurs d'assainissement enterréssans pression - Poly(chlorure de vinyle) non plastifié (PVC-U) - Partie 1 : Spécifications pour tubes, raccords et lesystèmeKunststoff-Rohrleitungssysteme für erdverlegte druckloseAbwasserkanäle und-leitungen - WeichmacherfreiesPolyvinylchlorid (PVC-U) - Teil 1: Anforderungen an Rohre,Formstücke und das RohrleitungssystemThis European Standard was approved by CEN on 10 January 2009.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the CEN Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as theofficial versions.CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre:

Avenue Marnix 17,

B-1000 Brussels© 2009 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1401-1:2009: ESIST EN 1401-1:2009

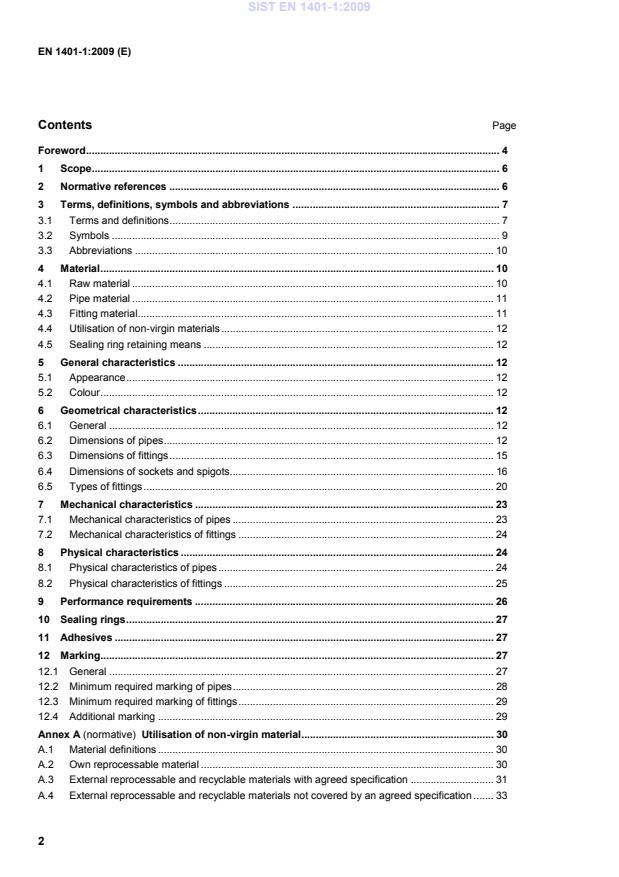

Utilisation of non-virgin material . 30 A.1 Material definitions . 30 A.2 Own reprocessable material . 30 A.3 External reprocessable and recyclable materials with agreed specification . 31 A.4 External reprocessable and recyclable materials not covered by an agreed specification . 33 SIST EN 1401-1:2009

General characteristics of PVC-U pipes and fittings . 34 B.1 General . 34 B.2 Compound characteristics . 34 B.3 Ring stiffness . 34 B.4 Creep ratio . 34 B.5 Chemical resistance . 35 B.6 Abrasion resistance . 35 B.7 Hydraulic roughness . 35 B.8 Diametric deflection . 35 Annex C (informative)

Product standards . 36 Bibliography . 37

application area code for the area more than 1 m from the building to which the buried piping system is connected; D:

application area code for the area under and within 1 m from the building where the pipes and the fittings are buried in ground and are connected to the soil and waste discharge system of the building NOTE In code D application areas, the existence of hot water discharge in addition to the external forces from the surroundings is usual. 3.1.2 nominal size DN numerical designation of the size of a component, other than a component designated by thread size, which is approximately equal to the manufacturing dimension, in millimetres (mm) 3.1.3 nominal size DN/OD nominal size, related to the outside diameter 3.1.4 nominal outside diameter dn specified outside diameter, in millimetres, assigned to a nominal size DN/OD 3.1.5 outside diameter de value of the measurement of the outside diameter through its cross section at any point of a pipe or spigot, rounded to the next greater 0,1 mm 3.1.6 mean outside diameter dem value of the measurement of the outer circumference of a pipe or spigot end of a fitting in any cross section, divided by π (≈ 3,142), rounded to the next greater 0,1 mm 3.1.7 mean inside diameter of a socket dsm arithmetical mean of a number of measurements of the inside diameter of a socket in the same cross-section 3.1.8 out-of-roundness ovality difference between the measured maximum and the measured minimum outside diameter in the same cross section of a component SIST EN 1401-1:2009

length of engagement a :

circumferential side cover of a saddle branch B :

length of lead-in C :

depth of sealing zone de :

outside diameter dem :

mean outside diameter dn :

nominal outside diameter dsm :

mean inside diameter of a socket d3 :

internal diameter of the groove e :

wall thickness em :

mean wall thickness e2 :

wall thickness of a socket e3 :

wall thickness in the groove area f :

groove width SIST EN 1401-1:2009

length of chamfer K :

K-value L :

axial cover of a saddle branch l :

effective length of a pipe L1 :

length of spigot L2 :

length of the solvent cement socket M :

length of spigot of a plug R :

radius of swept fittings Z :

design length of a fitting α :

nominal angle of a fitting 3.3 Abbreviations DN :

nominal size DN/OD :

nominal size, outside diameter related PVC-U :

unplasticized poly(vinyl chloride) SDR :

standard dimension ratio SN :

nominal ring stiffness TIR :

true impact rate 4 Material 4.1 Raw material The raw material shall be PVC-U to which are added those additives that are needed to facilitate the manufacture of components conforming to the requirements of this European Standard. When calculated on the basis of a known formulation, or in case of dispute or unknown formulation, determined in accordance with EN 1905, the PVC-content shall be at least 80 % by mass for pipes and 85 % by mass for injection-moulded fittings. A further reduction of the PVC-U content to ≥ 75 % by mass for pipes only is permitted provided the PVC-U is substituted by coated or uncoated CaCO3 conforming to the following. a) The composition of the CaCO3, before coating if any, shall conform to the following: content of CaCO3 ≥ 96 % by mass; content of MgCO3 ≤ 4 % by mass; content of CaCO3 and MgCO3 in total ≥ 98 % by mass. b) The physical properties of the material shall conform to the following: mean particle size D50 ≤ 2,5 µm; top cut D98 ≤ 20 µm. SIST EN 1401-1:2009

Test temperature Orientation Number of test pieces Circumferential (hoop) stress Conditioning period Type of test Test period Type A or B conforming to EN ISO 1167-1:2006 60 °C Free

3 10 MPa

1 h Water-in-water 1 000 h EN ISO 1167-1:2006

4.3 Fitting material When tested in accordance with the test method as specified in Table 2, using the indicated parameters, the fitting material shall have characteristics conforming to the requirements given in Table 2. The fitting material shall be tested, in the actual formulation, in the form of an extruded or injection-moulded pipe. Fabricated fittings or parts of fabricated fittings shall be made from pipes conforming to this European Standard, except for the requirements for the wall thickness, and/or mouldings from PVC-U which conform to material, mechanical and physical characteristics as required in this European Standard. Table 2 — Material characteristics of fittings Characteristic Requirements Test parameters Test method Resistance to internal pressure No failure during the test period End caps

Dimensions

Free length for injection-

moulded pipe Test temperature Orientation Number of test pieces Circumferential (hoop)

stress Conditioning period Type of test Test period Type A or B conforming to EN ISO 1167-1:2006 50 mm ≤ dn ≤ 110 mm 3 mm ≤ e ≤ 5 mm ≥ 140 mm

60 °C Free 3 6,3 MPa

1 h Water-in-water 1 000 h

EN ISO 1167-1:2006

1) According to RAL 840-HR, Colour register. SIST EN 1401-1:2009

dn dem,min dem,max 110 125 160 200 110 125 160 200 110,0 125,0 160,0 200,0 110,3 125,3 160,4 200,5 250 315 (355) 400 250 315 355 400 250,0 315,0 355,0 400,0 250,5 315,6 355,7 400,7 (450) 500 630 (710) 450 500 630 710 450,0 500,0 630,0 710,0 450,8 500,9 631,1 711,2 800 (900) 1000 800 900 1 000 800,0 900,0 1 000,0 801,3 901,5 1 001,6 a Non-preferred sizes are indicated in parenthesis.

6.2.2 Out of roundness The out-of-roundness, measured directly after production, shall be less than or equal to 0,024dn. 6.2.3 Length of pipes The effective length of a pipe, l, shall be not less than that declared by the manufacturer when measured as shown in Figure 1. SIST EN 1401-1:2009

Figure 1 — Effective length of pipes 6.2.4 Chamfering If a chamfer is applied, the angle of chamfering shall be between 15 ° and 45 ° to the axis of the pipe (see Figure 2 and Table 5 or Figure 7 and Table 8, as applicable). The remaining wall thickness of the end of the pipe shall be at least 1⁄3 of emin. 6.2.5 Wall thickness The wall thickness, e, shall conform to Table 4, where a maximum wall thickness at any point up to 1,2emin is permitted provided that the mean wall thickness, em, is less than or equal to the specified em,max. For U application, DN 200 and greater, a reduction of emin up to 5 % is permitted, provided em is equal or exceeds the values of emin given in Table 4. In such case, the ring stiffness shall be measured according to EN ISO 9969 and shall be greater than or equal to the nominal value. NOTE

For the calculation of the pipe stiffness the values of emin as given in Table 4 should be used. SIST EN 1401-1:2009

dn emin em,max emin em,max emin em,max 110 125 160 200 110 125 160 200 −− −− 3,2 3,9 −− −− 3,8 4,5 3,2 3,2 4,0 4,9 3,8 3,8 4,6 5,6 3,2 3,7 4,7 5,9 3,8 4,3 5,4 6,7 250 315 (355) 400 250 315 355 400 4,9 6,2 7,0 7,9 5,6 7,1 7,9 8,9 6,2 7,7 8,7 9,8 7,1 8,7 9,8 11,0 7,3 9,2 10,4 11,7 8,3 10,4 11,7 13,1 (450) 500 630 (710) 450 500 630 710 8,8 9,8 12,3 13,9 9,9 11,0 13,8 15,5 11,0 12,3 15,4 17,4 12,3 13,8 17,2 19,4 13,2 14,6 18,4 20,8 14,8 16,3 20,5 23,2 800 (900) 1000 800 900 1000 15,7 17,6 19,6 17,5 19,6 21,8 19,6 22,0 24,5 21,8 24,4 27,2 23,4 −− −− 26,8 −− −− a Non-preferred sizes are indicated in parenthesis. b SDR 51 is applicable for application area code "U" only.

6.3 Dimensions of fittings 6.3.1 Outside diameters The mean outside diameter, dem, of the spigot shall conform to Table 3. The out-of-roundness shall conform to the requirements given in 6.2.2. 6.3.2 Design lengths (Z) The Z-length(s) of fittings (see Figures 8 to 11 and Figures 13 to 18) shall be given by the manufacturer. NOTE The Z-lengths are intended to assist in the design of moulds and are not intended to be used for quality control purposes. ISO 265-1 [3] can be used as a guideline. 6.3.3 Wall thicknesses 6.3.3.1 Minimum wall thickness, emin, of the body or the spigot of a fitting shall conform to Table 4, except that a reduction of 5 % resulting from core shifting is permitted. In such a case, the average of two opposite wall thicknesses shall be equal to or exceed the values given in Table 4. 6.3.3.2 Where a fitting or adaptor provides for a transition between two nominal sizes, the wall thickness of each connecting part shall conform to the requirements for the applicable nominal size. In such a case, the wall thickness of the fitting body is permitted to change gradually from the one wall thickness to the other. SIST EN 1401-1:2009

dn dsm,min Amin Cmax L1,min H b 110 125 160 200 110 125 160 200 110,4 125,4 160,5 200,6 32 35 42 50 26 26 32 40 60 67 81 99 6 6 7 9 250 315 (355) 400 250 315 355 400 250,8 316,0 356,1 401,2 55 62 66 70 70 70 70 80 c 125 132 136 150 9 12 13 15 (450) 500 630 (710) 450 500 630 710 451,4 501,5 631,9 712,1 75 80 93 101 80 c 80 c 95 c 109 c 155 160 188 210 17 18 23 28 800 (900) 1 000 800 900 1 000 802,4 902,7 1 003,0 110 120 130 110 c 125 c 140 c 220 245 270 32 36 41 a Non-preferred sizes are indicated in parenthesis. b Approximate values, when a 15 ° chamfer is applied. c Higher values for C are allowed, provided the manufacturer states in his documentation the actual required L1,min according to the equation L1,min = Amin + C.

Figure 2 — Basic dimensions of sockets and spigots for elastomeric ring seal joints

Figure 3 — Typical groove designs for elastomeric ring seal sockets

Figure 4 — Example for measuring the effective sealing point 6.4.1.2 Wall thicknesses of sockets The wall thickn

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...