EN 16603-20-06:2020

(Main)Space engineering - Spacecraft charging

Space engineering - Spacecraft charging

This activity will be the update of EN16603-20-06 (published 2014).

This activity was started in ECSS to implement as urgent classified Change Requests.

Raumfahrttechnik - Aufladung von Raumfahrzeugen

Ingéniérie spatiale - Charges électrostatiques des engins spatiaux

La présente norme s'inscrit dans la hiérarchie des normes ECSS. Elle est rattachée à la discipline « génie électrique et électronique » (ECSS-E-ST-20) de la branche ingénierie du système ECSS (ECSS-E). Elle contient des dispositions claires et cohérentes relatives à l'application de mesures visant à prévenir et minimiser les effets dangereux associés à la charge électrostatique des engins spatiaux, ainsi que les autres effets environnementaux sur le comportement électrique d'un engin spatial.

Cette norme s'applique à tout type d'engin spatial, y compris les lanceurs, au-dessus de l'atmosphère terrestre.

Bien que les systèmes d'engins spatiaux soient clairement soumis à des interactions électriques lorsqu'ils sont au sol (par exemple, éclair et électricité statique pendant la manutention), ces aspects ne sont pas couverts par la présente norme puisqu'ils sont communs aux systèmes terrestres et font l'objet d'autres publications. La présente norme s'attache plus particulièrement aux effets électriques survenant dans l'espace (c'est-à-dire au-delà de l'ionosphère).

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d’un projet spatial, conformément à l’ECSS-S-ST-00.

Vesoljska tehnika - Napajanje vesoljskih plovil

General Information

- Status

- Published

- Publication Date

- 08-Sep-2020

- Withdrawal Date

- 30-Mar-2021

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5/WG 6 - Upstream standards

- Current Stage

- 9020 - Submission to 2 Year Review Enquiry - Review Enquiry

- Start Date

- 15-Oct-2025

- Completion Date

- 15-Oct-2025

Relations

- Effective Date

- 16-Sep-2020

Overview

EN 16603-20-06:2020 - a CEN standard in the space engineering series - defines engineering requirements and verification practices for spacecraft charging. Superseding the 2014 edition, this 2020 update consolidates requirements for surface and internal charging, secondary arcing, high-voltage systems, tethers and electric propulsion interactions with the plasma environment. The standard provides terms, protection programme guidance, material and grounding rules, testing and validation methods, plus normative and informative annexes (including an electrical hazard mitigation plan and physical background).

Key topics and requirements

- Scope and terminology: clear definitions, abbreviated terms and nomenclature used for spacecraft charging and plasma interactions.

- Surface material requirements: material selection, electrical continuity, grounding of metallic parts, limits on permitted voltages and resistivity, and material/assembly qualification and testing.

- Surface charging analysis: modelling guidelines and verification approaches to predict floating potentials and discharge risks.

- Secondary arc requirements: prevention and mitigation of arcing (with focused provisions for solar arrays and exposed power-system parts).

- High-voltage system requirements: design, validation and verification practices for HV systems on spacecraft.

- Internal/deep-dielectric charging: assessment of charge deposition, dielectric fields, grounding and validation of internal components.

- Tether requirements: hazards from conductive tethers, current collection, insulation continuity, and electrodynamic effects.

- Electric propulsion: requirements covering spacecraft neutralization, beam neutralization, sputtering, contamination, and validation (ground testing, modelling and in‑flight monitoring).

- Verification and testing: material tests, qualification, computer modelling characteristics, ESD triggering criteria and in‑flight validation.

- Annexes: Annex A (normative) - Electrical hazard mitigation plan (DRD); Annex B - tailoring guidelines for LEO/MEO/GEO, tethers, active spacecraft; Annex C - physical background on sheaths, Debye length, charging processes.

Applications

EN 16603-20-06:2020 is applied where spacecraft interact with space plasma and where charging poses a hazard:

- Design and verification of satellites (LEO, MEO, GEO and planetary missions)

- Solar array and power subsystem design to prevent secondary arcs

- Electric propulsion system integration and plume/sputtering assessment

- Tethered spacecraft projects and electrodynamic tether missions

- Spacecraft materials selection and qualification for ESD and charging resilience

Who uses this standard

- Systems, electrical and spacecraft architects designing power and HV systems

- Materials engineers and test laboratories performing surface and dielectric qualification

- Mission assurance, risk and safety engineers preparing mitigation plans (DRDs)

- Propulsion teams and mission planners addressing plasma–spacecraft interactions

- Standards and compliance teams aligning to CEN/CENELEC and ECSS processes

Related standards (applicability note)

EN 16603-20-06:2020 is part of the EN/ECSS family addressing space systems and should be used alongside other spacecraft environmental and electrical standards for comprehensive mission compliance and safety planning.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 16603-20-06:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space engineering - Spacecraft charging". This standard covers: This activity will be the update of EN16603-20-06 (published 2014). This activity was started in ECSS to implement as urgent classified Change Requests.

This activity will be the update of EN16603-20-06 (published 2014). This activity was started in ECSS to implement as urgent classified Change Requests.

EN 16603-20-06:2020 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16603-20-06:2020 has the following relationships with other standards: It is inter standard links to EN 16603-20-06:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16603-20-06:2020 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16603-20-06:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-november-2020

Nadomešča:

SIST EN 16603-20-06:2014

Vesoljska tehnika - Napajanje vesoljskih plovil

Space engineering - Spacecraft charging

Raumfahrttechnik - Aufladung von Raumfahrzeugen

Ingéniérie spatiale - Charges électrostatique des vehicules spatiales

Ta slovenski standard je istoveten z: EN 16603-20-06:2020

ICS:

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 16603-20-06

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2020

ICS 49.140

Supersedes EN 16603-20-06:2014

English version

Space engineering - Spacecraft charging

Ingéniérie spatiale - Charges électrostatiques des Raumfahrttechnik - Teil 20-06: Aufladung von

engins spatiaux Raumfahrzeugen

This European Standard was approved by CEN on 3 May 2020.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2020 CEN/CENELEC All rights of exploitation in any form and by any means Ref. No. EN 16603-20-06:2020 E

reserved worldwide for CEN national Members and for

CENELEC Members.

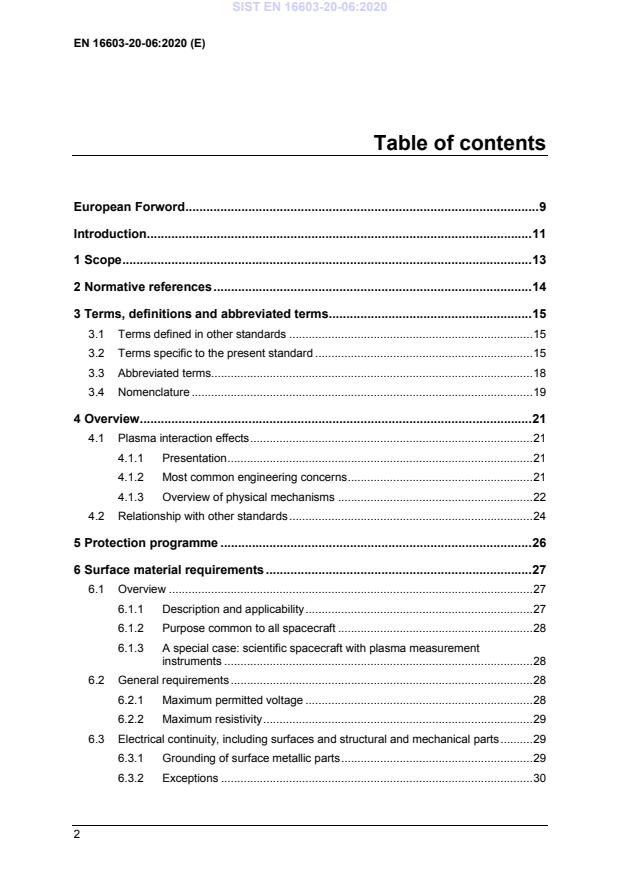

Table of contents

European Forword . 9

Introduction . 11

1 Scope . 13

2 Normative references . 14

3 Terms, definitions and abbreviated terms . 15

3.1 Terms defined in other standards . 15

3.2 Terms specific to the present standard . 15

3.3 Abbreviated terms. 18

3.4 Nomenclature . 19

4 Overview . 21

4.1 Plasma interaction effects . 21

4.1.1 Presentation . 21

4.1.2 Most common engineering concerns . 21

4.1.3 Overview of physical mechanisms . 22

4.2 Relationship with other standards . 24

5 Protection programme . 26

6 Surface material requirements . 27

6.1 Overview . 27

6.1.1 Description and applicability . 27

6.1.2 Purpose common to all spacecraft . 28

6.1.3 A special case: scientific spacecraft with plasma measurement

instruments . 28

6.2 General requirements . 28

6.2.1 Maximum permitted voltage . 28

6.2.2 Maximum resistivity . 29

6.3 Electrical continuity, including surfaces and structural and mechanical parts . 29

6.3.1 Grounding of surface metallic parts . 29

6.3.2 Exceptions . 30

6.3.3 Electrical continuity for surface materials . 31

6.4 Surface charging analysis . 35

6.5 Deliberate potentials . 35

6.6 Testing of materials and assemblies . 35

6.6.1 General . 35

6.6.2 Material characterization tests . 37

6.6.3 Material and assembly qualification . 37

6.7 Scientific spacecraft with plasma measurement instruments . 38

6.8 Verification . 38

6.8.1 Grounding . 38

6.8.2 Material selection . 39

6.8.3 Environmental effects . 39

6.8.4 Computer modelling . 39

6.9 Triggering of ESD . 40

7 Secondary arc requirements . 41

7.1 Description and applicability . 41

7.2 Solar arrays . 42

7.2.1 Overview . 42

7.2.2 General requirement . 42

7.2.3 Testing of solar arrays . 43

7.3 Other exposed parts of the power system including solar array drive

mechanisms . 47

8 High voltage system requirements . 48

8.1 Description . 48

8.2 Requirements . 48

8.3 Validation . 48

9 Internal parts and materials requirements . 49

9.1 Description . 49

9.2 General . 49

9.2.1 Internal charging and discharge effects . 49

9.2.2 Grounding and connectivity . 49

9.2.3 Dielectric electric fields and voltages . 50

9.3 Validation . 51

10 Tether requirements . 55

10.1 Description . 55

10.2 General . 55

10.2.1 Hazards arising on tethered spacecraft due to voltages generated by

conductive tethers . 55

10.2.2 Current collection and resulting problems . 55

10.2.3 Hazards arising from high currents flowing through the tether and

spacecraft structures . 56

10.2.4 Continuity of insulation. . 56

10.2.5 Hazards from undesired conductive paths . 56

10.2.6 Hazards from electro-dynamic tether oscillations . 56

10.2.7 Other effects . 56

10.3 Validation . 57

11 Electric propulsion requirements . 58

11.1 Overview . 58

11.1.1 Description . 58

11.1.2 Coverage of the requirements . 58

11.2 General . 60

11.2.1 Spacecraft neutralization . 60

11.2.2 Beam neutralization . 61

11.2.3 Contamination . 62

11.2.4 Sputtering . 62

11.2.5 Neutral gas effects . 62

11.3 Validation . 63

11.3.1 Ground testing . 63

11.3.2 Computer modelling characteristics . 63

11.3.3 In-flight monitoring. 63

11.3.4 Sputtering . 63

11.3.5 Neutral gas effects . 64

Annex A (normative) Electrical hazard mitigation plan - DRD . 65

A.1 DRD identification . 65

A.1.1 Requirement identification and source document . 65

A.1.2 Purpose and objective . 65

A.2 Expected response . 65

A.2.1 Scope and content . 65

A.2.2 Special remarks . 66

Annex B (informative) Tailoring guidelines . 67

B.1 Overview . 67

B.2 LEO . 67

B.2.1 General . 67

B.2.2 LEO orbits with high inclination . 68

B.3 MEO and GEO orbits . 68

B.4 Spacecraft with onboard plasma detectors . 68

B.5 Tethered spacecraft . 69

B.6 Active spacecraft . 69

B.7 Solar Wind . 69

B.8 Other planetary magnetospheres . 69

Annex C (informative) Physical background to the requirements . 70

C.1 Introduction . 70

C.2 Definition of symbols . 70

C.3 Electrostatic sheaths . 70

C.3.1 Introduction . 70

C.3.2 The electrostatic potential . 71

C.3.3 The Debye length . 71

C.3.4 Presheath . 72

C.3.5 Models of current through the sheath . 73

C.3.6 Thin sheath – space-charge-limited model . 73

C.3.7 Thick sheath – orbit motion limited (OML) model . 74

C.3.8 General case . 75

C.3.9 Magnetic field modification of charging currents . 75

C.4 Current collection and grounding to the plasma . 75

C.5 External surface charging . 76

C.5.1 Definition . 76

C.5.2 Processes . 76

C.5.3 Effects . 77

C.5.4 Surface emission processes . 77

C.5.5 Floating potential . 78

C.5.6 Conductivity and resistivity . 79

C.5.7 Time scales . 81

C.6 Spacecraft motion effects . 81

C.6.1 Wakes . 81

C.6.2 Motion across the magnetic field . 84

C.7 Induced plasmas . 85

C.7.1 Definition . 85

C.7.2 Electric propulsion thrusters . 86

C.7.3 Induced plasma characteristics . 86

C.7.4 Charge-exchange effects . 87

C.7.5 Neutral particle effects . 88

C.7.6 Effect on floating potential . 88

C.8 Internal and deep-dielectric charging . 88

C.8.1 Definition . 88

C.8.2 Relationship to surface charging . 89

C.8.3 Charge deposition . 90

C.8.4 Material conductivity . 90

C.8.5 Time dependence . 93

C.8.6 Geometric considerations. 93

C.8.7 Isolated internal conductors . 94

C.8.8 Electric field sensitive systems . 94

C.9 Discharges and transients . 95

C.9.1 General definition . 95

C.9.2 Review of the process . 95

C.9.3 Dielectric material discharge . 96

C.9.4 Metallic discharge . 98

C.9.5 Internal dielectric discharge . 99

C.9.6 Secondary powered discharge . 100

C.9.7 Discharge thresholds . 100

Annex D (informative) Charging simulation . 102

D.1 Surface charging codes . 102

D.1.1 Introduction . 102

D.2 Internal charging codes . 104

D.2.1 DICTAT . 104

D.2.2 ESADDC . 104

D.2.3 GEANT-4 . 105

D.2.4 NOVICE . 105

D.3 Environment model for internal charging . 105

D.3.1 FLUMIC . 105

D.3.2 Worst case GEO spectrum . 105

Annex E (informative) Testing and measurement. . 106

E.1 Definition of symbols . 106

E.2 Solar array testing. 106

E.2.1 Solar cell sample . 106

E.2.2 Pre-testing of the solar array simulator (SAS) . 107

E.2.3 Solar array test procedure . 109

E.2.4 Other elements . 113

E.2.5 The solar panel simulation device . 114

E.3 Measurement of conductivity and resistivity . 116

E.3.1 Determination of intrinsic bulk conductivity by direct measurement . 116

E.3.2 Determination of radiation-induced conductivity coefficients by direct

measurement . 117

E.3.3 Determination of conductivity and radiation-induced conductivity by

electron irradiation. 118

E.3.4 The ASTM method for measurement of surface resistivity and its

adaptation for space used materials . 118

References . 120

Bibliography . 124

Figures

Figure 6-1: Applicability of electrical continuity requirements . 32

Figure 7-1: Solar array test set-up . 45

Figure C-1 : Schematic diagram of potential variation through sheath and pre-sheath. . 72

Figure C-2 : Example secondary yield curve . 78

Figure C-3 : Schematic diagram of wake structure around an object at relative motion

with respect to a plasma . 82

Figure C-4 : Schematic diagram of void region . 83

Figure C-5 : Schematic diagram of internal charging in a planar dielectric . 89

Figure C-6 : Dielectric discharge mechanism. . 97

Figure C-7 :Shape of the current in relation to discharge starting point. . 97

Figure C-8 : Example of discharge on pierced aluminized Teflon® irradiated by

electrons with energies ranging from 0 to 220 keV. . 98

Figure C-9 : Schematic diagram of discharge at a triple point in the inverted voltage

gradient configuration with potential contours indicated by colour scale. . 99

Figure E-1 : Photograph of solar cells sample – Front face & Rear face

(Stentor Sample. Picture from Denis Payan - CNES®). 107

Figure E-2 : Schematic diagram of power supply test circuit . 108

Figure E-3 : Example of a measured power source switch response . 108

Figure E-4 : Example solar array simulator . 109

Figure E-5 : Absolute capacitance of the satellite . 110

Figure E-6 : Junction capacitance of a cell versus to voltage . 112

Figure E-7 : The shortened solar array sample and the missing capacitances . 113

Figure E-8 : Discharging circuit oscillations . 114

Figure E-9 : Effect of an added resistance in the discharging circuit (SAS + resistance) . 114

Figure E-10 : Setup simulating the satellite including flashover current . 115

Figure E-11 : Basic arrangement of apparatus for measuring dielectric conductivity in

planar samples . 116

Figure E-12 : Arrangement for measuring cable dielectric conductivity and cross-

section through co-axial cable . 116

Figure E-13 : Arrangement for carrying out conductivity tests on planar samples under

irradiation . 118

Figure E-14 : Basic experimental set up for surface conductivity . 119

Tables

Table 4-1: List of electrostatic and other plasma interaction effects on space systems . 23

Table 7-1: Tested voltage-current combinations . 42

Table 7-2: Typical inductance per unit length for cables . 46

Table C-1 : Parameters in different regions in space . 72

Table C-2 : Typical plasma parameters for LEO and GEO . 83

Table C-3 : Plasma conditions on exit plane of several electric propulsion thrusters . 87

Table C-4 : Emission versus backflow current magnitudes for several electric

propulsion thrusters . 87

Table C-5 : Value of Ea for several materials . 91

European Forword

This document (EN 16603-20-06:2020) has been prepared by Technical

Committee CEN-CENELEC/TC 5 “Space”, the secretariat of which is held by

DIN.

This document (EN 16603-20-06:2020) originates from ECSS-E-ST-20-06C Rev.1.

This European Standard shall be given the status of a national standard, either

by publication of an identical text or by endorsement, at the latest by March

2021, and conflicting national standards shall be withdrawn at the latest by

March 2021.

Attention is drawn to the possibility that some of the elements of this document

may be the subject of patent rights. CEN [and/or CENELEC] shall not be held

responsible for identifying any or all such patent rights.

This document supersedes 16603-20-06:2004.

The main changes with respect to 16603-20-06:2004 are listed below:

Addition of definition for the term "flashover current"

Addition of abbreviated terms "RIC" and "SPIS"

Addition of the “Nomenclature” in clause 3.4

Addition of informative text in 6.1.3 about neutralizers after deletion of

requirement 6.7e

Changes to maximum permitted voltages and acceptance of higher

voltages if the effect of worst-case ESD would be acceptable

Simplification of the grounding requirements for surface materials

Change in the permitted ESD energy where surface ESD cannot be

excluded

Change to explicitly allow surface charging analysis to justify acceptance

For surface charging analysis , removal of acceptance by similarity and

statement of the need for material testing

For internal charging, completely embedded floating metals may be

accepted under specified conditions

This document has been prepared under a standardization request given to

CEN by the European Commission and the European Free Trade Association.

This document has been developed to cover specifically space systems and has

therefore precedence over any EN covering the same scope but with a wider

domain of applicability (e.g. : aerospace).

According to the CEN-CENELEC Internal Regulations, the national standards

organizations of the following countries are bound to implement this European

Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic,

Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

The subject of spacecraft plasma interactions has been part of the spacecraft

design process since spacecraft surface charging was first encountered as a

problem in the earliest geostationary spacecraft. However, spacecraft surface

charging is only one of the ways in which the space environment can adversely

affect the electrical state of spacecraft and satellite technology has evolved over

the years.

A need was identified for a standard that is up to date and comprehensive in its

treatment of all the main environment-induced plasma and charging processes

that can affect the performance of satellites in geostationary and medium and

low Earth orbits. This standard is intended to be used by a number of users,

with their own design rules, and therefore it has been done to be compatible

with different alternative approaches.

This document aims to satisfy these needs and provides a consistent standard

that can be used in design specifications. The requirements are based on the

best current understanding of the processes involved and are not radical,

building on existing de-facto standards in many cases.

As well as providing requirements, it aims to provide a straightforward brief

explanation of the main effects so that interested parties at all stages of the

design chain can have a common understanding of the problems faced and the

meaning of the terms used. Guide for tailoring of the provisions for specific

mission types are described in Annex B. Further description of the main

processes are given in Annex C. Some techniques of simulation, testing and

measurement are described in Annex D and Annex E.

Electrical interactions between the space environment and a spacecraft can arise

from a number of external sources including the ambient plasma, radiation,

electrical and magnetic fields and sunlight. The nature of these interactions and

the environment itself can be modified by emissions from the spacecraft itself,

e.g. electric propulsion, plasma contactors, secondary emission and

photoemission. The consequences, in terms of hazards to spacecraft systems

depend strongly on the sensitivity of electronic systems and the potential for

coupling between sources of electrical transients and fields and electronic

components.

Proper assessment of the effects of these processes is part of the system

engineering process as defined in ECSS-E-ST-20. General assessments are

performed in the early phases of a mission when consideration is given to e.g.

orbit selection, mass budget, thermal protection, and materials and component

selection policy. Further into the design of a spacecraft, careful consideration is

given to material selection, coatings, radiation shielding and electronics

protection.

This standard begins with an overview of the electrical effects occurring in

space (Clause 4). The requirements, in terms of spacecraft testing, analysis and

design that arise from these processes (Clause 5 to Clause 11) form the core of

this document. Annex B holds a discussion of types of orbits and how to tailor

the requirements according to the mission. Annex C discusses the quantitative

assessment of the physical processes behind these main effects. Annex D

describes computer simulations and Annex E describes testing and

measurement.

Scope

This standard is a standard within the ECSS hierarchy. It forms part of the

electrical and electronic engineering discipline (ECSS-E-ST-20) of the

engineering branch of the ECSS system (ECSS-E). It provides clear and

consistent provisions to the application of measures to assess, in order to avoid

and minimize hazardous effects arising from spacecraft charging and other

environmental effects on a spacecraft’s electrical behaviour.

This standard is applicable to any type of spacecraft including launchers, when

above the atmosphere.

Although spacecraft systems are clearly subject to electrical interactions while

still on Earth (e.g. lightning and static electricity from handling), these aspects

are not covered, since they are common to terrestrial systems and covered

elsewhere. Instead this standard covers electrical effects occurring in space (i.e.

from the ionosphere upwards).

This standard may be tailored for the specific characteristic and constrains of a

space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through

reference in this text, constitute provisions of this ECSS Standard. For dated

references, subsequent amendments to, or revision of any of these publications

do not apply, However, parties to agreements based on this ECSS Standard are

encouraged to investigate the possibility of applying the more recent editions of

the normative documents indicated below. For undated references, the latest

edition of the publication referred to applies.

EN reference Reference in text Title

EN 16601-00-01 ECSS-S-ST-00-01 ECSS system - Glossary of terms

Terms, definitions and abbreviated terms

3.1 Terms defined in other standards

For the purpose of this Standard, the terms and definitions from

ECSS-S-ST-00-01 apply.

3.2 Terms specific to the present standard

3.2.1 aluminium equivalent thickness

thickness of aluminium with a mass density per unit area equal to that of the

material being described

-2

NOTE The mass density is normally measured in (g cm ).

3.2.2 auroral zone

region at a latitude between 60 and 70 degrees north or south where aurorae are

formed

3.2.3 deep-dielectric charging

electrical charge deposition within the bulk of an external or internal material

3.2.4 dielectric

pertaining to a medium in which an electric field can be maintained

NOTE Depending on their resistivity, dielectric materials

can be described as insulating, antistatic,

moderately conductive or conductive. The

following gives a classic example of classification

according to the resistivity:

more than 10 m: insulating

2 9

between 10 m and 10 m: antistatic

3 6

between 10 m and 10 m: static dissipative

-2 2

between 10 m and 10 m: moderately

conductive

-2

less than 10 m: conductive

3.2.5 dose

energy absorbed locally per unit mass as a result of radiation exposure

3.2.6 downstream

on side of an object in the same direction as the plasma velocity vector

3.2.7 electrostatic

pertaining to static electricity or electricity at rest

3.2.8 electrostatic breakdown

failure of the insulation properties of a dielectric, resulting in a sudden release

of charge and risk of damage to the dielectric concerned

3.2.9 electrostatic discharge

rapid, spontaneous transfer of electrical charge induced by a high electrostatic

field

3.2.10 external charging

electric charge deposition on external materials

3.2.11 flashover current

current arising from a surface propagating discharge

3.2.12 fluence

time-integration of the flux

3.2.13 insulator

insulating dielectric

3.2.14 internal charging

electrical charge deposition on internal materials shielded at least by the

spacecraft skin due to penetration of charged particles from the ambient

medium

NOTE Materials can be conductors or dielectrics.

3.2.15 internal dielectric charging

internal charging of dielectric materials

3.2.16 ion engine

propulsion system which operates by expelling ions at high velocities

3.2.17 L shell

parameter of the geomagnetic field

NOTE 1 It is also referred as L, and is used as a co-ordinate

to describe positions in near-Earth space.

NOTE 2 L or L shell has a complicated derivation based on

an invariant of the motion of charged particles in

the terrestrial magnetic field. However, it is useful

in defining plasma regimes within the

magnetosphere because, for a dipole magnetic

field, it is equal to the geocentric altitude in Earth-

radii of the local magnetic field line where it

crosses the equator.

3.2.18 omnidirectional flux

scalar integral of the flux over all directions

NOTE This implies that no consideration is taken of the

directional distribution of the particles which can

be non-isotropic. The flux at a point is the number

of particles crossing a sphere of unit cross-sectional

surface area (i.e. of radius). An omnidirectional

flux is not to be confused with an isotropic flux.

3.2.19 outgassing rate

mass of molecular species evolving from a material per unit time and unit

surface area

-2 -1

NOTE The units of outgassing rates are g cm s . It can

also be given in other units, such as in relative

-1 -1 -1 -2

mass unit per time unit: (g s ), (% s ) or (% s cm ).

3.2.20 plasma

partly or wholly ionized gas whose particles exhibit collective behaviour

through its electromagnetic field

3.2.21 primary discharge

initial electrostatic discharge which, by creating a temporary conductive path,

can lead to a secondary arc

3.2.22 radiation

transfer of energy by means of a particle (including photons)

NOTE In the context of this Standard, electromagnetic

radiation below the UV band is excluded. This

therefore excludes visible, thermal, microwave and

radio-wave radiation.

3.2.23 radiation belt

area of trapped or quasi-trapped energetic particles, contained by the Earth’s

magnetic field

3.2.24 ram

volume adjacent to the spacecraft and located in the same direction of the

spacecraft motion where modification to the surface or plasma can occur due to

the passage of the spacecraft through the medium

3.2.25 secondary arc

passage of current from an external source, such as a solar array, through a

conductive path initially generated by a primary discharge

3.2.26 surface charging

electrical charge deposition on the surface of an external or internal material

3.2.27 tether

flexible conductive or non-conductive cable linking two spacecraft or two parts

of the same spacecraft not mechanically attached in any other way

3.2.28 thruster

device for altering the attitude or orbit of a spacecraft in space through reaction

NOTE E.g. rocket, cold-gas emitter, and electric

propulsion.

3.2.29 triple point

point where dielectric, metal and vacuum meet

3.2.30 upstream

on the side of the object in the opposite direction to the plasma velocity vector

3.2.31 wake

volume adjacent to a spacecraft and located in the opposite direction to the

spacecraft motion where the ambient plasma is modified by the passage of the

spacecraft through the medium

3.3 Abbreviated terms

The following abbreviated terms are defined and used within this Standard.

Abbreviation Meaning

AOCS attitude and orbital control system

DGD direct gradient discharge

EMC electromagnetic compatibility

emf electro-motive force

EP electric propulsion

ESD electrostatic discharge

ETFE ethylene-tetrafluoroethylene copolymer

eV electron volt (also keV, MeV)

FEEP field emission electric propulsion

FEP fluoroethylene-propylene

GEO geostationary Earth orbit

HEO

highly eccentric orbit

ISS International Space Station

IVG inverted voltage gradient

IVGD inverted voltage gradient discharge

LEO

low Earth orbit

MEMS micro-electromechanical system(s)

MEO medium (altitude) Earth orbit

MLI multi-layer insulation

MLT magnetic local time

NASA National Aeronautics and Space Administration

NGD normal gradient discharge

PCB printed circuit board

PEO polar Earth orbit

PTFE poly-tetrafluoroethylene

PVA photo-voltaic assembly

RIC radiation induced conductivity

r.m.s. root-mean-square

SAS solar array simulator

SPIS spacecraft plasma interaction simulation

SPT stationary plasma thruster

SSM second surface mirror

UV ultra-violet light

3.4 Nomenclature

The following nomenclature applies throughout this document:

a. The word “shall” is used in this Standard to express requirements. All

the requirements are expressed with the word “shall”.

b. The word “should” is used in this Standard to express recommendations.

All the recommendations are expressed with the word “should”.

NOTE It is expected that, during tailoring,

recommendations in this docume

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...