EN 12499:2003

(Main)Internal cathodic protection of metallic structures

Internal cathodic protection of metallic structures

This standard specifies the structures, electrolytes, metals, surfaces which can be protected against corrosion by application of internal cathodic protection - specifies the conditions necessary to the application of internal cathodic protection - give guidances on realisation and operation of an efficient cathodic protection system of specific structures, namely - Domestic water heaters, appliances for heating and storage, feed tank with variable level, filtering tanks, internal surface of wells casing, internal surface of pipes, tubular heat exchangers.

Kathodischer Korrosionsschutz für die Innenflächen von metallischen Anlagen

Diese Europäische Norm legt die Anlagen, die Metalle und Oberflächen, die durch Anwenden des inneren kathodischen Schutzes gegen Korrosion geschützt werden können, die Elektrolytlösungen und die für einen kathodischen Innenschutz erforderlichen Bedingungen fest. Ferner gibt sie Anleitungen für die Installation und für den Betrieb eines wirksamen kathodischen Schutzsystems.

Diese Norm betrifft die Anwendung des inneren kathodischen Schutzes von häuslichen Wassererwärmern, Warm- und Kaltwasserbehältern, Wasserzirkulationsleitungen, Kondensatoren, Wärmetauschern sowie ganz allgemein Anlagen, die eine Elektrolytlösung enthalten, so dass der kathodische Schutz technisch möglich ist. Diese Norm gilt für metallische Anlagen, die gespeichertes oder fließendes Wasser enthalten, das stagnierend oder ausgetauscht sowie kalt oder warm sein kann. Sie gilt für Trinkwasser oder Betriebswässer und selbst für wässrige Suspension.

ANMERKUNG Es wird davon ausgegangen, dass die Elektrolytlösungen eine Leitfähigkeit über 10-3 S m-1 und einen pH Wert über 4,5 haben. Falls der pH-Wert unter 5,5 oder die Leitfähigkeit unter 10-2 S m-1 sinkt, sollten 5.4 und 6.9.2.2 beachtet werden.

Diese Norm gilt für metallische Anlagen, die aus einem Werkstoff oder zusammen mit weiteren Werkstoffen hergestellt sind. Diese Werkstoffe sind:

Eisen und niedriglegierte Stähle;

schmelztauchverzinkter Stahl;

Kupfer und Kupferlegierungen;

Blei;

Zinn;

nichtrostende Stähle;

Aluminium und Zink;

Titan.

Diese Norm gilt sowohl für unbeschichtete Metalle als auch für solche, die bereits mit nieder- oder hochohmigen Beschichtungen versehen sind.

Protection cathodique interne des structures métalliques

La présente Norme européenne spécifie les structures, les métaux et les surfaces susceptibles d'être protégés contre la corrosion par l'application d'une protection cathodique interne, ainsi que les solutions d'électrolytes et les conditions nécessaires pour l'application d'une protection cathodique interne, et donne des indications sur l'application et le fonctionnement d'un système de protection cathodique interne efficace.

La présente norme s'applique à la protection cathodique interne des chauffe-eau domestiques, des réservoirs d'eau chaude et d'eau froide, des canalisations de circulation d'eau, des condensateurs, des échangeurs de chaleur et, de façon générale, de toute structure contenant une solution d'électrolytes qu'il est possible, du point de vue technique, de protéger cathodiquement. La présente norme s'applique aux structures métalliques qui contiennent de l'eau accumulée ou en circulation, dormante ou renouvelée, chaude ou froide, de l'eau potable ou de l'eau industrielle, ainsi que des suspensions aqueuses.

NOTE Les solutions d'électrolytes ont, par hypothèse, une conductivité > 10-3 Siemens m-1, et un pH > 4,5. Lorsque le pH < 5,5 ou lorsque la conductivité est < 10-2 Siemens m-1, voir 5.4 et 6.9.2.2.

La présente norme est applicable aux structures métalliques composées des métaux suivants, isolément ou en combinaison :

fonte et acier faiblement allié ;

acier galvanisé ;

cuivre et alliages de cuivre ;

plomb ;

étain ;

aciers inoxydables ;

aluminium et zinc ;

titane.

La présente norme est applicable à la protection cathodique des métaux non revêtus et des métaux munis de revêtements à résistance d'isolement faible ou élevée.

Notranja katodna zaščita kovinskih konstrukcij

General Information

- Status

- Published

- Publication Date

- 07-Jan-2003

- Withdrawal Date

- 30-Jul-2003

- Technical Committee

- CEN/TC 219 - Cathodic protection (provisional)

- Drafting Committee

- CEN/TC 219 - Cathodic protection (provisional)

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 10-Apr-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN ISO 8044:1999 - Corrosion of metals and alloys - Basic terms and definitions (ISO 8044:1999) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Overview - EN 12499:2003 (Internal cathodic protection)

EN 12499:2003 is the CEN European standard that defines requirements, criteria and guidance for the internal cathodic protection of metallic structures containing an electrolytic solution. It covers which structures, metals and internal surfaces can be protected, the electrolytes and environmental limits (e.g., typical conductivity and pH ranges), and practical rules for design, commissioning, measurement and operation of effective internal cathodic protection systems.

Key structures explicitly addressed include:

- domestic water heaters and hot water storage appliances

- feed tanks with variable level, condensates and similar appliances

- filtering tanks, well casings, internal pipe surfaces

- tubular heat exchangers and circulating water systems

Key topics and technical requirements

- Scope and materials: Applicable to metals such as iron/low-alloy steel, galvanised steel, copper and copper alloys, lead, tin, stainless steels, aluminium, zinc and titanium.

- Principles and protection criteria: Protection is achieved by lowering the metal/electrolyte potential to within specified protection potential ranges (see Table 1 in the standard). Potentials are reported as IR‑free and compared to reference electrodes.

- Electrolyte conditions: Typical assumption is conductivity > 10‑3 S·m‑1 and pH > 4.5; special provisions if pH < 5.5 or conductivity < 10‑2 S·m‑1.

- Anode types and systems: Guidance on galvanic (sacrificial) anodes, soluble/impressed current anodes, continuous anodes, and impressed‑current stations (transformer‑rectifiers, potentiostats).

- Measurements and instrumentation: Structure-to-electrolyte potentials (on/off/instantaneous off), IR‑free potential, use of reference electrodes (Ag/AgCl and standard H2), sensing electrodes and permanent reference installations.

- Design, commissioning and O&M: Requirements for electrical continuity, coating resistance assessment (specific coating resistance), commissioning tests, monitoring, and avoiding overprotection (gas evolution, coating damage).

- Annexes: Normative test for galvanic anode potential (Annex A) and informative guidance on protection potential ranges vs Ag/AgCl in different waters (Annex B).

Practical applications and users

EN 12499:2003 is used by:

- corrosion engineers and cathodic protection designers

- manufacturers of domestic water heaters, heat exchangers and storage tanks

- building services and HVAC engineers, water utilities and asset owners

- inspection and maintenance contractors implementing internal CP systems

Typical applications: preventing internal corrosion in potable and industrial water tanks, internal pipework, well casings and tubular heat exchangers where electrolytic solutions are present.

Related standards

Normative references include EN ISO 8044 (corrosion terminology), EN 60335‑2‑21 (safety of storage water heaters), and electrical standards for hazardous atmospheres (EN 50014). Annexes in EN 12499 provide additional test and reference guidance useful for implementation.

Keywords: EN 12499:2003, internal cathodic protection, cathodic protection of metallic structures, protection potential, galvanic anode, impressed current, Ag/AgCl reference electrode, water heaters, heat exchangers.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 12499:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Internal cathodic protection of metallic structures". This standard covers: This standard specifies the structures, electrolytes, metals, surfaces which can be protected against corrosion by application of internal cathodic protection - specifies the conditions necessary to the application of internal cathodic protection - give guidances on realisation and operation of an efficient cathodic protection system of specific structures, namely - Domestic water heaters, appliances for heating and storage, feed tank with variable level, filtering tanks, internal surface of wells casing, internal surface of pipes, tubular heat exchangers.

This standard specifies the structures, electrolytes, metals, surfaces which can be protected against corrosion by application of internal cathodic protection - specifies the conditions necessary to the application of internal cathodic protection - give guidances on realisation and operation of an efficient cathodic protection system of specific structures, namely - Domestic water heaters, appliances for heating and storage, feed tank with variable level, filtering tanks, internal surface of wells casing, internal surface of pipes, tubular heat exchangers.

EN 12499:2003 is classified under the following ICS (International Classification for Standards) categories: 77.060 - Corrosion of metals. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12499:2003 has the following relationships with other standards: It is inter standard links to EN 60335-2-21:2021, EN IEC 60079-0:2018, EN ISO 8044:1999, EN 17243:2020, EN 15257:2006, EN 14095:2003, EN 12499:2003/AC:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12499:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kathodischer Korrosionsschutz für die Innenflächen von metallischen AnlagenProtection cathodique interne des structures métalliquesInternal cathodic protection of metallic structures91.080.10Kovinske konstrukcijeMetal structures25.220.40Kovinske prevlekeMetallic coatingsICS:Ta slovenski standard je istoveten z:EN 12499:2003SIST EN 12499:2003en01-december-2003SIST EN 12499:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12499January 2003ICS 77.060English versionInternal cathodic protection of metallic structuresProtection cathodique interne des structures métalliquesKathodischer Korrosionsschutz für die Innenflächen vonmetallischen AnlagenThis European Standard was approved by CEN on 7 November 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12499:2003 ESIST EN 12499:2003

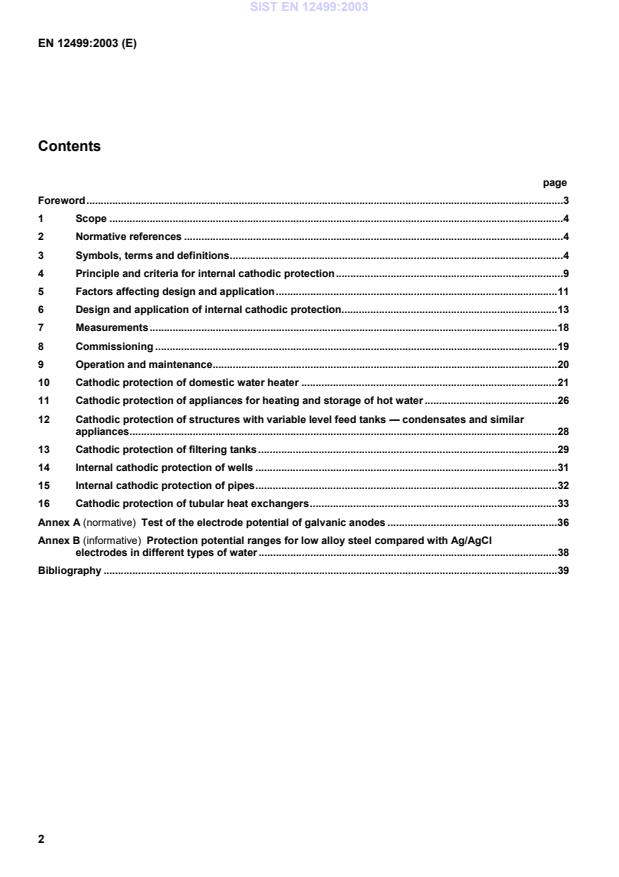

Test of the electrode potential of galvanic anodes.36Annex B (informative)

Protection potential ranges for low alloy steel compared with Ag/AgClelectrodes in different types of water.38Bibliography.39SIST EN 12499:2003

Terms and definitions3.2.1anaerobicwithout free oxygen in the electrolytic solution adjacent to a metallic structure3.2.2anodic areapart of a structure surface which acts as an anode3.2.3cathodic areapart of a structure surface which acts as a cathodeSIST EN 12499:2003

V)3.2.20IR -free potentialpotential measured without the voltage error caused by the IR drop (EIR FREE)3.2.21isolating jointelectrically discontinuous joint or coupling between two lengths of pipe, inserted in order to provide electricaldiscontinuity between them3.2.22measuring pointpoint at which the actual measurement takes placeNOTEIn the case of structure to electrolytic solution potentials this refers to the location of the reference electrode.3.2.23on potentialstructure to electrolytic solution potential measured with the structure cathodic protection current flowing3.2.24overprotectionstate in which the structure to electrolytic solution potentials are more negative than those recommended forsatisfactory cathodic protectionNOTEOverprotection provides no useful function and can cause damage to the structure by excessive production of gaseswhich can constitute an explosion hazard, embrittlement of metals, or protective coating damage.3.2.25permanent anodesimpressed current anodes for which the rate of corrosion is much smaller than the rate calculated in accordancewith Faraday’s Law3.2.26permanent reference electrodepermanent installed reference electrode designed for a long life3.2.27potential gradientdifference in potential between two separate points in the same electrolytic solutionSIST EN 12499:2003

The current delivered by the generator, the protection current, is controlled by the structure potential measured by areference electrode.3.2.29protected structurestructure to which cathodic protection is effectively applied3.2.30protection current (Ip)current made to flow into a metallic structure from its electrolytic environment in order to effect cathodic protectionof the structure3.2.31resistance bondbond with significant resistance to limit the flow of current to within prescribed limitsNOTEResistance can be achieved by the insertion of resistors into the bond connection.3.2.32soluble anodeimpressed current anode which is consumed in accordance with Faraday’s Law by the impressed anodic currentNOTEThe adjectives soluble and sacrificial used alone do not specify if anodes are working by galvanic action or byimpressed current. To avoid confusion it is proposed to apply the following convention: "galvanic anode" for sacrificial galvanicanode; "soluble anode" for soluble impressed current anode.3.2.33standard reference electrodereference electrode whose potential does not depend on the concentrations of various elements in the electrolyticsolution of the corrosion system3.2.34sensing electrodepermanently installed reference electrode used to measure the structure to electrolytic solution potential and toprovide a signal to control the protection current of an automatic impressed current system3.2.35silver/silver chloride reference electrodeAg/AgCl reference electrodeelectrode consisting of silver, coated with silver chloride, in an electrolytic solution containing chloride ionsNOTEThe potential of this electrode changes when the electrolytic solution concentration of the chloride ions changes(see annex B).3.2.36silver/silver chloride standard electrodeAg/AgCl standard electrodereference electrode consisting of silver, coated with silver chloride, in an electrolytic solution containing a fixedconcentration of chloride ions3.2.37specific coating resistancemeasurement derived from the variation of potential induced by a variation of the protection current i.e. the absolutevalue of the variation of potential divided by the corresponding variation of current density (see 7.4)NOTEThis is expressed in ×m2.SIST EN 12499:2003

This group of bacteria is found in most soils and natural waters, but is active only under anaerobic conditions of nearneutrality and free of oxygen.3.2.41transformer-rectifierdevice that transforms the alternating voltage and then rectifies it to direct currentNOTEDirect current derived in this way is used as a power source for impressed current cathodic protection systems.3.2.42utilisation factorproportion of a galvanic anode that may be consumed before the anode ceases to provide a current output inaccordance with the cathodic protection design4 Principle and criteria for internal cathodic protection4.1 PrincipleThe decrease of the corrosion rate is achieved by lowering the corrosion potential to reach the protection potentialrange. Cathodic protection is achieved when all the metallic surfaces to be protected have reached the protectionpotential range.The lowering of the potential is achieved by means of a protection current passing from the electrolytic solution tothe metal surface. This current enters the electrolytic solution from the surface of an anode.Throughout clause 4 all electrode potentials are IR-free potentials.4.2 CriteriaThe protection potential depends on the physical and chemical conditions at the interface between the metal andthe electrolytic solution. The coverage of the metal by calcareous deposits and the rate of diffusion of ions issuingfrom metal are different according to the medium.Protection potential values are determined by practical experience.One single potential criterion cannot cover the range of different situations that arise in internal cathodic protectionapplications.The only criterion that cannot be disputed is a lack of corrosion established by inspection.Some practical values are listed in Table 1. Precautions additional to those listed may need to be taken to protectagainst

effects caused by the simultaneous presence of different metals or by the precipitation of some ions.SIST EN 12499:2003

-0,1See footnote aCopper and copperalloyCold or hot water - 0,20TinCold or hot water - 0,35- 1,0ZincCold or hot water - 0,90 - 1,0 bLeadNeutral cold water - 0,33 - 0,65Cold or hot water- 0,45 - 0,80 bAluminium and alloyswith Magnesium orManganeseSea water - 0,55 - 0,80 bCold or hot water - 0,60 - 0,80Aluminium zinc alloysSea water - 0,70 - 0,90TitaniumSea water-0,75aProtection potentials shall be determined by testing in each case as well as the limiting critical potentials forferritic and martensitic steel. There is no limiting critical potential for austenitic steel.bAluminium and zinc cannot be polarised to such a negative potential that the anodic reaction rate becomesnegligible. These metals are self protected by their oxidation products. Cathodic polarisation can regularise thisinitial oxidation.When the metal potential is measured between the metal and a reference electrode other than a standardhydrogen electrode, the EH metal potential with respect to the standard hydrogen electrode is calculated as follows:EH = EM + ER; orEM = EH - ER (see annex B)whereEMis the measured algebraic value of the potential difference between the metal and the reference electrode;ERis the measured algebraic value of the potential difference between the reference electrode and astandard hydrogen electrode.SIST EN 12499:2003

shall be taken to ensure effective cathodic protection:¾ adjust the number and location of cathodic protection anodes;¾ electrically isolate parts of the structure.When it is necessary to electrically isolate parts it may be useful to introduce resistive bonds between these partsand cathodes to ensure that unacceptable anodic corrosion is avoided on the isolated part.Non-metallic electron conducting materials such as charcoal can impair current distribution on the structure to beprotected. In this case it is essential that electrical insulation of the structure from conducting materials is achieved.6.4 Isolating jointsWherever possible, interruptions to the electrical continuity of the structure to be protected should be avoided. Ifisolating joints are nevertheless used they can introduce a risk of corrosion by concentrating current flow from theisolated part or foreign cathode to the main part of the structure at the isolating joint itself (see Figures 1 and 2).This risk is determined mainly by the level of d.c. current, the conductivity of the electrolytic solution, and the lengthof the isolation joint, but not by the corrosiveness of the electrolytic solution.The distance between parts separated by the isolating piece shall be designed in such a way that the currentflowing from the isolated part to the main part of the structure causes only negligible corrosion damage.It is essential that the insulated pieces and insulating components withstand the electrical, mechanical, thermal andcorrosive chemical stresses which develop in the installation and during service.The isolating materials used shall not contain any electron conducting filling materials.Isolating pieces in areas where there is a danger of explosion shall conform to the requirements of EN 50014.6.5 Anode6.5.1 GeneralThe selection of the anode will depend of the electrolytic solution and such service conditions as:¾ no evolution of hydrogen gas;¾ no evolution of oxygen gas;¾ no decrease of oxygen concentration;SIST EN 12499:2003

8.2). The location of the permanent measurement points should take into account thefollowing points:¾ areas where the least protection is anticipated;SIST EN 12499:2003

Release of hydrogen gasIn impressed current systems, and with galvanic anodes (particulary magnesium anodes), excessive polarisationcan cause evolution of hydrogen gas on the protected structure. Thus, in situations such as closed tanks wherehydrogen can collect, an explosion hazard can arise. To avoid this hazard, it is necessary for all designs to includeadequate venting to prevent the build up of a significant gaseous volume of hydrogen.Where hydrogen evolution could produce an explosion hazard, the structure/electrolytic solution potential should becarefully monitored.6.9.2.3

Chlorine evolutionFor an impressed current cathodic protection in electrolytic solutions having a high rate of chloride, specially at lowpH, the anodic reaction can result in the electrolytic formation of chlorine. Such a formation can cause eitherphysical discomfort or downstream corrosion effects.In order to reduce chlorine production, the anodic current density can be reduced by a reduction in the cathodicprotection demand current and by an increase in the surface area of the anodes.6.9.3 Emptying and openingBefore opening an enclosed structure the impressed cathodic protection system shall be turned off. The structureshall be completely filled with electrolytic solution and degassed. Only after that may the structure be emptied withthe intake of air and opened.SIST EN 12499:2003

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...