EN 12954:2019

(Main)General principles of cathodic protection of buried or immersed onshore metallic structures

General principles of cathodic protection of buried or immersed onshore metallic structures

This document describes the general principles for the implementation and management of a system of cathodic protection against corrosive attacks on structures which are buried or in contact with soils, surface fresh waters or underground waters, with and without the interference of external electrical sources. It specifies the protection criteria to be achieved to demonstrate the cathodic protection effectiveness.

For structures that cannot be electrically isolated from neighbouring influencing structures, it may be impossible to use the criteria defined in the present document. In this case, EN 14505 will be applied (see 9.4 "Electrical continuity/discontinuity").

To assist in forming a decision whether or not to apply cathodic protection the corrosion likelihood can be evaluated using Annex A. Annex A summarizes the requirements of EN 12501-1 [2] and EN 12501-2 [3].

Cathodic protection of structures immersed in seawater is covered by EN 12473 and a series of standards more specific for various applications.

Cathodic protection for reinforced concrete structures is covered by EN ISO 12696.

This document is applicable in conjunction with:

- EN ISO 15589-1 for application for buried or immersed cathodically pipelines,

- EN 50162 to manage d.c. stray currents,

- EN ISO 18086 to manage corrosion due to a.c. interference from high voltage power sources and a.c. traction systems,

- EN 13509 for cathodic protection measurement techniques

- EN 50443 to manage protection for touch and step voltage.

Grundlagen des kathodischen Korrosionsschutzes von metallenen Anlagen in Böden und Wässern

Dieses Dokument beschreibt die allgemeinen Grundsätze für die Implementierung und das Management eines Systems zum kathodischen Schutz gegen korrosive Angriffe auf Anlagen, die erdverlegt sind oder sich in Kontakt mit Böden, Oberflächensüßwasser oder Grundwasser befinden, mit und ohne Beeinflussung durch Fremdströme. Es legt die zum Nachweis der Wirksamkeit des kathodischen Korrosionsschutzes einzuhaltenden Schutzkriterien fest.

Bei Anlagen, die nicht elektrisch von benachbarten beeinflussenden Anlagen getrennt werden können, können die in dem vorliegenden Dokument festgelegten Kriterien möglicherweise nicht angewendet werden. In diesem Fall wird EN 14505 angewendet (siehe 9.4 „Elektrische Längsleitfähigkeit/elektrische Trennung“).

ANMERKUNG Zur Erleichterung der Entscheidung für oder gegen die Anwendung eines kathodischen Korrosionsschutzes kann die Korrosionswahrscheinlichkeit mithilfe des informativen Anhangs A beurteilt werden, worin die Anforderungen von EN 12501 1 [2] und EN 12501 2 [3] zusammengefasst sind.

Der kathodische Korrosionsschutz von Anlagen in Meerwasser oder Brackwasser wird in EN 12473 sowie einer Reihe spezifischerer Normen für unterschiedliche Anwendungen behandelt.

Der kathodische Korrosionsschutz für Anlagen aus Stahlbeton wird in EN ISO 12696 behandelt.

Dieses Dokument ist anwendbar in Verbindung mit:

- EN ISO 15589 1 zur Anwendung für kathodisch korrosionsgeschützte Rohrleitungen in Böden und Wässern;

- EN 50162 zur Steuerung von Gleichstromsteuströmen;

- EN ISO 18086 zum Schutz vor Korrosion aufgrund von Wechselspannungsbeeinflussung durch Hochspannungsquellen und durch mit Wechselstrom betriebene Bahnanlagen;

- EN 13509 zu Messverfahren für den kathodischen Korrosionsschutz;

- EN 50443 zum Schutz vor Berührungs und Schrittspannung.

Principes généraux de la protection cathodique des structures métalliques à terre enterrées ou immergées

Le présent document décrit les principes généraux qui gouvernent la mise en œuvre et la gestion d'un système de protection cathodique afin de protéger contre la corrosion les structures qui sont enterrées ou en contact avec des sols, des eaux douces de surface ou des eaux souterraines, qu'elles subissent ou non l'influence de sources électriques extérieures. Il spécifie les critères de protection à atteindre pour démontrer l'efficacité de la protection cathodique.

Pour les structures qui ne peuvent pas être isolées électriquement par rapport à des structures avoisinantes exerçant une influence, l'utilisation des critères définis dans le présent document peut s'avérer impossible. Dans ce cas, l'EN 14505 sera appliquée (voir 9.4, « Continuité/discontinuité électrique »).

NOTE Pour aider à la prise de décision quant à la pertinence ou non d'appliquer une protection cathodique, le risque de corrosion peut être évalué en utilisant l'Annexe A, informative, qui présente une synthèse des exigences de l’EN 12501 1 [2] et de l’EN 12501 2 [3].

La protection cathodique des structures immergées en eau de mer ou en eaux saumâtres est couverte par l'EN 12473 et par une série de normes plus spécifiques concernant diverses applications.

La protection cathodique des structures en béton armé est couverte par l'EN ISO 12696.

Le présent document s'applique conjointement avec :

— l’EN ISO 15589 1, qui s'applique aux conduites enterrées ou immergées protégées par voie cathodique,

— l'EN 50162 pour la gestion des courants vagabonds des systèmes à courant continu,

— l'EN ISO 18086 pour la gestion de la corrosion occasionnée par l'influence des lignes électriques haute tension en courant alternatif et des systèmes de traction à courant alternatif,

— l’EN 13509 pour les techniques de mesures applicables en protection cathodique,

— l’EN 50443 pour la gestion de la protection contre les tensions de toucher et de pas.

Splošna načela katodne zaščite vkopanih ali potopljenih kovinskih konstrukcij

Ta evropski standard določa splošna načela za uvedbo sistema katodne zaščite vkopanih ali potopljenih kovinskih konstrukcij pred korozijo z vplivom zunanjih električnih virov ali brez njih.

General Information

- Status

- Published

- Publication Date

- 20-Aug-2019

- Withdrawal Date

- 28-Feb-2020

- Technical Committee

- CEN/TC 219 - Cathodic protection (provisional)

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 04-Mar-2025

- Completion Date

- 04-Mar-2025

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12954:2019 - "General principles of cathodic protection of buried or immersed onshore metallic structures" (CEN) defines the general principles, protection criteria and management practices for applying cathodic protection (CP) to metallic structures in contact with soils, fresh surface waters or groundwater. It helps demonstrate CP effectiveness and guides design, installation, commissioning, monitoring and maintenance of CP systems for onshore buried or immersed assets (excluding seawater/brackish water and reinforced concrete).

Key topics and technical requirements

- Protection criteria and measurement - The standard specifies the criteria required to demonstrate effective cathodic protection and references measurement techniques (see EN 13509). It includes tabulated potentials and alternative assessment methods such as the 100 mV cathodic potential shift (Annex B).

- Principles of CP - Covers electrochemical basis, system types (impressed current and galvanic anode systems), and how direct current shifts metal-to-electrolyte potentials to reduce corrosion.

- Prerequisites for application - Addresses electrical continuity and isolation, the role of protective coatings, and when EN 14505 applies for complex or electrically interconnected structures.

- Design considerations - Guidance on estimating current demand, selecting anode type and groundbeds, lifetime design, cable and installation practices, and decoupling devices for AC/DC interference.

- Commissioning, monitoring and maintenance - Requirements for start-up checks, polarization assessment, periodic monitoring, inspection and documentation to verify long‑term CP performance.

- Competence and safety - Emphasises work by competent personnel (see EN ISO 15257) and references standards for managing stray currents, AC interference and safety (EN 50162, EN ISO 18086, EN 50443).

Practical applications and users

Who uses EN 12954:

- Corrosion engineers and CP designers preparing CP schemes for buried tanks, pipelines (note: on-land pipeline specifics are covered by EN ISO 15589-1), storage vessels, and buried steel structures

- Asset owners, operators and maintenance teams responsible for integrity management of buried or immersed metallic infrastructure

- Contractors and inspection agencies performing installation, commissioning and monitoring of CP systems

- Certification and compliance teams assessing CP effectiveness against recognized protection criteria

Practical benefits:

- Provides a standardized basis to design and validate CP systems

- Reduces corrosion risk when used with coatings and complementary standards

- Supports regulatory compliance and asset life‑cycle integrity planning

Related standards (use in conjunction)

- EN ISO 15589-1 - on-land pipeline CP applications

- EN 13509 - CP measurement techniques

- EN 50162 - stray d.c. current management

- EN ISO 18086 - AC interference criteria

- EN 14505 - complex structures / electrical continuity issues

- EN 12473 / EN ISO 12696 - seawater and reinforced concrete CP guidance

EN 12954:2019 is a practical reference for implementing reliable cathodic protection systems on onshore buried or immersed metallic structures and should be used with the complementary standards listed above.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 12954:2019 is a standard published by the European Committee for Standardization (CEN). Its full title is "General principles of cathodic protection of buried or immersed onshore metallic structures". This standard covers: This document describes the general principles for the implementation and management of a system of cathodic protection against corrosive attacks on structures which are buried or in contact with soils, surface fresh waters or underground waters, with and without the interference of external electrical sources. It specifies the protection criteria to be achieved to demonstrate the cathodic protection effectiveness. For structures that cannot be electrically isolated from neighbouring influencing structures, it may be impossible to use the criteria defined in the present document. In this case, EN 14505 will be applied (see 9.4 "Electrical continuity/discontinuity"). To assist in forming a decision whether or not to apply cathodic protection the corrosion likelihood can be evaluated using Annex A. Annex A summarizes the requirements of EN 12501-1 [2] and EN 12501-2 [3]. Cathodic protection of structures immersed in seawater is covered by EN 12473 and a series of standards more specific for various applications. Cathodic protection for reinforced concrete structures is covered by EN ISO 12696. This document is applicable in conjunction with: - EN ISO 15589-1 for application for buried or immersed cathodically pipelines, - EN 50162 to manage d.c. stray currents, - EN ISO 18086 to manage corrosion due to a.c. interference from high voltage power sources and a.c. traction systems, - EN 13509 for cathodic protection measurement techniques - EN 50443 to manage protection for touch and step voltage.

This document describes the general principles for the implementation and management of a system of cathodic protection against corrosive attacks on structures which are buried or in contact with soils, surface fresh waters or underground waters, with and without the interference of external electrical sources. It specifies the protection criteria to be achieved to demonstrate the cathodic protection effectiveness. For structures that cannot be electrically isolated from neighbouring influencing structures, it may be impossible to use the criteria defined in the present document. In this case, EN 14505 will be applied (see 9.4 "Electrical continuity/discontinuity"). To assist in forming a decision whether or not to apply cathodic protection the corrosion likelihood can be evaluated using Annex A. Annex A summarizes the requirements of EN 12501-1 [2] and EN 12501-2 [3]. Cathodic protection of structures immersed in seawater is covered by EN 12473 and a series of standards more specific for various applications. Cathodic protection for reinforced concrete structures is covered by EN ISO 12696. This document is applicable in conjunction with: - EN ISO 15589-1 for application for buried or immersed cathodically pipelines, - EN 50162 to manage d.c. stray currents, - EN ISO 18086 to manage corrosion due to a.c. interference from high voltage power sources and a.c. traction systems, - EN 13509 for cathodic protection measurement techniques - EN 50443 to manage protection for touch and step voltage.

EN 12954:2019 is classified under the following ICS (International Classification for Standards) categories: 23.040.99 - Other pipeline components; 77.060 - Corrosion of metals. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12954:2019 has the following relationships with other standards: It is inter standard links to EN 12954:2001, EN IEC 60079-10-1:2021, EN 50162:2004, EN ISO 18086:2020, EN ISO 9351:2025, EN 14505:2005, EN 13509:2003, EN ISO 15257:2017, EN ISO 8044:2025, EN ISO 12696:2012, EN 15257:2006, EN 15001-2:2023, EN ISO 13174:2012, EN 15112:2022, EN 12595:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12954:2019 is associated with the following European legislation: Standardization Mandates: M/617. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12954:2019 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2020

Nadomešča:

SIST EN 12954:2003

Splošna načela katodne zaščite vkopanih ali potopljenih kovinskih konstrukcij

General principles of cathodic protection of buried or immersed onshore metallic

structures

Grundlagen des kathodischen Korrosionsschutzes von metallenen Anlagen in Böden

und Wässern

Principes généraux de la protection cathodique des structures métalliques à terre

enterrées ou immergées

Ta slovenski standard je istoveten z: EN 12954:2019

ICS:

25.220.40 Kovinske prevleke Metallic coatings

91.080.10 Kovinske konstrukcije Metal structures

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12954

EUROPEAN STANDARD

NORME EUROPÉENNE

August 2019

EUROPÄISCHE NORM

ICS 23.040.99; 77.060 Supersedes EN 12954:2001

English Version

General principles of cathodic protection of buried or

immersed onshore metallic structures

Principes généraux de la protection cathodique des Grundlagen des kathodischen Korrosionsschutzes von

structures métalliques à terre enterrées ou immergées metallenen Anlagen in Böden und Wässern

This European Standard was approved by CEN on 28 July 2019.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2019 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12954:2019 E

worldwide for CEN national Members.

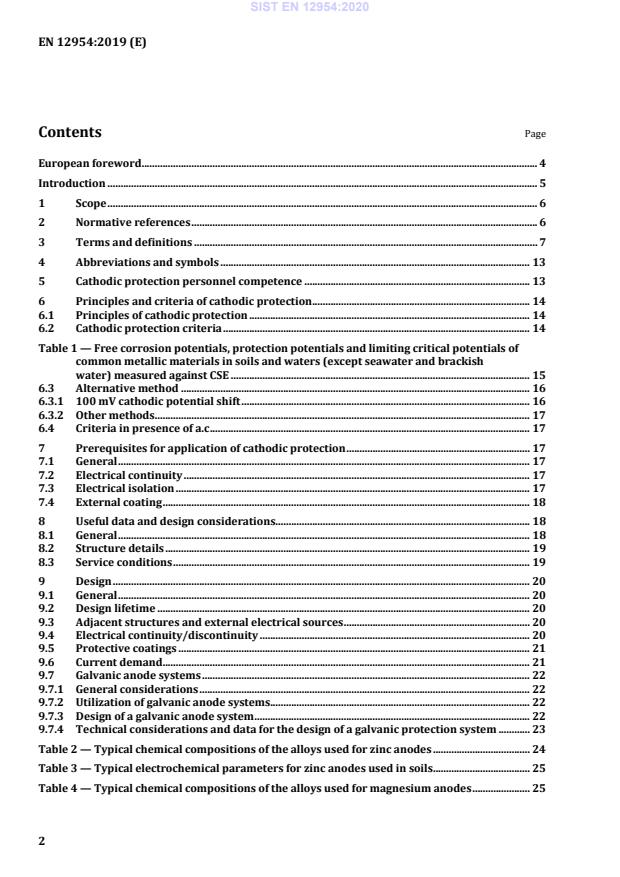

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Abbreviations and symbols . 13

5 Cathodic protection personnel competence . 13

6 Principles and criteria of cathodic protection . 14

6.1 Principles of cathodic protection . 14

6.2 Cathodic protection criteria . 14

Table 1 — Free corrosion potentials, protection potentials and limiting critical potentials of

common metallic materials in soils and waters (except seawater and brackish

water) measured against CSE . 15

6.3 Alternative method . 16

6.3.1 100 mV cathodic potential shift . 16

6.3.2 Other methods . 17

6.4 Criteria in presence of a.c . 17

7 Prerequisites for application of cathodic protection . 17

7.1 General . 17

7.2 Electrical continuity . 17

7.3 Electrical isolation . 17

7.4 External coating . 18

8 Useful data and design considerations . 18

8.1 General . 18

8.2 Structure details . 19

8.3 Service conditions . 19

9 Design . 20

9.1 General . 20

9.2 Design lifetime . 20

9.3 Adjacent structures and external electrical sources . 20

9.4 Electrical continuity/discontinuity . 20

9.5 Protective coatings . 21

9.6 Current demand . 21

9.7 Galvanic anode systems . 22

9.7.1 General considerations . 22

9.7.2 Utilization of galvanic anode systems. 22

9.7.3 Design of a galvanic anode system . 22

9.7.4 Technical considerations and data for the design of a galvanic protection system . 23

Table 2 — Typical chemical compositions of the alloys used for zinc anodes . 24

Table 3 — Typical electrochemical parameters for zinc anodes used in soils. 25

Table 4 — Typical chemical compositions of the alloys used for magnesium anodes . 25

Table 5 — Typical electrochemical parameters for magnesium anodes used in soils . 26

Figure 1 — Current capacity of magnesium alloy versus current density [9] . 27

9.8 A.C. and/or d.c. decoupling devices . 28

9.9 Impressed current cathodic protection (ICCP) system . 28

9.10 Monitoring . 29

9.11 Cable . 29

9.12 Impressed current groundbeds . 30

10 Installation of cathodic protection systems . 31

11 Commissioning . 31

11.1 General . 31

11.2 Preliminary checking . 31

11.3 Start-up . 32

11.4 Assessment of the cathodic protection effectiveness . 32

11.5 Documentations . 33

12 Monitoring, inspection and maintenance . 33

12.1 General . 33

12.2 Monitoring . 34

12.3 Inspection . 35

12.4 Maintenance . 35

Annex A (informative) Corrosion likelihood in soils . 36

Annex B (informative) Reduction of the corrosion rate by using a 100 mV cathodic

polarization — 100 mV cathodic potential shift . 38

B.1 Measurement method during polarization . 38

Figure B.1 — Polarization formation method . 38

B.2 Measurement method during depolarization . 39

Figure B.2 — Polarization decay method . 39

Bibliography . 40

European foreword

This document (EN 12954:2019) has been prepared by Technical Committee CEN/TC 219 “Cathodic

protection”, the secretariat of which is held by BSI.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by February 2020, and conflicting national standards shall

be withdrawn at the latest by February 2020.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12954:2001.

This document describes general principles for applying external cathodic protection on onshore metallic

structures in contact with soils, fresh surface waters or underground waters, except those which are

embedded in concrete and those which are in sea-waters or brackish waters.

This edition of EN 12954 does not cover specific applications for on-land pipelines.

NOTE On-land pipeline applications is now completely covered by EN ISO 15589-1 [1].

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Cathodic protection is a technique based on the application of electrochemical principles. It is achieved

by the supply of sufficient direct current to the external surface, such that the metallic structure-to-

electrolyte potential is shifted to more negative values where external corrosion becomes insignificant.

Cathodic protection covers a wide range of materials and equipment and requires a variety of

measurement techniques.

This document is applicable to the protection of external surfaces of all types of buried or immersed

metallic structures. However, in order to allow for structures having specific features with regards to

shape, use, detailed configuration, construction, commissioning or operation, provision has been made

for complementary standards to be used in conjunction with this one to deal with the peculiarities of such

structures.

To achieve effective cathodic protection design installation, commissioning, inspection and maintenance

it is essential that the works are performed by competent personnel.

This document specifies conditions necessary to consider cathodic protection as an efficient method

which can be applied to mitigate corrosion. It is normally used in combination with a coating.

Alternative solutions to those provided in this standard may be applied if it is demonstrated that they

give equivalent effectiveness and they are well documented.

1 Scope

This document describes the general principles for the implementation and management of a system of

cathodic protection against corrosive attacks on structures which are buried or in contact with soils,

surface fresh waters or underground waters, with and without the interference of external electrical

sources. It specifies the protection criteria to be achieved to demonstrate the cathodic protection

effectiveness.

For structures that cannot be electrically isolated from neighbouring influencing structures, it may be

impossible to use the criteria defined in the present document. In this case, EN 14505 will be applied

(see 9.4 “Electrical continuity/discontinuity”).

NOTE To assist in forming a decision whether or not to apply cathodic protection the corrosion likelihood can

be evaluated using informative Annex A which summarizes the requirements of EN 12501-1 [2] and

EN 12501-2 [3].

Cathodic protection of structures immersed in seawater or brackish waters is covered by EN 12473 and

a series of standards more specific for various applications.

Cathodic protection for reinforced concrete structures is covered by EN ISO 12696.

This document is applicable in conjunction with:

— EN ISO 15589-1 for application for buried or immersed cathodically protected pipelines,

— EN 50162 to manage d.c. stray currents,

— EN ISO 18086 to manage corrosion due to a.c. interference from high voltage power sources and a.c.

traction systems,

— EN 13509 for cathodic protection measurement techniques

— EN 50443 to manage protection for touch and step voltage.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12496, Galvanic anodes for cathodic protection in seawater and saline mud

EN 13509, Cathodic protection measurement techniques

EN 14505, Cathodic protection of complex structures

EN 50162, Protection against corrosion by stray current from direct current systems

EN 60079-10-1, Explosive atmospheres – Part 10-1: Classification of areas - Explosive gas atmospheres

(IEC 60079-10-1)

EN ISO 8044, Corrosion of metals and alloys - Basic terms and definitions (ISO 8044)

EN ISO 15257, Cathodic protection - Competence levels of cathodic protection persons - Basis for

certification scheme (ISO 15257)

EN ISO 18086, Corrosion of metals and alloys - Determination of AC corrosion - Protection criteria (ISO

18086)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 8044 and the following

apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

anaerobic conditions

lack of free oxygen in the electrolyte adjacent to a metallic structure

3.2

anode backfill

added material immediately surrounding a buried anode

3.3

electrical bond

metal conductor, usually copper, connecting two points on the same structure or on different structures

3.4

cathodic protection system

all active and passive components associated with the provision of active external corrosion protection

and its monitoring

Note 1 to entry: Cathodic protection is provided either by impressed current or by galvanic anodes using one or

more stations.

Note 2 to entry: Impressed current and galvanic anode systems consist of all the equipment necessary for the

application of cathodic protection, such as impressed current stations, galvanic anodes, electrical bonds and

isolating joints.

3.5

coating breakdown factor

fc

ratio of current density required to polarize a coated steel surface as compared to a bare steel surface

3.6

average coating resistance

average structure to soil resistance

r

co

value derived from the ratio of the difference between the ON and OFF potentials to the protection

current and the surface area of the structure in question

Note 1 to entry: It is usually expressed in Ω.m .

Note 2 to entry: It is mainly determined by the size and number of coating defects, coating porosity and the

electrolyte resistivity.

3.7

complex structure

structure composed of the structure to be protected and of one or more foreign electrodes, which, for

safety or technical reason, are not electrically separated from it

3.8

copper/saturated copper sulphate reference electrode

CSE

reference electrode consisting of piece of copper in a saturated solution of copper sulphate

3.9

coupon

representative metal sample with known bare surface area dimensions

Note 1 to entry: A coupon can be electrically connected to the structure.

3.10

d.c. decoupling device

equipment that provides a low-impedance path for a.c. and high resistance for d.c

Note 1 to entry: Polarization cells, capacitors or diodes assemblies are examples.

3.11

depolarization

anodic change of potential of a cathodically polarized electrode after disconnection or loss of the cathodic

protection source

3.12

design current

maximum current necessary to protect a structure for the lifetime of a cathodic protection system

Note 1 to entry: This current can be the result of calculation or test (on existing structure). It can be affected by a

design allowance (according to laying conditions, ageing of coating, environmental conditions, operating

conditions…).

3.13

drainage

electrical drainage

transfer of stray current from the affected structure to its source by mean of a deliberate electrical bond

Note 1 to entry: For drainage devices (direct drainage bond, resistance drainage bond, unidirectional drainage

bond and forced drainage bond) see EN 50162.

3.14

drainage station

equipment and materials required to provide drainage of stray currents from affected systems

3.15

driving voltage

difference between the structure/electrolyte potential and the anode/electrolyte potential when the

cathodic protection is operating

3.16

earthing system

arrangement of connections and devices necessary to earth equipment or a system separately or jointly

3.17

electrical continuity

physical state of a structure such that a current circulating within it does not produce a significant voltage

drop

3.18

electrical isolation

lack of electrical continuity between structures or components

3.19

foreign structure

foreign electrode

metallic structure or electrode (anode or cathode), in contact with the structure under consideration

Note 1 to entry: A foreign anode is a foreign electrode, which has a more negative potential than the structure, a

foreign cathode is a foreign electrode, which has a more positive potential than the structure.

3.20

galvanic anode

electrode that provides current for cathodic protection by means of galvanic action

3.21

groundbed

system of buried or immersed galvanic or impressed current anodes

3.22

holiday

defect in a protective coating at which metal is exposed to the environment

3.23

immersed structure

metal construction, or part of a construction laid in a liquid environment such as fresh water (rivers,

lakes)

3.24

impressed current anode

electrode that supplies current for cathodic protection by means of an impressed current source

3.25

impressed current station

station which comprises the equipment and materials required to provide cathodic protection by

impressed current

Note 1 to entry: Such materials and equipment include impressed current anodes, cables, one or several d.c.

sources (e.g. transformer rectifier) and tests facilities.

3.26

insulated flanges

flanged joint between adjacent lengths of pipe in which the nuts and bolts are electrically insulated from

the flange(s) and the gasket is non-conducting, so that there is an electrical discontinuity in the structure

(e.g. pipeline, piping system) at that point

3.27

interference

phenomenon resulting from conductive, capacitive, or inductive coupling between a structure and a

foreign d.c. or a.c. electrical source or between two structures, and which can cause malfunction,

dangerous voltage, damage, etc

Note 1 to entry: Capacitive and inductive coupling are related to a.c. interference.

3.28

interference test

test to determine the electrical interaction between two structures

3.29

IR drop

voltage, due to any current, developed in any part of the circuit, such as the electrolyte (typically soil), in

accordance with Ohm's Law

Note 1 to entry: In this standard, when IR Drop is discussed, it is mainly the one present in the electrolyte

(typically soil), between the reference electrode and the metal of the structure.

Note 2 to entry: IR drops in the electrolyte can affect the accuracy of the structure-to-electrolyte potential.

3.30

IR free potential

E

IR free

structure-to-electrolyte potential measured without the voltage error caused by the IR drop due to the

protection current or any other current

3.31

isolating joint

electrically-insulating component between two parts of a structure, in order to provide electrical

discontinuity between them

EXAMPLE Monobloc/monolithic isolating joint, insulated flange, isolating coupling.

3.32

limiting critical potential

IR free potential below which there is a risk of detrimental effect on the protected material

3.33

OFF-potential

E

OFF

structure-to-electrolyte potential measured immediately after synchronous interruption of all sources of

applied cathodic protection current and before significant depolarization of the structure

Note 1 to entry: EOFF can be misleading in presence of d.c. or a.c. interference.

3.34

ON-potential

E

ON

structure-to-electrolyte potential measured with the cathodic protection current and/or any other

current flowing

3.35

polarization

electrode polarization

change in the structure-to-electrolyte potential as the result of current flow to or from that structure

3.36

protected structure

structure to which cathodic protection is applied

3.37

protection current

current made to flow onto a metallic structure from its electrolytic environment in order to effect

cathodic protection of the structure

3.38

protection potential

structure-to-electrolyte potential at which the metal corrosion rate is acceptable for the structure

3.39

remote earth

part of the electrolyte in which no noticeable voltage, caused by current flow, occur between any two

points

Note 1 to entry: This situation generally prevails outside the zone of influence of an earth electrode, an earthing

system, an impressed current groundbed or a protected structure.

3.40

remote monitoring

measurement made using telecommunication systems for transmission of data

Note 1 to entry: It can include an automatic reporting system when pre-set upper and lower limits are exceeded.

3.41

standard hydrogen electrode

reference electrode, used as a standard in laboratories, consisting of an inert metal, such as platinum, in

an electrolyte containing hydrogen ions at unit activity and saturated with hydrogen gas at one standard

atmosphere

3.42

stray current

current flowing through paths other than the intended circuits

3.43

structure

metallic construction, whether coated or not, which is in contact with an electrolyte

Note 1 to entry: Examples of electrolyte are soil or water.

Note 2 to entry: The structure can represent a construction of great length, such as underground electric cables,

as well as constructions on a smaller scale such as piles, sheet pilings, tanks or other underground constructions.

3.44

structure-to-electrolyte potential

difference in potential between the metallic surface of a structure in contact with an electrolyte and a

reference electrode in contact with the electrolyte at a point sufficiently close to, but not touching the

structure

3.45

sulphate reducing bacteria

SRB

group of bacteria found in most soils and natural waters, but active only in conditions of near neutrality

and freedom from oxygen

Note 1 to entry: Sulphate reducing bacteria reduce sulphates in their environment, with the production of

sulphides and accelerate the corrosion.

3.46

test point

location where the potential measurement is carried out

Note 1 to entry: This can be at a test station, but can be at any location where potential can be measured.

Note 2 to entry: It corresponds to the location where the reference electrode is placed.

3.47

probe

device incorporating a coupon that provides measurements of key parameters to assess the effectiveness

of cathodic protection and/or corrosion likelihood

3.48

test station

installation that provides measuring and test facilities for the buried or immersed structure

Note 1 to entry: Such installations can include cabling and structure connections or can be a direct contact for

measurement purposes.

3.49

transformer rectifier

device that transforms the a.c. voltage and rectifies it to d.c. voltage

Note 1 to entry: d.c. voltage derived in this way is used as a power source for impressed current cathodic

protection systems.

4 Abbreviations and symbols

I Current

ICCP Impressed current cathodic protection

E Potential

R Resistance

j Current density

a.c. Alternating current

d.c. Direct current

E Metal or structure-to-electrolyte potential with respect to a copper/saturated copper

Cu

sulphate reference electrode

E IR free potential

IR Free

E Limiting critical potential

l

E Off potential

OFF

E On potential

ON

E Protection potential

p

E Free corrosion potential

cor

E Metal or structure-to-electrolyte potential with respect to a standard hydrogen electrode

H

f Coating breakdown factor

c

f Final coating breakdown factor

f

f Initial coating breakdown factor

i

Δf Average yearly increase in the coating breakdown factor

I Protection current demand

p

t Total current demand

tot

k Contingency factor

S Surface area

SPD Surge protective device

T Temperature

t Time

t Design life time

dl

ρ Resistivity

5 Cathodic protection personnel competence

Personnel who undertake the design, supervision of installation, commissioning, supervision of

operation, measurements, monitoring inspection, and supervision of maintenance of cathodic protection

systems shall have the appropriate level of competence for the tasks undertaken.

EN ISO 15257 constitutes a suitable method of assessing competence of cathodic protection personnel.

Competence of cathodic protection personnel to the appropriate level for tasks undertaken can be

demonstrated by certification in accordance with prequalification procedures such as EN ISO 15257 or

by another equivalent scheme.

6 Principles and criteria of cathodic protection

6.1 Principles of cathodic protection

The corrosion rate of a metal in soil or water is a function of the electrode potential, E, of the material in

its surrounding media. Except in the case of metals or alloys which can passivate or can be corroded at

high pH, the corrosion rate decreases as the potential is shifted in the negative direction. This negative

potential shift is achieved by applying sufficient direct current from anodes via the soil or water to the

metal surface of the structure to be protected. In the case of coated structures, the current flows to the

metal surface at holidays. The protection current can be provided by impressed current stations or

galvanic anodes.

Cathodic protection is effective if the surface current density is sufficient to lower the potential to a level

capable of achieving an acceptable residual corrosion rate of the structure. Detrimental conditions that

can cause shielding of the cathodic protection current typically include disbonded coatings, thermal

insulating coatings, insulating objects or electrolytes with a high resistivity.

6.2 Cathodic protection criteria

The criteria are most often based on the potential of the metal to be protected in the corrosive electrolyte

(soil or water). The metal protection potential, Ep, corresponds to a threshold at which the corrosion rate

of the metal is reduced to a level considered as acceptably low for practical purposes. The cathodic

protection criteria is therefore:

E ≤ E (1)

p

The cathodic protection system shall be capable of polarizing all parts of the buried structure to potentials

more negative than E , and to maintain such potentials throughout the design life of the structure.

p

The protection potential E depends on the metal in its environment.

p

For carbon steel, low alloyed steels and cast iron, the residual corrosion rate corresponding to E is

p

considered to be 0,01 mm per year.

Some metals may be subject to corrosion damage at very negative potentials. For such metals, the

potential shall therefore not be more negative than a limiting critical potential E. In such cases the

l

criterion for cathodic protection is:

E ≤ E ≤ E (2)

p

l

E and E potentials are those which exist at the metal–to-electrolyte interface, i.e. they shall be considered

p l

IR free, IR being the ohmic drop in the electrolyte between the reference electrode and the metal at the

location where the potential is measured (e.g. at a coating defect).

Procedures for measuring the metal-to-electrolyte potentials are detailed in EN 13509.

The protection, and any limiting critical potentials, of the most common metals to be cathodically

protected in soils and waters are listed in Table 1. For all materials not listed in Table 1, the protection

and limiting critical potentials shall be documented or determined experimentally.

The IR Free potential, E , shall meet the criteria given by Formula (1) and, if applicable, Formula (2).

IR Free

Table 1 presents free corrosion potentials E , protection potentials E and limiting critical potentials E

cor p l

for different metals in different environmental conditions.

Table 1 — Free corrosion potentials, protection potentials and limiting critical potentials of

common metallic materials in soils and waters (except seawater and brackish water) measured

against CSE

Limiting

Protection

Free corrosion

critical

potential: E

p

Metals or potential: E

cor

potential:

Environmental conditions

(V)

alloys (V) Indicative

El (V)

values

(IR Free)

(IR Free)

Soils and waters in all conditions

a

−0,65 to −0,40 −0,85

except those hereunder described

b a

Soils and waters at 40°C < T < 60°C -

c c a

Soils and waters at T > 60°C −0,80 to −0,50 −0,95

Soils and waters in aerobic conditions

Carbon steels,

a

at T < 40°C with −0,50 to −0,30 −0,75

low alloyed

100 Ω.m < ρ < 1 000 Ω.m

steels and cast

iron

Soils and waters in aerobic conditions

a

at T < 40°C with

−0,40 to −0,20 −0,65

ρ > 1 000 Ω.m

Soils and waters in anaerobic

a

conditions and with a risk of Sulphate −0,80 to −0,65 −0,95

Reducing Bacteria activity

Austenitic

stainless steels

d

with Pitting −0,10 to +0,20 −0,50

Resistance

Equivalent < 40

Austenitic

stainless steels Neutral and alkaline soils and waters

with Pitting at ambient temperatures −0,10 to +0,20 −0,30 -

Resistance

Equivalent > 40

Martensitic or

austeno-ferritic

e

- 0,10 to +0,20 −0,50

(duplex)

stainless steels

All stainless Acid soils and waters at ambient

e e

−0,10 to +0,20

steels temperatures

Limiting

Protection

Free corrosion

critical

potential: E

Metals or potential: E p

cor

potential:

Environmental conditions

(V)

alloys (V) Indicative

E (V)

l

values

(IR Free)

(IR Free)

Copper or

−0,20 to 0,00 −0,20 -

copper alloys

Lead - 0,50 to - 0,40 −0,65 −0,95

Soils and waters at ambient

temperatures

Aluminium

g

- 0,70 to - 0,50 −0,8 −1,15

f

alloys

Galvanized steel - 1,10 to - 0,90 - 1,20 -

During the lifetime of the structure any possible changes of resistivity of the medium around the

structure shall be taken into account.

NOTE All potentials are IR free and refer to a copper/saturated copper sulphate reference electrode,

E = E – 0,32 V.

Cu H

a

To prevent hydrogen embrittlement on high strength non alloyed and low alloyed steels with designed yield

−2

strength exceeding 550 N.mm , the limiting critical potential shall be documented or determined experimentally.

b

For temperatures 40°C ≤ T ≤ 60°C, the protection potential can be interpolated linearly between the potential

value determined for 40 °C (−0,65 V, −0,75 V, −0,85 V or –0,95 V) and the potential value for 60°C (−0,95 V).

c

The risk of high pH stress corrosion cracking increases with increase of temperature.

d

In case of presence of any martensitic or ferritic phase (e.g. due to hardening), the risk of hydrogen

embrittlement should be determined by documentation or experimentally.

e

To be determined by documentation or determined experimentally.

f

These values are only valid for aluminium alloys without Zn and Cu (e.g. AIMgSi-alloys). For all other

aluminium alloys the protection potential may be different.

g

Corrosion risk because of alkalinity caused by cathodic protection which dissolves the passive layer.

Protective coatings can become damaged or disbonded under the influence of cathodic protection. Coated

structures should not generally be cathodically polarized beyond −1,2 V Cu/CuSO (IR Free). Values more

negative than −1,2 V Cu/CuSO (IR Free) can be used if experience or data for the particular coating

system and its application demonstrate that more negative values do not cause significant detrimental

coating damage or disbondment in the field.

For steels with a specified minimum yield strength greater than 550 MPa and for corrosion-resistant

alloys such as martensitic and duplex stainless steels, the limiting critical potential shall be determined

with respect to the detrimental effects in the material due to hydrogen formation at the metal surface.

NOTE A tolerably low rate of corrosion of stainless steels and other corrosion resistant alloys can generally be

achieved without polarizing to −850 mV (Cu/CuSO ). Specific grades of stainless steel may be damaged by polarizing

to −850 mV (Cu/CuSO ). For grades of Corrosion Resistant Alloy that are not susceptible to damage by excessive

-

polarization (e.g. resulting from H2 or OH ), it is generally acceptable to polarize them to the protection potential

defined for carbon steel.

6.3 Alternative method

6.3.1 100 mV cathodic potential shift

If the criteria defined in Table 1 cannot be achieved, a cathodic protection shift of 100 mV is considered

as an acceptable alternative method to reduce the corrosion rate (see NACE Publication n°35108 [3]). A

residual corrosion rate less than 0,01 mm/y might not be achieved.

NOTE Informative Annex B provides guidance for measurement of the formation or decay of potential shift.

The application of the 100 mV potential shift shall be avoided at operating temperatures above 40°C, in

soils containing sulfate reducing bacteria; or when interference currents, equalizing currents or telluric

currents might be present. Furthermore, the potential shift method shall not be used in the case of

pipelines connected to or consisting of mixed metal components.

6.3.2 Other methods

Alternative methods may be used if it can be demonstrated that the control of corrosion is achieved.

NOTE The use of corrosion or ER probe are an alternative method that can be used.

6.4 Criteria in presence of a.c

In locations where a.c. interference is suspected, measurements of a.c. voltage and current density shall

be carried out to evaluate the level of the a.c. interference.

In the presence of a.c. voltage on the structure, the protection potentials defined in Table 1 shall be

maintained as a minimum.

For pipelines, EN ISO 18086 gives guidelines for the a.c. corrosion likelihood and defines detailed criteria

to respect.

7 Prerequisites for application of cathodic protection

7.1 General

The effective application of cathodic protection will depend on the size and shape of the structure, the

effectiveness of any coating, the corrosivity of the surrounding medium (e.g. soil, water), a.c. or d.c.

interference, specific requirements in national regulations, and also on the technical and economic

criteria.

To achieve cathodic protection the following conditions shall be satisfied.

7.2 Electrical continuity

The structure, or a section of the whole structure, to be protected, shall be electrically continuous.

Continuity testing can be performed to confirm that the intended continuity has been achieved.

The resistance of the structure to be protected may affect the design of the CP system. Lowering the

electrical resistance of a structure is generally beneficial to uniformity of current distribution. For a

pipeline or a piping system, lowering the longitudinal resistance of the pipe and associated welds will

allow the cathodic protection system to be more efficient. Components (e.g. flanges or expanders) which

may increase the longitudinal resistance of the structure should have low resistance metal bonds.

The resistance of electrical bonds should be low to avoid voltage drops within the structure. Bonds can

be made using metallic conductors such as electrical cables as defined in 9.11 or structural connections.

If cathodic protection is to be applied on non-welded longitudinal structures (e.g. sheet steel piling), the

electrical continuity of the longitudinal structures shall be ensured. Tests of the electrical continuity of

the structure should be performed. When necessary or if problems during the operational lifetime of the

structure are foreseen, permanent electrical bonds (or additional welding) shall be installed.

7.3 Electrical isolation

Whenever possible, the structure to be protected should be electrically isolated from any foreign

structure that will have an adverse effect on the effectiveness of the cathodic protection (e.g. copper

earthing system, rebar in concrete, foreign piping). It is especially important if the structure to be

protected is coated.

If the structure to be protected cannot be electrically isolated from any foreign structure, then it is

required to adequately design the cathodic protection system, and the structure will be considered as

complex one (see EN 14505).

If the structure requires to be earthed, this can be made compatible with the cathodic protection by

installing d.c. decoupling devices and they shall be suitably specified and rated for the purpose. If the

safety earthing circuit is used, the decoupling shall conform to national electrical regulations.

Electrical earth systems can interact with CP systems and can drain current from them. Depending on

national regulations, the following techniques can be used to limit the drain on a CP system:

a) electrically isolate the protected structure from the earth connection and from any items electrically

connected to the earth system;

b) ensure that electrical safety for equipment connected to the CP system is achieved by isolation

(e.g. classes II or III as defined in EN 61140);

c) earth the it

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...