EN 16983:2016

(Main)Disc springs - Quality specifications - Dimensions

Disc springs - Quality specifications - Dimensions

This standard specifies the set of requirements that ensure the correct functioning of disc spring. These include requirements relating to the materials and manufacturing process, tolerances on dimensions and spring forces, and also the permissible relaxation and fatigue life of such springs as a function of stress.

All requirements specified here are minimum requirements.

This standard covers three dimensional series of disc springs.

NOTE In this standard, disc springs are divided into three groups and three dimensional series. Classification into groups is based on the manufacturing process, which is a function of the material thickness. The assignment of disc springs to dimensional series is governed by the h0 /t ratio.

Tellerfedern - Qualitätsanforderungen - Maße

Diese Norm legt die Anforderungen fest, die Tellerfedern erfüllen müssen, damit ihre ordnungsgemäße Funktion sichergestellt ist. Dazu gehören Anforderungen an Werkstoffe und Herstellungsprozesse, Grenzabmaße und Federkrafttoleranzen sowie die zulässige Relaxation und Lebensdauer solcher Federn in Abhängigkeit von der Beanspruchung.

Bei den hier genannten Anforderungen handelt es sich um Mindestanforderungen.

Diese Norm beinhaltet drei Maßreihen von Tellerfedern.

ANMERKUNG In dieser Norm werden Tellerfedern in drei Gruppen und drei Maßreihen unterteilt. Die Unterteilung in Gruppen liegt dem Herstellungsprozess und der damit verbundenen Materialdicke zugrunde. Die Einteilung der Tellerfedern in Maßreihen erfolgt in Abhängigkeit des Verhältnisses h0/t.

Rondelles ressorts - Spécification de qualité - Dimensions

La présente norme spécifie l'ensemble des exigences garantissant le bon fonctionnement de la rondelle ressort. Celles-ci se rapportent notamment aux matériaux et au procédé de fabrication, aux tolérances relatives aux dimensions et aux tensions du ressort, ainsi qu'à la relaxation et à la résistance à la fatigue admissibles pour de tels ressorts en tant que fonction de la contrainte.

Toutes les exigences spécifiées dans la présente norme sont des exigences minimales.

La présente norme couvre trois séries dimensionnelles de rondelles ressorts.

NOTE Dans la présente norme, les rondelles ressorts sont classées en trois groupes et en trois séries dimensionnelles. La classification en groupes découle du procédé de fabrication en fonction de l'épaisseur du matériau employé. La série dimensionnelle des rondelles ressorts est déterminée par le rapport h0/t.

Krožnikaste vzmeti - Specifikacije kakovosti - Mere

Ta standard določa sklop zahtev, ki zagotavljajo pravilno delovanje krožnikastih vzmeti. Sem spadajo zahteve glede materialov in postopka izdelave, tolerance za mere in sile vzmeti ter dovoljena razbremenitev in čas obrabe take vzmeti, ki je posledica obremenitve.

Vse zahteve, navedene v tem standardu, so minimalne zahteve.

Ta standard zajema tri dimenzijske skupine krožnikastih vzmeti.

OPOMBA: v tem standardu so krožnikaste vzmeti razdeljene v tri skupine in tri dimenzijske skupine. Razdelitev v skupine je odvisna od postopka izdelave, ki je odvisen od debeline materiala. Razdelitev krožnikastih vezi v dimenzijske skupine je odvisna od razmerja h0 /t.

General Information

- Status

- Published

- Publication Date

- 15-Nov-2016

- Withdrawal Date

- 30-May-2017

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 21-Nov-2023

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 10132:2021 - Cold rolled narrow steel strip for heat treatment - Technical delivery conditions - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 16983:2016 (CEN) - "Disc springs - Quality specifications - Dimensions" defines minimum quality and dimensional requirements to ensure correct functioning of disc (conical) springs. The standard covers material selection, manufacturing, dimensional tolerances, spring forces, allowable relaxation (creep) and fatigue life as a function of stress. It applies to three dimensional series and divides disc springs into three groups (based on manufacturing process and material thickness) with assignment to a dimensional series governed by the h0/t ratio.

Key topics and technical requirements

- Scope and classification

- Division into three groups (manufacturing process linked to thickness) and three dimensional series (A, B, C) based on the h0/t ratio.

- Materials

- Steel grades referenced (EN 10083 series, EN 10089, EN 10132-4); notes for other materials (stainless steel EN 10151, copper alloys EN 1654) requiring manufacturer consultation.

- Design modulus of elasticity for steel: E = 206 000 MPa (used for calculations in the standard).

- Dimensions & designation

- Nominal sizes, outer/inner diameters (De, Di), thickness (t), initial cone height (h0), free overall height (l0) and designation format.

- Manufacturing processes

- Heat treatment, shot peening, presetting, surface finish and corrosion protection, plus surface quality requirements.

- Tolerances & performance

- Tolerances on diameters, thickness, free overall height and spring load (single and stacked springs).

- Creep/relaxation limits and permissible stresses for static, rarely alternating and dynamic loading; fatigue life guidance as a function of stress.

- Testing & inspection

- Dimensional checks, spring force tests, hardness testing, and reference to acceptance inspection practices.

Applications and users

Who benefits from EN 16983:2016:

- Spring manufacturers - for production tolerances, heat treatment and surface treatments.

- Design & mechanical engineers - specifying disc springs for stacked arrangements, static or fatigue-loaded applications.

- Quality & procurement teams - ensuring supplied springs meet minimum CEN requirements.

- Test labs and certification bodies - verifying compliance with dimensional and mechanical properties.

Typical practical uses:

- Stackable disc springs in preload, damping and compensation systems where predictable force-deflection, relaxation and fatigue behaviour are critical.

Related standards

Normative and referenced documents include:

- EN 10083 series, EN 10089, EN 10132-4 (spring steels)

- EN 10151 (stainless steel strip for springs)

- EN 1654 (copper alloys strip)

- EN ISO 3269 (acceptance inspection), EN ISO 6507 / EN ISO 6508 (hardness tests)

EN 16983:2016 is essential when you need standardized disc spring dimensions, quality specifications, and reliable data for design and procurement decisions.

Frequently Asked Questions

EN 16983:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Disc springs - Quality specifications - Dimensions". This standard covers: This standard specifies the set of requirements that ensure the correct functioning of disc spring. These include requirements relating to the materials and manufacturing process, tolerances on dimensions and spring forces, and also the permissible relaxation and fatigue life of such springs as a function of stress. All requirements specified here are minimum requirements. This standard covers three dimensional series of disc springs. NOTE In this standard, disc springs are divided into three groups and three dimensional series. Classification into groups is based on the manufacturing process, which is a function of the material thickness. The assignment of disc springs to dimensional series is governed by the h0 /t ratio.

This standard specifies the set of requirements that ensure the correct functioning of disc spring. These include requirements relating to the materials and manufacturing process, tolerances on dimensions and spring forces, and also the permissible relaxation and fatigue life of such springs as a function of stress. All requirements specified here are minimum requirements. This standard covers three dimensional series of disc springs. NOTE In this standard, disc springs are divided into three groups and three dimensional series. Classification into groups is based on the manufacturing process, which is a function of the material thickness. The assignment of disc springs to dimensional series is governed by the h0 /t ratio.

EN 16983:2016 is classified under the following ICS (International Classification for Standards) categories: 21.160 - Springs. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16983:2016 has the following relationships with other standards: It is inter standard links to EN ISO 6507-3:2018, EN 1654:1997, EN ISO 6507-2:2018, EN ISO 683-3:2022, EN ISO 683-7:2024, EN ISO 6507-4:2018, EN ISO 6508-2:2023, EN ISO 683-17:1999, EN ISO 683-4:2018, EN ISO 683-3:2019, EN ISO 6508-1:2023, EN ISO 6507-1:2023, EN ISO 3269:2019, EN 10132:2021, EN ISO 683-1:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16983:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Krožnikaste vzmeti - Specifikacije kakovosti - MereTellerfedern - Qualitätsanforderungen - MaßeRondelles ressorts - Spécification de qualité - DimensionsDisc springs - Quality specifications - Dimensions21.160VzmetiSpringsICS:Ta slovenski standard je istoveten z:EN 16983:2016SIST EN 16983:2017en,fr,de01-januar-2017SIST EN 16983:2017SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 16983

November

t r s x ICS

t sä s x r English Version

Disc springs æ Quality specifications æ Dimensions Rondelles ressorts æ Spßcification de qualitß æ Dimensions

Tellerfedern æ Qualitätsanforderungen æ Maße This European Standard was approved by CEN on

s w August

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s x { z uã t r s x ESIST EN 16983:2017

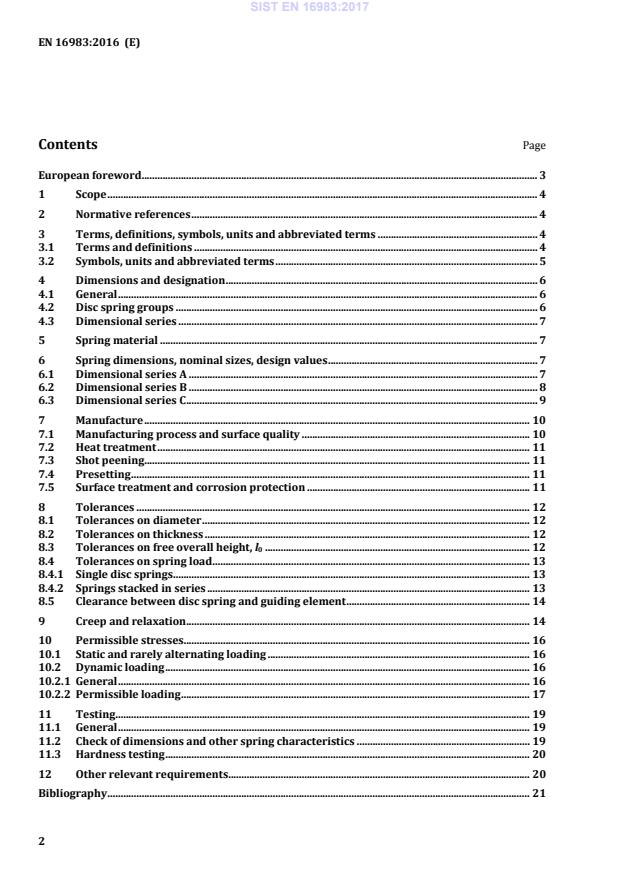

(E) 2 Contents Page European foreword . 3 1 Scope . 4 2 Normative references . 4 3 Terms, definitions, symbols, units and abbreviated terms . 4 3.1 Terms and definitions . 4 3.2 Symbols, units and abbreviated terms . 5 4 Dimensions and designation . 6 4.1 General . 6 4.2 Disc spring groups . 6 4.3 Dimensional series . 7 5 Spring material . 7 6 Spring dimensions, nominal sizes, design values . 7 6.1 Dimensional series A . 7 6.2 Dimensional series B . 8 6.3 Dimensional series C . 9 7 Manufacture . 10 7.1 Manufacturing process and surface quality . 10 7.2 Heat treatment . 11 7.3 Shot peening . 11 7.4 Presetting . 11 7.5 Surface treatment and corrosion protection . 11 8 Tolerances . 12 8.1 Tolerances on diameter . 12 8.2 Tolerances on thickness . 12 8.3 Tolerances on free overall height, l0 . 12 8.4 Tolerances on spring load . 13 8.4.1 Single disc springs . 13 8.4.2 Springs stacked in series . 13 8.5 Clearance between disc spring and guiding element . 14 9 Creep and relaxation . 14 10 Permissible stresses. 16 10.1 Static and rarely alternating loading . 16 10.2 Dynamic loading . 16 10.2.1 General . 16 10.2.2 Permissible loading . 17 11 Testing . 19 11.1 General . 19 11.2 Check of dimensions and other spring characteristics . 19 11.3 Hardness testing . 20 12 Other relevant requirements . 20 Bibliography . 21 SIST EN 16983:2017

European foreword This document (EN 16983:2016) has been prepared by Technical Committee CEN/TC 407 “Cylindrical helical springs made from round wire and bar - Calculation and design”, the secretariat of which is held by AFNOR. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by May 2017, and conflicting national standards shall be withdrawn at the latest by May 2017. This European Standard has been prepared by the initiative of the Association of the European Spring Federation ESF and is based on the German Standard DIN 2093 “Disc springs – Quality specifications – Dimensions”, which is known and used in many European countries. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN shall not be held responsible for identifying any or all such patent rights. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 16983:2017

(E) 4 1 Scope This standard specifies the set of requirements that ensure the correct functioning of disc spring. These include requirements relating to the materials and manufacturing process, tolerances on dimensions and spring forces, and also the permissible relaxation and fatigue life of such springs as a function of stress. All requirements specified here are minimum requirements. This standard covers three dimensional series of disc springs. NOTE In this standard, disc springs are divided into three groups and three dimensional series. Classification into groups is based on the manufacturing process, which is a function of the material thickness. The assignment of disc springs to dimensional series is governed by the h0 /t ratio. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 1654, Copper and copper alloys - Strip for springs and connectors EN 10083 (all parts), Steels for quenching and tempering EN 10089, Hot-rolled steels for quenched and tempered springs - Technical delivery conditions EN 10132-4, Cold rolled narrow steel strip for heat treatment - Technical delivery conditions - Part 4: Spring steels and other applications EN 10151, Stainless steel strip for springs - Technical delivery conditions EN ISO 3269, Fasteners - Acceptance inspection (ISO 3269) EN ISO 6507 (all parts), Metallic materials - Vickers hardness test (ISO 6507) EN ISO 6508 (all parts), Metallic materials - Rockwell hardness test (ISO 6508) 3 Terms, definitions, symbols, units and abbreviated terms 3.1 Terms and definitions For the purposes of this document, the terms and definition given in EN ISO 26909 apply. NOTE Disc springs are annular coned elements that offer resistance to a compressive load applied axially. They may be designed as single disc springs or as disc springs stacked in parallel or in series, either singly or in multiples. They may be subjected to both static and fatigue loading, and may have flat bearings. SIST EN 16983:2017

¿F N Relaxation L0 mm Length of springs stacked in series or in parallel, in the initial position Lc mm Design length of springs stacked in series or in parallel, in the flattened position N

Number of cycles to failure R N/mm Spring rate W N mm Energy capacity of spring h0 mm Initial cone height of springs without flat bearings, h0 = l0

« t h'0 mm Initial cone height of springs with flat bearings, hB"0 = l0

« t' i

Number of disc springs or packets stacked in series l0 mm Free overall height of spring in its initial position lt mm Test length of disc spring, lt = l0

«

rá y w h0 s mm Deflection of single disc spring s1, s2, s3 . mm Spring deflections related to spring loads F1, F2, F3… t mm Thickness of single disc spring t ' mm Reduced thickness of single disc spring with flat bearings (group 3) µ

Poisson’s ratio

MPa Design stress

II,

III,

OM MPa Design stresses at the points designated II, III, OM (see Figure 1) h MPa Fatigue stress related to the deflection of springs subject to fatigue loading O MPa Maximum fatigue stress U MPa Minimum fatigue stress H = O U MPa Permanent range of fatigue stress P

Theoretical centre of rotation of disc spring cross section (see Figure 1) V, V B"

Lever arms SIST EN 16983:2017

(E) 6 Symbol Unit Description Ra

Mean surface roughness 4 Dimensions and designation 4.1 General

a) without flat bearings: b) with flat bearings:

Group 1 Group 2

Group 3 Figure 1 — Single disc spring of group 1, 2 or 3 (sectional view), including the relevant points of loading Designation of a disc spring of dimensional series A with an outer diameter, De of 40 mm: Disc spring EN 16983 — A 40 4.2 Disc spring groups Table 2 — Disc spring groups Group t With flat bearings and reduced thickness 1 < 1,25 No 2 1,25

¶ t

¶ 6 No 3 6 < t

¶ 14 Yes SIST EN 16983:2017

Tables 4 to 6 then cease to apply. In such cases, it is recommended to consult the spring manufacturer. 6 Spring dimensions, nominal sizes, design values 6.1 Dimensional series A Table 4 — Disc springs with ≈18eDt; ≈00,4ht; E = 206 000 MPa; µ = 0,3 Group De Di t or (ta h0 l0 Ft lt b OM h12 H12 s approximately 0,75 h0 s = h0

8 4,2 0,4 0,2 0,6 210 0,45 1 218

«1 605

10 5,2 0,5 0,25 0,75 325 0,56 1 218

«1 595

12,5 6,2 0,7 0,3 1 660 0,77 1 382

«1 666 1 14 7,2 0,8 0,3 1,1 797 0,87 1 308

«1 551

16 8,2 0,9 0,35 1,25 1 013 0,99 1 301

«1 555

18 9,2 1 0,4 1,4 1 254 1,1 1 295

«1 558

20 10,2 1,1 0,45 1,55 1 521 1,21 1 290

«1 560

22,5 11,2 1,25 0,5 1,75 1 929 1,37 1 296

«1 534

25 12,2 1,5 0,55 2,05 2 926 1,64 1091

«1 622

28 14,2 1,5 0,65 2,15 2 841 1,66 1 274

«1 562

31,5 16,3 1,75 0,7 2,45 3 871 1,92 1 296

«1 570

35,5 18,3 2 0,8 2,8 5 187 2,2 1 332

«1 611

40 20,4 2,25 0,9 3,15 6 500 2,47 1 328

«1 595

45 22,4 2,5 1 3,5 7 716 2,75 1 296

«1 534 2 50 25,4 3 1,1 4,1 11 976 3,27 1 418

«1 659

56 28,5 3 1,3 4,3 11 388 3,32 1 274

«1 565

(E) 8 Group De Di t or (ta h0 l0 Ft lt b OM h12 H12 s approximately 0,75 h0 s = h0

63 31 3,5 1,4 4,9 15 025 3,85 1 296

«1 524

71 36 4 1,6 5,6 20 535 4,4 1 332

«1 594

80 41 5 1,7 6,7 33 559 5,42 1 453

«1 679

90 46 5 2 7 31 354 5,5 1 295

«1 558

100 51 6 2,2 8,2 48 022 6,55 1 418

«1 663

112 57 6 2,5 8,5 43 707 6,62 1 239

«1 505

125 64 8 (7,5) 2,6 10,6 85 926 8,65 1 326

«1 708

140 72 8 (7,5) 3,2 11,2 85 251 8,8 1 284c

«1 675

160 82 10 (9,4) 3,5 13,5 138 331 10,87 1 338

«1 753 3

180 92 10 (9,4) 4 14 125 417 11 1 201c

«1 576

200 102 12 (11,25) 4,2 16,2 183 020 13,05 1 227

«1 611

225 112 12 (11,25) 5 17 171 016 13,25 1 137c

«1 489

250 127 14 (13,1) 5,6 19,6 248 828 15,4 1 221c

«1 596 a The values specified for t are nominal values. In the case of springs with flat bearings (cf. Group 3 in Clause 4), the desired spring load, F (where s approximately 0,75 h0), is to be obtained by reducing the thickness of single disc springs, t, which then gives the value tB"ä In the case of dimensional series A and B, tB" approximately

rá { v × t, and in the case of dimensional series C, tB" approximately

rá { x × t. b The values specified apply for the largest calculated tensile stress on the lower edges of the spring. c The values specified apply for t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...