EN 1777:2004+A1:2009

(Main)Hydraulic platforms (HPs) for fire fighting and rescue services - Safety requirements and testing

Hydraulic platforms (HPs) for fire fighting and rescue services - Safety requirements and testing

General

This document identifies the significant hazards (see 4) in the use of all sizes of HP by fire fighting and rescue services, on the basis that they are supplied in a complete form, tested and ready for use, and gives methods for the elimination or reduction of these hazards and for the use of safe working practices.

NOTE The principles of this standard have been used for HPs ranging from the smallest up to working heights exceeding 70 m, and are expected to be applicable to all foreseeable developments of HPs for Fire Services.

This document deals with HPs, the base of which is normally a motor vehicle, but can also be static or fixed, or mobile in the form of:

- a trailer or de-mountable unit

- any other type of self-propelled vehicle

For vehicle mounted HPs this document is intended to be used in conjunction with EN 1846-2, Fire fighting and rescue service vehicles -Part 2: Common requirements - Safety and performance.

This document is not applicable to HPs which were manufactured before the date of publication of this document by CEN.

1.2 This document is applicable to the structural design calculations and stability criteria, constructional details and tests of HPs, and gives guidance on the intended life limits for HPs (see 5.2.5.2.2).

NOTE This document may also be used for machines similar to HPs equipped with monitors, surveillance or other equipment for firefighting use but not intended for lifting persons.

1.3 This document does not specify the special requirements for:

- HPs operated by programmable electronic systems and/or radio which do not rely on cables;

- use in underground work (mines);

- use in potentially explosive atmospheres;

- the use of pneumatic cylinders to operate load carrying components.

1.4 Classification

HPs are divided into two main types:

Type A: HPs where the vertical projection of the centre of gravity of the load is always inside the tipping lines.

Type B: HPs where the vertical projection of the centre o

Hubrettungsfahrzeuge für Feuerwehren und Rettungsdienste, Hubarbeitsbühnen (HABn) - Sicherheitstechnische Anforderungen und Prüfung

Dieses Dokument legt die wesentlichen Gefährdungen (siehe Abschnitt 4) bei Verwendung aller HABn-

Größen für die Feuerwehr und Rettungsdienste fest, vorausgesetzt, sie werden in komplettem, geprüftem und

einsatzbereitem Zustand ausgeliefert; außerdem legt die Norm Verfahren zur Beseitigung oder Verminderung

dieser Gefährdungen und die Anwendung sicherer Arbeitstechniken fest.

ANMERKUNG Die Grundsätze dieser Norm sind auf HABn mit sehr geringen Arbeitshöhen sowie auf HABn mit

Arbeitshöhen über 70 m angewendet worden; es wird vorausgesetzt, dass sie auch auf alle zukünftigen Entwicklungen

von HABn für Feuerwehren anwendbar sind.

Dieses Dokument behandelt HABn, deren Untergestell im Normalfall ein Kraftfahrzeug ist, die jedoch auch

feststehend oder ortsfest oder auf folgende Weise beweglich sein können:

Anhänger oder absetzbare Einheit;

jede andere Art von Fahrzeug mit Eigenantrieb.

Für HABn, deren Untergestell ein Kraftfahrzeug ist, gilt dieses Dokument in Verbindung mit EN 1846-2,

Feuerwehrfahrzeuge Teil 2: Allgemeine Anforderungen Sicherheit und Leistung.

Dieses Dokument gilt nicht für HABn, die hergestellt wurden, bevor CEN diese Norm veröffentlichte.

1.2 Gültigkeit

Dieses Dokument gilt für Festigkeitsberechnungen, Standsicherheitskriterien, bauliche Einzelheiten und

Prüfungen der HABn; sie liefert eine Richtlinie für die voraussichtlichen Grenzen der Lebensdauer von HABn

(siehe 5.2.5.2.2).

ANMERKUNG Dieses Dokument darf auch auf Maschinen angewendet werden, die wie HABn mit Strahlrohren, Überwachungs-

oder sonstigen Einrichtungen zur Brandbekämpfung, jedoch nicht als Hebezeuge für Personen vorgesehen

sind.

Bras Élevateur Aérien (BEA) des services d'incendie et de secours - Prescriptions de sécurité et essais

1.1 Généralités

Le présent document identifie les phénomènes dangereux significatifs (voir Article 4) pour toutes les tailles de BEA

utilisés par des services de secours et de lutte contre l’incendie, tel qu’ils sont fournis sous leur forme finale, ayant

été soumis à essai et prêts à être utilisés, et fournit des méthodes pour éliminer ou réduire ces phénomènes

dangereux et pour appliquer des pratiques de travail sans danger.

NOTE Les principes de cette norme ont été utilisés pour les BEA allant des plus petites hauteurs de travail jusqu’aux

hauteurs de travail dépassant 70 m, et sont destinés à être appliqués à tous les développements envisageables pour les BEA

destinés aux services de lutte contre l’incendie.

Le présent document traite des BEA normalement montés sur un véhicule à moteur, mais qui peuvent également être

statiques ou fixes, ou mobiles sous la forme :

— d’une remorque ou d’une unité démontable ;

— de tout autre type de véhicule automoteur.

Pour les BEA sur véhicule porteur, le présent document est destiné à être utilisée conjointement avec l'EN 1846-2,

Véhicules des services de secours et de lutte contre l'incendie : Prescriptions communes — Sécurité et

performances.

Le présent document n’est pas applicable aux BEA qui ont été fabriqués avant la date de publication du présent

document par le CEN.

1.2 Le présent document est applicable aux calculs théoriques de résistance et aux critères de stabilité, aux détails

de construction et aux essais de BEA, et fournit des indications sur les limites de vie prévues pour les BEA

(voir 5.2.5.2.2).

NOTE Le présent document peut également être utilisé pour des machines similaires aux BEA équipés de lances, de

dispositifs de surveillance ou d’autres équipements destinés à lutter contre l'incendie mais non destinés à soulever

des personnes.

Hidravlične ploščadi (HPs) za gasilske in reševalne enote - Varnostne zahteve in preskušanje

General Information

- Status

- Withdrawn

- Publication Date

- 03-Mar-2009

- Withdrawal Date

- 09-Mar-2010

- Technical Committee

- CEN/TC 192 - Fire service equipment

- Drafting Committee

- CEN/TC 192 - Fire service equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Mar-2010

- Completion Date

- 10-Mar-2010

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 20-Jan-2009

- Effective Date

- 20-Jan-2009

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 1777:2004+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Hydraulic platforms (HPs) for fire fighting and rescue services - Safety requirements and testing". This standard covers: General This document identifies the significant hazards (see 4) in the use of all sizes of HP by fire fighting and rescue services, on the basis that they are supplied in a complete form, tested and ready for use, and gives methods for the elimination or reduction of these hazards and for the use of safe working practices. NOTE The principles of this standard have been used for HPs ranging from the smallest up to working heights exceeding 70 m, and are expected to be applicable to all foreseeable developments of HPs for Fire Services. This document deals with HPs, the base of which is normally a motor vehicle, but can also be static or fixed, or mobile in the form of: - a trailer or de-mountable unit - any other type of self-propelled vehicle For vehicle mounted HPs this document is intended to be used in conjunction with EN 1846-2, Fire fighting and rescue service vehicles -Part 2: Common requirements - Safety and performance. This document is not applicable to HPs which were manufactured before the date of publication of this document by CEN. 1.2 This document is applicable to the structural design calculations and stability criteria, constructional details and tests of HPs, and gives guidance on the intended life limits for HPs (see 5.2.5.2.2). NOTE This document may also be used for machines similar to HPs equipped with monitors, surveillance or other equipment for firefighting use but not intended for lifting persons. 1.3 This document does not specify the special requirements for: - HPs operated by programmable electronic systems and/or radio which do not rely on cables; - use in underground work (mines); - use in potentially explosive atmospheres; - the use of pneumatic cylinders to operate load carrying components. 1.4 Classification HPs are divided into two main types: Type A: HPs where the vertical projection of the centre of gravity of the load is always inside the tipping lines. Type B: HPs where the vertical projection of the centre o

General This document identifies the significant hazards (see 4) in the use of all sizes of HP by fire fighting and rescue services, on the basis that they are supplied in a complete form, tested and ready for use, and gives methods for the elimination or reduction of these hazards and for the use of safe working practices. NOTE The principles of this standard have been used for HPs ranging from the smallest up to working heights exceeding 70 m, and are expected to be applicable to all foreseeable developments of HPs for Fire Services. This document deals with HPs, the base of which is normally a motor vehicle, but can also be static or fixed, or mobile in the form of: - a trailer or de-mountable unit - any other type of self-propelled vehicle For vehicle mounted HPs this document is intended to be used in conjunction with EN 1846-2, Fire fighting and rescue service vehicles -Part 2: Common requirements - Safety and performance. This document is not applicable to HPs which were manufactured before the date of publication of this document by CEN. 1.2 This document is applicable to the structural design calculations and stability criteria, constructional details and tests of HPs, and gives guidance on the intended life limits for HPs (see 5.2.5.2.2). NOTE This document may also be used for machines similar to HPs equipped with monitors, surveillance or other equipment for firefighting use but not intended for lifting persons. 1.3 This document does not specify the special requirements for: - HPs operated by programmable electronic systems and/or radio which do not rely on cables; - use in underground work (mines); - use in potentially explosive atmospheres; - the use of pneumatic cylinders to operate load carrying components. 1.4 Classification HPs are divided into two main types: Type A: HPs where the vertical projection of the centre of gravity of the load is always inside the tipping lines. Type B: HPs where the vertical projection of the centre o

EN 1777:2004+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 13.220.10 - Fire-fighting. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1777:2004+A1:2009 has the following relationships with other standards: It is inter standard links to EN 1777:2004/prA1, EN 1777:2004, EN 1777:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1777:2004+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1777:2004+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SUHVNXãDQMHHubrettungsfahrzeuge für Feuerwehren und Rettungsdienste, Hubarbeitsbühnen (HABn) - Sicherheitstechnische Anforderungen und PrüfungBras Élevateur Aérien (BEA) des services d'incendie et de secours - Prescriptions de sécurité et essaisHydraulic platforms (HPs) for fire fighting and rescue services - Safety requirements and testing13.220.10Gašenje požaraFire-fightingICS:Ta slovenski standard je istoveten z:EN 1777:2004+A1:2009SIST EN 1777:2005+A1:2009en,fr,de01-junij-2009SIST EN 1777:2005+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1777:2004+A1

March 2009 ICS 13.220.10 Supersedes EN 1777:2004English Version

Hydraulic platforms (HPs) for fire fighting and rescue services - Safety requirements and testing

Bras Élevateur Aérien (BEA) des services d'incendie et de secours - Prescriptions de sécurité et essais

Hubrettungsfahrzeuge für Feuerwehren und Rettungsdienste, Hubarbeitsbühnen (HABn) - Sicherheitstechnische Anforderungen und Prüfung This European Standard was approved by CEN on 2 September 2004 and includes Amendment 1 approved by CEN on 11 January 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1777:2004+A1:2009: ESIST EN 1777:2005+A1:2009

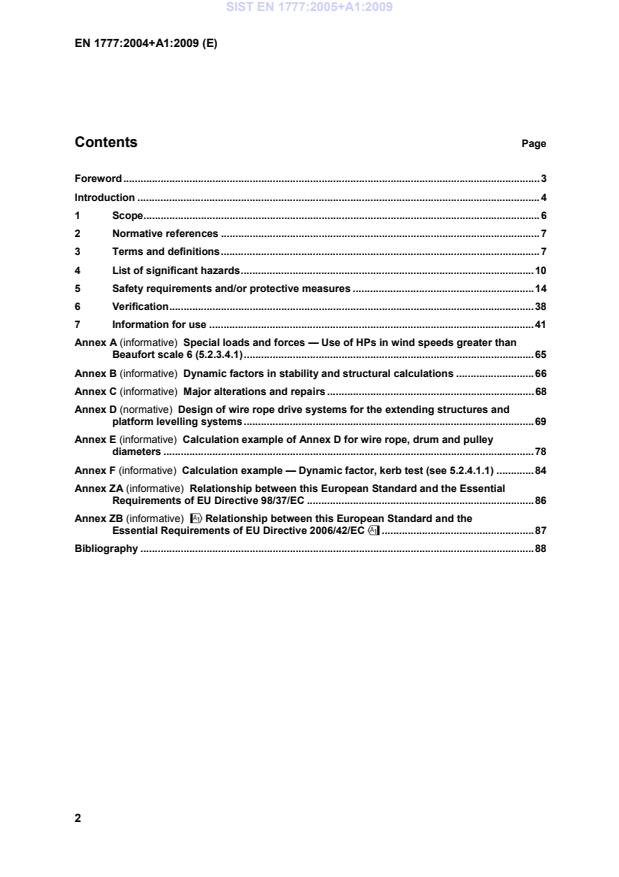

Special loads and forces — Use of HPs in wind speeds greater than Beaufort scale 6 (5.2.3.4.1) . 65Annex B (informative)

Dynamic factors in stability and structural calculations . 66Annex C (informative)

Major alterations and repairs . 68Annex D (normative)

Design of wire rope drive systems for the extending structures and platform levelling systems . 69Annex E (informative)

Calculation example of Annex D for wire rope, drum and pulley diameters . 78Annex F (informative)

Calculation example — Dynamic factor, kerb test (see 5.2.4.1.1) . 84Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 86Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 87Bibliography . 88 SIST EN 1777:2005+A1:2009

Where the mass/rigidity of the base does not provide inherent stability, stability is assured by stabilizers interlocked with movements of the extending structure. The movements of the extending structure are normally made by fluid power (hydraulics). The platform is self-levelling and is primarily used to carry one or more persons and any necessary equipment and/or materials. It can be fitted with one or more monitors for projecting water or other fire-fighting fluids or semi-solid materials. Controls are provided at the platform and at the base, to control movements of the extending structure. They can also control movements of the monitor(s) and of the base if it is mobile. The extended positions of the platform can be above and/or below and horizontally beyond the surface supporting the base. The extent to which hazards are covered is indicated in the scope of this document. The safety requirements of this document have been drawn up on the basis that HPs are periodically maintained by persons trained according to manufacturer's instructions, working conditions, frequency of use, and national regulations. It is also assumed that HPs are not put into operation unless all required control- and safety-devices are available and in working order and that persons operating HPs are adequately trained. When mention is made of a design for the sake of clarity, this should not be considered to be the only possible design; any other solution may be applied if it is at least equally safe. As no satisfactory explanation could be found for the dynamic factors used for stability calculations in previous national standards, the results of the tests carried out by CEN/TC 98 "Lifting Platforms" to determine a suitable factor and stability calculation method for mobile elevating work platforms (MEWPs) have been adopted. The test method is described in Annex B as a guide for manufacturers wishing to use higher or lower operating speeds and to take advantage of developments in control systems. SIST EN 1777:2005+A1:2009

Travelling is only allowed with the HP in its transport position. Group 2:

Travelling with raised platform is controlled only from a point of control at the chassis. SIST EN 1777:2005+A1:2009

(Self-propelled) Travelling with raised platform is controlled from a point of control at the platform. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 349, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 418, Safety of machinery — Emergency stop equipment, functional aspects — Principles for design EN 1846-1:1998, Firefighting and rescue service vehicles — Part 1: Nomenclature and designation EN 1846-2:2001, Firefighting and rescue service vehicles — Part 2: Common requirements — Safety and performance EN 60204-1:1997, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:1997 EN 60529, Degrees of protection provided by enclosures (IP code) (IEC 60529:1989) EN 60947-5-1, Low-voltage switchgear and controlgear — Part 5-1: Control circuit devices and switching elements — Electromechanical control circuit devices (IEC 60947-5-1:2003) EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003) ISO 2408:2004, Steel wire ropes for general purposes — Minimum requirements ISO 4305, Mobile cranes — Determination of stability ISO 4309, Cranes — Wire ropes — Care, maintenance, installation, examination and discard 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN 1846-1:1998 and the following apply. 3.1 The abbreviation HP is used for Hydraulic Platform 3.2 platform fenced platform in which persons and equipment are carried and which can be moved under load to the required working position by the extending structure and/or by movement of the base. Secondary platforms include extended floors outside guardrails for rescue purposes, landings for access to boom ladders, etc 3.3 extending structure scissor mechanism or one or more rigid or telescopic or articulating mechanisms, or any combination of them in the form of booms and/or ladders. It may or may not slew on the base SIST EN 1777:2005+A1:2009

NOTE There may be more than one combination of rated load (see 3.13) and working envelope. 3.15 residual slope deviation from horizontal of the base or any slewing mechanism after deployment of the stabilizers SIST EN 1777:2005+A1:2009

Hazard Corresponding requirements

4.1 Mechanical hazards:

4.1.1 Crushing hazards 5.3.17, 5.4.4, 5.3.16,

5.3.18, 5.6.7 4.1.2 Shearing hazards 5.3.17, 5.4.4 4.1.3 Cutting or Severing hazard 5.7.11 4.1.4 Entanglement hazard 5.3.19 4.1.5 Drawing-in or trapping hazard 5.3.19 4.1.6 Impact hazard 7.1.2g and p 4.1.7 Stabbing or puncture hazard NA 4.1.8 Friction or abrasion hazard 7.1.7.e) 4.1.9 High pressure fluid injection hazard 5.7.16 4.1.10 Ejection of parts NA 4.1.11 Loss of stability (of machinery and machine parts) 5.2.4 4.1.12 Slip, trip and fall hazards 5.3.23, 5.6.3, 5.6.6,

5.6.7 4.2 Electrical hazards, caused for example by:

4.2.1 Electrical contact, direct or indirect 7.1.2g) 4.2.2 Electrostatic phenomena NA 4.2.3 Thermal radiation 5.8.1 4.2.4 External influences on electrical equipment 5.8.1 4.3 Thermal hazards, resulting for example in:

4.3.1 Burns and scalds by a possible contact of persons by flames

or explosions and also by the radiation of heat sources 5.3.19 4.3.2 Health-damaging effects by hot or cold work environment 5.3.19 4.4 Hazards generated by noise, resulting for example in:

4.4.1 Hearing losses (deafness) other physiological disorders

e.g. loss of balance, loss of awareness etc.) 5.3.10 4.4.2 Interference with speech communication, acoustic signals etc 5.3.10 4.5 Hazards generated by vibration(resulting in a variety of

neurological and vascular disorders) 7.1.2k 4.6 Hazards generated by radiation, especially by:

4.6.1 Electrical arcs NA 4.6.2 Lasers NA 4.6.3 Ionising radiation sources NA 4.6.4 Machine making use of high frequency electromagnetic fields 5.8.1 4.7 Hazards generated by materials and substances processed,

used or exhausted by machinery for example:

4.7.1 Hazards resulting from contact with or inhalation of harmful

fluids, gases, mists, dusts and fumes 5.3.21 4.7.2 Fire or explosion hazard 5.3.22 4.7.3 Biological and micro-biological (viral or bacterial) hazards NA

Hazard Corresponding requirements

4.8 Hazards generated by neglecting ergonomic principles in

machine design (mismatch of machinery with human

characteristics and abilities) caused e.g. by:

4.8.1 Unhealthy postures or excessive efforts 5.6.7 4.8.2 Inadequacy with human hand-arm or foot-leg anatomy 5.7.4, 5.7.5 4.8.3 Neglected use of personal protection equipment 5.7.4, 5.7.5 4.8.4 Inadequate local lighting 5.7.1 4.8.5 Mental overload or under-load, stress, etc. 5.3.24, 5.7.1, 5.7.6 4.8.6 Human errors 5.9.8, 5.10.12 4.9 Hazard combinations

4.10 Hazards caused by failure of energy supply, breaking down

of machinery parts, and other functional disorders e.g.:

4.10.1 Failure of energy supply(of power and/or control circuits) 5.7.9, 5.7.12, 5.7.15 4.10.2 Unexpected ejection of machine parts or fluids 5.7.16 4.10.3 Failure/disorder of control system 5.7.1, 7.2.2 4.10.4 Errors of fitting 5.8.3, 5.9.8, 5.10.12 4.10.5 Overturn, unexpected loss of machine stability 5.2.4, 6.1.2, 6.1.5 4.11 Hazards caused by (temporary) missing and/or incorrectly

positioned safety-related measures/means, e.g.:

4.11.1 All kinds of guard 5.3.19 4.11.2 All kinds of safety related(protection) devices 5.3.17, 5.4.4 4.11.3 Starting and stopping devices 5.7.1, 5.7.7 4.11.4 Safety signs and tags 5.10.11, 7.2.2 4.11.5 All kinds of information or warning devices 5.3.1, 5.3.9, 7.1.7c,

7.2 4.11.6 Energy supply disconnecting devices 5.10.11 4.11.7 Emergency devices 5.7.7, 5.7.12 4.11.8 Feeding/take-off means of work pieces NA 4.11.9 Essential equipment and accessories for safe adjusting

and/or maintaining 7.1.7 d 4.11.10 Equipment evacuating gases etc. 5.3.21 4.12 Inadequate lighting of moving/working area 5.7.1 4.13 Hazards due to sudden movement, instability etc. during

handling 5.2, 5.2.3 4.14 Inadequate/non ergonomic design of driving/operating

position:

4.14.1 Hazards due to dangerous environments (contact with

moving parts, exhaust gases etc) 5.3.19, 5.3.21 4.14.2 Inadequate visibility from driver's/operator's position 5.3.18, 5.7.6 4.14.3 Inadequate seat/seating (seat index point) 5.3.24 4.14.4 Inadequate/non ergonomic design/positioning of controls 5.7.1 4.14.5 Starting/moving of self-propelled machinery 5.3.16, 5.7.2 4.14.6 Road traffic or self-propelled machinery 5.3.12, 5.3.14

Hazard Corresponding requirements

4.15

Mechanical hazards:

4.15.1 Hazards to exposed persons due to uncontrolled movement 5.7.1 4.15.2 Hazards due to break-up and/or ejection of parts 5.2 4.15.3 Hazards due to rolling over (ROPs) NA 4.15.4 Hazards due to falling objects (FOPs) NA 4.15.5 Inadequate means of access 5.3.23, 5.6.7 4.15.6 Hazards due to towing, coupling, connecting, NA

transmission etc

4.15.7 Hazards due to batteries, fire, emissions etc. 5.3.22, 5.3.25 4.16.1 Lack of stability 5.4.1, 6.1.2 4.16.2 Derailment of machinery NA 4.16.3 Loss of mechanical strength of machinery and lifting

accessories 5.2.5, 5.4.1 4.16.4 Hazards caused by uncontrolled movements 5.4.1, 5.5.1.1, 5.5.1.3 4.17 Inadequate view of trajectories of the moving parts 5.7.6 4.18 Hazards caused by lightning !5.3.26" 4.19 Hazards due to loading/overloading etc. 5.4.1 4.20 General:

4.20.1 Mechanical strength 5.5.2.1.2, 5.5.3.1.2 4.20.2 Loading control 5.4.1 4.21 Controls:

4.21.1 Controls in carrier 5.7.6 4.21.2 Safe travel control 5.23.13, 5.7.6 4.21.3 Safe speed control 5.3.13, 5.7.2 4.22 Fall prevention:

4.22.1 Personal Protective Equipment in carrier NA 4.22.2 Trapdoors 5.6.8 4.22.3 Carrier tilt control 5.6.1, 5.6.2 4.23 Carrier falling/overturning:

4.23.1 Falling/overturning 5.5.1.1, 5.6.1, 5.6.2 4.23.2 Acceleration/braking 5.7.2 4.23.3 Markings 7.2 NOTE

N/A = not applicable

This clause of the document contains several requirements for the design of the safety related parts of the control system of HPs.

As the terminology is not in accordance with that of the relevant harmonised standard, EN 954-1 (see Foreword) these requirements should be interpreted on the basis of the principles of EN 954-1 pending the planned revision of this document. 5.2 Stability and structural calculations 5.2.1 General It is the manufacturer's responsibility for stability calculations, to identify the various positions of the HP and combinations of loads, forces and removable items creating together conditions of minimum stability and for structural calculations, to evaluate the individual loads and forces in their positions, directions and combinations producing the most unfavourable stresses in the components. NOTE It is the user's responsibility to refer other uses to the manufacturer for approval. 5.2.2 Loads and forces The following loads and forces shall be taken into account: a) Rated load; b) Structural loads; c) Wind loads; d) Manual forces; e) Additional loads and forces; f) Those resulting from operation on any residual slope; g) Those created by use of the emergency stop 5.7.7. SIST EN 1777:2005+A1:2009

1,1 × rated load (see 6.1.5.1.3). The calculated stresses shall not exceed permissible values. The calculated safety factors shall not fall below the required values. NOTE Manufacturers are recommended, by strain-gauge tests or equivalent methods of analysis, to check peak stresses under the above dynamic test conditions (see also Annex B). The permissible values of stresses and the required values of safety factors depend on the material, the load combination and the calculation method. For the design of hydraulic cylinders see 5.11. 5.2.5.2.2 Analysis a) The general stress analysis The general stress analysis is the proof against failure by yielding or fracturing. The analysis shall be made for all load bearing components and joints. b) Elastic stability analysis The elastic stability analysis is the proof against failure by elastic instability (e.g. buckling, crippling). The analysis shall be made for all load bearing components subjected to compressive loads. c) Fatigue stress analysis SIST EN 1777:2005+A1:2009

Mechanical means shall be provided to prevent uncontrolled movements of the stabilizers from the transport position. The stabilizers shall be locked in the transport position by two separate locking devices for each stabilizer, at least one of which operates automatically, e.g. a gravity locking pin plus a detent. Powered stabilizers meeting the requirements of 5.11 meet this requirement Verification: by design check and functional test. 5.3.6 For HPs with stabilizers for levelling the extending structure these shall be capable of levelling it within the maximum residual slope when operating on the maximum slope specified by the manufacturer. Verification: by functional test. NOTE The normally accepted supporting surface variations within which HPs for general fire service use may be operated without restriction are:

longitudinal and transverse slopes, up to 7 °; depressions, up to 50 mm; humps (kerbs, etc.), up to 150 mm. 5.3.7 The movements of stabilizers shall be limited by mechanical stops. These stops shall be of sufficient strength to absorb the maximum force exerted. The ends of hydraulic cylinders, if properly constructed for the purpose, fulfil this requirement. Verification: by design check. 5.3.8 Any stabilizer feet shall be constructed to accommodate ground unevenness of at least 15 ° in any direction. Verification: by visual examination and measurement. 5.3.9 Vehicle mounted HPs shall be equipped with an indicator visible to the driver to indicate if the HP is not in its transport condition. Verification: by functional test. 5.3.10 Vehicle mounted HPs shall comply with all of the noise reduction requirements of EN 1846-2. 5.3.11 HPs which are operated in public traffic areas shall satisfy the national road traffic and lighting regulations. Verification: by visual examination. 5.3.12 Group 3 HPs shall be equipped with brakes or other stopping devices which engage automatically when power is removed or fails, and remain effective if any one wheel lifts clear of the supporting surface due to operation of the extending structure or travelling. After being engaged, the brakes shall not depend on an exhaustible energy source. SIST EN 1777:2005+A1:2009

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...