EN 15061:2007+A1:2008

(Main)Safety of machinery - Safety requirements for strip processing line machinery and equipment

Safety of machinery - Safety requirements for strip processing line machinery and equipment

This European Standard defines the health and safety requirements of strip processing lines (see 3.1).

This European Standard deals with all significant hazards, hazardous situations and events relevant for strip processing line machinery and equipment, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse.

This European Standard specifies the requirements to ensure the safety of persons which are to be considered and met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment.

This European Standard applies to:

Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment).

Terminal equipment for: Processing and terminal equipment for: Terminal equipment for:

Entry section

Pickling (5.3.5) (1)

Pre-treatment (5.3.6) (1)

Hot dipping (5.3.7) (1)

Electro plating (5.3.8) (1)

Tension levelling/scale breaking (5.3.9) (1)

Organic coating by roll coater (5.3.10) (1)

Chemical post-treating (5.3.11) (1)

Annealing (1), (2)

(1) it may include also terminal equipment according to 5.2

(2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by

this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3

Exit section

This European Standard does not cover:

Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3;

Dryers and ovens in accordance with EN 1539;

Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks a

Sicherheit von Maschinen - Sicherheitsanforderungen an Bandbehandlungsanlagen und Einrichtungen

Diese Europäische Norm beschreibt die Gesundheits- und Sicherheitsanforderungen an automatisierte

Anlagen zur Bandbehandlung (siehe 3.1).

Diese Europäische Norm beschreibt alle signifikanten Gefährdungen, Gefährdungssituationen und -ereignisse

für Bandbehandlungsanlagen und Ausrüstung, falls diese unter den vom Hersteller vorgesehenen

Bedingungen eingesetzt wird, beinhaltet aber auch vorhersehbare Fehler und Fehlfunktionen bei fehlerhafter

Nutzung.

Diese Europäische Norm beschreibt die Anforderungen zur Gewährleistung der Sicherheit von Personen, die

bei Konstruktion, Montage, Transport, Inbetriebnahme, Betrieb, Wartung und Außerbetriebnahme der Anlage

zu berücksichtigen sind.

Diese Europäische Norm gilt für:

Bandbehandlungsanlagen zur Behandlung von Metallband: vom Übergabepunkt (siehe 3.6) des Einlaufteils

(mechanische Einrichtung, siehe 3.2) über den Prozess (Prozess- und mechanische Einrichtung, siehe 3.3

und 3.2) bis zum Übergabepunkt im Auslaufteil oder der Schnittstelle zu anderen Anlagen (mechanische

Einrichtung).

Sécurité des machines - Prescriptions de sécurité pour machines et installations de traitement des bandes

La présente Norme européenne définit les prescriptions d’hygiène et de sécurité générales des lignes de traitement des bandes (voir 3.1).

La présente Norme européenne traite tous les phénomènes, situations et événements dangereux significatifs appropriés aux machines et équipements des lignes de traitement des bandes !durant l’utilisation normale" et dans les conditions prévues par le fabricant, mais aussi les défauts et les dysfonctionnements prévisibles !en cas de mauvais usage".

Le présent document spécifie les prescriptions à satisfaire pour garantir la sécurité des personnes pendant la conception, la construction, le transport, la mise en service, le fonctionnement, la maintenance et la mise hors service de l’équipement.

La présente Norme européenne s'applique aux :

Lignes de traitement des bandes métalliques : depuis le point de reprise (voir 3.6) de la section d'entrée (équipement terminal, voir 3.2) en passant par le procédé (équipement de traitement et terminal, voir 3.3 et 3.2) jusqu'au point de reprise de la section de sortie ou l'interface vers d'autres lignes (équipement terminal).

Équipement

terminal pour : Équipement de traitement et terminal pour : Équipement

terminal pour :

Section d'entrée

Décapage (5.3.5) (1)

Prétraitement (5.3.6) (1)

Galvanisation (5.3.7) (1)

Électrodéposition (5.3.8) (1)

Planage par étirage/Décalaminage (5.3.9) (1)

Revêtement organique par enducteur (5.3.10) (1)

Post-traitement chimique (5.3.11) (1)

Recuit (1) (2)

(1) Peut également inclure l’équipement terminal selon 5.2.

(2) Pour les lignes de recuit, les prescriptions relatives aux équipements de traitement (5.3.5 à 5.3.11) sont couverts par la présente norme. Les prescriptions pour les fours des lignes de recuit sont couvertes par les EN 746-1, EN 746-2 et EN 746-3.

Section de sortie

La présente Norme européenne ne couvre pas :

les fours conformes aux EN 746-1, EN 746-2 et EN 746-3 ;

Varnost strojev - Varnostne zahteve za linijske stroje in opremo za obdelavo (kovinskih) trakov

General Information

- Status

- Withdrawn

- Publication Date

- 25-Nov-2008

- Withdrawal Date

- 10-Feb-2026

- Drafting Committee

- CEN/TC 322/WG 4 - Strip processing lines

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 09-Mar-2022

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 74, C 74, C 74, C 74, C 74, C 74, C 74, C 74, C, OJ Date: 28-Mar-2009

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 06-Feb-2019

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 60825-1:2014 - Safety of laser products - Part 1: Equipment classification and requirements - Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 15061:2007+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Safety of machinery - Safety requirements for strip processing line machinery and equipment". This standard covers: This European Standard defines the health and safety requirements of strip processing lines (see 3.1). This European Standard deals with all significant hazards, hazardous situations and events relevant for strip processing line machinery and equipment, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be considered and met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This European Standard applies to: Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment). Terminal equipment for: Processing and terminal equipment for: Terminal equipment for: Entry section Pickling (5.3.5) (1) Pre-treatment (5.3.6) (1) Hot dipping (5.3.7) (1) Electro plating (5.3.8) (1) Tension levelling/scale breaking (5.3.9) (1) Organic coating by roll coater (5.3.10) (1) Chemical post-treating (5.3.11) (1) Annealing (1), (2) (1) it may include also terminal equipment according to 5.2 (2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3 Exit section This European Standard does not cover: Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; Dryers and ovens in accordance with EN 1539; Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks a

This European Standard defines the health and safety requirements of strip processing lines (see 3.1). This European Standard deals with all significant hazards, hazardous situations and events relevant for strip processing line machinery and equipment, when used as intended and under conditions foreseen by the manufacturer, but also includes foreseeable faults and malfunctions in case of misuse. This European Standard specifies the requirements to ensure the safety of persons which are to be considered and met during the design, assembly, transport, commissioning, operation, maintenance and decommissioning of the equipment. This European Standard applies to: Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment). Terminal equipment for: Processing and terminal equipment for: Terminal equipment for: Entry section Pickling (5.3.5) (1) Pre-treatment (5.3.6) (1) Hot dipping (5.3.7) (1) Electro plating (5.3.8) (1) Tension levelling/scale breaking (5.3.9) (1) Organic coating by roll coater (5.3.10) (1) Chemical post-treating (5.3.11) (1) Annealing (1), (2) (1) it may include also terminal equipment according to 5.2 (2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3 Exit section This European Standard does not cover: Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; Dryers and ovens in accordance with EN 1539; Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks a

EN 15061:2007+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 77.180 - Equipment for the metallurgical industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15061:2007+A1:2008 has the following relationships with other standards: It is inter standard links to EN 15061:2007, EN 15061:2022, ISO 3864-1:2002, ISO 3287:1999, EN 61310-1:2008, EN 60825-1:1994, EN IEC 60825-4:2024, EN IEC 61496-3:2025, CLC/TR 50404:2003, EN IEC 61496-1:2020, EN 60825-1:2014, EN ISO 11064-7:2006, EN 2286:1989, EN ISO 13854:2019, EN 12094-1:2003. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15061:2007+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15061:2007+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Varnost strojev - Varnostne zahteve za linijske stroje in opremo za obdelavo (kovinskih) trakovSicherheit von Maschinen - Sicherheitsanforderungen an Bandbehandlungsanlagen und EinrichtungenSécurité des machines - Prescriptions de sécurité pour machines et installations de traitement des bandesSafety of machinery - Safety requirements for strip processing line machinery and equipment77.180Oprema za metalurško industrijoEquipment for the metallurgical industry13.110Varnost strojevSafety of machineryICS:Ta slovenski standard je istoveten z:EN 15061:2007+A1:2008SIST EN 15061:2008+A1:2009en01-januar-2009SIST EN 15061:2008+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15061:2007+A1

November 2008 ICS 77.180 Supersedes EN 15061:2007 English Version

Safety of machinery - Safety requirements for strip processing line machinery and equipment

Sécurité des machines - Prescriptions de sécurité pour machines et installations de traitement des bandes

Sicherheit von Maschinen - Sicherheitsanforderungen an Bandbehandlungsanlagen und Einrichtungen This European Standard was approved by CEN on 23 September 2007 and includes Amendment 1 approved by CEN on 23 October 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15061:2007+A1:2008: ESIST EN 15061:2008+A1:2009

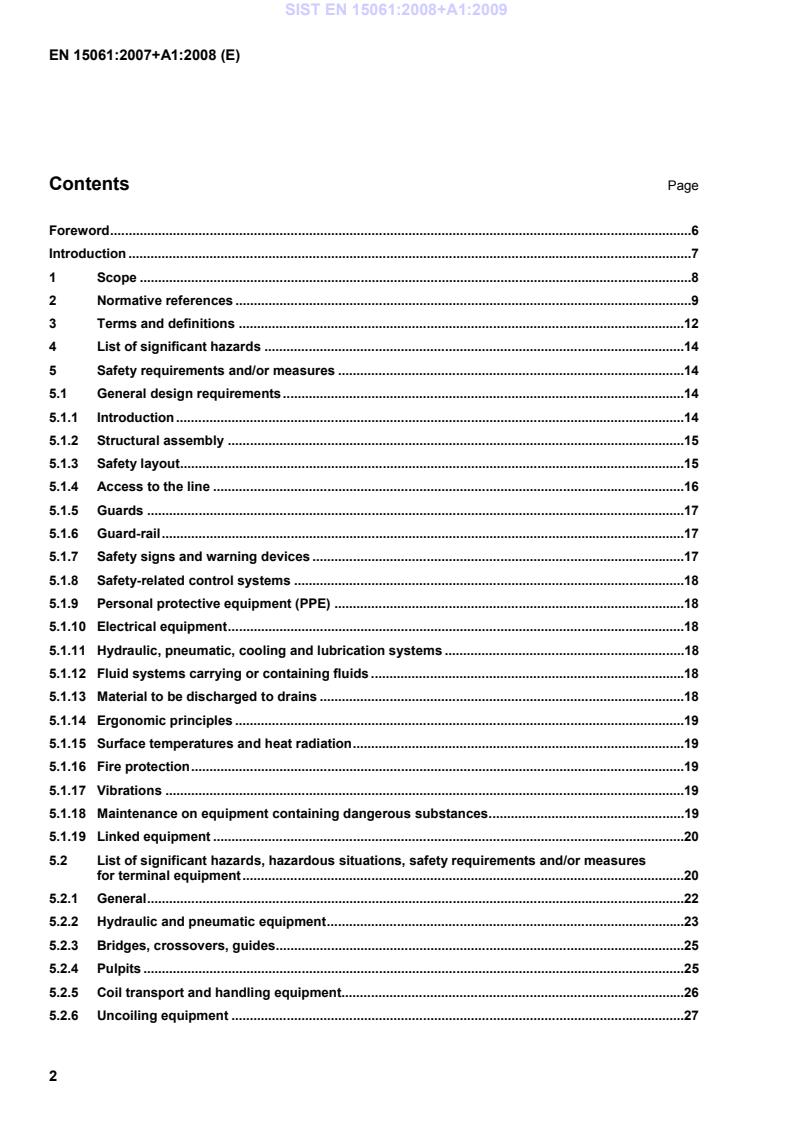

Safety requirements and/or measures for electrical equipment.72 Annex B (normative)

Noise test code.76 Annex C (informative)

Example for manufacturer's safety instructions for maintenance at strip processing lines.80 Annex D (informative)

Exemplary solutions.82 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC.88 Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC".89 Bibliography.90

Tables Table 1 — List of significant hazards, hazardous situations, safety requirements and/or measures for terminal equipment.22 Table 2 — List of significant hazards, hazardous situations, safety requirements and/or measures for processing equipment.39 Table 3 — Noise sources of strip processing lines and exemplary noise reduction measures.67 Table A.1 — Stop functions.74 Table B.1 — Example of declared dual-number noise emission values for work stations and specified measuring points.79

This European Standard applies to: Strip processing lines for treating metal strip: from take-over point (see 3.6) of the entry section (terminal equipment, see 3.2) through the process (processing and terminal equipment, see 3.3 and 3.2) up to the take-over point of the exit section or interface to other lines (terminal equipment). Terminal equipment for: Processing and terminal equipment for: Terminal equipment for: Entry section

Pickling (5.3.5) (1)

Pre-treatment (5.3.6) (1)

Hot dipping (5.3.7) (1)

Electro plating (5.3.8) (1)

Tension levelling/scale breaking (5.3.9) (1)

Organic coating by roll coater (5.3.10) (1)

Chemical post-treating (5.3.11) (1) Annealing (1), (2) (1) it may include also terminal equipment according to 5.2 (2) for annealing lines the requirement for related processing equipment (5.3.5 to 5.3.11) is covered by this standard. The requirements for the furnace of annealing lines are covered by EN 746-1, EN 746-2 and EN 746-3

Exit section

This European Standard does not cover: Furnaces in accordance with EN 746-1, EN 746-2 and EN 746-3; Dryers and ovens in accordance with EN 1539; Coil transporting system before take-over-point at the entry section and after take-over-point at the exit section, e. g., hook conveyors, overhead cranes, fork lift and railway trucks and other vehicles; Storage equipment for coils; Rolling mill stands (i. e., skin pass and reduction stands) according to prEN 15094; SIST EN 15061:2008+A1:2009

EN 13480-4, Metallic industrial piping — Part 4: Fabrication and installation EN 13480-5, Metallic industrial piping — Part 5: Inspection and testing EN 60204-1:2006, Safety of machinery — Electrical equipment of machines — Part 1: General requirements (IEC 60204-1:2005, modified) prEN 60825-1, Safety of laser products — Part 1: Equipment classification and requirements EN 60825-4, Safety of laser products - Part 4: Laser guards (IEC 60825-4:2006)

1) Will be replaced by prEN ISO 14121-1. 2 Attention, see 5.1.11 SIST EN 15061:2008+A1:2009

EN ISO 11064-6, Ergonomic design of control centres - Part 6: Environmental requirements for control centres (ISO 11064-6:2005) EN ISO 11064-7, Ergonomic design of control centres - Part 7: Principles for the evaluation of control centres (ISO 11064-7:2006)

EN ISO 11202, Acoustics - Noise emitted by machinery and equipment - Measurement of emission sound pressure levels at a work station and at other specified positions - Survey method in situ (ISO 11202:1995) EN ISO 11688-1, Acoustics - Recommended practice for the design of low-noise machinery and equipment - Part 1: Planning (ISO/TR 11688-1:1995) EN ISO 12100-1:2003, Safety of machinery - Basic concepts, general principles for design - Part 1: Basic terminology, methodology (ISO 12100-1:2003) EN ISO 12100-2:2003, Safety of machinery - Basic concepts, general principles for design - Part 2: Technical principles (ISO 12100-2:2003) EN ISO 13732-1, Ergonomics of the thermal environment - Methods for the assessment of human responses to contact with surfaces - Part 1: Hot surfaces (ISO 13732-1:2006)

3) To be amended by EN 61496-1/prA1 (2006-06). SIST EN 15061:2008+A1:2009

!EN ISO 13857:2008, Safety of machinery – Safety distances to prevent hazard zones being reached by upper and lower limbs (ISO 13857:2008)" EN ISO 14122-1, Safety of machinery - Permanent means of access to machinery - Part 1: Choice of fixed means of access between two levels (ISO 14122-1:2001) EN ISO 14122-2, Safety of machinery - Permanent means of access to machinery - Part 2: Working platforms and walkways (ISO 14122-2:2001) EN ISO 14122-3, Safety of machinery - Permanent means of access to machinery - Part 3: Stairs, stepladders and guard-rails (ISO 14122-3:2001) EN ISO 14122-4, Safety of machinery - Permanent means of access to machinery - Part 4: Fixed ladders (ISO 14122-4:2004) EN ISO 15004-1, Ophthalmic instruments - Fundamental requirements and test methods - Part 1: General requirements applicable to all ophthalmic instruments (ISO 15004-1:2006) ISO 3864-1, Graphical symbols — Safety colours and safety signs — Part 1: Design principles for safety signs in workplaces and public areas ISO 7000, Graphical symbols for use on equipment — Index and synopsis IEC 61496-2, Safety of machinery — Electro-sensitive protective equipment — Part 2: Particular requirements for equipment using active opto-electronic protective devices (AOPDs) CLC/R 044-001:1999, Safety of machinery — Guidance and recommendations for the avoidance of hazards due to static electricity 3 Terms and definitions For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 and the following apply. NOTE Definitions used in EN and ISO standards referred to in this document are also valid for this document. 3.1 strip processing line interconnection of equipment described in 3.2 and 3.3 in which several machines or stages are linked 3.2 terminal equipment equipment for moving, guiding, connecting, dividing and trimming the metal strip, coil handling equipment and related auxiliary equipment like hydraulic and pneumatic equipment 3.3 processing equipment equipment for treating the surface and/or modifying the product properties 3.4 plating section various number of electroplating cells in the process section of an electro processing line SIST EN 15061:2008+A1:2009

design and function of the machinery; degree of access to be permitted to a danger zone; frequency of access required. Further guidance to the selection of types of guards is given in Clause 6 of EN 953:1997. Instead of fixed guards, movable guards (e. g., doors with interlocking devices with guard locking) shall be used if frequent access is required to a danger zone. The design and construction of guards shall be in accordance with EN 953. With regard to safety distances !deleted text", EN 349 and !EN ISO 13857" shall be applied. In particular, distance guards (e. g., perimeter fences, protective structures) shall be at least 1 400 mm high, provided that the other requirements of !EN ISO 13857" are met. 5.1.6 Guard-rail Guard-rails instead of guards can

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...