EN 14056-1:2025

(Main)Laboratory furniture - Recommendations for design and installation - Part 1: General

Laboratory furniture - Recommendations for design and installation - Part 1: General

This document is applicable to biology, chemistry and physics laboratories where research, preparative, analytical, process activities take place and which can involve work with hazardous substances, including higher education (college and university teaching and post-graduate research).

This document does not cover the requirements of schools, i.e. precollege/pre-university (refer to EN 13150), or highly specialist laboratories which need very specific, bespoke solutions to enable them to function.

This document specifies requirements for installation and design of laboratory benches, associated storage units, and for the provision and connection of services integral or delivered to the laboratory benches. This document gives guidelines for all parties involved in the planning, design, manufacture, installation, testing of a new laboratory or in the refurbishment of an existing laboratory.

For safety storage cabinets for flammable liquids EN 14470-1 and for pressurized gas cylinders EN 14470-2 applies.

Laboreinrichtungen - Empfehlungen für Anordnung und Montage - Teil 1: Allgemeines

Dieses Dokument ist anwendbar für biologische, chemische und physikalische Labore, in denen Forschungs-, Präparations-, Analyse-, Prozesstätigkeiten, unter anderem im Hochschulwesen (in der Ausbildung an Fach- und Hochschulen und der Postgraduierten-Forschung), durchgeführt werden, die den Umgang mit Gefahrstoffen einschließen können.

Dieses Dokument legt nicht die Anforderungen von Schulen, d. h. vor der Hochschulausbildung (siehe EN 13150) oder hoch spezialisierten Fachlaboren, für deren Funktionsfähigkeit sehr spezifische, bedarfsangepasste Lösungen erforderlich sind, fest.

Dieses Dokument legt Anforderungen fest für die Montage und Auslegung von Labortischen, zugehörigen Stauräumen sowie für die Bereitstellung und den Anschluss von Medien, wobei die Medienversorgung entweder in die Labortische integriert ist oder durch Zuführung erfolgt. Dieses Dokument gibt Leitlinien für alle Parteien, die an Planung, Gestaltung, Bau, Montage und Prüfung eines neuen Labors oder am Umbau eines bestehenden Labors beteiligt sind.

Für Sicherheitsschränke für brennbare Flüssigkeiten gilt EN 14470 1 und für druckbeaufschlagte Gasflaschen gilt EN 14470 2.

Mobilier de laboratoire - Recommandations de conception et d'installation - Partie 1 : Généralités

Le présent document s’applique aux laboratoires de biologie, de chimie et de physique où se déroulent des activités de recherche, de préparation, d’analyse et de processus et qui peuvent impliquer des travaux avec des substances dangereuses, y compris l’enseignement supérieur (enseignement collégial et universitaire et recherche post-universitaire).

Le présent document ne couvre pas les exigences des écoles, c’est-à-dire collège/pré-université (voir l’EN 13150), ou des laboratoires hautement spécialisés qui ont besoin de solutions sur mesure très spécifiques pour leur permettre de fonctionner.

Le présent document spécifie les exigences pour l’installation et la conception des paillasses de laboratoire, des unités de stockage associées, ainsi que pour la fourniture et le raccordement des services intégrés ou livrés aux paillasses de laboratoire. Le présent document donne des lignes directrices à l’intention de toutes les parties impliquées dans la planification, la conception, la fabrication, l’installation, les essais d’un nouveau laboratoire ou dans la rénovation d’un laboratoire existant.

Pour les armoires de stockage de sécurité pour liquides inflammables, l’EN 14470-1 s'applique et pour les armoires de stockage de sécurité pour bouteilles de gaz comprimé, l’EN 14470-2 s'applique.

Laboratorijsko pohištvo - Priporočila za načrtovanje in namestitev - 1. del: Splošno

General Information

- Status

- Published

- Publication Date

- 04-Nov-2025

- Technical Committee

- CEN/TC 332 - Laboratory equipment

- Drafting Committee

- CEN/TC 332/WG 2 - Fittings and fixtures

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 05-Nov-2025

- Due Date

- 30-Nov-2025

- Completion Date

- 05-Nov-2025

Relations

- Effective Date

- 24-Jan-2024

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 14175-8:2022 - Fume cupboards - Part 8: Fume cupboards for work with radioactive materials - Effective Date

- 28-Jan-2026

Overview

EN 14056-1:2025 (CEN) - Laboratory furniture - Recommendations for design and installation - Part 1: General - gives general requirements and practical guidance for the design, selection, installation and handover of laboratory benches, associated storage units and services distribution for biology, chemistry and physics laboratories. It applies to research, preparative, analytical and process activities (including higher education and post‑graduate research) and is the first part of an EN 14056 series that supersedes EN 14056:2003.

This Part 1 provides an overarching framework for bench assemblies, service distribution carriers (spines, ducts, overhead and bench‑mounted systems), worktops, support frames and under‑bench storage, and includes normative annexes on delivery/installation, services outlets and documentation.

Key topics and technical requirements

- Scope and applicability: Intended for higher education and research labs; excludes pre‑college schools (see EN 13150) and highly specialist bespoke laboratories.

- Bench assemblies: Definitions and examples of single‑sided, island, peninsula and double‑sided benches; worktop and support frame types (fixed pedestal, cantilever T‑frame, C‑frame, H‑frame, etc.).

- Services distribution: Guidance on integrated channels, bench‑mounted carriers, wall/floor carriers and overhead delivery systems; placement and clearances for gas, water, electrical and IT outlets.

- Storage and ergonomics: Typical under‑bench storage units, plinths, clearances, working heights and usable worktop space considerations.

- Dimensions and layout: Recommendations on heights, depths and space requirements to support safe, ergonomic workflows.

- Design & installation process: Planning roles, delivery, offloading, safe installation, inspection and handover procedures (normative Annex A).

- Documentation & labelling: Requirements for marking, labelling and handover documentation to support safe operation and maintenance (Annex C).

- Normative references: Includes links to EN 13792 (tap/valve colour coding) and EN 60529 (IP code) and points users to EN 14470‑1/‑2 for flammable liquid cabinets and pressurised gas cylinder storage.

Applications and users

Who benefits: architects, laboratory planners, furniture manufacturers, installers, facilities managers, safety officers, procurement teams, and university/research lab managers. Practical uses include:

- Designing new lab fit‑outs and bench layouts

- Specifying and procuring laboratory furniture and services carriers

- Refurbishment and upgrade projects to meet current safety and ergonomic guidance

- Preparing installation, testing and handover protocols

Related standards

- EN 14056 series (future parts): Part 2 (table frames), Part 3 (worktops), Part 4 (storage units), Part 5 (services distribution carriers), Part 6 (services supply)

- EN 13150 - laboratory furniture for schools (precollege)

- EN 14470‑1 / EN 14470‑2 - safety storage cabinets for flammable liquids and pressurised gas cylinders

- EN 13792, EN 60529

Keywords: EN 14056-1:2025, laboratory furniture, laboratory benches, design and installation, services distribution carriers, worktops, storage units, lab fit‑out, CEN.

Get Certified

Connect with accredited certification bodies for this standard

ECOCERT

Organic and sustainability certification.

Eurofins Food Testing Global

Global leader in food, environment, and pharmaceutical product testing.

Intertek Bangladesh

Intertek certification and testing services in Bangladesh.

Sponsored listings

Frequently Asked Questions

EN 14056-1:2025 is a standard published by the European Committee for Standardization (CEN). Its full title is "Laboratory furniture - Recommendations for design and installation - Part 1: General". This standard covers: This document is applicable to biology, chemistry and physics laboratories where research, preparative, analytical, process activities take place and which can involve work with hazardous substances, including higher education (college and university teaching and post-graduate research). This document does not cover the requirements of schools, i.e. precollege/pre-university (refer to EN 13150), or highly specialist laboratories which need very specific, bespoke solutions to enable them to function. This document specifies requirements for installation and design of laboratory benches, associated storage units, and for the provision and connection of services integral or delivered to the laboratory benches. This document gives guidelines for all parties involved in the planning, design, manufacture, installation, testing of a new laboratory or in the refurbishment of an existing laboratory. For safety storage cabinets for flammable liquids EN 14470-1 and for pressurized gas cylinders EN 14470-2 applies.

This document is applicable to biology, chemistry and physics laboratories where research, preparative, analytical, process activities take place and which can involve work with hazardous substances, including higher education (college and university teaching and post-graduate research). This document does not cover the requirements of schools, i.e. precollege/pre-university (refer to EN 13150), or highly specialist laboratories which need very specific, bespoke solutions to enable them to function. This document specifies requirements for installation and design of laboratory benches, associated storage units, and for the provision and connection of services integral or delivered to the laboratory benches. This document gives guidelines for all parties involved in the planning, design, manufacture, installation, testing of a new laboratory or in the refurbishment of an existing laboratory. For safety storage cabinets for flammable liquids EN 14470-1 and for pressurized gas cylinders EN 14470-2 applies.

EN 14056-1:2025 is classified under the following ICS (International Classification for Standards) categories: 71.040.10 - Chemical laboratories. Laboratory equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14056-1:2025 has the following relationships with other standards: It is inter standard links to EN 14056:2003, EN 60529:1991, EN 13792:2002, EN 14175-8:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14056-1:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2026

Laboratorijsko pohištvo - Priporočila za načrtovanje in namestitev - 1. del: Splošno

Laboratory furniture - Recommendations for design and installation - Part 1: General

Laboreinrichtungen - Empfehlungen für Anordnung und Montage - Teil 1: Allgemeines

Mobilier de laboratoire - Recommandations de conception et d'installation - Partie 1 :

Généralités

Ta slovenski standard je istoveten z: EN 14056-1:2025

ICS:

71.040.10 Kemijski laboratoriji. Chemical laboratories.

Laboratorijska oprema Laboratory equipment

97.140 Pohištvo Furniture

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 14056-1

EUROPEAN STANDARD

NORME EUROPÉENNE

November 2025

EUROPÄISCHE NORM

ICS 71.040.10 Supersedes EN 14056:2003

English Version

Laboratory furniture - Recommendations for design and

installation - Part 1: General

Mobilier de laboratoire - Recommandations de Laboreinrichtungen - Empfehlungen für Anordnung

conception et d'installation - Partie 1 : Généralités und Montage - Teil 1: Allgemeines

This European Standard was approved by CEN on 25 September 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 14056-1:2025 E

worldwide for CEN national Members.

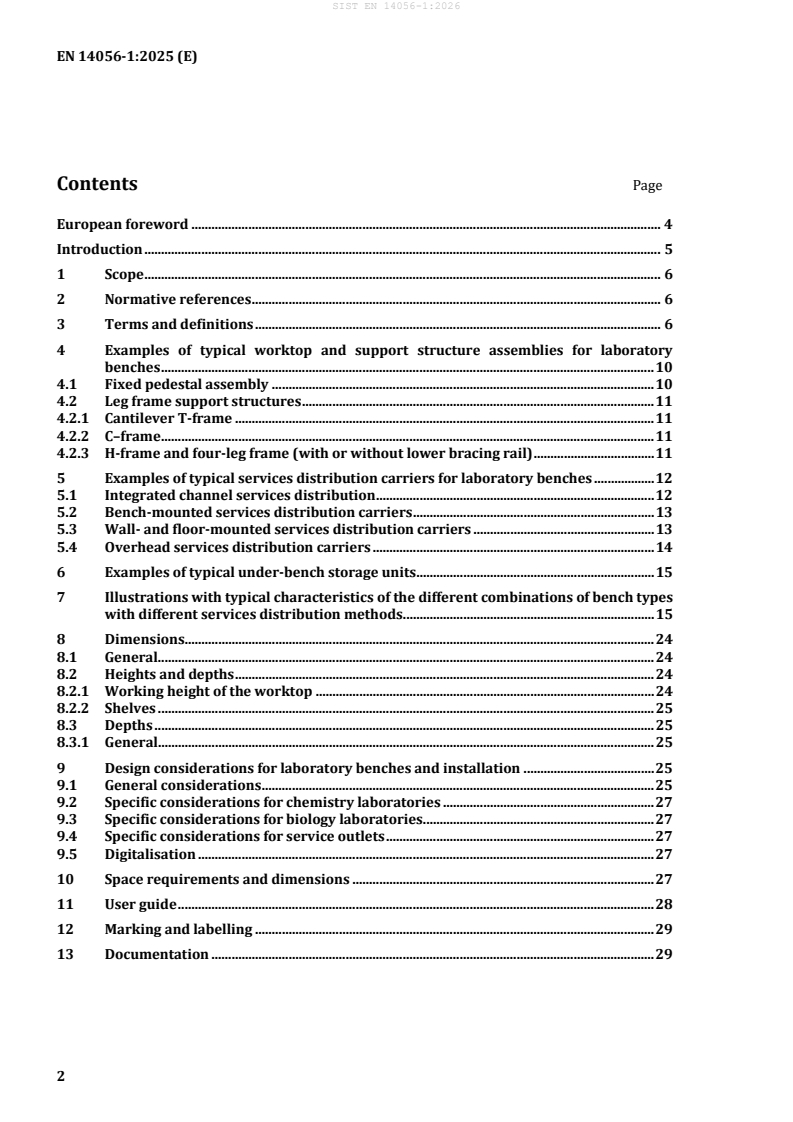

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 6

4 Examples of typical worktop and support structure assemblies for laboratory

benches . 10

4.1 Fixed pedestal assembly . 10

4.2 Leg frame support structures . 11

4.2.1 Cantilever T-frame . 11

4.2.2 C–frame . 11

4.2.3 H-frame and four-leg frame (with or without lower bracing rail) . 11

5 Examples of typical services distribution carriers for laboratory benches . 12

5.1 Integrated channel services distribution . 12

5.2 Bench-mounted services distribution carriers . 13

5.3 Wall- and floor-mounted services distribution carriers . 13

5.4 Overhead services distribution carriers . 14

6 Examples of typical under-bench storage units . 15

7 Illustrations with typical characteristics of the different combinations of bench types

with different services distribution methods . 15

8 Dimensions. 24

8.1 General. 24

8.2 Heights and depths . 24

8.2.1 Working height of the worktop . 24

8.2.2 Shelves . 25

8.3 Depths . 25

8.3.1 General. 25

9 Design considerations for laboratory benches and installation . 25

9.1 General considerations . 25

9.2 Specific considerations for chemistry laboratories . 27

9.3 Specific considerations for biology laboratories. 27

9.4 Specific considerations for service outlets . 27

9.5 Digitalisation . 27

10 Space requirements and dimensions . 27

11 User guide . 28

12 Marking and labelling . 29

13 Documentation . 29

Annex A (normative) Recommendations for the safe and effective delivery, offloading,

distribution and installation of a laboratory bench . 30

A.1 Delivery to site and offloading . 30

A.2 Distribution . 30

A.3 Conditions required for safe and ergonomic installation . 31

A.4 Installations . 31

A.5 Inspection, acceptance and handover . 32

Annex B (normative) Guideline and overview of services outlets for laboratory benches . 33

B.1 Services distribution areas for laboratory benches . 33

B.2 Services connections . 33

B.3 Services outlets . 34

Annex C (normative) Recommendations for the documentation of a laboratory bench

installation . 37

Bibliography . 39

European foreword

This document (EN 14056-1:2025) has been prepared by Technical Committee CEN/TC 332 “Laboratory

equipment”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by May 2026, and conflicting national standards shall be

withdrawn at the latest by May 2026.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 14056:2003.

This document includes the following significant technical changes with respect to EN 14056:2003:

— fundamental revision of the document to give recommendations for design and installation, moving

requirements and recommendations on separate parts of laboratory benches in future further parts

of the standard series.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

The revision of EN 14056:2003 is the first step towards the establishment of an EN 14056 standard

series. This document is now Part 1 of this series, describing various combinations and general

requirements, while further details regarding the single parts will be provided within the following parts:

— Part 2: Table frames;

— Part 3: Worktops;

— Part 4: Storage units;

— Part 5: Services distribution carriers;

— Part 6: Services supply (not final yet, will possibly be integrated into part 5).

NOTE National regulations can apply in the design and environment of a workplace.

1 Scope

This document is applicable to biology, chemistry and physics laboratories where research, preparative,

analytical, process activities take place and which can involve work with hazardous substances, including

higher education (college and university teaching and post-graduate research).

This document does not cover the requirements of schools, i.e. precollege/pre-university (refer to

EN 13150), or highly specialist laboratories which need very specific, bespoke solutions to enable them

to function.

This document specifies requirements for installation and design of laboratory benches, associated

storage units, and for the provision and connection of services integral or delivered to the laboratory

benches. This document gives guidelines for all parties involved in the planning, design, manufacture,

installation, testing of a new laboratory or in the refurbishment of an existing laboratory.

For safety storage cabinets for flammable liquids EN 14470-1 and for pressurized gas cylinders

EN 14470-2 applies.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 13792, Colour coding of taps and valves for use in laboratories

EN 60529, Degrees of protection provided by enclosures (IP code) (IEC 60529)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

laboratory bench

assembly of individual components, combined to create a facility within a laboratory to enable laboratory

work

Note 1 to entry: A laboratory bench may include but is not limited to a worktop, leg frame support structure,

shelving, storage units, worktop-mounted service outlets (gases, water, electricity, IT) a services spine and services

provision. Services may also be delivered via a separate overhead delivery system.

Note 2 to entry: A laboratory bench may be fixed to the building structure (e.g. wall or floor) or may be free-

standing (not fixed to the building structure).

3.1.1

total depth

d

horizontal distance between front edge and rear edge of the laboratory bench (perpendicular to the

length w ) including possible areas for services supply and distribution

Note 1 to entry: The total depth is applicable for single and double-sided assemblies.

3.1.2

total length

w

horizontal distance from the extreme left to the extreme right end of the laboratory bench

3.1.3

single-sided laboratory bench

laboratory bench for single sided use, usually fixed to a wall

3.1.4

island bench

laboratory bench, which is not fixed to a wall and is a stand-alone assembly

3.1.5

peninsula bench

laboratory bench, which may be attached, usually at right angles to a wall or wall bench

3.1.6

double-sided laboratory bench

either island bench (3.1.4) or peninsula bench (3.1.5)

3.2

storage unit

cupboard, drawer packs, tray units or basket units which are located under the worktop fixed in place or

moveable

3.2.1

plinth recess

d

horizontal distance between plinth vertical front and worktop vertical front edge

3.2.2

plinth height

castor height

h

vertical distance from the floor to the lower edge of the storage unit body

3.2.3

clearance

h

vertical clear distance between the top of a moveable storage unit and the underside of a worktop support

frame or worktop where there is no frame

3.3

worktop

horizontal surface to enable laboratory work

3.3.1

working height of the worktop

h

vertical distance between floor and worktop surface

3.3.2

depth of the worktop

d

horizontal distance between front edge and rear edge of the worktop

3.3.3

worktop length

w

horizontal distance between the left and right edge of the worktop

3.4

services distribution carrier

support structure by which services such as gases, water, electricity and IT are distributed to services

outlets which comprise part of the lab bench assembly (spine, duct, bridge, void, channel)

3.4.1

height of the services distribution carrier

h

vertical distance between lower and upper edge of the services distribution carrier

3.4.2

height of the highest shelf

h

vertical distance between floor and top of a shelf

3.4.3

depth of the shelf

d

horizontal distance between front edge and rear edge of the shelf

3.4.4

lower edge of services distribution carrier

h4

vertical distance between the floor and the lower edge of the services carrier - this height describes the

clear height under the services distribution carrier, where applicable

3.4.5

depth of the services distribution carrier

d

horizontal distance between front edge and rear edge of the services distribution carrier

3.4.6

length of the services distribution carrier

w3

horizontal distance from the left to the right edge of the services distribution carrier

3.4.7

clearance height below the services distribution carrier

vertical distance between the upper edge of the work surface and the lower edge of the services

distribution carrier included of the services outlets

Note 1 to entry: This height describes the useful height under the services distribution carrier.

3.4.8

distance below the lowest services outlet above the floor

h

vertical distance between the floor and the lower edge of the services outlet

Note 1 to entry: This height describes the clear height under the services outlet.

3.4.9

distance below the lowest services outlet above the worktop

h11

vertical distance between the worktop and the lower edge of the services outlet

Note 1 to entry: This height describes the clear height under the services outlet.

3.5

services outlet

outlet to which cabling or piping connects to enable users to access services

Note 1 to entry: Examples for services outlets are electrical or IT sockets and gases or water taps.

3.6

useable space on the worktop

clear space on the worktop free of obstructions, such as services outlets, services distribution carriers,

shelves, etc.

3.6.1

height of useable space on the worktop

h

useable vertical distance between the surface of the worktop and the underside of the lowest component

(e.g. shelf, services distribution carrier) located above the work surface

3.6.2

depth of the useable space on the worktop

d

useable horizontal distance between front edge and rear edge of the worktop, minus space required for

service outlets, services distribution carriers, front or rear edge (e.g. upstand or marine edge)

3.6.3

length of the useable space on the worktop

w

useable horizontal distance between the left and right edge of the worktop, minus space required for

service outlets, services distribution carriers, edge (e.g. upstand or marine edge)

3.7

useable space below the worktop

clear space below the worktop free of obstructions, such as installation frames, etc.

3.7.1

height of useable space below the worktop

h

useable vertical distance between the bottom of the worktop and the floor

3.7.2

depth of the useable space below the worktop

d

useable horizontal distance between front edge of the worktop and rear abutment (e.g. wall, support

structure, cover panel)

3.7.3

length of the useable space below the worktop

w

useable horizontal distance between the left and right abutments (e.g. walls, storage units or support

structures)

3.8

moveable

ability to relocate a laboratory bench or component of the same, which can involve some

disassembly/unfastening of components and means of transportation (e.g. trolleys, skids, lifting

equipment)

3.9

mobile

ability to relocate a laboratory bench or component of the same freely and easily with little or no

disassembly/unfastening or requirement for means of transportation (e.g. lightweight components,

storage units and laboratory bench assemblies which include casters)

4 Examples of typical worktop and support structure assemblies for laboratory

benches

4.1 Fixed pedestal assembly

A fixed pedestal assembly utilizes floor-mounted under-bench storage units which are fixed in under the

worktop and which provide the support structure for the worktop, see Figure 1. This system is not

designed to be quickly and easily reconfigured.

Figure 1 — Schematic depiction of fixed pedestal assembly

4.2 Leg frame support structures

4.2.1 Cantilever T-frame

A T-frame support structure is usually fixed to a wall or to the floor, see Figure 2. The leg frame provides

support for the worktop which is independent of under-bench storage units. This allows the under-bench

storage units to be moved and repositioned. The storage units can be suspended (for cleaning under and

for maintenance purposes, access to services, etc.) from the underside of the support structure or push

under either on castors or glides.

Figure 2 — Schematic depiction of cantilever T-frame assembly

4.2.2 C–frame

A C-frame support structure functions like a T-frame but includes a floor-level horizontal foot, see

Figure 3. The frame can be fixed to a wall or floor for stability but can also be free-standing or mounted

on castors. This allows the under-bench storage units to be moved and repositioned. Where not fixed to

a wall or floor, the whole bench assembly can also be moved. The storage units can be suspended (for

cleaning under and for maintenance purposes, access to services, etc.) from the underside of the support

structure or push under on castors or glides.

Figure 3 — Schematic depiction of C-frame assembly

4.2.3 H-frame and four-leg frame (with or without lower bracing rail)

An H-frame and four-leg frame support structure functions like a C-frame but includes an additional front

vertical support, see Figures 4 and 5. This is provided where there is a requirement for heavier load

bearing capability. The frame can be fixed to a wall for stability but is rarely floor fixed and can also be

free-standing or mounted on castors. This allows the under-bench storage units to be moved and

repositioned. Where not fixed to a wall, the whole assembly can be moved. The storage units can be

suspended (for cleaning under and for maintenance purposes, access to services, etc.) from the underside

of the support structure or push under on castors or glides.

Figure 4 — Schematic depiction of H-frame

Figure 5 — Schematic depiction of four-leg frame

5 Examples of typical services distribution carriers for laboratory benches

5.1 Integrated channel services distribution

An integrated channel method enables services to be delivered from main supply lines and distributed to

various services outlets fixed on the laboratory bench through channels under the worktop, behind and

between under-bench storage units, see Figure 6. This method is not designed for laboratory bench

systems to be quickly and easily reconfigured.

Figure 6 — Schematic depiction of an integrated channel services distribution

5.2 Bench-mounted services distribution carriers

A bench-mounted services carrier can be fixed directly onto the worktop or elevated as a bridge to

provide a space under, see Figure 7. The services are distributed horizontally through the carrier to the

services outlets which are part of the carrier assembly. The carrier, when disconnected from the main

supply lines can be moved and relocated as a whole and when fixed to a free-standing laboratory bench

can be moved and relocated as part of the overall bench assembly.

Figure 7 — Schematic depiction of a bench-mounted services carrier

5.3 Wall- and floor-mounted services distribution carriers

Wall and floor carriers can be fixed to wall, floor or the bench support structure, see Figure 8. Depending

on the fixing arrangement, the carrier can be independent of the worktop and support structure

assembly. The carriers contain the services supply lines and deliver them to the services outlets

positioned as part of the carrier module. This services distribution system facilitates the movement and

relocation of free-standing laboratory benches because they are not constrained by connections to main

supply lines. The carriers can also be moved and relocated but this would require disconnection from and

reconnection to services main supply lines in the new location.

Figure 8 — Schematic depiction of a wall and floor fixed services carrier

5.4 Overhead services distribution carriers

Overhead services distribution carriers are usually suspended from the ceiling above and are completely

independent of a laboratory bench, see Figure 9. The carrier contains the services supply lines and

delivers them down vertically to services outlets, or can connect into a secondary channel which runs

horizontally and distributes to the services outlets positioned as part of the carrier module. This services

distribution system facilitates the movement and repositioning of free-standing laboratory benches

because they are not constrained by connections to main supply lines. The carriers can also be moved

and relocated but this would require the disconnection from and reconnection to main supply lines in the

new location.

Figure 9 — Schematic depiction of an overhead services carrier

6 Examples of typical under-bench storage units

Storage units can be typically plinth-mounted, fixed to the underside of a worktop or suspended, on

castors or on glides in combination with a leg frame system. Storage units can consist of, e.g. drawers,

doors and trays, see Figure 10.

Storage cabinet Storage cabinet Storage cabinet Push under

with plinth fitted to suspended from fitted with storage cabinet

worktop underside of castors with plinths

worktop and leg

frame assembly

Figure 10 — Schematic depiction of storage unit mountings

7 Illustrations with typical characteristics of the different combinations of

bench types with different services distribution methods

In Figures 11 to 18, examples of possible combinations are shown schematically.

There are different types of laboratory benches used in combination with different services distribution

methods. Various combinations will provide different levels of flexibility defined in terms of the ability to

move part or all of the laboratory bench assembly for access to services, maintenance, cleaning and/or

re-configuring the benching layout as user requirements change.

The level of flexibility facilitated is affected by the type of leg frame support structure used, if any and the

extent to which they are wall or floor fixed. The way in which services are delivered and distributed also

has a significant bearing. Where services run through or are fixed to the bench, the ability to reconfigure

the bench easily and quickly, if at all, can be limited, typically to under-bench storage units. Where

services delivery and distribution are by means of separate carriers (not fixed to the bench) which are

wall fixed, floor fixed or overhead, movement of the whole bench assembly is more readily

accommodated.

It should be noted that laboratory bench assemblies can be large and heavy and this as much as anything,

can be seen as an obstacle due to time needed and health and safety considerations, for regular

reconfiguration even in situations where there is no wall or floor fixing.

It should also be noted that whilst services can be delivered to laboratory bench assemblies via carriers

which are independent of the bench, drainage is very often provided by means of fixed gravity discharge

points. This can also have a constraining effect on the extent to which some laboratory benches can be

quickly and easily reconfigured.

Dimensions in relation to the laboratory bench Dimensions in relation to the storage space

assembly and the support structure

h working height of the worktop d plinth recess

1 7

w total length h plinth height/castor height

1 8

d total depth h clearance

1 9

d depth of the worktop

w worktop length

Dimensions in relation to the services Dimensions describing the useable spaces

distribution carrier

h height of the services distribution carrier h height of useable space on the worktop

3 6

w length of the services distribution carrier w length of the useable space on the worktop

3 6

d depth of the services distribution carrier d depth of the useable space on the worktop

3 6

h height of the highest shelf h distance below the lowest services outlet above

5 7

the floor

d depth of the shelf h height of useable space below the worktop

5 10

w length of the useable space below the worktop

d depth of the useable space below the worktop

Figure 11 — Floor-mounted services distribution carrier with horizontal services arrangement

Dimensions in relation to the laboratory Dimensions in relation to the storage space

bench assembly and the support structure

h working height of the worktop d plinth recess

1 7

w total length h plinth height/castor height

1 8

d total depth h clearance

1 9

d depth of the worktop

w worktop length

Dimensions in relation to the services Dimensions describing the useable spaces

distribution carrier

h3 height of the services distribution carrier h6 height of the useable space on the worktop

w length of the services distribution carrier w length of the useable space on the worktop

3 6

d depth of the services distribution carrier d depth of the useable space on the worktop

3 6

h distance below the lowest services outlet above

the floor

h height of useable space below the worktop

w length of the useable space below the worktop

d depth of the useable space below the worktop

Figure 12 — Floor-mounted services distribution carrier with horizontal services arrangement

Dimensions in relation to the laboratory Dimensions in relation to the storage space

bench assembly and the support structure

h working height of the worktop d plinth recess

1 7

w total length h plinth height/castor height

1 8

d total depth h clearance

1 9

d depth of the worktop

worktop length

w2

Dimensions in relation to the services Dimensions describing the useable spaces

distribution carrier

h height of the services distribution carrier h height of the useable space on the worktop

3 6

w length of the services distribution carrier w length of the useable space on the worktop

3 6

d depth of the services distribution carrier d depth of the useable space on the worktop

3 6

h height of the highest shelf h distance below the lowest services outlet above

5 7

the floor

d depth of the shelf h height of useable space below the worktop

5 10

w length of the useable space below the worktop

depth of the useable space below the worktop

d10

Figure 13 — Floor-mounted services distribution carrier with vertical services arrangement

Dimensions in relation to the laboratory Dimensions in relation to the storage spa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...