EN 13947:2006

(Main)Thermal performance of curtain walling - Calculation of thermal transmittance

Thermal performance of curtain walling - Calculation of thermal transmittance

This European Standard specifies a method for calculating the thermal transmittance of curtain walls consisting of glazed and/or opaque panels fitted in, or connected to, frames.

The calculation includes:

different types of glazing, e.g. glass or plastic; single or multiple glazing; with or without low emissivity coating; with cavities filled with air or other gases;

frames (of any material) with or without thermal breaks;

different types of opaque panels clad with metal, glass, ceramics or any other material.

Thermal bridge effects at the rebate or connection between the glazed area, the frame area and the panel area are included in the calculation.

The calculation does not include:

effects of solar radiation;

heat transfer caused by air leakage;

calculation of condensation;

effect of shutters;

additional heat transfer at the corners and edges of the curtain walling;

connections to the main building structure nor through fixing lugs;

curtain wall systems with integrated heating.

Wärmetechnisches Verhalten von Vorhangfassaden - Berechnung des Wärmedurchgangskoeffizienten

Diese Europäische Norm legt ein Verfahren zur Ermittlung des Wärmedurchgangskoeffizienten von Vorhangfassaden fest, die aus verglasten und/oder opaken Paneelen, die in Rahmen eingebaut werden oder mit Rahmen verbunden sind, bestehen.

Die Berechnung umfasst

unterschiedliche Verglasungsarten, z. B. aus Glas oder Kunststoff, einfache und mehrfache Verglasungen, Verglasungen mit oder ohne Beschichtungen mit niedrigem Emissionsgrad sowie Verglasungen mit einem Zwischenraum, der mit Luft oder anderen Gasen gefüllt ist;

Rahmen (aus einem beliebigen Material), mit oder ohne wärmetechnische Trennung;

verschiedene Arten von opaken Paneelen, die mit Metall, Glas, Keramik oder einem anderen Material verkleidet sind.

Die Berechnung berücksichtigt den Einfluss von Wärmebrücken am Falz oder an der Fuge zwischen der verglasten Fläche, dem Rahmen und dem Paneel.

Folgende Faktoren werden in der Berechnung nicht berücksichtigt:

Einflüsse aus der Sonneneinstrahlung;

Wärmeübertragung durch Luftdurchlässigkeit;

Tauverhalten;

Einfluss von Abschlüssen;

zusätzliche Wärmeübertragung an den Ecken und Kanten der Vorhangfassade;

Verbindungen mit das Tragwerk und die dazu verwendeten Verbindungsmittel;

Vorhangfassaden mit eingebauter Heizung.

Performances techniques des façades légères - Calcul du coefficient de transmission thermique

La présente Norme européenne indique une méthode de calcul du coefficient de transmission thermique des façades légères composées de panneaux vitrés et/ou opaques montés dans, ou raccordés à des encadrements.

Le calcul prend en compte :

- les différents types de vitrage, par exemple, verre ou plastique ; les vitrages simples ou multiples ; avec ou sans revêtement à basse émissivité ; avec des cavités remplies d’air ou de gaz ;

- les encadrements (en tous matériaux) avec ou sans coupures thermiques ;

- les différent types de parement de panneaux opaques en métal, verre, céramique ou tout autre matériau.

Les effets de pont thermique au niveau de la feuillure ou de la jonction entre l’aire vitrée, l’aire de l’encadrement et l’aire du panneau.

Le calcul ne tient pas compte :

- du rayonnement solaire ;

- du transfert thermique provoqué par les fuites d’air ;

- du calcul de la condensation ;

- de l’effet des fermetures ;

- du transfert thermique supplémentaire au niveau des angles et des bords de la façade légère ;

- des jonctions à la structure principale du bâtiment ou des pattes de fixation ;

des systèmes de façade légère avec chauffage intégré.

Toplotne značilnosti obešenih fasad - Izračun toplotne prehodnosti

General Information

- Status

- Withdrawn

- Publication Date

- 12-Dec-2006

- Withdrawal Date

- 30-Sep-2012

- Technical Committee

- CEN/TC 89 - Thermal performance of buildings and building components

- Drafting Committee

- CEN/TC 89/WG 7 - Thermal properties of doors and windows

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Oct-2012

- Completion Date

- 01-Oct-2012

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 03-Oct-2009

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13947:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal performance of curtain walling - Calculation of thermal transmittance". This standard covers: This European Standard specifies a method for calculating the thermal transmittance of curtain walls consisting of glazed and/or opaque panels fitted in, or connected to, frames. The calculation includes: different types of glazing, e.g. glass or plastic; single or multiple glazing; with or without low emissivity coating; with cavities filled with air or other gases; frames (of any material) with or without thermal breaks; different types of opaque panels clad with metal, glass, ceramics or any other material. Thermal bridge effects at the rebate or connection between the glazed area, the frame area and the panel area are included in the calculation. The calculation does not include: effects of solar radiation; heat transfer caused by air leakage; calculation of condensation; effect of shutters; additional heat transfer at the corners and edges of the curtain walling; connections to the main building structure nor through fixing lugs; curtain wall systems with integrated heating.

This European Standard specifies a method for calculating the thermal transmittance of curtain walls consisting of glazed and/or opaque panels fitted in, or connected to, frames. The calculation includes: different types of glazing, e.g. glass or plastic; single or multiple glazing; with or without low emissivity coating; with cavities filled with air or other gases; frames (of any material) with or without thermal breaks; different types of opaque panels clad with metal, glass, ceramics or any other material. Thermal bridge effects at the rebate or connection between the glazed area, the frame area and the panel area are included in the calculation. The calculation does not include: effects of solar radiation; heat transfer caused by air leakage; calculation of condensation; effect of shutters; additional heat transfer at the corners and edges of the curtain walling; connections to the main building structure nor through fixing lugs; curtain wall systems with integrated heating.

EN 13947:2006 is classified under the following ICS (International Classification for Standards) categories: 91.060.10 - Walls. Partitions. Facades; 91.120.10 - Thermal insulation of buildings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13947:2006 has the following relationships with other standards: It is inter standard links to EN ISO 12631:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13947:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, TRRTP126; Standardization Mandates: M/101. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13947:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Thermal performance of curtain walling - Calculation of thermal transmittanceLPerformances thermiques des façades légeres - Calcul du coefficient de transmission thermiqueWärmetechnisches Verhalten von Vorhangfassaden - Berechnung des WärmedurchgangskoeffizientenTa slovenski standard je istoveten z:EN 13947:2006SIST EN 13947:2007en91.120.10Toplotna izolacija stavbThermal insulation91.060.10Stene. Predelne stene. FasadeWalls. Partitions. FacadesICS:SLOVENSKI

STANDARDSIST EN 13947:200701-februar-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13947December 2006ICS 91.060.10; 91.120.10 English VersionThermal performance of curtain walling - Calculation of thermaltransmittancePerformances thermiques des façades légères - Calcul ducoefficient de transmission thermiqueWärmetechnisches Verhalten von Vorhangfassaden -Berechnung des WärmedurchgangskoeffizientenThis European Standard was approved by CEN on 9 November 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13947:2006: E

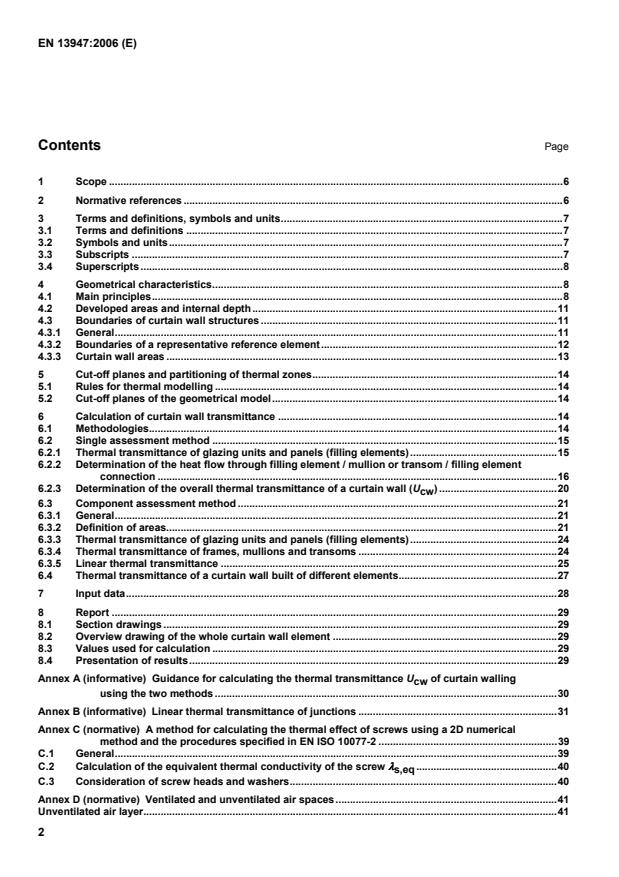

Guidance for calculating the thermal transmittance Ucw of curtain walling using the two methods.30 Annex B (informative)

Linear thermal transmittance of junctions.31 Annex C (normative)

A method for calculating the thermal effect of screws using a 2D numerical method and the procedures specified in EN ISO 10077-2.39 C.1 General.39 C.2 Calculation of the equivalent thermal conductivity of the screw λλλλs,eq.40 C.3 Consideration of screw heads and washers.40 Annex D (normative)

Ventilated and unventilated air spaces.41 Unventilated air layer.41

Component method: Calculation example.44 E.1 Data for examples.44 E.2 Frames.46 E.2.1 Definition and evaluation of areas.46 E.2.2 Evaluation of Uf values.47 E.3 Glazing units.48 E.3.1 Definition and evaluation of areas.48 E.3.2 Evaluation of Ug values.48 E.3.3 Definition of lg and evaluation of g, m,f and t,f.48 E.4 Panels.49 E.4.1 Definition and evaluation of areas.49 E.4.2 Evaluation of Up values.49 E.4.3 Definition of lp and evaluation of the p values.50 E.4.4 Calculation of a complete element.50 Annex F (informative)

Single assessment method: Calculation example.51 F.1 General description of examples.51 F.2 Centre U-value of the glazing unit.52 F.3 Centre U-value of the spandrel panel.52 F.4 U-values of thermal joints.52 F.5 Overall U-value of the curtain wall.53

which is derived using the procedures specified in EN ISO 10077-2.

summation

ε emissivity

3.3 Subscripts cw curtain walling d developed e external eq equivalent f frame f,g frame/glazing FE filling element g glazing i internal j joint m mullion

Key 1

structure fixing bracket A-A

vertical section Figure 1 — Principle of curtain walling construction: unitised construction

Key 1

structure fixing bracket A-A

vertical section Figure 2 — Principle of curtain walling construction: stick construction

Key 1 internal 2 external di internal depth of mullion or transom Ad,i

internal developed area Ad,e

external developed area

Figure 3 — Internal and external developed area, internal depth 4.3 Boundaries of curtain wall structures 4.3.1 General To evaluate the thermal transmittance of façades representative reference areas should be defined. The following subclauses define the various areas.

Figure 4 — Boundaries of a representative reference element of a façade

Key 1 mullion 2 transom 3 sash and frame 4 glazing 5 panel Figure 5 — Areas with different thermal properties

Figure 6 — Thermal section representing the full curtain wall

6.2 Single assessment method 6.2.1 Thermal transmittance of glazing units and panels (filling elements) The thermal transmittance of opaque panels Up shall be evaluated according to prEN ISO 6946. The thermal transmittance of glazing units Ug shall be evaluated according to EN 673, EN 674 or EN 675. In some cases, there is a different filling element at each side of the thermal joint (mullion, transom), so that two thermal transmittances have to be determined.

Figure 7a — Definition of the areas when using UTJ (example: glazing, mullion, panel) The heat flow rate ΦTJ, which represents the additional heat flow rate due to making a thermal joint between two filling elements, can be calculated as: ΦTJ = Φtot – (UFE1 AFE1 + UFE2 AFE2) ∆T (1a) where ∆T is the temperature difference between internal and external environments used to simulate the heat transfer. The thermal transmittance of the joint UTJ is calculated as: UTJ = ΦTJ / (A TJ ∆T) (2a) where ATJ is the projected area of the thermal joint; ∆T is the temperature difference between the internal and external environment used for the simulation. 6.2.2.3 Determination of the linear joint thermal transmittance ΨΨΨΨTJ

The definition of the filling element areas is different from the definition in Figure 7a and is as specified in Figure 7b. The calculation of ΦTJ

is according to Equation (1b). The heat flow rate ΦTJ can be calculated as: ΦTJ

= Φtot – (UFE1 A*FE1 + UFE2 A*FE2) ∆T (1b) where ∆T is the temperature difference between inside and outside air used to simulate the heat transfer.

Figure 7b — Definition of the areas when using ΨΨΨΨTJ (example: glazing, mullion, panel) The linear thermal transmittance of the joint ΨTJ is calculated as: ΨTJ = ΦTJ / (lTJ ∆T) (2b) where ∆T is the temperature difference between the internal and external environments used for the simulation. 6.2.2.4 Definitions of areas for other combinations Figures 8 to 11 give further examples of how the curtain wall can be decomposed into parts for analysis by the single assessment method. The area of the joint ATJ is the largest of the projected areas between the two filling elements. The length lTJ is the length of the thermal joint connecting the filling elements.

Key Aj

Ajoint

Aw

area window Acw

curtain walling

Af

area frame Ap

panel area

Ag

area glazing Am

mullen Figure 8 — Example 1: Framed curtain wall

Key ATJ

area of thermal joint Ag

glazing area Figure 9 — Example 2: Structural silicone glazing

Key TJ thermal joint Figure 10 — Example 3: Structural glazing

Figure 11 — Example 4: Rain screen

6.2.3 Determination of the overall thermal transmittance of a curtain wall (Ucw) 6.2.3.1 Using the area-related thermal transmittance UTJ The overall thermal transmittance of the curtain wall element Ucw is calculated as the area-weighted average of all the thermal transmittances of the joints, glazing units and panels. TJpgTJTJppggcwAAAUAUAUAU∑+∑+∑∑+∑+∑= (3a) where the areas Ag and Ap are defined according to Figure 7a. 6.2.3.2 Using the length-related linear thermal transmittance TJ The overall thermal transmittance of the curtain wall element Ucw is calculated as the area-weighted average of all the thermal transmittances of glazing units and panels and the linear thermal transmittances of the joints.

cwft,ft,fm,fm,ppgt,gt,gm,gm,gf,gf,ttmmffppggcwAllllllUAUAUAUAUAU∑+∑∑∑∑∑∑+∑+∑+∑+∑= (4) where Ug, Up are the thermal transmittances of glazing and panels; Uf, Um, Ut are the thermal transmittances of frames, mullions and transoms; Ψf,g, Ψm,g, Ψt,g, Ψp are the linear thermal transmittances due to the combined thermal effects of glazing unit or panel and frame or mullion or transom; Ψm,f, Ψt,f, are the linear thermal transmittances due to the combined thermal effects of frame-mullion and frame-transom and the other symbols are defined in Clause 3. The area of the curtain walling shall be calculated according to Equation (5): Acw = Ag + Ap + Af + Am + At (5) where Acw

is the area of curtain walling; Ag

is the total area of glazing; Ap

is the total area of panels; Af

is the total area of frames; Am

is the total area of mullions; At

is the total area of transoms. 6.3.2 Definition of areas 6.3.2.1 Glazed areas The glazed area, Ag, or the opaque panel area, Ap, of a component is the smaller of the visible areas that can be seen from both sides (see Figures 12 and 13). Any overlapping of the glazed area by the gaskets is ignored.

Key 1 glass Figure 12 — Illustration of the glazed area and perimeter 6.3.2.3 Areas of frames, mullions and transoms For the definition of the areas see also Figures 13 and 14. Am,i / At,i is the internal projected mullion/transom area, equal to the area of the projection of the internal mullion/transom on a plane parallel to the wall; Am,e / At,e is the external projected mullion/transom area, equal to the area of the projection of the external mullion/transom on a plane parallel to the wall; Am / At is the mullion/transom area, equal to the larger of the two projected areas seen from either side; Af,i is the internal projected frame area, equal to the area of the projection of the internal frame on a plane parallel to the wall; Af,e is the external projected frame area, equal to the area of the projection of the external frame on a plane parallel to the wall; Af is the frame area, equal to the larger of the two projected areas seen from either side.

Am = max (Am,i ; Am,e) At = max (At,i ; At,e) Af = max (Af,i ; Af,e) Aw = Af,i;+ Ag

In Figure 13 only a mullion is shown. The general principal is also applicable for transoms. .

Key 1 internal

Acw

curtain walling

Af

area frame 2 external

Ap

panel area

Ag

glazing area

3 frame (fixed)

Am,i

internal mullen area

Am,e

external mullen area 4 sash (movable)

Am

mullen 5 mullion/ transom

Af,e

external frame area

Figure 13 — Illustration of the various areas on mullion or transom sections, panels and glazing

Key 1 internal 2 external 3 sash (movable) 4 frame (fixed) Figure 14 — Illustration of the various areas on frame-sash sections and glazing

6.3.2.4 Area of a module of curtain walling If the internal or external frame has a complex geometrical shape, the frame section Af is determined according to Figure 14, the mullion and transom section Am and At are determined according to Figure 13. The total area Acw, of an element of curtain walling is the sum of the mullion/transom area, Am / At, the frame area, Af, the glazing area, Ag, and the panel area, Ap (see also Figure 13). 6.3.3 Thermal transmittance of glazing units and panels (filling elements) The thermal transmittance of opaque panels Up shall be evaluated according to prEN ISO 6946. The thermal transmittance of glazing units Ug shall be evaluated according to EN 673, EN 674 or EN 675. In some cases, there is a different filling element at each side of the thermal joint (mullion, transom), so that two thermal transmittances have to be calculated. 6.3.4 Thermal transmittance of frames, mullions and transoms

The Uf values of the sash and frame sections can be evaluated according to EN 12412-2, EN ISO 10077-1 or EN ISO 10077-2. See also Annex B concerning the boundary conditions for the calculation of Uf for frames which are integrated in the façade. The Ut and Um values for the transom and mullion sections can be evaluated according to EN 12412-2 or EN ISO 10077-2. The U-value calculated according to EN ISO 10077-2 does not take into account the effect of screws connecting the internal to the external sections of mullions and transoms. The effect of screws shall be included using Equations (6a) and (6b).

∆U depends on the distance between the connectors, the diameter and the materials used. An alternative to using the values given in Table 2 is to measure ûU using the procedures specified in EN 12412-2. In this case ∆U is derived from the difference between measured values for specimens with metal screws and those on the same specimen but using plastic screws (which are assumed to have a negligible effect). ∆U can also be evaluated by a three dimensional calculation according to EN ISO 10211 obeying the specific rules for cavities given in EN ISO 10077-2. A second alternative is to calculate the influence of the screws according to Annex C. It is common practice to produce "profile systems" comprising a large number of different frames, having a wide range of geometric shapes but having similar thermal properties. This is because in these groups of frames, the important parameters such as the size, material and design of the thermal break, are the same. The thermal transmittance of a profile or profile combination of a "profile system" can be evaluated by: using the highest value of Uf or Um /Ut of the profiles or profile combinations within the profile system, or using trend lines that show the relationship between Uf or Um /Ut and defined geometrical characteristics. In the latter case the data points for the trend line are evaluated on selected profile cross-sections, taken from the profile system in question. Detailed procedures are described in [1], [2] and [3] of the Bibliography. 6.3.5 Linear thermal transmittance Values for the linear thermal transmittance of glazing units, Ψg, are given in Annex B, Table B.1, Table B.2, Table B.3, Table B.4 or can be calculated using EN ISO 10077-2. In the case of single glazing, Ψg in Equation (4) shall be taken as zero (no spacer effect) because any correction is negligible. Values for the linear thermal transmittance Ψp of panels are given in Table B.5 or can be calculated using EN ISO 10077-2. The interaction between the frame and the mullion or transom caused by the installation of the frame into the rebate of the mullion or transom (Figure 15) is accounted for with the linear thermal transmittances Ψm,f and Ψt,f.

Key 1 transom or mullion 2 frame (fixed) 3 sash (movable) 4 infill, panel Figure 15 — Illustration of a window integrated in a transom or mullion section

6.4 Thermal transmittance of a curtain wall built of different elements The calculation of Ucw,tot of the overall curtain wall built with different sizes or design of elements shall be calculated as the area-weighted average thermal transmittance of all modules according to Equation (8). ∑∑=jjjAUA(U,cw,cwcw,totcw,) (8) where ΣUcw,j

Acw,j is the sum of the products of thermal transmittances and corresponding areas of the different modules; ΣAcw,j is the sum of the areas of the different modules.

The sources of all data shall be stated unambiguously. Ensure that numerical values used relate exactly to the areas as defined in Clause 4. If the results are to be used for comparison of the performance of different curtain walling, the sources of the numerical values of each parameter shall be the same for each type of curtain walling included in the comparison. Results obtained for the purposes of comparison of products (declared values) shall be calculated or measured for horizontal heat flow. Design values should be determined for the actual position and boundary conditions, by including the effect of the inclination of the curtain wall in the determination of Ug. However, the Um, Ut, Uf and Ψ as determined for the curtain wall in the vertical position are used for all inclinations of the curtain wall. Values for the surface thermal resistance can be obtained from EN ISO 10077-1:2006, Annex A.

Guidance for calculating the thermal transmittance Ucw of curtain walling using the two methods Table A.1 — Summary of the procedure for determining Ucw of curtain walling Component assessment method Single assessment method 1 Frames 1. Frames (joints) 1.1 Definition and evaluation of areas according to 4.2 1.1 Definition and evaluation of areas according to 4.2 1.2 Evaluation of Uf , Um und Ut values according to EN ISO 10077-2 (with Equation (6)) or EN 12412-2 1.2 Evaluation of UTJ or ΨTJ according to 6.2 1.3 Evaluation of Ψm,f / Ψt,f according to Table B.6 of this European Standard or EN ISO 10077-2

2 Glazing 2 Gl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...