EN 13022-2:2014

(Main)Glass in building - Structural sealant glazing - Part 2: Assembly rules

Glass in building - Structural sealant glazing - Part 2: Assembly rules

This European Standard deals with the assembling and bonding of glass elements in a frame, window, door or curtain walling construction, or directly into the building by means of structural bonding of the glass element into or onto framework or directly into the building.

It gives information to the assembler to enable him to organize his work and comply with requirements regarding quality control.

Structural sealant glazing can be incorporated into the façades (curtain walls, doors and windows) or roofs as follows:

- either vertically; or

- up to 7° from the horizontal, i.e. 83° from the vertical.

This European Standard only deals with the bonding to glass surfaces, i.e. coated or uncoated or enamelled, and metallic surfaces, i.e. aluminium (anodised or coated), stainless steel, as considered in G.2 of EN 15434:2006+A1:2010.

Glas im Bauwesen - Geklebte Verglasungen - Teil 2: Verglasungsvorschriften für Structural-Sealant-Glazing (SSG-) Glaskonstruktionen

Diese Europäische Norm gilt für die Montage und die Verklebung von Verglasungselementen in Rahmen, Fenstern, Türen oder Vorhangfassadenkonstruktionen und die Montage von Verglasungselementen durch lastübertragendes Verkleben in oder auf eine Unterkonstruktion oder direkt in oder auf das Gebäude.

Sie enthält Angaben für den Monteur zur Unterstützung bei der Einteilung seiner Arbeit und zum Erreichen der Übereinstimmung mit den Anforderungen an die Qualitätskontrolle.

Geklebte lastabtragende Verglasungen können wie folgt in Fassaden (Vorhangfassaden, Türen und Fenster) oder Dächer eingefügt werden:

- entweder vertikal oder

- bis 7° von der Horizontalen, d. h. 83° von der Vertikalen.

Diese Europäische Norm behandelt nur die Verklebung an Glasoberflächen, d. h. beschichtete, unbeschichtete oder emaillierte sowie an metallischen Oberflächen, d. h. Aluminium (anodisiert oder beschichtet), Edelstahl, nach EN 15434:2006A1:2010, G.2.

Verre dans la construction - Système de vitrage extérieur collé (VEC) - Partie 2: Règles d'assemblage

La présente Norme européenne traite de l’assemblage des éléments de verre sur une fenêtre, une porte ou une façade rideau, ou directement sur le bâtiment par le biais du collage structurel de l'élément de verre sur ou dans l’ossature, voire directement sur le bâtiment.

La présente norme donne des informations à l’assembleur lui permettant d'organiser son travail et de satisfaire aux exigences relatives au contrôle qualité.

Le vitrage extérieur collé peut être intégré aux façades (façades rideaux, portes et fenêtres) ou aux toits comme suit :

- verticalement ; ou

- incliné jusqu’à 7° par rapport à l’horizontale, soit 83° par rapport à la verticale.

La présente Norme européenne ne couvre que le collage sur supports verriers, par exemple à couches, sans couche ou émaillé, et surfaces métalliques, par exemple, aluminium (anodisé ou thermolaqué), acier inoxydable, comme prévu en G.2 de l’EN 15434:2006+A1:2010.

Steklo v gradbeništvu - Strukturna zasteklitev - 2. del: Pravila za zastekljevanje

Standard EN 13022-2 obravnava zastekljevanje in vezanje steklenih elementov v konstrukcijo okvira, okna, vrat ali zidov za zavese ali neposredno v stavbo s strukturnim vezanjem steklenega elementa v ali na okvir ali neposredno v stavbo. Zastekljevalcu podaja informacije, ki mu omogočajo organiziranje dela in skladnost z zahtevami v zvezi z nadzorom kakovosti. Strukturno zasteklitev je mogoče vgraditi v fasade (zidove za zavese, vrata in okna) ali strehe, kot sledi: – navpično ali – do 7 ° od vodoravne, tj. 83 ° od navpične. Ta evropski standard obravnava samo vezanje na steklene površine, tj. prevlečene ali neprevlečene ali emajlirane, in na kovinske površine, tj. aluminij (anodiziran ali prevlečen), nerjavno jeklo, kot je obravnavano v oddelku G.2 standarda EN 15434:2006+A1:2010.

General Information

- Status

- Published

- Publication Date

- 03-Jun-2014

- Withdrawal Date

- 30-Dec-2014

- Technical Committee

- CEN/TC 129 - Glass in building

- Drafting Committee

- CEN/TC 129/WG 16 - Structural glazing

- Current Stage

- 9092 - Decision on results of review/2YR ENQ - revise - Review Enquiry

- Start Date

- 22-Sep-2025

- Completion Date

- 11-Feb-2026

Relations

- Replaces

EN 13022-2:2006+A1:2010 - Glass in building - Structural sealant glazing - Part 2: Assembly rules - Effective Date

- 13-Mar-2013

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 15434-1:2023 - Bonding sealants - Part 1: Bonded glazing sealants for direct light exposure - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13022-2:2014 - Glass in building - Structural sealant glazing - Part 2: Assembly rules is a European Standard published by CEN that defines requirements and practical guidance for assembling and structurally bonding glass elements into frames, curtain walls, doors, windows or directly into a building. The standard covers vertical façades and installations up to 7° from the horizontal (i.e., 83° from vertical). It applies to bonding onto glass surfaces (coated, uncoated or enamelled) and metallic supports such as aluminium (anodised or coated) and stainless steel.

Key Topics and Requirements

- Scope and application: Structural bonding of glass into/onto framework or directly to the building for façades and roofs (vertical to 7° from horizontal).

- Environmental controls for assembling:

- Surface and ambient temperatures between 10 °C and 35 °C.

- Relative humidity at least 5% below the dew point of the support surface.

- Dust‑free environment and secure fixation of glass until sealant fully cures.

- Quality management and organization:

- Assembler responsibilities, organization of work and factory production control requirements.

- Inspection and testing tables to structure quality control during assembling/bonding.

- Adhesion and performance testing:

- Dynamic tensile and peel tests (Annex A) for verification.

- Adhesion test methods for assembling/bonding control (Annex C): peel, static tensile and dynamic tensile tests.

- Tests for two‑component sealant mixing and air inclusions (Annex D) and hardness measurements (Annex E).

- Design and assembly guidance:

- Informative design guidance (Annex B) covering characteristic details, safety (fire reaction, release of substances), and structural seal dimensions.

- Third‑party involvement:

- Voluntary provisions for external certification, marking and labelling (Annex F).

Applications and Users

Who uses EN 13022-2:2014:

- Façade contractors, window and curtain wall fabricators, glazing installers and sub‑contractors.

- Structural engineers and façade designers specifying structural sealant glazing (SSG) systems.

- Quality managers and testing laboratories performing adhesion, tensile and peel tests.

- Manufacturers of structural sealants and glass products for compliance and production control.

Practical uses:

- Establishing on‑site assembly procedures and environmental controls for SSG.

- Preparing inspection and test regimes to ensure durable bonding of glass to metal frames.

- Verifying sealant mixing quality and adhesion performance during production and installation.

Related Standards

- EN 13022-1:2014 - Glass products for structural sealant glazing systems.

- EN 15434:2006+A1:2010 - Product standard for structural and/or UV‑resistant sealant.

Keywords: EN 13022-2:2014, structural sealant glazing, assembly rules, glass in building, structural bonding, curtain wall, adhesion tests, dynamic tensile test, peel test, façade installation.

Frequently Asked Questions

EN 13022-2:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Glass in building - Structural sealant glazing - Part 2: Assembly rules". This standard covers: This European Standard deals with the assembling and bonding of glass elements in a frame, window, door or curtain walling construction, or directly into the building by means of structural bonding of the glass element into or onto framework or directly into the building. It gives information to the assembler to enable him to organize his work and comply with requirements regarding quality control. Structural sealant glazing can be incorporated into the façades (curtain walls, doors and windows) or roofs as follows: - either vertically; or - up to 7° from the horizontal, i.e. 83° from the vertical. This European Standard only deals with the bonding to glass surfaces, i.e. coated or uncoated or enamelled, and metallic surfaces, i.e. aluminium (anodised or coated), stainless steel, as considered in G.2 of EN 15434:2006+A1:2010.

This European Standard deals with the assembling and bonding of glass elements in a frame, window, door or curtain walling construction, or directly into the building by means of structural bonding of the glass element into or onto framework or directly into the building. It gives information to the assembler to enable him to organize his work and comply with requirements regarding quality control. Structural sealant glazing can be incorporated into the façades (curtain walls, doors and windows) or roofs as follows: - either vertically; or - up to 7° from the horizontal, i.e. 83° from the vertical. This European Standard only deals with the bonding to glass surfaces, i.e. coated or uncoated or enamelled, and metallic surfaces, i.e. aluminium (anodised or coated), stainless steel, as considered in G.2 of EN 15434:2006+A1:2010.

EN 13022-2:2014 is classified under the following ICS (International Classification for Standards) categories: 81.040.20 - Glass in building. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13022-2:2014 has the following relationships with other standards: It is inter standard links to EN 13022-2:2006+A1:2010, EN 13022-1:2014, EN 15434:2006+A1:2010, EN 50583-1:2016, EN 50583-2:2016, EN 13830:2015, CEN/TS 19100-1:2021, EN 1279-6:2002, EN 16759:2021, EN 15434-1:2023, EN 13830:2015+A1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13022-2:2014 is associated with the following European legislation: EU Directives/Regulations: 88/609/EEC; Standardization Mandates: M/135. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13022-2:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steklo v gradbeništvu - Strukturna zasteklitev - 2. del: Pravila za zastekljevanjeGlas im Bauwesen - Geklebte Verglasungen - Teil 2: VerglasungsvorschriftenVerre dans la construction - Système de vitrage extérieur collé (VEC) - Partie 2: Règles d'assemblageGlass in building - Structural sealant glazing - Part 2: Assembly rules81.040.20Steklo v gradbeništvuGlass in buildingICS:Ta slovenski standard je istoveten z:EN 13022-2:2014SIST EN 13022-2:2014en,fr,de01-september-2014SIST EN 13022-2:2014SLOVENSKI

STANDARDSIST EN 13022-2:2006+A1:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13022-2

June 2014 ICS 81.040.20 Supersedes EN 13022-2:2006+A1:2010English Version

Glass in building - Structural sealant glazing - Part 2: Assembly rules

Verre dans la construction - Système de vitrage extérieur collé (VEC) - Partie 2: Règles d'assemblage

Glas im Bauwesen - Geklebte Verglasungen - Teil 2: Verglasungsvorschriften für Structural-Sealant-Glazing (SSG-) Glaskonstruktionen This European Standard was approved by CEN on 9 February 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13022-2:2014 ESIST EN 13022-2:2014

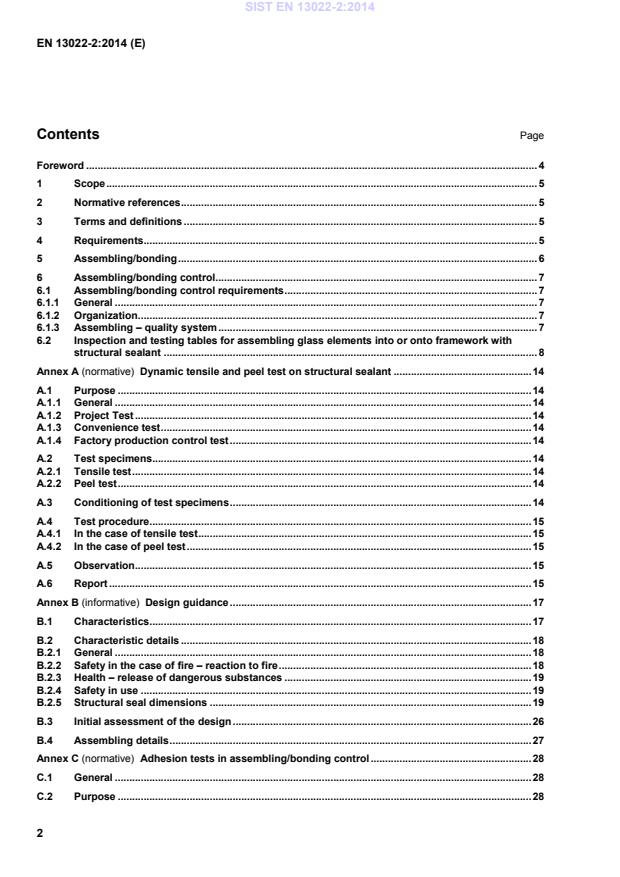

Foreword . 4 1 Scope . 5 2 Normative references . 5 3 Terms and definitions . 5 4 Requirements. 5 5 Assembling/bonding . 6 6 Assembling/bonding control . 7 6.1 Assembling/bonding control requirements . 7 6.1.1 General . 7 6.1.2 Organization . 7 6.1.3 Assembling – quality system . 7 6.2 Inspection and testing tables for assembling glass elements into or onto framework with structural sealant . 8 Annex A (normative)

Dynamic tensile and peel test on structural sealant . 14 A.1 Purpose . 14 A.1.1 General . 14 A.1.2 Project Test . 14 A.1.3 Convenience test . 14 A.1.4 Factory production control test . 14 A.2 Test specimens. 14 A.2.1 Tensile test . 14 A.2.2 Peel test . 14 A.3 Conditioning of test specimens . 14 A.4 Test procedure. 15 A.4.1 In the case of tensile test . 15 A.4.2 In the case of peel test . 15 A.5 Observation . 15 A.6 Report . 15 Annex B (informative)

Design guidance . 17 B.1 Characteristics. 17 B.2 Characteristic details . 18 B.2.1 General . 18 B.2.2 Safety in the case of fire – reaction to fire . 18 B.2.3 Health – release of dangerous substances . 19 B.2.4 Safety in use . 19 B.2.5 Structural seal dimensions . 19 B.3 Initial assessment of the design . 26 B.4 Assembling details . 27 Annex C (normative)

Adhesion tests in assembling/bonding control . 28 C.1 General . 28 C.2 Purpose . 28 SIST EN 13022-2:2014

Two-component sealant: Check on the thoroughness of mixing and air inclusions . 32 D.1 General . 32 D.2 Purpose . 32 D.3 Test specimen . 32 D.4 Test procedure . 32 D.5 Report . 32 Annex E (informative)

Sealants, hardness measurements . 34 E.1 General . 34 E.2 Purpose . 34 E.3 Definitions . 34 E.3.1 Curing time . 34 E.3.2 Free surface . 34 E.4 Instruments . 34 E.5 Calibration . 34 E.6 Test specimens . 35 E.7 Test procedure . 35 E.8 Report . 35 Annex F (informative)

Provisions for voluntary involvement of third party(ies) . 37 F.1 General . 37 F.2 Voluntary tasks for third parties . 37 F.3 Marking and labelling . 37 Bibliography . 38

EN 15434:2006+A1:2010 and the following apply. 3.1 structural bonding assembling of glass elements into or onto window, door or curtain walling framework by means of a structural seal 3.2 structural sealant elastic sealant used for making a structural seal 4 Requirements The assembling of the glass elements into or onto the window, door or curtain-walling framework or directly in the building or construction shall take place under the following controlled environmental conditions: — temperature of the surface of the frame and of the glass and of the near environment shall be not less than 10 °C and not more than 35 °C; — for a given temperature, the RH value shall be at least 5 % below the value corresponding to the dew point of the support to which the seal is being applied; SIST EN 13022-2:2014

1) ETA: European Technical Agreement. SIST EN 13022-2:2014

1.1.1 packaging and label Visual See purchase specification Each delivery No 1.1.2 Identification Visual See purchase specification Each delivery Yes 1.2 Glass products

1.2.1 packaging and label Visual See purchase specification Each delivery No 1.2.2 identification (according to relevant standards) Visual See purchase specification Each delivery Yes 1.2.3 Dimensions Measurement See purchase specification Each package and thickness No 1.3 Structural sealant

1.3.1 Packaging, label and quality control report of the sealant supplier Visual See purchase specification Each delivery No 1.3.2 shelf life Visual Suppliers’ specification Each delivery Yes 1.3.3

Convenience test adhesion test when no delivery information a on the sealant from the sealant supplier available shall be carried out together) Annex A and Annex C Peel test only accepted Annex A Rupture 100 % cohesive failure Each delivery of sealant, glass or framework b Yes 1.4 Bond breaker material

1.4.1 packaging and labelling Visual See purchase specification Each delivery No 1.4.2 Identification Visual See purchase specification Each delivery Yes 1.5 Spacer material

1.5.1 packaging and labelling Visual See purchase specification Each delivery No 1.5.2 Identification Visual See purchase specification Each delivery Yes SIST EN 13022-2:2014

1.6.1 packaging and labelling Visual See purchase specification Each delivery No 1.6.2 Identification Visual See purchase specification Each delivery Yes 1.7 Finishing material

1.7.1 packaging and labelling Visual See purchase specification Each delivery No 1.7.2 Identification Visual See purchase specification Each delivery Yes 1.8 Retaining devices

1.8.1 packaging and labelling Visual See purchase specification Each delivery No 1.8.2 Identification Visual See purchase specification Each delivery Yes 1.9 Retaining clips

1.9.1 packaging and labelling Visual See purchase specification Each delivery No 1.9.2 Identification Visual See purchase specification Each delivery Yes 1.10 Cleaning products

1.10.1 packaging and labelling Visual See purchase specification Each delivery No 1.10.2 Identification Visual See purchase specification Each delivery Yes 1.11 Primer

1.11.1 packaging and labelling Visual See purchase specification Each delivery No 1.11.2 Identification Visual See purchase specification Each delivery Yes SIST EN 13022-2:2014

2.0.1 Temperature and RH Measurement Clause 4 Every day Yes 2.1 Component preparation

2.1.1 dry and clean framework surface Visual No visible contamination Continually No 2.1.2 dry and clean glass surface Visual No visible contamination Continually No 2.2 Structural sealant application

2.2.1 preparation (including application primer) and positioning glass elements and/or framework Visual Assembling manual Continually No 2.2.2 extrusion of structural sealant and application retaining clips Visual Assembling manual Continually No 2.2.3 storage after initial cure Visual Assembling manual Continually No 2.2.4 installation on building with retaining devices (if relevant) Visual Assembling manual Continually No 2.2.5 finishing work Visual Assembling manual Continually No 2.2.6 application weather sealant (if relevant) Visual Assembling manual Continually No 2.3 Structural sealant

2.3.1 Adhesion on relevant substrates Annex C C.3 Method 1 Annex C (2 × per working day): 2 specimens Yes 2.3.2 mixing ratio See equipment and sealant specifications See sealant specification See assembling control manual Yes 2.3.3 thoroughness of mixing Mixing check (Annex D) No marbling Each working day: 1 Yes SIST EN 13022-2:2014

3 Final assembling

3.1 where applicable, storage conditions Visual See assembling control manual Once per shift No 3.2 dimensions and positioning structural seal

Measurement See design specification See designers specification Yes 3.3 control of the visible surface of the sealant Visual See design specification See designers specification Yes 3.4 positioning glass element versus framework Measurement See design specification See designers specification Yes 3.5 positioning of the retainer devices if relevant Measurement See design specification See designers specification Yes 3.6 application of weather seal if relevant Measurement See design specification See designers specification Yes 3.7 general aspect of window, door or

curtain-walling Visual See design specification Randomly five times per shift No a Results available 6 months maximum. b One delivery of anodised aluminium: group of anodised aluminium profile in the same bath, at the same time for 1 working shift.

One delivery of coated aluminium is a production done from a same colour, same gloss, same finish, same powder, from a same supplier from a single coater.

One delivery of stainless steel: means one day production. SIST EN 13022-2:2014

Dynamic tensile and peel test on structural sealant A.1 Purpose A.1.1 General This annex gives possible methods to evaluate the constancy of the cohesive strength of the structural sealant and of the adherence to materials as defined in EN 15434:2006+A1:2010, Annex G. The description of the test methods given below is intended to help sealant suppliers as well as sealant users. Every effort has been made to keep these methods as simple as possible without detracting from the achievement of consistency of quality in the manufactured products. Three levels are considered: A.1.2 Project Test Test performs on one sample representative of the surface tested according to EN 15434:2006+A1:2010, Annex G. This test should be only be performed when the structural sealant manufacturer has not made available

this information with the sealant shipped to the purchaser A.1.3 Convenience test Test performs according to 6.2, Table 1 – Section Material control – line 1.3.3 This test should be only be performed when the structural sealant manufacturer has not made available

this information with the sealant shipped to the purchaser A.1.4 Factory production control test Test performs according to 6.2, Table 1 – Section Assembling control – line 2.3.1 A.2 Test specimens A.2.1 Tensile test Eight test standard specimens shall be prepared and cured in accordance with EN 15434:2006+A1:2010, 5.3.2, and following the sealant manufacturer's recommendations. A.2.2 Peel test Height test standard specimens shall be prepared and cured in accordance with C.3.1 of this European Standard and in accordance with the sealant’s manufacturer's recommendations. A.3 Conditioning of test specimens Condition the eight test standard specimens for the selected test (tensile or peel) and ensure that they conform to the selected alternative conditioning. The various conditioning requirements are described in more detail below: SIST EN 13022-2:2014

(50 ± 5) % relative humidity. Table A.1 — Level of control Type of surface Project test Convenience test Assembling control Anodised aluminium Conditioning d Conditioning b and c Conditioning a Coated aluminium Conditioning d Conditioning c and d Conditioning a A.4 Test procedure A.4.1 In the case of tensile test All eight test specimens should be subject to tensile rupture with a separation speed of (5 ± 0,5) mm/min at a temperature of (23 ± 2) °C. A.4.2 In the case of peel test All eight test specimens should be subject to the peel test in accordance with C.3.3 of this European Standard. A.5 Observation After the four conditioning periods have been applied: — type of breakage shall be 100 % cohesive; — breaking values shall comply with the sealant manufacturer's declaration. After the conditioning period: the minimum elongation value shall be ≥ 50 % and Ru5 ≥ 0,50 MPa. A.6 Report The report should include: — selected alternative possibility; SIST EN 13022-2:2014

Design guidance B.1 Characteristics Within the multitude of design aspects for windows, doors and curtain walling, the following characteristics should have particular attention: — safety in the case of fire: — resistance to fire; — reaction to fire; — fire propagation; — external fire behaviour; — health: — water tightness; — dangerous substances; — safety in use: — bullet resistance; — explosion resistance; — burglar resistance; — pendulum body impact resistance; — resistance against sudden temperature changes and temperature differentials; — resistance against wind load, snow load, permanent load and/or imposed loads; — direct airborne sound reduction; — energy conservation and heat retention: — air tightness; — radiation properties; — thermal conductance; SIST EN 13022-2:2014

Refer to EN 15434:2006+A1:2010. — ability to prevent mutual degradation of it and of the materials in contact, or in close environment of it (compatibility).

Refer to EN 15434:2006+A1:2010. B.2.5 Structural seal dimensions B.2.5.1 Actions For the determination of the action

F refer to: — EN 1991-1-1; — EN 1991-1-3; — EN 1991-1-4; — EN 1991-1-5 and the related national application documents (NAD) or others national specifications. If it is found that on the construction site a Eurocode part is not applicable, then the current (existing) method of determination of the action, valid for the construction site, should be used. B.2.5.2 Mechanical resistance: characteristic ultimate limit state value, Calculation model B.2.5.2.1 Numerical border conditions Whatever the outcome of calculations, the following dimensional conditions of the structural seal should be respected (see Figure B.1 and Figure B.2): SIST EN 13022-2:2014

e: minimal

e =

6 mm, maximal e =

h; — height

h : h ≥ e with a minimum of 6 mm; and h ≤ 3e with a maximum of 20 mm for the mono component sealant; — distance edge-bonding surface

R ≤ 40 mm.

Key e structural seal thickness h structural seal height R distance edge-bonding surface Figure B.1 — Illustrative examples of the structural seal and its position to the glass edge SIST EN 13022-2:2014

Key 1 glass element 2 structural seal 3 framework B width or horizontal dimension of the glass element H height or vertical dimension of the glass element a smallest dimension (when H < B, a = H) Figure B.2 — Structural element B.2.5.2.2 Supported systems – Bite thickness e The load in the plane of the glass surface, derived from temperature differences between glass element and framework, determines the bite thickness. The load generates shear stress in the structural seal. The maximum shear stress is considered to develop in the corners of the pane, and for a rectangular pane it can be calculated as: eGfs∆=sshear; (B.1) where SIST EN 13022-2:2014

is the bite thickness in mm; G is the shear modulus; ûs is the shear deformation in m and is calculated as: ()()22sf0fg0g2BTTTTHαα∆=−−−+ (B.2) where B is the horizontal dimension of the glass element in m; H is the vertical dimension of the glass element in m; Tf is the temperature of the framework at moment t in K; Tg is the temperature of the glass element at moment t in K; T0 is the temperature during extrusion of structural sealant in K; .f is the linear elongation coefficient of the framework in m/K; .g is the linear elongation coefficient of the glass element in m/K. The selected thickness should ensure that: shear;sshear,dfR≤ (B.3) where shear,dR is the design stress value for structural sealant in shear; see B.2.5.2.6 B.2.5.2.3 Supported and unsupported systems – Bite height h The loads perpendicular to the glass surface, derived from wind loads, snow loads, densities, self-weight and impacts, determine the bite height. These loads generate tensile/compression stresses in the structural seal. The maximum tensile stress is considered to develop at the centre of the longest side of the pane, and can be calculated as:

hFf2tensilea= (B.4) where h is the bite height in m; a is the smallest edge of a rectangular pane in m; F is the load to be taken into consideration in N in accordance with B.2.5.1. The selected bite height should ensure that: SIST EN 13022-2:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...