EN 15573:2008

(Main)Earth-moving machinery - Design requirements for circulation on the road

Earth-moving machinery - Design requirements for circulation on the road

This European Standard specifies the requirements for earth-moving machinery described in EN ISO 6165 [2], intended to travel on the road.

This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards, hazardous situations and events during on road travel of earth-moving machinery.

This European Standard does not apply to earth-moving machinery with a width exceeding 3 metres (see 4.2.5).

This European Standard does not apply to earth-moving machinery on legs e.g. walking excavators.

This European Standard does not cover the hazards relevant to non-riding and remote control earth-moving machinery.

This European Standard is not applicable to earth-moving machines manufactured before the publication date of this European Standard by CEN.

Erdbaumaschinen - Ausrüstungsanforderungen für den Betrieb auf der Straße

Diese Norm legt die Anforderungen an in der EN ISO 6165 beschriebene Erdbaumaschinen fest, die zum Fahren auf der Straße konstruiert sind.

Diese Norm legt die geeigneten technischen Maßnahmen zum Eliminieren oder Reduzieren von Risken fest, die sich aus den bedeutenden Gefahren, gefährlichen Situationen und Ereignissen bei der Fahrt von Erdbau¬maschinen auf der Straße ergeben können.

Diese Norm gilt nicht für Erdbaumaschinen, die sich auf Beinen (z. B. Schreit(kufen)bagger) bewegen.

Diese Norm behandelt keine Gefahren, die für führerlose Erdbaumaschinen von Bedeutung sind, d. h. gehgelenkt (flurgesteuert) oder daneben stehend, oder Erdbaumaschinen, die mit einer Fernsteuerung bedient werden.

Diese Norm ist nicht auf Erdbaumaschinen anwendbar, die vor dem Veröffentlichungsdatum der vorliegenden Norm durch CEN produziert wurden.

Engins de terrassement - Prescriptions de conception pour la circulation sur route

La présente Norme européenne spécifie les prescriptions applicables aux engins de terrassement décrits

dans l’EN ISO 6165 [2] et conçus pour circuler sur route.

La présente Norme européenne spécifie les mesures techniques appropriées pour éliminer ou réduire les

risques liés aux phénomènes dangereux significatifs, situations et événements dangereux significatifs

pendant la circulation sur route des engins de terrassement.

La présente Norme européenne ne s’applique pas aux engins de terrassement de largeur supérieure à 3 m

(voir 4.2.5).

La présente Norme européenne ne s’applique pas aux engins de terrassement sur jambes, par exemple, les

pelles araignées.

La présente Norme européenne ne couvre pas les phénomènes dangereux liés aux engins de terrassement

qui sont à conducteur non-porté ou commandés à distance.

La présente Norme européenne ne s’applique pas aux engins de terrassement fabriqués avant sa date de

publication par le CEN.

Stroji za zemeljska dela - Zahteve projektiranja za uporabo na cesti

General Information

- Status

- Published

- Publication Date

- 06-May-2008

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Drafting Committee

- CEN/TC 151/WG 1 - Earth-moving machinery - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 20-May-2021

- Completion Date

- 09-Feb-2026

Relations

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15573:2008 - published by CEN - specifies design requirements for earth-moving machinery intended to travel on the road. It harmonises technical measures to eliminate or reduce risks arising from hazards during on‑road travel of machines classified under EN ISO 6165. The standard applies across the EEA but excludes machines wider than 3 metres, walking‑leg machines (e.g., walking excavators), non‑riding or remote‑control machines, and machines manufactured before the standard’s publication.

Key Topics

The standard focuses on practical, safety‑oriented design requirements for road circulation. Major technical topics include:

- Dimensions and masses - maximum mass, axle loads, length, width and height limits relevant to road travel.

- Speed and marking - design speeds, speed marking and speedometer requirements.

- Road preservation - tyre, rim and track requirements to reduce pavement damage.

- Dynamic stability and steering - stability under motion and requirements for steering systems (power assisted and full power steering).

- Brake systems and braking tests - performance requirements, test methods and special provisions for hydrostatic drives (see normative Annex C).

- Trailer connections - coupling devices, braking interface and lighting sockets for towed equipment.

- Operator’s station - visibility, mirrors, restraint systems and ergonomic control layout to avoid inadvertent activation.

- Enclosed cab systems - demisting/defrosting, wipers, doors and windows requirements.

- Lighting, signalling and marking - headlamps, width marker lamps, reflex‑reflectors and special warning plates.

- Plates, inscriptions and identification - manufacturer plates, registration and identification number guidance.

- Other safety aspects - warning devices, noise emission measurement, protruding appliance protection, uncontrolled motion prevention, fenders and fuel tank safety.

- Verification and annexes - includes informative and normative annexes for speed marking (A), ground contact pressure (B) and braking requirements and tests (C).

Applications

EN 15573 is used by:

- Manufacturers and design engineers to design earth‑moving machines that are safe and compliant for road travel.

- Safety and compliance teams for type‑approval, CE marking alignment and risk mitigation.

- Regulators, fleet owners and contractors when assessing machine suitability for public roads and drafting procurement specifications.

- Test laboratories for verifying braking, noise and stability performance per the annexed test methods.

Practical uses include designing road‑capable machines, preparing technical documentation for approval, and specifying maintenance and retrofit measures to meet on‑road safety requirements.

Related standards

- EN ISO 6165 - classification of earth‑moving machinery (referenced by EN 15573).

- EN ISO 12100 - general principles for risk assessment and type C standard classification.

- CEN technical guidance and national adoption documents for implementation across EEA.

Frequently Asked Questions

EN 15573:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Earth-moving machinery - Design requirements for circulation on the road". This standard covers: This European Standard specifies the requirements for earth-moving machinery described in EN ISO 6165 [2], intended to travel on the road. This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards, hazardous situations and events during on road travel of earth-moving machinery. This European Standard does not apply to earth-moving machinery with a width exceeding 3 metres (see 4.2.5). This European Standard does not apply to earth-moving machinery on legs e.g. walking excavators. This European Standard does not cover the hazards relevant to non-riding and remote control earth-moving machinery. This European Standard is not applicable to earth-moving machines manufactured before the publication date of this European Standard by CEN.

This European Standard specifies the requirements for earth-moving machinery described in EN ISO 6165 [2], intended to travel on the road. This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards, hazardous situations and events during on road travel of earth-moving machinery. This European Standard does not apply to earth-moving machinery with a width exceeding 3 metres (see 4.2.5). This European Standard does not apply to earth-moving machinery on legs e.g. walking excavators. This European Standard does not cover the hazards relevant to non-riding and remote control earth-moving machinery. This European Standard is not applicable to earth-moving machines manufactured before the publication date of this European Standard by CEN.

EN 15573:2008 is classified under the following ICS (International Classification for Standards) categories: 53.100 - Earth-moving machinery. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15573:2008 has the following relationships with other standards: It is inter standard links to ISO 14401-2:2009, ISO 14401-1:2009, ISO 5010:2007, EN 474-9:2022, EN 500-2:2006+A1:2008, EN 474-4:2022, EN 10245-1:2011, EN ISO 9396:2000, EN ISO 12690:2010, EN 500-5:1995, EN 500-6:2006+A1:2008, EN ISO 3450:1996, EN 474-8:2022, EN 474-2:2022, CEN/TS 17286:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15573:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2008

Stroji za zemeljska dela - Zahteve projektiranja za uporabo na cesti

Earth-moving machinery - Design requirements for circulation on the road

Erdbaumaschinen - Anforderungen an die Anwendung auf der Straße

Engins de terrassement - Prescriptions de conception pour la circulation sur route

Ta slovenski standard je istoveten z: EN 15573:2008

ICS:

53.100 Stroji za zemeljska dela Earth-moving machinery

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 15573

NORME EUROPÉENNE

EUROPÄISCHE NORM

May 2008

ICS 53.100

English Version

Earth-moving machinery - Design requirements for circulation on

the road

Engins de terrassement - Prescriptions de conception pour Erdbaumaschinen - Anforderungen an die Anwendung auf

la circulation sur route der Straße

This European Standard was approved by CEN on 7 March 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2008 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15573:2008: E

worldwide for CEN national Members.

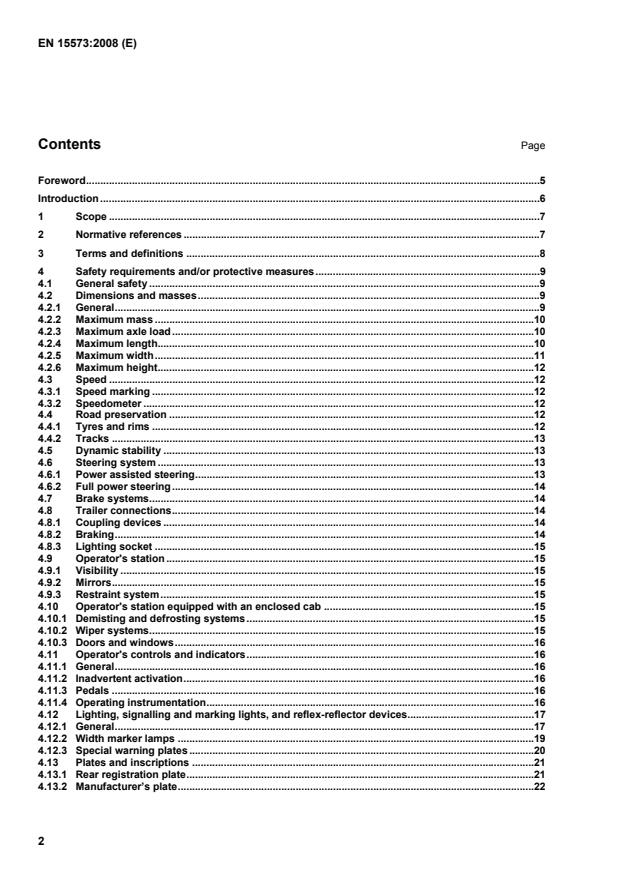

Contents Page

Foreword.5

Introduction .6

1 Scope .7

2 Normative references .7

3 Terms and definitions .8

4 Safety requirements and/or protective measures.9

4.1 General safety .9

4.2 Dimensions and masses.9

4.2.1 General.9

4.2.2 Maximum mass .10

4.2.3 Maximum axle load.10

4.2.4 Maximum length.10

4.2.5 Maximum width.11

4.2.6 Maximum height.12

4.3 Speed .12

4.3.1 Speed marking .12

4.3.2 Speedometer .12

4.4 Road preservation .12

4.4.1 Tyres and rims .12

4.4.2 Tracks .13

4.5 Dynamic stability .13

4.6 Steering system .13

4.6.1 Power assisted steering.13

4.6.2 Full power steering.14

4.7 Brake systems.14

4.8 Trailer connections.14

4.8.1 Coupling devices .14

4.8.2 Braking.14

4.8.3 Lighting socket .15

4.9 Operator's station .15

4.9.1 Visibility .15

4.9.2 Mirrors.15

4.9.3 Restraint system.15

4.10 Operator's station equipped with an enclosed cab .15

4.10.1 Demisting and defrosting systems.15

4.10.2 Wiper systems.15

4.10.3 Doors and windows.16

4.11 Operator's controls and indicators.16

4.11.1 General.16

4.11.2 Inadvertent activation.16

4.11.3 Pedals .16

4.11.4 Operating instrumentation.16

4.12 Lighting, signalling and marking lights, and reflex-reflector devices.17

4.12.1 General.17

4.12.2 Width marker lamps .19

4.12.3 Special warning plates .20

4.13 Plates and inscriptions .21

4.13.1 Rear registration plate.21

4.13.2 Manufacturer’s plate.22

4.13.3 Identification Number.22

4.14 Warning devices .22

4.15 Noise emission measurement.22

4.15.1 Limits .22

4.15.2 Conditions of measurement.22

4.15.3 Method of Measurement .23

4.15.4 Interpretation of results .23

4.16 Protruding appliance protection.24

4.17 Uncontrolled motion .24

4.18 Fenders.24

4.19 Fuel tanks.24

5 Verification of safety requirements and/or protective measures.24

Annex A (informative) Speed marking signs.26

A.1 General .26

A.2 Colour .26

A.3 Size.26

Annex B (normative) Ground contact pressure.27

B.1 General .27

B.2 Definitions .27

B.2.1 Crawler base, L .27

B.2.2 Tread contact area, T .28

A

B.3 Requirements.28

B.3.1 Calculation of average ground contact pressure, PG – dual track systems.28

B.3.2 Calculation of average ground contact pressure, PG – multi-track systems .28

Annex C (normative) Braking requirements .29

C.1 Machines with a design speed ≤ 40 km/h .29

C.2 Machines with a design speed > 40 km/h .29

C.2.1 Test conditions.29

C.2.2 Performance tests .29

C.3 Machines with a hydrostatic drive system .30

C.3.1 General requirements .30

C.3.2 Failure of the brakes .31

C.3.3 Brake testing.32

C.3.4 Machine recovery .33

Annex D (informative) Equivalent requirements.34

Annex E (informative) A-deviations.35

Bibliography.37

Figures

Figure 1. 11

Figure 2 — Alignment of the width marker lamps. 19

Figure 3 — Installation arrangement of panels. 21

Figure 4 — Measuring positions . 23

Figure A.1 — Speed marking . 26

Figure B.1 — Crawler base . 27

Figure B.2 — Track tread profiles. 28

Tables

Table 1 — Maximum mass . 10

Table 2 — Maximum axle load . 10

Table 3 — Maximum length. 11

Table 4 — Deviations from ISO 12509. 18

Table 5 — Alignment of width marker lamps. 20

Table A.1 — Speed marking/classification . 26

Table C.1 — Performance requirements (informative). 29

Table C.2 — Performance requirements. 32

Foreword

This document (EN 15573:2008) has been prepared by Technical Committee CEN/TC 151 “Construction

equipment and building material machines - Safety”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical

text or by endorsement, at the latest by November 2008, and conflicting national standards shall be withdrawn

at the latest by November 2008.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights.

This standard intends to harmonise the various technical requirements of the EEA applicable to earth-moving

machinery for their circulation on the road. Earth-moving machinery fulfilling the requirements of this standard

may be subject to certain administrative provisions before being permitted to travel on the road.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech

Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia,

Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain,

Sweden, Switzerland and the United Kingdom.

Introduction

This European Standard is a type C standard as stated in EN ISO 12100.

The machinery concerned and the extent to which hazards, hazardous situations and events are covered are

indicated in the scope of this standard.

When provisions of this type C standard are different from those which are stated in type A or B standards, the

provisions of this type C standard take precedence over the provisions of the other standards, for machines

that have been designed and built according to the provisions of this type C standard.

1 Scope

This European Standard specifies the requirements for earth-moving machinery described in EN ISO 6165 [2],

intended to travel on the road.

This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from

the significant hazards, hazardous situations and events during on road travel of earth-moving machinery.

This European Standard does not apply to earth-moving machinery with a width exceeding 3 metres (see

4.2.5).

This European Standard does not apply to earth-moving machinery on legs e.g. walking excavators.

This European Standard does not cover the hazards relevant to non-riding and remote control earth-moving

machinery.

This European Standard is not applicable to earth-moving machines manufactured before the publication date

of this European Standard by CEN.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

EN 474 (all parts), Earth-moving machinery — Safety

EN 500 (all parts), Mobile road construction machinery — Safety

EN ISO 3450:1996, Earth-moving machinery — Braking systems of rubber-tyred machines — Systems and

performance requirements and test procedures (ISO 3450:1996)

EN ISO 3457, Earth-moving machinery — Guards — Definitions and requirements (ISO 3457:2003)

EN ISO 6683, Earth-moving machinery — Seat belts and seat belt anchorages – Performance requirements

and tests (ISO 6683:2005)

EN ISO 12100-1:2003, Safety of machinery — Basic concepts, general principles for design — Part 1: Basic

terminology, methodology (ISO 12100-1:2003)

ISO 1724:2003, Road vehicles — Connectors for the electrical connection of towing and towed vehicles —

7-pole connector type 12 N (normal) for vehicles with 12 V nominal supply voltage

ISO 5006:2006, Earth-moving machinery — Operator's field of view – Test method and performance criteria

ISO 5010, Earth-moving machinery — Rubber-tyred machines — Steering requirements

ISO 5676:1983, Tractors and machinery for agriculture and forestry — Hydraulic coupling — Braking circuit

ISO 6011, Earth-moving machinery — Visual display of machine operation

ISO 6014, Earth-moving machinery — Determination of ground speed

ISO 6016, Earth-moving machinery — Methods of measuring the masses of whole machines, their equipment

and components

ISO/FDIS 6395:2007, Earth-moving machinery — Determination of sound power level — Dynamic test

conditions

ISO 6489-3:2004, Agricultural vehicles — Mechanical connections between towed and towing vehicles —

Part 3: Tractor drawbar

ISO 6746-1, Earth-moving machinery — Definitions of dimensions and codes — Part 1: Base machine

ISO 6746-2, Earth-moving machinery — Definitions of dimensions and codes — Part 2: Equipment and

attachments

ISO 9533, Earth-moving machinery — Machine mounted forward and reverse audible warning alarm —

Sound test method

ISO 10261, Earth-moving machinery — Product identification numbering system

ISO 10263-5, Earth-moving machinery — Operator enclosure environment — Part 5: Windscreen defrosting

system test method

ISO 10265, Earth-moving machinery — Crawler machines — Performance requirements and test procedures

for braking systems

ISO 10968, Earth-moving machinery — Operator's controls

ISO 12509:2004, Earth-moving machinery — Lighting, signalling and marking lights, and reflex-reflector

devices

ISO/DIS 14401-1:2007, Earth-moving machinery — Field of vision of surveillance and rear-view mirrors —

Part 1: Test methods

ISO/DIS 14401-2:2007, Earth-moving machinery — Field of vision of surveillance and rear-view mirrors —

Part 2: Performance criteria

ISO/DIS 15998:2005, Earth-moving machinery — Machine-control systems (MCS) using electronic

components — Performance criteria and tests for functional safety

ISO 21507, Earth-moving machinery — Performance requirements for non-metallic fuel tanks

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100-1:2003 apply.

Earth-moving machinery and their families are defined in EN ISO 6165 [2].

Definitions used in EN and ISO standards referred to in this European Standard are also valid for this

document.

Additional definitions specifically needed for this European Standard are added below.

3.1

intended operation

use in earth-moving operation e.g. excavation, loading, transportation, drilling, spreading, compacting or

trenching of earth, rock or other materials

3.2

road

public traffic area for use by motor vehicles for travel or transportation, with the exception of the sites of

temporary road works e.g. for repairs, maintenance, alterations, improvements, installations or any other

works to, above or under a road, including works to road equipment (lighting, barriers, walls…) and roads not

open to the public e.g. on new housing and industrial developments, to which public traffic is not permitted

3.3

travel on the road

use on the road for purposes other than intended operation i.e. travelling between sites of work, to and from

the site of normal storage, or travelling for refuelling of the machine

3.4

tracklaying

(tracked/crawler)

machine with endless track drive system

3.5

multiple wheel

(roller)

machine with more than two wheels on one or more of the axles, used primarily for compaction performance

(for road levelling)

4 Safety requirements and/or protective measures

4.1 General safety

Earth-moving machinery intended for travel on the road shall comply with the requirements and/or protective

measures of EN 474 or EN 500, so far as not modified by requirements of this European Standard.

NOTE Machinery is covered by directive 98/37/EC [29].

4.2 Dimensions and masses

4.2.1 General

Machines shall be designed in accordance with the requirements of 4.2.2 to 4.2.6, and equipped so that their

dimensions and mass minimise disruptions to the traffic on public roads.

Dimensions and masses of earth-moving machinery shall be determined in accordance with ISO 6016. Unless

specifically designed for the purpose of carrying loads during travel on the road i.e. dumpers, the mass of

earth-moving machinery does not include any load other than loose tools or appliances necessary for the

intended operation and carried on the machine during travel on the road.

Dimensional measurements of earth-moving machinery shall be in accordance with ISO 6746-1 and

ISO 6746-2.

Machines shall be assessed with equipment and attachments in the transport configuration as specified by the

manufacturer. See also Annex A of ISO 5006.

NOTE One or more A-deviations are relevant to this requirement. See Annex E.

Motor vehicles as defined in directive 70/156/EEC [11].

4.2.2 Maximum mass

The maximum mass of earth-moving machinery designed to travel on the road should not exceed the limits

defined in Table 1:

Table 1 — Maximum mass

Machine configuration Maximum mass

kg

2-axle machines 19 000

3-axle machines 26 000

4-axle machines 32 000

Tracklaying machines 24 000

Multiple wheel machines 19 000

Subject to local conditions i.e. bridge capacities, the maximum mass of earth-moving machinery on certain

roads may be increased according to the following formula:

M ≤ 12 000 ×A

where

M is the maximum mass (kg)

A is the number of axles

NOTE 1 Earth-moving machinery with a maximum mass exceeding the limits shown in Table 1 may be considered as

abnormal transport and be subject to local use restrictions which are not dealt with in this European Standard.

NOTE 2 Load restrictions on roads may vary according to seasonal changes e.g. in very low or very high temperature

conditions.

4.2.3 Maximum axle load

The maximum axle loads of earth-moving machinery designed to travel on the road shall not exceed the limits

defined in Table 2.

Table 2 — Maximum axle load

Machine configuration Maximum axle load

Driven and non-driven axles 13 000 kg

Tracklaying machines 9 000 kg/m between first and last track roller (see also 4.4.2)

NOTE One or more A-deviations are relevant to this requirement. See Annex E.

4.2.4 Maximum length

The maximum length of earth-moving machinery designed to travel on the road shall not exceed the limits

defined in Table 3. The maximum length includes any mounted equipment or attachments located in the travel

position as specified by the manufacturer (see also Annex A of ISO 5006).

Table 3 — Maximum length

Machine configuration Maximum length

m

Rigid machines 12

Articulated machines The length of the machine must be such that it is able to manoeuvre in left

and right directions for a complete circular trajectory (360°) inside an area

defined by two concentric circles, the outer circle having a radius of 12,5 m

and the inner circle having a radius of 5,3 m, without any of the machine's

outermost points (excluding mirrors, indicators, tyre bulge, folding

components – lift-up steps and flexible mud-flaps) projecting outside the

circumferences of the circles (see Figure 1).

NOTE Earth-moving machinery with a maximum length exceeding the limits shown in Table 3 may be considered as

abnormal transport and be subject to local use restrictions which are not dealt with in this European Standard.

R = 12,5 m

r = 5,3 m

Figure 1

4.2.5 Maximum width

The maximum width of earth-moving machinery designed to travel on the road shall not exceed 3 m.

The maximum width includes any mounted equipment or attachments located in the travel position as

specified by the manufacturer (see also Annex A of ISO 5006) but shall exclude mirrors, indicators, tyre bulge,

folding components – lift-up steps (in their working position) and flexible mud-flaps.

Above 2,55 m additional requirements/protective measures for travel on the road are specified in this

European Standard.

NOTE Earth-moving machinery with a maximum width exceeding 2,55 m may be considered as abnormal transport

and be subject to local use restrictions which are not dealt with in this European Standard.

4.2.6 Maximum height

The maximum height of earth-moving machinery designed to travel on the road shall not exceed 4 m with

maximum size (rolling radius) tyres – excluding a flexible aeriel. The maximum height includes any mounted

equipment or appliances located in the travel position as specified by the manufacturer (see also Annex A of

ISO 5006).

4.3 Speed

The maximum speed shall be verified in accordance with ISO 6014. A tolerance on the speed of + 10 % or

+ 3 km/h, whichever is the least, is permitted. The test shall be conducted with maximum size (rolling radius)

tyres at the recommended cold inflation pressure as specified by the manufacturer and with the machine in

the lightest operational condition.

Maximum on-road speed of an earth-moving machine equipped with one or more smooth steel wheels (roller)

is limited to 10 km/h.

NOTE The speed of earth-moving machinery with smooth steel wheels may be subject to local use restrictions which

are not dealt with in this European Standard.

4.3.1 Speed marking

Earth-moving machinery with a design speed < 60 km/h shall have an allocated space at the rear for a sign

indicating the permissible on-road speed.

The space shall allow for the installation of a speed marking sign at the rear of the machine (substantially

vertical) at a height 300 mm to 1 500 mm from the ground. This may be increased to 2 100 mm if required by

the design and shape of the machine.

Information for the sign (format and size) is given in Annex A.

The need for a sign and the marked permissible speed is dependent on local requirements, and can change

depending on use, license and insurance.

4.3.2 Speedometer

Earth-moving machinery with a maximum speed > 30 km/h shall be equipped with a speedometer.

The speedometer shall comply with the requirements in 4.11.4.

4.4 Road preservation

The design of earth-moving machinery shall minimise the risk of road damage.

4.4.1 Tyres and rims

Tyres should be compatible with the axle loading and design speed of the machine and shall be marked with

the manufacturer's name (tyre manufacturer), the load index and speed rating.

In circumstances where it is necessary to install tyres which have a speed rating which is not compatible with

the maximum speed of the machine e.g. a low speed high capacity tyre for the intended operation, a

warning/instruction shall be provided to the operator to show the maximum allowable speed for the installed

tyres.

NOTE Load index and speed rating data should be determined in accordance with the European Tyre and Rim

Technical Organisation (ETRTO) Standards Manual.

Tyres may be pneumatic or solid. Solid tyres are permissible on earth-moving machinery with a maximum

speed ≤ 17 km/h.

Pneumatic tyres may be foam filled (to protect against loss of stability in case of puncture or rupture) or have a

liquid ballast. In case the use of liquid ballast is permitted, advice shall be given concerning the maximum

travel speed (if less than the maximum speed of the machine).

Treadless tyres are permissible on earth-moving machinery with a design speed ≤ 30 km/h.

Steel wheels/tyres i.e. rollers, are permissible for travel on the road provided that they do not have any tread

pattern.

4.4.2 Tracks

Tracklaying machines shall have a tread lug pattern such that static ground contact pressure is ≤ 0.8 N/mm²

measured in accordance with Annex B.

Steel tracked machines shall have a resilient material interposed between the ground and the track and be

arranged so that the steel parts of the track do not contact the road.

4.5 Dynamic stability

Machine behaviour during travel on the road shall be assessed at various speeds, including maximum speed

and during turning. Control of the machine shall be ensured at all times.

ISO 15037-2 [9] and ISO 14792 [8] may provide suitable information for determining machine behaviour

during travel on the road.

Where necessary, means of ensuring controllability by the operator e.g. equipment/attachment, axle or wheel

suspension shall be fitted.

4.6 Steering system

The performance of the steering system of wheeled earth-moving machinery (including machines with a

design speed ≤ 20 km/h) shall comply with ISO 5010.

The weight distribution of the machine shall ensure a minimum static axle load of 20 % of the total machine

mass on the steered axle(s) measured on a substantially horizontal surface.

The steering system shall be such that the movement of the steering control (steering wheel, lever or pedal)

shall correspond to the intended direction of steering. It shall be designed to assure safe and easy machine

control during normal and secondary operating conditions.

If the steering system has switchable steer modes (e.g. 2WS, 4WS, crab or inversed function in certain

machine configurations), it shall be possible to positively engage the mode required for travel on the road.

Inadvertent activation of other steer modes shall be minimised in accordance with the requirements of 4.11.2.

It should be possible to easily identify the steering mode that is engaged.

If the machine has more than one steering control, it shall be possible to deactivate the control system that is

not recommended for travel on the road. Deactivation shall be in accordance with the requirements of 4.11.2.

The steering system of tracklaying machines with a design speed (forward/reverse) > 20 km/h shall be

gradual.

4.6.1 Power assisted steering

A secondary steering system is not required for machines with a design speed ≤ 20 km/h.

For machines with a design speed > 20 km/h, a secondary steering system is required where the steering

input force under emergency conditions (failure of the normal steering) exceeds 350 N.

It shall be possible to verify the function of the secondary steering system during normal operation.

4.6.2 Full power steering

A secondary steering system is required.

For machines with a design speed more than 60 km/h the required system redundancy shall be evaluated in

accordance with ISO/DIS 15998:2005.

It shall be possible to verify the function of the secondary steering system during normal operation.

4.7 Brake systems

Earth-moving machinery shall be equipped with a service brake system, a secondary brake system and a

parking brake system, efficient under the manufacturer's intended conditions of service, load, speed, terrain

and slope, for travel on the road.

The operation of the service and secondary brake shall be gradual.

The braking equipment shall not be adversely affected by any vibration that it may be subjected to in normal

use. The equipment shall be able to resist the corrosion and ageing phenomena which could lead to a sudden

loss of braking efficiency.

Brake systems of crawler machines shall comply with ISO 10265.

Brake systems of wheeled machines shall comply with the requirements in Annex C.

Wheeled machines shall have braking capacity of equal nominal rating on each wheel of a braked axle.

4.8 Trailer connections

4.8.1 Coupling devices

The mechanical coupling devices enabling the connection of a trailer shall be so designed that the safety

according to the state of the art is provided. The connections and their locking mechanisms shall ensure that

under normal operating conditions no unintentional unlatching can occur. Sufficient angular movement shall

be ascertained.

Coupling devices should be in accordance with ISO 6489-3:2004.

NOTE Other devices e.g. ISO 6489-1 [5], ISO 6489-2 [6], ISO 6489-4 [7] and national trailer couplings are

acceptable according to customer requirements.

4.8.2 Braking

Earth-moving machinery designed and equipped to tow a trailer more than 20 km/h and where the sum of the

trailed axle loads is more than 3 500 kg shall be equipped with a trailer braking circuit according to

ISO 5676:1983.

The parking braking system of the machine shall be capable of holding the machine combination, machine

and an un-braked trailer 3 500 kg mass (or less if the permissible un-braked towable mass as specified by the

machine manufacturer is less) stationary on a 12 % up or down gradient.

4.8.3 Lighting socket

Earth-moving machinery designed and equipped to tow a trailer shall be equipped with a lighting socket

according to ISO 1724:2003.

4.9 Operator's station

4.9.1 Visibility

Earth-moving machines shall comply with ISO 5006 so that the operator has sufficient visibility from the

operator's station in relation to the travel areas of the machine that are necessary for travel on the road.

4.9.2 Mirrors

Earth-moving machines shall be equipped with rear view mirrors according to ISO/DIS 14401-1:2007 and

ISO/DIS 14401-2:2007.

Mirrors shall be of an approved type e.g. ECE R 46 [35] (see Bibliography), unless they are fitted to meet only

the requirements of ISO 5006.

If the bottom edge of the mirror is less than 2 metres above the ground, the mirror shall not project laterally

more than 0,20 metres from the machine (measured without mirrors and mirror mounting devices).

Mirrors that project laterally by more than 0,20 metres from the machine (and installed more than 2 metres

above the ground) shall be of the foldable type so that they can easily be put back in position after being

knocked out of alignment.

NOTE One or more A-deviations are relevant to this requirement. See Annex E.

4.9.3 Restraint system

Machines fitted with an operator protective structure (ROPS, TOPS) shall have an operator restraint system

that meets the requirements specified in EN ISO 6683.

4.10 Operator's station equipped with an enclosed cab

4.10.1 Demisting and defrosting systems

4.10.1.1 Demisting system

Facilities shall be provided to demist the front windscreen.

4.10.1.2 Defrosting system

A system shall be provided to defrost the front windscreen and rear window, for example by means of a

heating system or a particular defrosting device. The defrosting system for the windscreen shall meet the

requirements specified in ISO 10263-5.

4.10.2 Wiper systems

The front window shall be fitted with motorised windscreen wiper(s) and washer(s). The area swept by the

wiper(s) must ensure an unobstructed forward view corresponding to a chord of the semi-circle of vision at

least 8 m long within the sector of vision as described in ISO 5006. The wiper(s) shall have a frequency of ≥

20 cycles/min.

If it is necessary to view through the rear window using an internally mounted rear view mirror, the rear

window shall also be fitted with a motorised wiper and washer.

The tank of the window washer(s) shall be easily accessible. The system shall function in the temperature

range of – 18°C to + 65°C. The function shall not decrease if the solution (water and washer fluid) contains up

to 50 % methyl or isopropyl alcohol (or equivalent) washer fluid.

4.10.3 Doors and windows

Doors and windows shall be securely held in their functional positions; measures shall be taken for preventing

inadvertent opening. Doors shall be retained at their intended operating position(s) by a positive engagement

device.

Windscreens and windows shall be made of safety glass or other material, which provides similar safety

performance and shall be of an approved type e.g. ECE R 43 [34], 92/22/EEC [27], 89/173/EEC [26], FMVSS

No 205 [38], ANSI Z26.1 [39](see Bibliography).

For machines with a maximum speed > 30 km/h, only laminated windscreens are permitted.

4.11 Operator's controls and indicators

4.11.1 General

The controls (hand levers, pedals, switches, etc.) and indicators of the machine, equipment, attachment, shall

be chosen, designed, constructed and arranged according to ISO 10968.

4.11.2 Inadvertent activation

Controls which, if operated intentionally or due to inadvertent activation during travel on the road, could cause

a hazard due to movement of equipment, shall be so arranged or deactivated or guarded as to minimise the

risk. Arrangement shall minimise inadvertent activation during travel e.g. permissioning controls. Deactivation

devices shall either be self-acting or acting by compulsory actuation of the relevant device. Guarding may

include mechanical locking of the control.

4.11.3 Pedals

Pedals shall have an appropriate size, shape and be adequately spaced. The pedals shall have a slip-

resistant surface and shall be easy to clean.

If the pedals of an earth-moving machine have the same function (clutch, brake and accelerator) as on a

motor vehicle, they shall be arranged in the same manner to avoid the risk of confusion.

4.11.4 Operating instrumentation

Control indicators for safe and proper operation of the machine shall follow the safety colours and safety

signs/requirements according to ISO 6011.

If the earth-moving machine is equipped with a speedometer (see Clause 4.3.2), the speedometer shall

comply with the visual display characteristics as defined in ISO 6011. The speedometer shall display the

speed in km/h or mph in accordance with the requirements of the market in which the machine is first placed.

NOTE For countries in which mph is used and in the case of an analogue display, it is permissible for the display to

show speed in both mph and km/h.

On earth-moving machinery with a design speed more than 40 km/h, there shall be the following relationship

between the indicated speed (v1 ) and the true speed (v2 ):

v2

Displays in km/h 0 ≤v1 −v2 ≤ + 4km /h

v2

Displays in mph 0 ≤v1 −v2 ≤ + 2.5mph

4.12 Lighting, signalling and marking lights, and reflex-reflector devices

4.12.1 General

Earth-moving machines shall be equipped with lighting, signalling devices and reflectors

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...