EN 13042-1:2007+A1:2009

(Main)Machines and plants for the manufacture, treatment and processing of hollow glass - Safety requirements - Part 1: Gob feeder

Machines and plants for the manufacture, treatment and processing of hollow glass - Safety requirements - Part 1: Gob feeder

1.1 This European Standard applies to the design and installation of gob feeders which provide hollow glass forming machines with gobs.

1.2 This European Standard deals with the significant hazards, hazardous situations and events relevant to gob feeders, when they are used as intended and under the conditions foreseeable by the manufacturer (see Clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks which can arise from these significant hazards during commissioning, operation and maintenance.

1.3 This European Standard does not deal with bowl firing.

1.4 This European Standard is not applicable to gob feeders which are manufactured before the date of publication of this European Standard by CEN.

Maschinen und Anlagen für die Herstellung - Be- und Verarbeitung von Hohlglas - Sicherheitsanforderungen - Teil 1: Tropfenspeiser

1.1 Diese Europäische Norm gilt für die Konstruktion und Installation von Tropfenspeisern, die Hohlglas-Formgebungsmaschinen mit Tropfen versorgen.

1.2 !Diese Europäische Norm behandelt die signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die auf Tropfenspeiser zutreffen, wenn sie bestimmungsgemäß und unter den Bedingungen des Missbrauchs, die vernünftigerweise vom Hersteller vorhersehbar sind, verwendet werden (siehe Abschnitt 4). Lärm ist keine Gefährdung für diese Art von Maschinen. Diese Europäische Norm spezifiziert die entsprechenden technischen Maßnahmen zur Beseitigung oder Verminderung der Risiken, die von den signifikanten Gefährdungen während der Inbetriebnahme, Bedienung und Wartung ausgehen."

1.3 Diese Europäische Norm befasst sich nicht mit der Beheizung der Speiserschüssel.

1.4 Diese Europäische Norm gilt nicht für Tropfenspeiser, die hergestellt wurden, bevor CEN diese Europäische Norm veröffentlichte.

Machines et installations pour la production, le façonnage et la transformation du verre creux - Exigences de sécurité - Partie 1: Mécanisme d'alimentation en paraisons

1.1 La présente Norme européenne contient les prescriptions de sécurité destinées à la conception et à l'installation des mécanismes d’alimentation en paraison qui alimentent en paraisons les machines de formage du verre creux.

1.2 !La présente Norme européenne traite des phénomènes dangereux, situations et événements dangereux significatifs relatifs aux mécanismes d'alimentation en paraisons lorsque ces derniers sont utilisés normalement et dans les conditions de mauvais usage raisonnablement prévisibles par le fabricant (voir Article 4). Le bruit n'est pas un phénomène dangereux significatif pour ce type de machine. La présente Norme européenne spécifie les mesures techniques appropriées permettant d’éliminer ou de réduire les risques dus aux phénomènes dangereux significatifs rencontrés lors de la mise en service, du fonctionnement et de la maintenance."

1.3 La présente Norme européenne ne traite pas des réchauffeurs de verre.

1.4 La présente Norme européenne ne s'applique pas aux mécanismes d'alimentation en paraisons fabriqués avant la date d'approbation de cette Norme européenne par le CEN.

Stroji in obrati za proizvodnjo, obdelavo in predelavo votlega stekla - Varnostne zahteve - 1. del: Dovajalnik za regulacijo kaplje

Ta evropski standard velja za načrtovanje in namestitev dovajalnikov za regulacijo kaplje, ki dovajajo kaplje strojem za oblikovanje votlega stekla. ! Ta evropski standard obravnava velike nevarnosti, nevarne situacije in primere, ki se tičejo dovajalnikov za regulacijo kaplje, kadar se uporabljajo kot predvideno in pod pogoji napačne uporabe, ki jih razumno predvidi proizvajalec (glej Klavzulo 4). Hrup ne predstavlja velike nevarnosti za ta tip stroja. Standard opredeljuje ustrezne tehnične ukrepe za odpravo ali zmanjševanje tveganj, ki nastanejo zaradi velikih nevarnosti med usposobitvijo za zagon, obratovanjem in vzdrževanjem. Ta evropski standard se ne nanaša na žganje posod. Ta evropski standard ne velja za dovajalnike za regulacijo kaplje, ki so proizvedeni pred datumom, ko je CEN objavil ta evropski standard.

General Information

- Status

- Published

- Publication Date

- 10-Nov-2009

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 19-May-2021

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 19-Sep-2009

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13042-1:2007+A1:2009 (CEN) is the European safety standard for gob feeders used in the manufacture, treatment and processing of hollow glass. It applies to the design and installation of gob feeders that supply hollow‑glass forming machines with gobs, and addresses the significant hazards, hazardous situations and events that can arise during commissioning, operation and maintenance when machines are used as intended or under reasonably foreseeable misuse. The standard excludes bowl firing and does not apply retroactively to gob feeders manufactured before its publication.

Key topics and requirements

EN 13042-1 focuses on practical safety measures and contains requirements and guidance on:

- Risk assessment and identification of significant hazards specific to gob feeders (mechanical, electrical, thermal, ergonomic and material-generated hazards).

- Starting, stopping and prevention of unexpected start‑up, including remote starts and stop latching devices to prevent automatic restart.

- Emergency‑stop (E‑stop) design and accessibility in accordance with EN ISO 13850.

- Guarding and access protection for moving parts, shears, chains, belts and pulleys to prevent crushing, entanglement and drawing‑in.

- Lockout/blocking of shears and safe procedures for maintenance and exchange of expendables.

- Hydraulic/pneumatic systems safety and high‑pressure fluid hazards (note: ejection risks identified for systems above 50 bar).

- Electrical safety and energy isolation in line with EN 60204‑1 and related requirements for safety‑related control systems (the document references performance requirements such as PL c under EN ISO 13849‑1 where applicable).

- Hot surfaces and glass flow safeguarding, refractory handling (quick‑release chucks, lifting devices) and measures to reduce burn and puncture risks.

- Verification, testing and information for use, including marking and instruction handbook content for safe installation, operation and maintenance.

Practical applications & users

This standard is intended for:

- Manufacturers and designers of gob feeders and hollow glass forming lines who must design equipment that meets European safety requirements.

- Safety engineers and compliance teams preparing CE marking and conformity documentation under the Machinery Directive (see informative annexes relating to EU directives).

- Plant integrators and maintenance personnel responsible for safe installation, commissioning, operation and servicing of gob feeders.

- Procurement and quality managers specifying safety features in new equipment purchases.

Using EN 13042-1 helps reduce workplace injuries, ensure regulatory compliance, and improve safe interoperability between gob feeders and hollow‑glass forming machines.

Related standards

Normative references cited in EN 13042-1 include (among others):

- EN ISO 12100 (machine safety principles)

- EN ISO 13850 (emergency stop)

- EN ISO 13849‑1 (safety‑related control systems)

- EN 60204‑1 (electrical equipment of machines)

- EN 982 / EN 983 (fluid power safety)

- EN 953, EN 894‑3 (guarding and controls ergonomics)

Keywords: EN 13042-1, gob feeder, hollow glass, safety requirements, CEN, machine safety, risk assessment, guarding, emergency stop, CE marking.

Frequently Asked Questions

EN 13042-1:2007+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Machines and plants for the manufacture, treatment and processing of hollow glass - Safety requirements - Part 1: Gob feeder". This standard covers: 1.1 This European Standard applies to the design and installation of gob feeders which provide hollow glass forming machines with gobs. 1.2 This European Standard deals with the significant hazards, hazardous situations and events relevant to gob feeders, when they are used as intended and under the conditions foreseeable by the manufacturer (see Clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks which can arise from these significant hazards during commissioning, operation and maintenance. 1.3 This European Standard does not deal with bowl firing. 1.4 This European Standard is not applicable to gob feeders which are manufactured before the date of publication of this European Standard by CEN.

1.1 This European Standard applies to the design and installation of gob feeders which provide hollow glass forming machines with gobs. 1.2 This European Standard deals with the significant hazards, hazardous situations and events relevant to gob feeders, when they are used as intended and under the conditions foreseeable by the manufacturer (see Clause 4). This European Standard specifies the appropriate technical measures to eliminate or reduce risks which can arise from these significant hazards during commissioning, operation and maintenance. 1.3 This European Standard does not deal with bowl firing. 1.4 This European Standard is not applicable to gob feeders which are manufactured before the date of publication of this European Standard by CEN.

EN 13042-1:2007+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 81.100 - Equipment for the glass and ceramics industries. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13042-1:2007+A1:2009 has the following relationships with other standards: It is inter standard links to EN 13042-1:2007/FprA1, EN 13042-1:2007, EN 2286:1989, EN ISO 4871:1996, EN ISO 13850:2015, EN 982:1996, EN ISO 11204:1995, EN ISO 13849-1:2008, EN ISO 12100-2:2003, EN ISO 11202:1995, EN 894-3:2000, EN ISO 12100-1:2003, EN ISO 11201:1995, EN 1037:1995, EN 983:1996. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13042-1:2007+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13042-1:2007+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji in obrati za proizvodnjo, obdelavo in predelavo votlega stekla - Varnostne zahteve - 1. del: Dovajalnik za regulacijo kapljeMaschinen und Anlagen für die Herstellung, Be- und Verarbeitung von Hohlglas - Sicherheitsanforderungen - Teil 1: TropfenspeiserMachines et installations pour la production, le façonnage et la transformation du verre creux - Exigences de sécurité - Partie 1: Mécanisme d'alimentation en paraisonsMachines and plants for the manufacture, treatment and processing of hollow glass - Safety requirements - Part 1: Gob feeder81.100Equipment for the glass and ceramics industriesICS:Ta slovenski standard je istoveten z:EN 13042-1:2007+A1:2009SIST EN 13042-1:2007+A1:2010en,fr01-januar-2010SIST EN 13042-1:2007+A1:2010SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13042-1:2007+A1

November 2009 ICS 81.100 Supersedes EN 13042-1:2007English Version

Machines and plants for the manufacture, treatment and processing of hollow glass - Safety requirements - Part 1: Gob feeder

Machines et installations pour la production, le façonnage et la transformation du verre creux - Exigences de sécurité - Partie 1: Mécanisme d'alimentation en paraisons

Maschinen und Anlagen für die Herstellung, Be- und Verarbeitung von Hohlglas - Sicherheitsanforderungen - Teil 1: Tropfenspeiser This European Standard was approved by CEN on 15 December 2006 and includes Amendment 1 approved by CEN on 10 October 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13042-1:2007+A1:2009: ESIST EN 13042-1:2007+A1:2010

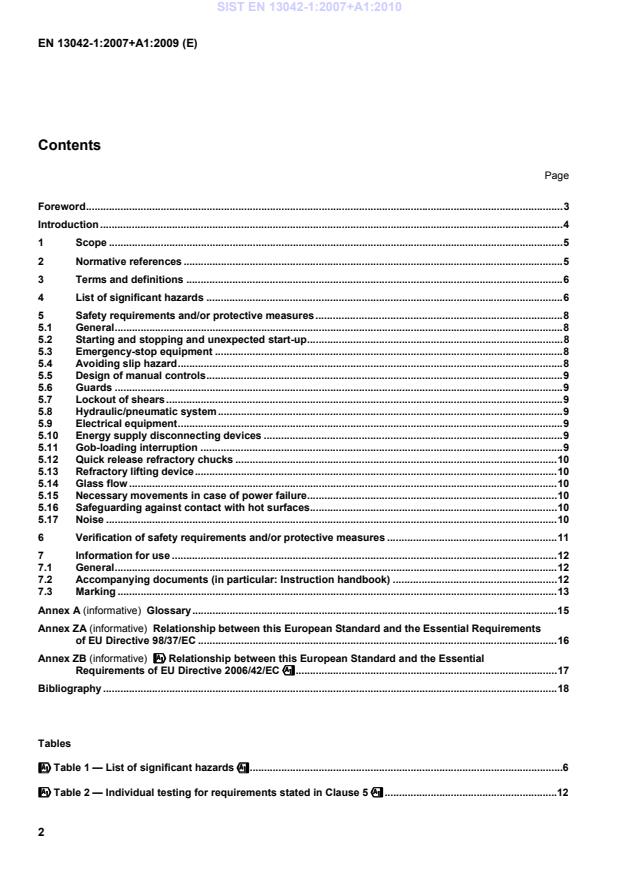

Glossary . 15Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC . 16Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""" . 17Bibliography . 18

Tables !!!!Table 1 — List of significant hazards"""" . 6!!!!Table 2 — Individual testing for requirements stated in Clause 5"""" .12 SIST EN 13042-1:2007+A1:2010

1 Scope 1.1 This European Standard applies to the design and installation of gob feeders which provide hollow glass forming machines with gobs. ! 1.2 This European Standard deals with the significant hazards, hazardous situations and events relevant to gob feeders, when they are used as intended and under the conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). Noise is not a significant hazard for this type of machine. This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards during commissioning, operation and maintenance." 1.3 This European Standard does not deal with bowl firing. 1.4 This European Standard is not applicable to gob feeders which are manufactured before the date of publica-tion of this European Standard by CEN. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 294:1992, Safety of machinery — Safety distances to prevent danger zones being reached by the upper limbs !deleted text" EN 894-3:2000, Safety of machinery — Ergonomics requirements for the design of displays and control actuators — Part 3: Control actuators EN 953:1997, Safety of machinery — Guards — General requirements for the design and construction of fixed and movable guards !deleted text" EN 982:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Hy-draulics EN 983:1996, Safety of machinery — Safety requirements for fluid power systems and their components — Pneu-matics EN 1037:1995, Safety of machinery — Prevention of unexpected start-up !deleted text" !EN ISO 4871:1996, Acoustics — Declaration and verification of noise emission values of machinery and equip-ment (ISO 4871:1996) EN ISO 11201:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Engineering method in an essentially free field over a reflecting plane (ISO 11201:1995) EN ISO 11202:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Survey method in situ (ISO 11202:1995) EN ISO 11204:1995, Acoustics — Noise emitted by machinery and equipment — Measurement of emission sound pressure levels at a work station and at other specified positions — Method requiring environmental corrections (ISO 11204:1995)" SIST EN 13042-1:2007+A1:2010

NOTE All mechanisms that comprise the gob feeder maintain a synchronised timing relationship with any hollow-glass forming machine 3.2 start-up beginning of the working cycle of the whole feeder with shearing 4 List of significant hazards This clause contains the significant hazards, hazardous situations and events, as far as they are dealt with in this European Standard, identified by risk assessment as significant for gob feeders and which require action to elimi-nate or reduce the risk. Before using this European Standard, it is important to carry out a general risk assessment of the machine in ques-tion. !!!!Table 1 — List of significant hazards Clause Hazards Dangerous items Preventive measures: see clause: 4.1 Mechanical hazards:

4.1.1 Crushing moving parts against other moving or stationary parts 5.6 4.1.2 Shearing edge tools (shear blade)

5.7 4.1.3 Cutting or severing broken glass 7.2.4 4.1.4 Entanglement chain and sprocket and belt and pulley drives of various feeder components 5.6 4.1.5 Drawing-in or trapping shear mechanism, plunger mecha-nism 5.6

Table 1 (concluded) Clause Hazards Dangerous items Preventive measures: see clause: 4.1.6 Impact shear mechanism, plunger mecha-nism 5.6 4.1.7 Stabbing or puncture strands of glass 7.2.4 4.1.8 High pressure fluid ejection all mechanisms that use forced lu-brication systems or hydraulically operated mechanism with pressure above 50 bar 5.8; 5.10; 7.2.8 4.2 Electrical direct or indirect contact 5.9; 5.10; 7.2.8 4.3 Thermal resulting in:

4.3.1 Burns hot glass, hot machine parts 5.11 to 5.16; 7.2.3; 7.2.4 4.3.2 Damage to health feeder area in general 5.12; 5.13; 7.2.3; 7.2.4 4.4 Generated by materials and sub-stances processed or used by the machinery:

4.4.1 Fire or explosion flammable fluids 5.8 4.5 Generated by neglecting ergonomic principles in machin-ery design, e.g. hazards from:

4.5.1 Unhealthy postures or excessive efforts exchange of expendables 5.12; 5.13, 7.2.2 4.5.2 Neglected use of personal protec-tion equipment) all feeder area, hot glass and ex-changeables 7.2.4 4.5.3 Human error, human behaviour adjustment of feeder mechanisms by unqualified personnel 7.2.3 4.5.4 Inadequate design of manual con-trols manual controls (actuators) 5.5 4.6 Unexpected start-up, unexpected overrun from:

4.6.1 Failure/disorder of the control sys-tem all motion control 5.2.2; 5.3; 5.7; 5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...