EN 1917:2002/AC:2008

(Corrigendum)Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforced

Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforced

TC Correction of Figure H.1 (this third Corrigendum to EN 1916:2002 contains the text of AC1, AC2 and AC3)

Einsteig- und Kontrollschächte aus Beton, Stahlfaserbeton und Stahlbeton

Regards de visite et boîtes de branchement ou d'inspection en béton non armé, béton fibré acier et béton armé

Betonski vstopni in revizijski jaški, nearmirani, z jeklenimi vlakni in armirani

General Information

- Status

- Published

- Publication Date

- 22-Apr-2008

- Technical Committee

- CEN/TC 165 - Waste water engineering

- Drafting Committee

- CEN/TC 165 - Waste water engineering

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 23-Apr-2008

- Completion Date

- 23-Apr-2008

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Corrects

EN 1917:2002 - Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforced - Effective Date

- 22-Dec-2008

Frequently Asked Questions

EN 1917:2002/AC:2008 is a corrigendum published by the European Committee for Standardization (CEN). Its full title is "Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforced". This standard covers: TC Correction of Figure H.1 (this third Corrigendum to EN 1916:2002 contains the text of AC1, AC2 and AC3)

TC Correction of Figure H.1 (this third Corrigendum to EN 1916:2002 contains the text of AC1, AC2 and AC3)

EN 1917:2002/AC:2008 is classified under the following ICS (International Classification for Standards) categories: 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1917:2002/AC:2008 has the following relationships with other standards: It is inter standard links to EN 1917:2002/AC:2006, EN 1917:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1917:2002/AC:2008 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, 93/38/EEC; Standardization Mandates: M/118. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 1917:2002/AC:2008 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforcedBetonski vstopni in revizijski jaški, nearmirani, z jeklenimi vlakni in armiraniRegards de visite et boîtes de branchement ou d'inspection en béton non armé, béton fibré acier et béton arméEinsteig- und Kontrollschächte aus Beton, Stahlfaserbeton und Stahlbeton93.030Zunanji sistemi za odpadno vodoExternal sewage systemsICS:SIST EN 1917:2003/AC:2008en,fr,deTa slovenski standard je istoveten z:EN 1917:2002/AC:200801-julij-2008SIST EN 1917:2003/AC:2008SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1917:2002/ACApril 2008Avril 2008April 2008ICS 93.030English versionVersion FrançaiseDeutsche FassungConcrete manholes and inspection chambers, unreinforced, steel fibre andreinforcedRegards de visite et boîtes de branchementou d'inspection en béton non armé, bétonfibré acier et béton arméEinsteig- und Kontrollschächte aus Beton,Stahlfaserbeton und StahlbetonThis corrigendum becomes effective on 23 April 2008 for incorporation in the three official languageversions of the EN.Ce corrigendum prendra effet le 23 avril 2008 pour incorporation dans les trois versions linguistiquesofficielles de la EN.Die Berichtigung tritt am 23.April 2008 zur Einarbeitung in die drei offiziellen Sprachfassungen der ENin Kraft.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2008 CENAll rights of exploitation in any form and by any means reserved worldwide for CEN national Members.Tous droits d'exploitation sous quelque forme et de quelque manière que ce soit réservés dans le monde entier auxmembres nationaux du CEN.Alle Rechte der Verwertung, gleich in welcher Form und in welchem Verfahren, sind weltweit den nationalen Mitgliedernvon CEN vorbehalten.Ref. No.:EN 1917:2002/AC:2008 D/E/F

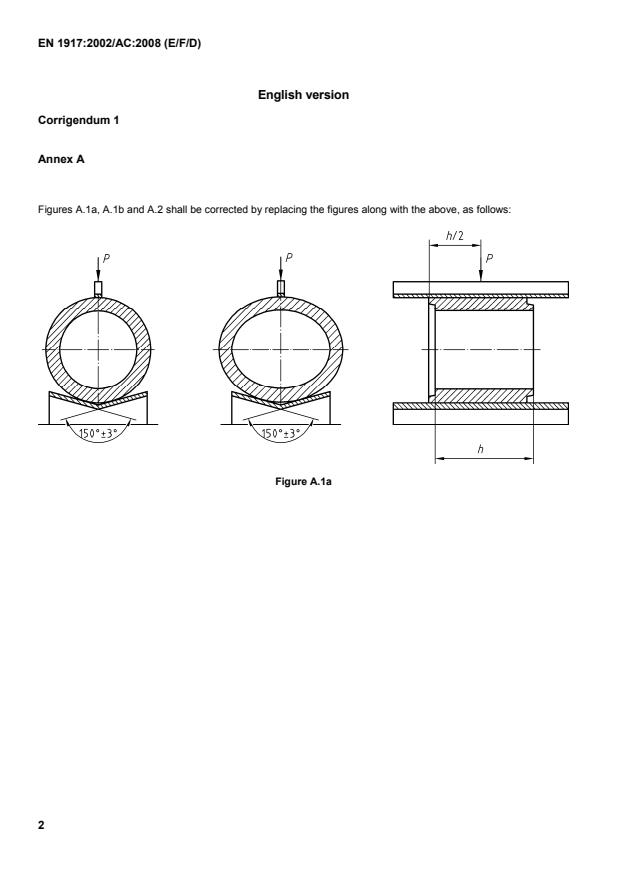

Corrigendum 1

Annex A

Figures A.1a, A.1b and A.2 shall be corrected by replacing the figures along with the above, as follows:

Figure A.1a

Figure A.1b Figure A.1 — Crushing test on units in a horizontal arrangement Dimensions in millimetres

Key 1 Sheet material to permit any sliding or removable support 2 Low carbon steel facing plate, 330 mm x 25 mm minimum cross-section Figure A.2 — Crushing test on units in a vertical arrangement

Step 8: Determine the acceptability as follows:

Consider the measured value x of the bending tensile stress at the ultimate (collapse) load Fu from the last n consecutive samples.

Calculate the mean value xand the standard deviation s of these n values.

Calculate the lower quality statistic Q for the lower specification limit:

Q = (x - fdes)/s

where

fdes

is the lower specification limit for the bending tensile stress,

then compare the quality statistic with the acceptability constant k obtained from the appropriate column in Table H.4. Interpolation for intermediate values of n is permissible. For acceptance, the quality statistic for the lower specification limit shall be greater than or equal to the acceptability constant.

3.1.1 Manhole

Add the following structures to Figure 1 and add "8

Capping unit" to the key:

Figure 1 — Typical structures

Key 1 Adjusting unit 2 Cover slab 3 Shaft unit 4 Base unit 5 Taper 6 Chamber unit 7 Reducing slab 8 Capping unit

5.2.5 Conformity of proof (crack) load tested units

Add the words "that have been" after "units" in the first sentence:

"Reinforced concrete units that have been tested only to proof (crack) load in accordance with 6.4 or 6.5 and meeting the requirements of 5.2.3 or 5.2.4 as appropriate conform to this European Standard."

6.1 General

Footnote a shall be changed as follows:

- T/R T/R T/Rb T/R a means only applicable to units whose conformity is not specified in this European Standard to be verified by routine performance testing, including the walls of capping units

6.8 Concrete strength in base units, capping unit walls, adjusting units and certain tapers

Correct the conversion factor for drilled 50 mm ± 1 mm diameter cores from 0,9 into 1,07:

"Tests shall be carried out on drilled cores with a height equal to their diameter ± 10 mm:

when 100 mm ± 1 mm diameter cores are used, the result shall be applied without any conversion factor;

when 50 mm ± 1 mm diameter cores are used, a conversion factor of 1,07 shall be applied to the results."

Annex B: B.2 Apparatus

Add requirements on application of test load and accuracy of testing machine in accordance with those that apply for the crushing test on chamber and shaft units and specify the dimensions of the steel or cast iron plates. Replace the first sentence as follows:

"The apparatus shall consist of a testing machine capable of applying the full test load without shock or impact and with an accuracy of 3 % of the specified test load. The apparatus shall be equipped with steel or cast iron plates, through which the specified load is applied to the unit whilst it is supported around its perimeter. The dimensions of the steel or cast iron plate shall not exceed more than 125 mm the dimensions of the access opening. The width of beddings in contact with the unit shall correspond to the conditions that would be achieved in the structure for which the unit was designed."

Annex B: B.4.2 Reinforced concrete units

Replace the plan views of Figures B.1 and B.2 by the following:

Figure B.1 — Vertical strength test for capping units, cover slabs and reducing slabs

Figure B.2 — Vertical strength test for certain tapers

Clarify the procedure for preventing the joint gap from closing by deleting the word "mean" in the 3rd sentence:

"The connecting pipe(s) or adaptor(s) shall be deflected to an angular deflection of 12 500/DN (or 12 500/WN, as appropriate to the shape of the bore of the connecting pipe(s) or adaptor(s)) in millimetres per metre or 50 millimetres per metre, whichever is the smaller, taking care to ensure that no structural damage is caused. In the case of an egg-shaped connecting pipe or adaptor the deflection shall be in the vertical plane. During this operation the joint gap(s) shall be prevented from closing at any point by, for example, interposing at the appropriate place(s) a packing with a thickness equal to the [ ] value of the clearance stated in the factory documents."

Annex C: C.7.3: Watertightness under shear load

Take into account that the pipe submitted to the watertightness test is not necessary completely filled with water: Add after the formula for Rs and the definition of Ww:

"Where the pipe is completely filled with water the value of Rs shall be calculated according to the following formula:

Rs = (Fs - Ww / 2) × l1 /( l1 - as) ≥ 0, in kilonewtons

where

Ww is the weight of one unit filled with water, in kilonewtons

Where the full length of the pipe barrel is not filled with water the formula shall be adjusted accordingly."

Annex D: D.4.1 Determination of mass of immersed sample m1

Clarify the procedure of immerging the sample, by inserting the word "minimum" to the 2nd sentence:

"The sample shall be brought to a temperature of 20 °C ± 3 °C, then immersed in tap water at the same temperature until a constant mass has been reached. This shall be achieved in stages by successively immersing the sample at intervals of one hour to approximately 1/3 of the height, approximately 2/3 of the height and the total height, with a minimum final water level of 20 mm above the top surface of the sample."

Annex G: Table G.1 :

Correct sampling procedures for concrete cover according to clauses 5.2.2: - by replacing the frequency 1 N for the initial type test by 1 S; - by adding the word "using" before "covermeter" for the initial type test; - by replacing the reference to 5.2.3 and 5.2.4 by the word "collapse" for the routine inspection."

Table G.1 — Sampling procedures Clause Test when specified Initial type test Routine inspection 5.2.2

Concrete cover 1 S using every unit that has been type-tested to 5.2.3 or 5.2.4, or using covermeter for other units Every unit that has been tested to collapse and, using convermeter, 2 N/day

Correct symbol for the standard deviation in the last lozenge of the right branch of the flow chart (δ → σ).

Figure H.1 — Flow chart for inspection of ultimate (collapse) load

on the basis of individual assessments (excluding inspection of unreinforced units using the Annex J option and basic inspection of reinforced units)

Annex H: H.4: Figure H.1

Replace Figure H.1 by the following, where in the first line of the last lozenge in the right branch of the flow chart in the equitation for the mean value xn, the minus (-) was replaced by plus (+).

Figure H.1 — Flow chart for inspection of ultimate (collapse) load

on the basis of individual assessments (excluding inspection of unreinforced units using the Annex J option and basic inspection of reinforced units)

Corrigendum 1

Les Figures A.1a, A.1b et A.2 doivent être corrigés comme suit:

Figure A.1a

Figure A.1b

Figure A.1 — Essai d'écrasement sur éléments en position horizontale

Légende 3 Feuille permettant un appui glissant ou amovible 4 Plaque d'acier doux avec une section minimale de 330 mm x 25 mm

Figure A.2 — Essai d'écrasement sur éléments en position verticale

3.1.1 regard de visite

Ajoutez les ouvrages types suivants à la Figure 1 ainsi que "8 Elément de couronnement" à la légende:

Figure 1 — Ouvrages types

Légende

1 Rehausse sous cadre 2 Dalle réductrice de couronnement 3 Elément droit (haut) 4 Elément de fond 5 Tête tronconique 6 Elément droit (bas) 7 Dalle réductrice intermédiaire

8 Elément de couronnement

Remplacez la Figure 2 par la suivante :

Figure 2.a) — Garniture d'étanchéité élastomère Figure 2.b) — Garniture d'étanchéité élastomère ou plastomère ou autre matériaux d'étanchéité Figure 2.c) — Garniture d'étanchéité élastomère ou plastomère ou autre matériaux d'étanchéité

Figure 2 — Assemblages types

6.1 Généralités

Précisez sous la note a du Tableau 5 que la résistance des carottes tirées des parois des éléments de couronnement est aussi sujet à des essais de type initiaux et de surveillance continue, même si la conformité des éléments de couronnement est vérifiée par un contrôle continu des performances:

Tableau 5 — Récapitulation des exigences concernant les essais Éléments verticaux Article Exigence Eléments droits Eléments de fond Eléments de couronnementDalles réductrices decouronnement,

têtes tronconiques, dalles réductrices intermédiaires Rehausses sous cadre 4.2.2.1 Résistance des carottes a – T/R T/R T/R b T/R a L'essai n'est applicable qu'aux éléments dont il n'est pas spécifié dans la présente Norme Européenne que la conformité doit être vérifiée par un contrôle continu des performances, y compris les parois des éléments de couronnement.

6.8 Résistance du béton des éléments de fond, éléments de couronnement, rehausses sous cadre et certaines têtes tronconiques Précisez que la résistance à la compression du béton des éléments de couronnement doit être déterminée sur des échantillons prélevés dans les parois de ces éléments:

"La résistance à la compression du béton doit être déterminée conformément à l'EN 12390-3. L'essai doit être réalisé sur des échantillons prélevés par carottage aux tiers de la hauteur intérieure des éléments de fond, des parois des éléments de couronnement et des têtes tronconiques comme prescrit au Tableau 5 (soit deux échantillons par élément), ainsi qu'à chaque quart de la circonférence ou du périmètre des rehausses sous cadre. On calcule ensuite à chaque fois la valeur moyenne des résultats."

Changez le coefficient de conversion pour les carottes d'un diamètre de (50

± 1) mm d de 0,9 à 1,07:

"La hauteur des carottes doit être égale à leur diamètre ± 10 mm :

lorsqu'on utilise des carottes d'un diamètre de (100 ± 1) mm, le résultat doit être exploité sans coefficient de conversion ;

lorsqu'on utilise des carottes d'un diamètre de (50 ± 1) mm, on doit appliquer un coefficient de conversion

...

표준 문서 SIST EN 1917:2003/AC:2008은 콘크리트 맨홀 및 검사 챔버에 대한 상세한 지침을 제공합니다. 이 표준은 비보강, 강섬유 및 보강된 맨홀을 포함하며, 설계 및 시공 시 고려해야 할 중요한 요소들을 규정합니다. 이 표준의 주요 강점은 다양한 형태의 맨홀 구조에 적용 가능하다는 점입니다. 각 유형의 맨홀 특징을 명확히 정의하여, 사용자들이 적합한 옵션을 선택할 수 있도록 돕습니다. 또한, TC 교정의 포함은 기존의 EN 1916:2002 문서에서 발생할 수 있는 혼란을 최소화하고, 명확한 시각적 지침을 제공하게 됩니다. SIST EN 1917:2003/AC:2008의 적용 범위는 산업 전반에 걸쳐 맨홀 설치 및 유지보수 관련 표준을 준수할 수 있도록 합니다. 이는 특히 하수도 및 도시 인프라 관리에 있어서 매우 중요하며, 환경 안전성과 관련된 법적 요구사항을 충족하는 데에도 기여합니다. 결론적으로, EN 1917:2002/AC:2008 표준은 현대 건설 및 엔지니어링 분야에 있어서 필수적인 자료로, 맨홀 및 검사 챔버와 관련하여 높은 수준의 신뢰성과 안전성을 보장합니다.

Die Norm EN 1917:2002/AC:2008 behandelt die Anforderungen und Prüfmethoden für Beton-Schächte und Inspektionskammern, die unarmiert, stahlfaserverstärkt oder verstärkt sind. Der Umfang dieser Norm ist umfassend und zielt darauf ab, die Qualitätssicherung im Bereich der Abwasserentsorgung und der Infrastruktur zu gewährleisten. Die Korrektur von Abbildung H.1 im dritten Berichtigungsblatt zu EN 1916:2002 verbessert die Klarheit und Verständlichkeit der Norm und trägt dazu bei, Missverständnisse bei der Anwendung zu vermeiden. Ein herausragendes Merkmal dieser Norm ist ihre Flexibilität in Bezug auf verschiedene Arten von Betonprodukten. Die Berücksichtigung unarmierter und verstärkter Varianten ermöglicht eine breite Anwendung in verschiedenen Bauprojekten. Dies steigert nicht nur die Effizienz, sondern auch die Sicherheit im Bauwesen. Ein weiterer entscheidender Vorteil der EN 1917:2002/AC:2008 ist die Betonung von verbesserten Herstellungsverfahren, die den Einsatz von stahlfaserverstärktem Beton fördern. Diese Technik bietet eine höhere Beständigkeit gegenüber mechanischen Belastungen und Umwelteinflüssen, wodurch die Lebensdauer von Schachtanlagen erheblich verlängert wird. Insgesamt zeigt die Norm eine hohe Relevanz für Bauherren, Ingenieure und die gesamte Bauindustrie, da sie klare Richtlinien und Standards für die Herstellung und Qualitätsprüfung von Beton-Schächten und Inspektionskammern festlegt. Die EN 1917:2002/AC:2008 stellt somit eine wichtige Referenz in der Normenlandschaft dar und fördert die Standardisierung und Sicherheit in der Wasserwirtschaft.

La norme SIST EN 1917:2003/AC:2008, intitulée "Chambres de visite et puits en béton, non armés, à fibres d'acier et armés", fournit un cadre rigoureux pour la conception, la fabrication et l'installation de structures en béton utilisées dans les systèmes de drainage. Cette norme est particulièrement pertinente pour les professionnels du secteur de la construction et de l'ingénierie, car elle garantit la durabilité et la fonctionnalité des installations. L'un des principaux points forts de cette norme réside dans son approche globale concernant les matériaux utilisés. Elle couvre non seulement les produits en béton non armés, mais également ceux renforcés et à fibres d'acier, ce qui permet une flexibilité dans le choix des matériaux en fonction des besoins spécifiques du projet. De plus, la norme aborde les exigences de performance et de sécurité, ce qui renforce la confiance des utilisateurs dans les systèmes conçus selon ses directives. La norme SIST EN 1917:2003/AC:2008 inclut également des corrections et des clarifications importantes, comme celles apportées par le corrigendum concernant la Figure H.1, qui facilite la compréhension et l'application des recommandations. Cela témoigne de l'engagement continu de la normalisation à améliorer et à adapter les documents pour répondre aux évolutions technologiques et aux retours d'expérience des utilisateurs. En somme, la norme SIST EN 1917:2003/AC:2008 est une référence essentielle pour tous les acteurs du domaine, en fournissant des lignes directrices claires et précises pour la création de puits de visite et autres structures en béton. Sa pertinence et son application dans le contexte actuel des besoins de construction en font un outil incontournable pour garantir la qualité et la sécurité des infrastructures.

The EN 1917:2002/AC:2008 standard, titled "Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforced," serves as a crucial guideline for the construction and design of concrete structures used for drainage and sewerage systems. This standard particularly addresses the unique requirements and specifications needed to ensure durability and functionality in various environmental conditions. The scope of this standard is highly relevant, as it provides clear definitions and standardized methodologies for the production and installation of concrete manholes and inspection chambers. The inclusion of unreinforced, steel fibre, and reinforced concrete options ensures that users can select the most appropriate method tailored to their specific project needs, which is a significant strength of this standard. One notable strength is its comprehensive correction of Figure H.1, which enhances clarity and accuracy in the representation of design specifications. This correction, as part of the third corrigendum to EN 1916:2002, showcases the standard's commitment to continuous improvement and adaptation to modern engineering practices. This aspect is crucial for maintaining high quality and safety standards in construction. Furthermore, the standard's emphasis on material properties and testing requirements for concrete not only streamlines compliance with engineering best practices but also assures stakeholders in the construction industry of the reliability of these structures. The integration of varying types of cementing agents and reinforcements demonstrates the standard's flexibility and pertinence to current construction technologies. Overall, the EN 1917:2002/AC:2008 standard is significant for ensuring that concrete manholes and inspection chambers meet the necessary quality and performance expectations, reinforcing its relevance in the field of civil engineering and infrastructure development.

SIST EN 1917:2003/AC:2008は、コンクリートマンホールおよび検査室に関する重要な標準を提供します。この標準は、補強なし、スチールファイバー、及び補強型のコンクリート構造に関する内容を網羅しており、さまざまな用途に適した素材の選定が可能です。 この標準の強みは、土木工事における信頼性と安全性を確保するための明確な規定を示している点です。特に、TCによる図H.1の修正は、実際の施工において発生しうる問題を解決するための重要なガイドラインを提供しています。これにより、施工業者はより確実で質の高い作業を行うことができ、結果的に公共インフラの品質向上に寄与します。 また、EN 1917:2002/AC:2008は、持続可能な開発を重要視しており、環境に配慮した材料選定や施工方法についても考慮されています。そのため、現代のニーズに合わせたコンクリート製品の設計や施工において、企業や技術者にとって非常に関連性の高い文書となっています。 総じて、SIST EN 1917:2003/AC:2008は、コンクリートマンホールと検査室の設計・施工において、業界標準としての役割を果たすことが期待され、専門家による広範な利用が求められています。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...