EN 12889:2022

(Main)Trenchless construction and testing of drains and sewers

Trenchless construction and testing of drains and sewers

This document is applicable to the trenchless construction, trenchless replacement techniques and testing of new drains and new sewers in the ground and usually operating as gravity or pressure pipelines, formed using prefabricated pipes and their joints.

Renovation techniques for existing pressure and non-pressure systems are not covered by this document.

Methods of trenchless construction include:

- manned and unmanned techniques;

- steerable and non-steerable techniques.

NOTE 1 Mining or tunnelling techniques for permanent structures (e.g. in situ construction or the use of prefabricated segments) are not covered by this document although some parts can apply to these methods.

NOTE 2 Trenchless insertion using a pipe plough system is a common method for installing small pipes and cables. The method does not exactly cope with the scope of this document. Therefore, it is described in the informative Annex D.

Requirements for associated pipeline installation work other than trenchless construction, e.g. for manholes and inspection chambers, are not covered by this document and are specified in EN 1610. This also applies to pipes that are subsequently installed within entry and exit shafts/pits.

Grabenlose Verlegung und Prüfung von Abwasserleitungen und -kanälen

Dieses Dokument ist anwendbar auf grabenlose Verlegungs- und Erneuerungsverfahren sowie die Prüfung neuer Abwasserleitungen und kanäle im Boden mit vorgefertigten Rohren und deren Verbindungen, die üblicherweise als Freispiegel- oder Druckrohrleitungen betrieben werden.

Renovierungsverfahren für vorhandene Druckrohrleitungen und drucklose Leitungen sind nicht Gegenstand dieses Dokuments.

Die Methoden zur grabenlosen Verlegung umfassen:

bemannte und unbemannte Verfahren;

steuerbare und nichtsteuerbare Verfahren.

ANMERKUNG 1 Bergmännische Bauverfahren und Tunnelbauverfahren für dauerhafte Bauwerke (z. B. In-Situ-Bauverfahren oder die Verwendung vorgefertigter Segmente) sind nicht Gegenstand dieses Dokuments, obwohl einzelne Festlegungen auf diese Verfahren anwendbar sein können.

ANMERKUNG 2 Das Pflugverfahren ist eine übliche Methode zum grabenlosen Einbau kleiner Rohre und Kabel. Das Verfahren fällt nicht vollständig in den Anwendungsbereich dieses Dokuments. Daher wird es im informativen Anhang D beschrieben.

Anforderungen für weitere Leitungseinbauten außer grabenlose Verlegung, z. B. im Zusammenhang mit Schächten und Inspektionsöffnungen, sind nicht im Anwendungsbereich dieses Dokuments, sondern sind in EN 1610 festgelegt. Dies gilt auch für Rohre, die im Anschluss an den grabenlosen Einbau in Start und Zielschächten bzw. Ein und Ausstiegen eingebaut werden.

Mise en oeuvre sans tranchée et essais des branchements et collecteurs d'assainissement

Le présent document s’applique aux techniques de construction et de remplacement sans tranchée, ainsi qu’aux essais de collecteurs et branchements neufs, enterrés et fonctionnant habituellement comme des canalisations à écoulement libre ou sous pression, formées de tuyaux préfabriqués et de leurs assemblages.

Les techniques de rénovation des systèmes sous pression et sans pression existants ne sont pas couvertes par le présent document.

Les méthodes de mise en œuvre sans tranchée comprennent :

- les techniques avec ou sans intervention humaine ;

- les techniques avec ou sans guidage.

NOTE 1 Les forages miniers ou les techniques d’exécution des tunnels pour les ouvrages permanents (par exemple, la construction in situ ou l’utilisation de voussoirs préfabriqués) ne sont pas couverts par le présent document, bien que certaines parties puissent s’appliquer à ces méthodes.

NOTE 2 L’insertion sans tranchée à l’aide d’un système de trancheuse est une méthode couramment utilisée pour installer les petits tuyaux et les câbles. La méthode ne rentre pas exactement dans le domaine d’application du présent document. Par conséquent, elle est décrite à l’Annexe D, informative.

Les exigences relatives à la mise en œuvre des ouvrages annexes autres que la construction sans tranchée, par exemple pour les regards de visite et boîtes d’inspection ou de branchement, ne sont pas couvertes par le présent document et sont spécifiées dans l’EN 1610. Ceci s’applique également aux tuyaux qui sont installés ultérieurement dans les puits d’entrée et de sortie.

Izvedba in preskušanje kanalov in drenaž brez izkopa

Ta dokument se uporablja za izgradnjo brez izkopa, tehnike zamenjave brez izkopa ter preskušanje novih kanalov in novih kanalizacijskih drenaž v tleh, ki običajno delujejo kot gravitacijski ali tlačni cevovodi, izdelani iz montažnih cevi in njihovih spojev.

Tehnike obnove obstoječih tlačnih in netlačnih sistemov niso zajete v tem dokumentu.

Metode izgradnje brez izkopa so:

– tehnike z osebjem ali brez njega;

– vodljive in nevodljive tehnike.

Ta dokument ne zajema rudarjenja ali tuneliranja (npr. gradnja na mestu samem ali uporaba montažnih segmentov), čeprav se lahko nekateri deli navezujejo na te metode.

Zahteve za pripadajoča montažna dela cevovoda, razen izgradnje brez izkopa, npr. za jaške in revizijske komore, niso zajete v tem dokumentu in so določene v standardu EN 1610. To velja tudi za cevi, ki se naknadno vgradijo v vstopne in izstopne jaške/jame.

General Information

- Status

- Published

- Publication Date

- 11-Oct-2022

- Technical Committee

- CEN/TC 165 - Waste water engineering

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 12-Oct-2022

- Due Date

- 24-Jun-2021

- Completion Date

- 12-Oct-2022

Relations

- Effective Date

- 23-Nov-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 12889:2022 - published by CEN - defines requirements for the trenchless construction, trenchless replacement techniques and testing of new drains and sewers formed from prefabricated pipes and joints. The standard covers pipelines that typically operate as gravity or pressure pipelines, using manned and unmanned, and steerable and non‑steerable trenchless methods. It applies to new installations and replacement techniques but does not cover renovation of existing pressure or non‑pressure systems. Informative annexes include guidance on systems, typical diameter/length ranges and a description of pipe‑plough insertion (Annex D).

Key topics and technical requirements

EN 12889:2022 addresses practical and technical aspects needed for safe, durable trenchless sewer and drain installation:

- Scope & definitions: Clarifies terms such as pipe jacking, overcut, reamer, expander, manned/unmanned techniques.

- Construction components & materials: Requirements for pipes and joints, site delivery, handling and storage of components.

- Classification of techniques: Detailed descriptions of unmanned (e.g., HDD, auger boring, microtunnelling) and manned methods, plus steerable vs non‑steerable approaches.

- Planning & design requirements: Ground and groundwater investigation, layout and tolerances, subsidence/cover considerations, starting/target pits, and structural calculations.

- Site operations: Working face support, soil conditioning, overcut/overbreak control, launch/reception shaft stability, and logging of jacking parameters.

- Inspection & testing: Post‑installation checks including visual inspection and leaktightness testing for installed pipelines.

- Qualifications: Competence requirements for personnel and contractors undertaking trenchless works.

- Exclusions: Manhole/inspection chamber installation requirements are referenced to EN 1610; mining/tunnelling for permanent structures is not covered.

Applications and who uses EN 12889:2022

This standard is intended for professionals involved in planning, specifying, constructing and accepting trenchless sewer and drain works:

- Municipal and utility engineers specifying new sewer/drain pipeline routes

- Civil and geotechnical engineers conducting ground investigations and structural calculations

- Trenchless contractors and tunnelling specialists selecting appropriate manned/unmanned and steerable/non‑steerable techniques

- Procurement and asset owners setting acceptance criteria and test regimes

- Inspectors and certifiers performing post‑installation visual and leaktightness tests

Typical applications include installation of new sewer mains beneath roads, rail corridors or sensitive urban areas, crossings where surface disruption must be minimised, and replacement of pipelines using trenchless insertion or pipe jacking.

Related standards

Relevant referenced standards to use alongside EN 12889:2022:

- EN 1610 - Construction and testing of drains and sewers (manholes/inspection chambers)

- EN 1295‑1 - Structural design of buried pipelines

- EN 752 - Drain and sewer systems outside buildings

- EN 476, EN 805, EN 1997‑2 - component, water supply, and geotechnical design references

Keywords: EN 12889:2022, trenchless construction, drains and sewers, pipe jacking, steerable techniques, unmanned techniques, sewer testing, CEN standard.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 12889:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Trenchless construction and testing of drains and sewers". This standard covers: This document is applicable to the trenchless construction, trenchless replacement techniques and testing of new drains and new sewers in the ground and usually operating as gravity or pressure pipelines, formed using prefabricated pipes and their joints. Renovation techniques for existing pressure and non-pressure systems are not covered by this document. Methods of trenchless construction include: - manned and unmanned techniques; - steerable and non-steerable techniques. NOTE 1 Mining or tunnelling techniques for permanent structures (e.g. in situ construction or the use of prefabricated segments) are not covered by this document although some parts can apply to these methods. NOTE 2 Trenchless insertion using a pipe plough system is a common method for installing small pipes and cables. The method does not exactly cope with the scope of this document. Therefore, it is described in the informative Annex D. Requirements for associated pipeline installation work other than trenchless construction, e.g. for manholes and inspection chambers, are not covered by this document and are specified in EN 1610. This also applies to pipes that are subsequently installed within entry and exit shafts/pits.

This document is applicable to the trenchless construction, trenchless replacement techniques and testing of new drains and new sewers in the ground and usually operating as gravity or pressure pipelines, formed using prefabricated pipes and their joints. Renovation techniques for existing pressure and non-pressure systems are not covered by this document. Methods of trenchless construction include: - manned and unmanned techniques; - steerable and non-steerable techniques. NOTE 1 Mining or tunnelling techniques for permanent structures (e.g. in situ construction or the use of prefabricated segments) are not covered by this document although some parts can apply to these methods. NOTE 2 Trenchless insertion using a pipe plough system is a common method for installing small pipes and cables. The method does not exactly cope with the scope of this document. Therefore, it is described in the informative Annex D. Requirements for associated pipeline installation work other than trenchless construction, e.g. for manholes and inspection chambers, are not covered by this document and are specified in EN 1610. This also applies to pipes that are subsequently installed within entry and exit shafts/pits.

EN 12889:2022 is classified under the following ICS (International Classification for Standards) categories: 23.040.05 - Pipeline and its parts for external sewage systems; 93.030 - External sewage systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12889:2022 has the following relationships with other standards: It is inter standard links to EN 12889:2000, EN 805:2025, EN 1997-2:2024, EN 1610:2015, EN 476:2022, EN 1295-1:2019, EN 1610:1997, EN 16932-1:2018, EN 752:2017, EN 752:2008, EN 19694-5:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12889:2022 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 93/38/EEC; Standardization Mandates: M/BC/CEN/88/15. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12889:2022 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-januar-2023

Nadomešča:

SIST EN 12889:2000

Izvedba in preskušanje kanalov in drenaž brez izkopa

Trenchless construction and testing of drains and sewers

Grabenlose Verlegung und Prüfung von Abwasserleitungen und -kanälen

Mise en oeuvre sans tranchée et essais des branchements et collecteurs

d'assainissement

Ta slovenski standard je istoveten z: EN 12889:2022

ICS:

91.140.80 Drenažni sistemi Drainage systems

93.030 Zunanji sistemi za odpadno External sewage systems

vodo

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12889

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2022

EUROPÄISCHE NORM

ICS 93.030; 23.040.05 Supersedes EN 12889:2000

English Version

Trenchless construction and testing of drains and sewers

Mise en oeuvre sans tranchée et essais des Grabenlose Verlegung und Prüfung von

branchements et collecteurs d'assainissement Abwasserleitungen und -kanälen

This European Standard was approved by CEN on 5 September 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12889:2022 E

worldwide for CEN national Members.

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 General . 7

4.1 Technical principles . 7

4.2 Safeguarding design decisions . 7

5 Construction components and materials . 8

5.1 General . 8

5.2 Pipes and joints . 8

5.3 Manholes and inspection chambers . 8

5.4 Delivery, handling and transportation on site . 8

5.5 Storage . 8

5.6 Other materials . 9

6 Techniques . 9

6.1 Classification . 9

6.2 Unmanned techniques . 11

6.2.1 General . 11

6.2.2 Non-steerable techniques . 11

6.2.3 Steerable techniques. 18

6.3 Manned techniques . 23

6.3.1 General . 23

6.3.2 Non-steerable techniques . 24

6.3.3 Steerable techniques. 24

6.3.4 Other manned techniques . 28

7 Requirements of planning and construction . 29

7.1 General . 29

7.2 Basic evaluation, design and construction planning . 29

7.2.1 General . 29

7.2.2 Survey of existing structures and systems . 30

7.2.3 Ground and groundwater . 31

7.2.4 Minimum clear dimensions . 33

7.2.5 Subsidence, heaves, cover . 33

7.2.6 Layout of the line . 33

7.2.7 Tolerances . 33

7.2.8 Starting, intermediate and target pits . 33

7.2.9 Working face support . 34

7.2.10 Additional measures in water bearing ground . 34

7.2.11 Obstacles . 34

7.2.12 Soil conditioning . 34

7.2.13 Structural calculation . 35

7.2.14 Construction site arrangement . 35

7.3 Work preparation and construction . 35

7.3.1 General . 35

7.3.2 Starting, intermediate and target pits . 36

7.3.3 Exit and entry processes . 36

7.3.4 Static calculation of launch and reception shafts . 36

7.3.5 Overcut . 36

7.3.6 Recording and logging of jacking parameters . 36

7.3.7 Support of the working face . 37

7.3.8 Lubricant and supporting medium . 37

7.4 Avoidance of damage . 37

8 Inspection and testing of pipelines after installation . 38

8.1 General . 38

8.2 Visual inspection . 38

8.3 Leaktightness . 38

9 Qualifications . 38

Annex A (informative) Additional information about the different systems. 39

Annex B (informative) Guide to typical ranges of application regarding diameters and

lengths in suitable soil . 49

Annex C (informative) Guide to typical ranges of application for selected trenchless

techniques regarding diameters and lengths in suitable soils . 51

Annex D (informative) Trenchless insertion using a pipe plough system . 52

Bibliography . 53

European foreword

This document (EN 12889:2022) has been prepared by Technical Committee CEN/TC 165 “Waste water

engineering”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by April 2023, and conflicting national standards shall be

withdrawn at the latest by April 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12889:2000.

In comparison with the previous edition, the following changes have been made:

a) editorial and technical revision of the complete document;

b) modification of terms and definitions;

c) adaptation of the description of all methods of trenchless techniques and installation of pipelines;

d) Clause 7 “Requirements of planning and construction” was added.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document is applicable to the trenchless construction, trenchless replacement techniques and

testing of new drains and new sewers in the ground and usually operating as gravity or pressure

pipelines, formed using prefabricated pipes and their joints.

Renovation techniques for existing pressure and non-pressure systems are not covered by this document.

Methods of trenchless construction include:

— manned and unmanned techniques;

— steerable and non-steerable techniques.

NOTE 1 Mining or tunnelling techniques for permanent structures (e.g. in situ construction or the use of

prefabricated segments) are not covered by this document although some parts can apply to these methods.

NOTE 2 Trenchless insertion using a pipe plough system is a common method for installing small pipes and

cables. The method does not exactly cope with the scope of this document. Therefore, it is described in the

informative Annex D.

Requirements for associated pipeline installation work other than trenchless construction, e.g. for

manholes and inspection chambers, are not covered by this document and are specified in EN 1610. This

also applies to pipes that are subsequently installed within entry and exit shafts/pits.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 476, General requirements for components used in drains and sewers

EN 752, Drain and sewer systems outside buildings - Sewer system management

EN 805, Water supply - Requirements for systems and components outside buildings

EN 1295-1, Structural design of buried pipelines under various conditions of loading - Part 1: General

requirements

EN 1610, Construction and testing of drains and sewers

EN 1997-2, Eurocode 7: Geotechnical design - Part 2: Ground investigation and testing

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at https://www.electropedia.org/

3.1

cutting head

tool or system of tools on a common support, which excavates at the face of a bore

Note 1 to entry: The term usually applies to mechanical methods of excavation.

3.2

expander

tool which enlarges a bore by displacement of the surrounding ground rather than by excavation

3.3

gravity pipeline

pipeline where flow is caused by the force of gravity and where the pipeline is designed usually to operate

partially full

3.4

overbreak

extent by which the excavated void including accidental ground losses initially exceeds the outside

dimension of the pipe

3.5

overcut

half of the difference of borehole diameter and external pipe diameter (ideally, an even annular space

around the pipeline)

3.6

pipe jacking

system of directly installing pipes behind a cutting head and/or shield, by hydraulic jacking from a drive

shaft, such that the pipes form a string in the ground

3.7

reamer

cutting head attached to the end of a drill string or pilot rod to enlarge the pilot diameter during a pull-

back or pushing operation, to enable a pipe or pipes to be installed

3.8

renovation

work incorporating all or part of the original fabric of the pipeline by means of which its current

performance is improved

[SOURCE: EN 15885:2018, 3.2]

3.9

replacement

construction of a new pipeline, on or off the line of an existing pipeline, where the function of the new

pipeline system incorporates that of the old

[SOURCE: EN 15885:2018, 3.4]

3.10

spoil

material excavated and removed in the course of installation

3.11

trenchless construction technique

technique for constructing pipelines in the ground without opening trenches

3.12

manned technique

technique involving the use of personnel working in the excavated bore during installation

3.13

unmanned technique

technique avoiding the use of personnel working in the excavated bore during installation

4 General

4.1 Technical principles

Pipelines, manholes and inspection chambers are engineering structures in which the combined

performance of construction components, bedding and fill or the surrounding ground constitutes the

basis for stability and safety in operation. The pipes, fittings and components for jointing supplied,

together with the work carried out at site, are all important factors in achieving a structure with adequate

performance over the intended service life.

The network owner and the planner shall coordinate the extent and the requirements of the engineering

services to be rendered each individual case.

The pipeline and any associated structures shall be designed during planning in accordance with

EN 1295-1 and EN 752 as applicable to ensure that they are capable of carrying all foreseeable imposed

and operational loads with a sufficient level of safety.

A procedure shall be established for the resolution of technical questions, agreement and recording of

changes to design decisions made during construction.

Additionally, other local or national regulations can apply, e.g. concerning health and safety, pavement

installation, tolerances for deviation in line and level and requirements for leaktightness testing.

4.2 Safeguarding design decisions

In the execution of the work it shall be ensured that the decisions made in the design are complied with

or adapted to changed conditions.

The design decisions can be affected by a variation of any of the following which should be checked during

installation:

— pipe support;

— ground conditions and soil types;

— construction traffic and assumptions concerning temporary loads;

— ground water level;

— existing infrastructure in the same proximity (e.g. pipelines, cables, structures);

— settlement and heave;

— deflection;

— deviation from line;

— pipe type, strength or class.

NOTE The above list is not exhaustive.

5 Construction components and materials

5.1 General

Construction components and materials shall conform to European Standards. In the absence of these,

the components and materials shall comply with design requirements and EN 476.

All written instructions of the manufacturer shall be complied with.

5.2 Pipes and joints

Installation shall not commence before the following criteria have been agreed between the designer and

installer. These shall be obtained from appropriate product standards or from the pipe manufacturer:

— internal pipe diameter;

— external pipe diameter;

— pipe length;

— tolerances on dimensions;

— permissible jacking load or pulling force;

— type and performance of joints;

— longitudinal flexibility (acceptable bending radius or angular deflection).

5.3 Manholes and inspection chambers

Manholes and inspection chambers shall comply with the design. Prefabricated components shall be

assembled and installed according to the instructions of the manufacturer and the designer.

5.4 Delivery, handling and transportation on site

Construction components and materials shall be inspected on delivery to ensure that they are

appropriately marked and comply with the design requirements.

Any handling or transportation instructions from the manufacturer shall be complied with.

Products shall be examined both on delivery and immediately prior to installation to ensure that they are

free from damage and in accordance with the relevant product standard.

5.5 Storage

Any instructions from the manufacturer and the requirements of the appropriate product standards shall

be complied with.

Construction components and materials shall be stored in such a manner to keep them clean and avoid

contamination or degradation, for example elastomeric jointing components shall be kept clean and be

protected from sources of ozone (e.g. electrical equipment), sunlight and oil, where necessary.

Pipes shall be secured to prevent rolling. Excessive stacking heights shall be avoided so that pipes in the

lower part of the stacks are not overloaded. Stacks of pipes shall not be placed close to open trenches.

Pipes with protective coatings shall be stored where necessary, on supports which keep them clear of the

ground to avoid damage to coatings and joints. All pipes should be stored on supports in very cold

weather to avoid freezing to the ground.

5.6 Other materials

The mechanical and environmental impact of other materials used during the construction process on:

— pipeline;

— surrounding soil;

— surface water and groundwater

shall be considered by the designer.

Consideration shall also be given to the following:

— production/origin;

— treatment and storage;

— leaching;

— cleanliness.

6 Techniques

6.1 Classification

Pre-fabricated pipes are jacked or pulled into the ground between the starting pit and the target pit. The

soil is either displaced and/or excavated at the working face and is mechanically, hydraulically or

pneumatically transported to the starting or target pit or in some techniques can be removed from the

pipe as an earth core after completion. There is a distinction between manned and unmanned processes.

Non-steerable or steerable jacking processes are selected depending on the required accuracy of

installation.

The selection of the process depends on:

— the planned/given jacking pipe;

— the required positional precision; this shall be defined by the client/ planner;

— the proximity to neighbouring utility services and sewers and other structures and systems;

— the external diameter;

— the jacking distance;

— the ground conditions;

— the groundwater conditions;

— the minimum depth of cover and

— the clear dimensions necessary for employing personnel inside the pipe string.

NOTE 1 The above list is not exhaustive.

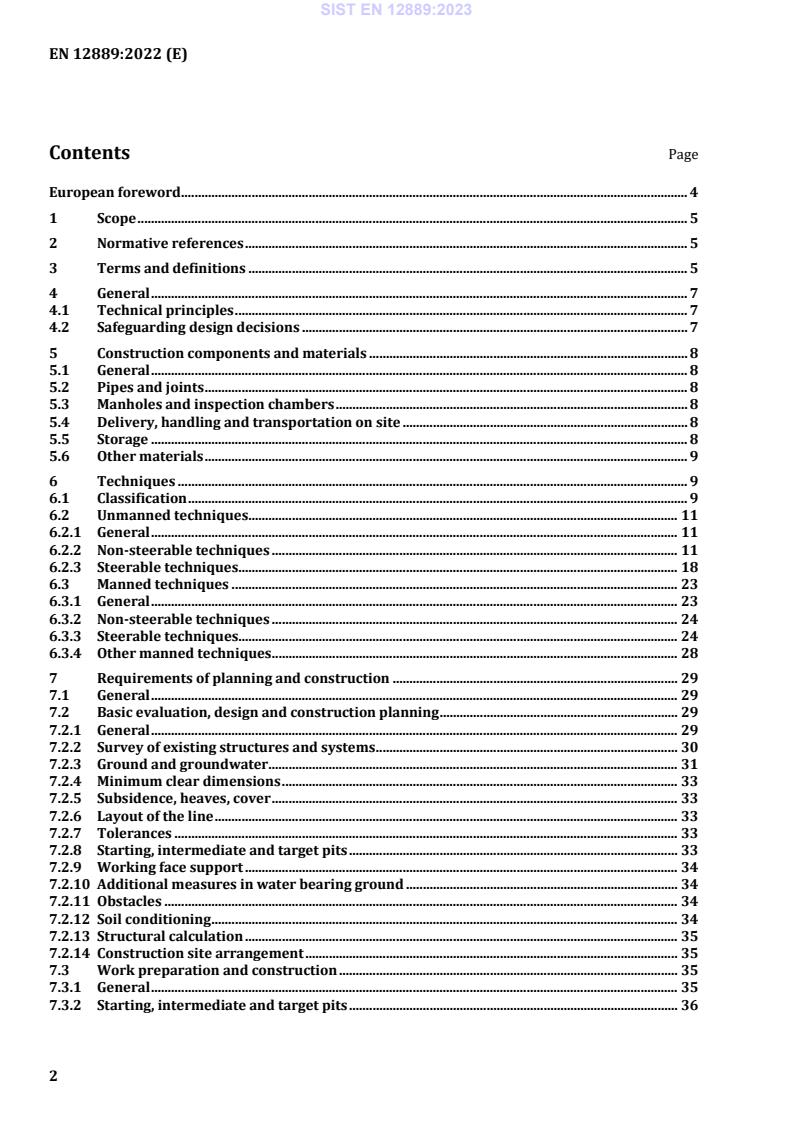

A schematic classification of trenchless techniques is given in Figure 1, representing techniques available

at the time of publication of this document.

The techniques are described and illustrated in 6.2 and 6.3.

Planning information for the application of different systems are given in Annex A, Table A.1.

NOTE 2 The list presented in Figure 1 is not exhaustive. Other techniques and combinations exist and can be

used.

Figure 1 — Classification of trenchless techniques

6.2 Unmanned techniques

6.2.1 General

Unmanned techniques do not require employment of personnel inside the pipe. Steerable Horizontal

Directional Drilling methods (HDD) as well as methods for trenchless replacement of pipelines on the

same line represent unmanned techniques that are related to pipe jacking. The prerequisite for

temporary employment of personnel inside the pipe string are described in 7.2.4.

6.2.2 Non-steerable techniques

6.2.2.1 General

The accuracy of non-steerable techniques in new construction is influenced by the ground (e.g. soil type),

intrusions and stratifications, the type of pipe joint, the external pipe diameter and the pipe wall thickness

and other things, and decreases overproportionally to the jacking distance. Therefore, the use of these

methods for pipelines that require an exact position is restricted for operational reasons. Damage to

adjacent systems has to be excluded by ensuring sufficient clearance. During new construction suitable

methods should be used to determine the position during jacking.

For use in water-bearing strata, additional measures such as groundwater retention can become

necessary.

Table B.1 contains empirical values for the area of application of the listed unmanned, non-steerable

techniques. The in situ ground conditions and project-specific boundary conditions shall always be taken

into consideration.

6.2.2.2 Soil displacement techniques

6.2.2.2.1 General

All listed techniques require soil that is displaceable.

6.2.2.2.2 Impact moling

Impact moling is a technique, generally considered to be non-steerable, using a pneumatic powered

torpedo shaped device, known as a mole (see Figure 2). This incorporates a reciprocating internal

hammer impacting on the back of a nose cone which in some cases can move independently of the main

body. The friction between the main body and the ground enables the nose cone to move forward at each

hammer blow, whilst the length of the main body keeps the mole on line. There are several designs of

nose cone, which claim to give better penetration, or to be less susceptible to being pushed off line by

lumps of stone.

Because the soil material has to be forced out into the surrounding ground, this technique is confined to

small pipe diameters. The pipe is generally pulled in behind the mole, or can be pulled back as the mole

is reversed out. The pipe installation is either done simultaneously or, in a sufficiently stable soil, by

subsequent pulling or pushing in. A shrinking of the bore diameter of the cavity by 5 % to 15 % has to be

taken into account.

Key

1 air compressor

2 starting pit

3 new (discrete) pipe

4 impact mole

5 planned route

6 target pit

7 typical nose cone

Figure 2 — Example of impact moling

6.2.2.2.3 Pipe ramming with a pipe closed at its leading end

Pipe ramming with a pipe closed at its leading end is a technique of forming a bore by driving a steel

casing with a closed end using a percussive hammer (see Figure 3). The soil is displaced by the leading

closed pipe end.

When dimensioning the pipes for trenchless installation with pipe ramming, additional dynamic loads

have to be taken into account. Product pipes with cement mortar lining and/or cement mortar coating

shall not be directly installed by pipe ramming.

Key

1 starting pit

2 ramming hammer

3 pipe

4 air compressor

5 end cone

6 planned route

7 target pit

Figure 3 — Example of pipe ramming with a pipe closed at its leading end

6.2.2.2.4 Rod pushing with an expander

Pushing a pilot rod displaces the soil. After having arrived in the target pit, the rod is connected to a

conical pushing head or a soil displacement hammer, which is also connected to the host or product pipes.

Afterwards, the entire string is pulled back (see Figure 4).

The upper part of Figure 4 shows the installation of pilot rod and initial displacement of soil. The lower

part shows the installation of the pipe and further displacement of soil.

The expander can be in the form of a displacement cone or a reamer.

Key

1 starting pit 5 target pit

2 ram system 6 rod

3 hydraulic unit 7 expander

4 pilot rod 8 pipe

Figure 4 — Example of the process of rod pushing with an expander

6.2.2.2.5 Pipe bursting

Replacement is done by bursting or splitting the existing pipe, and displacing it into the surrounding

ground, while simultaneously pulling in a new continuous or discrete pipe, of the same or larger diameter.

A bursting head with a cone with or without fixed blades is generally used for brittle pipe materials such

as clay, grey cast iron or fibre cement, whereas a splitting head with cutting blades or discs is generally

used for non-brittle pipe materials such as ductile iron, steel or plastics. Both types of head embody an

expansion cone to displace the existing burst or split pipe into the surrounding ground and form a bore

for the new pipe.

Additional measures can become necessary in water-bearing soils. The new pipe shall be dimensioned in

accordance with the structural calculation.

Methods used are static pipe bursting (see Figure 5) or dynamic pipe bursting (see Figure 6).

NOTE There are other systems known where the expander cone is hydraulically expandable.

Key

1 bursting head

2 expander cone

3 new pipe

4 pulling device

5 hydraulic unit

6 pipe fragments from the original pipe

7 pulling rod

Figure 5 — Example of replacement by static pipe bursting (here installing discrete pipes)

Key

1 bursting head/expander and hammer

2 new pipe

3 cable winch

4 air compressor

5 pipe fragments from the original pipe

6 starting pit

7 target pit

Figure 6 — Example of installation by dynamic pipe bursting (here installing continuous pipes)

6.2.2.2.6 Pipe extraction

Pipe extraction uses a rod puller to pull the old pipe through the ground, removing old pipe sections as

they arrive at the rod puller, while simultaneously pulling in new pipe (see Figure 7). This would typically

be used for pressure pipes, as it allows installation of continuous pipe, and leaves behind no shards of old

pipe.

When the diameter of the new pipe is larger than the old, an expander is used.

Additional measures can become necessary in water-bearing soils.

Due to the high friction forces, only a short length of pipe can be extracted between pits.

Key

1 new pipe

2 starting pit

3 pulling adapter for the new pipe

4 extraction adapter of the original pipe

5 existing pipe; pulling rod inserted

6 target pit

7 pipe splitting/cracking cone

8 hydraulic rod pulling device

9 hydraulic unit

Figure 7 — Example of replacement by pipe extraction

6.2.2.3 Soil removal techniques

6.2.2.3.1 Pipe ramming with an open ended pipe

A steel pipe string that is open at its leading end (sleeve or product pipe) is jacked by means of ramming

energy (see Figure 8). The earth core entering the pipe is usually pushed out, flushed out hydraulically,

or drilled out mechanically after having completed the jacking. Pushing-out by means of compressed air

is only permitted up to an internal pipe diameter of 500 mm subject to taking the necessary safety

measures.

Product pipes with cement mortar lining shall not be installed by pipe ramming.

In strongly swelling, plastic soils the application might not be possible, in rock it is impossible.

In water-bearing soils, additional measure such as lowering of groundwater can become necessary

depending on the groundwater level and soil type.

Key

1 starting pit 6 guide track

2 horizontal ram 7 steel pipe

3 jacking pipe, open 8 cutting ring

4 air compressor 9 planned route

5 target pit

Figure 8 — Example of pipe ramming with an open ended pipe

6.2.2.3.2 Auger boring

A steel pipe string (sleeve or product pipe) is pushed by means of a jacking station. The soil is

simultaneously mechanically excavated at the working face by using a cutting head and mechanically

conveying the spoil by means of augers (see Figure 9). The drive of the cutting head with augers is usually

located in the starting pit.

The selection of the cutting head depends on the ground conditions. A down-the-hole hammer can also

be used as a cut-ting head. In water-bearing soils, additional measures like groundwater lowering can be

necessary.

Key

1 starting pit 5 target pit

2 cutting head with auger 6 casing and auger

3 auger boring machine 7 planned route

4 hydraulic unit 8 cutting head

Figure 9 — Example of (non-steerable) auger boring

6.2.2.3.3 Hammer drilling

Hammer drilling is also known as down-hole hammer drilling. The method uses a pneumatic, percussive

hammer in front of a jacking pipe mainly in rock but also in loose ground. The rock or soil is fragmented

by repeated direct impacts of the hammer.

As the percussive hammer operates a cutting head in the excavated bore, the spoil is removed

mechanically by auger (see Figure 10), by water or compressed air.

NOTE Systems operating without casing are also known.

Key

1 starting pit 6 target pit

2 jacking device 7 planned route

3 new pipe or casing 8 hydraulic unit

4 rod string 9 air compressor

5 hammer with cutting head 10 auger

Figure 10 — Example of hammer drilling

6.2.2.3.4 Pipe eating

An existing pipeline is excavated possibly together with the surrounding soil, and the cutting head is

connected to the existing pipeline by means of a guiding shoe (see Figure 13).

The excavated material is milled and conveyed pneumatically or hydraulically or by means of augers.

In water bearing soils, additional measures can be necessary.

6.2.3 Steerable techniques

6.2.3.1 Microtunnelling

6.2.3.1.1 General

Microtunnelling is a remotely controlled form of pipe jacking originally designed for non-man-entry size

pipes. Technical developments allow using this technique for larger cross-sections (see Figure C.1).

Microtunnelling is a remote, one-stage technique for jacking product or sleeve pipes by using a jacking

machine and simultaneous continuous full-face soil excavation at the working face that is mechanically

supported and/or supported by fluid or earth pressure.

The microtunnelling process is cyclical. After one pipe has been jacked into the bore, the jacks are

retracted and another pipe is lowered into position in the starting pit and the process repeated.

The cutting head shall be adapted to the ground and groundwater conditions as well as the respective

technology. With larger excavation cross-sections, the requirements of supporting the working face and

the annular space is increased.

Excavated material is transported from the cutting head to the starting pit by either an auger or a slurry

system. Where a slurry system is used, separation plants are usually provided on the surface to remove

the spoil from the slurry water which is then recycled.

The alignment control is usually done by means of laser technology or by means of gyroscope and water

level. A hydraulically swivelling steering head changes the direction.

Starting and target shall be excavated and a thrust wall shall be constructed in the starting pit to provide

support for the jacking device and to safely transfer the jacking loads in the ground.

6.2.3.1.2 Microtunnelling with auger spoil removal

Spoil is removed by means of an auger located in a separate auxiliary pipe. The cutting head and the auger

are usually driven from the starting pit (see Figure 11).

It is also possible to drive the cutting head separately. For cohesive soils of firm consistency, the

excavation and removal of the soil can be simplified by adding water at the working face.

Water-bearing soils can require additional measures.

Key

1 target pit 7 conveying bucked

2 bentonite system 8 auger with auxiliary pipe

3 steering unit 9 jacking pipe

4 starting pit 10 steering head

5 lifting device 11 planned route

6 jacking device

Figure 11 — Example of microtunnelling with auger spoil removal

6.2.3.1.3 Slurry shield microtunnelling

The excavated soil is removed hydraulically and a separation unit (e.g. settling container; if required, with

screens, cyclones or other equipment) separates it from the transport medium (see Figure 12).

The type and quality of the transport medium shall be adapted to the ground and groundwater

conditions.

Key

1 target pit 9 starting pit

2 bentonite system 10 lifting device

3 setting basin 11 jacking device

4 separation unit 12 conveyor pump

5 feed pump 13 jacking pipe

6 operation container 14 steering head

7 conveyer pipe 15 planned route

8 feed pipe

Figure 12 — Example of slurry shield microtunnelling

6.2.3.1.4 Slurry shield microtunnelling with compressed air cushion (mixshield)

Basically, the technique is similar to slurry shield microtunnelling. An additional compressed air cushion

minimizes pressure variations at the working face.

6.2.3.1.5 Microtunnelling with earth pressure balance (EPB shield)

The excavated soil is removed from the excavation chamber by an auger and conveyed usually by means

of a muck pump. The use of conditioners broadens the area of application (see 7.2.12). Very soft soils can

be re-treated by means of hydraulic binding agents in order to minimize the costs of material transport

and disposal.

6.2.3.1.6 Microtunnelling spoil removal by other mechanical means

With these techniques, the excavated soil is conveyed by means of techniques other than those mentioned

previously (e.g. air or other mechanical techniques).

The necessity of additional measures in water-bearing soils depends on the technique used.

6.2.3.1.7 Microtunnelling incorporating pipe eating

Pipe eating uses a microtunnelling machine to crush the existing pipe and an auger or slurry system to

extract the pipe fragments together with the surrounding ground if enlargement is required

(see Figure 13). New discrete pipe sections are pushed in behind. The tunnelling machine can have an

extended guide running within the old pipe to keep the machine centred, and can incorporate a seal to

prevent slurry going forward. The pipes and bedding material have to be suitable for the technique.

Traversing on the same invert is possible.

To enable conveying or to improve steering, the existing pipe can previously be filled with suitable

material.

Additional measures in water-bearing soil depend on the technique employed.

Key

1 target pit 7 jacking device

2 cutting head 8 jacking pipe

3 hydraulic unit 9 auxiliary pipe

4 conveying bucket 10 auger

5 starting pit 11 existing old pipe

6 compressor

Figure 13 — Example of replacement by pipe eating

6.2.3.2 Pilot pipe jacking

Pilot pipe jacking is a multi-phase method displacing or excavating the soil (see Figure 14). In the first

phase a steered rigid pilot pipe is accurately installed. The alignment control is usually done by means of

a theodolite with electric camera or by means of a laser. The direction is changed by means of a steering

face (e.g. pilot point) by utilizing the reaction force of the ground.

Afterwards, sleeve or product pipes of the same or of a greater external diameter are driven

simultaneously pushing or pulling the pilot pipes out. Larger external diameters require extension by soil

displacement or excavation in one or more working steps.

In water-bearing soils, additional measures can be necessary.

a) Insertion of pilot pipe

b) Insertion of sleeve pipe

c) Insertion of product pipe

Key

1 pilot pipe head 6 starting pit

2 pilot pipe 7 jacking device

3 hydraulic unit 8 target pit

4 theodolite 9 extension

5 expander 10 product pipe

Figure 14 — Example of the process of pilot pipe jacking

6.2.3.3 Directional drilling (also called HDD – Horizontal directional drilling)

Directional drilling (see Figure 15) is using a machine in which flexible rods are rotated and pushed,

propelling a cutter which is generally slant headed through the ground. Steering is accomplished by the

reaction of the slant head against the ground when pushed without rotation. Supported by a location

device, this enables a pilot hole to be established to a planned line and grade, after which the hole is

enlarged by pulling back a rotating reamer. Simultaneously or in a separate process the product pipe is

pulled into the bore hole.

There are many different types of cutter to enable steering capability to be maintained in difficult ground

conditions such as rock, where a slant head cutter will not work effectively. No steering is done with

reamers.

When drilling, the soil or rock cuttings shall be removed. As drilling proceeds, this is carried out from the

hole by the drilling fluid that is continually pumped down the drilling rods, serving also to cool the

cutter/reamer, and support the hole to prevent it collapsing.

Key

1 HDD rig 9 back reamer for pipe pulling

2 measuring cable 10 swivel

3 bent sub 11 new pipe

4 non-magnetic drill rod 12 pulling head

5 probe/sonde/beacon 13 location device

6 drill head a) first process step

7 drill rod b) second process step

8 back reamer for bore hole expansion c) third process step

Figure 15 — Example of the process of horizontal directional drilling

6.3 Manned techniques

6.3.1 General

Manned pipe jacking techniques are marked by constant employment of personnel in the pipe string

and/or in the jacking machine during jacking.

6.3.2 Non-steerable techniques

In front of the pipeline, a steel jacket is driven in an unsteered way. Under the protection of this steel

jacket, the soil at the working face is excavated and removed. In water-bearing soils, additional measures

become necessary (groundwater lowering, soil stabilization, compressed air, etc.).

6.3.3 Steerable techniques

6.3.3.1 General

In these one-stage techniques, a pipe stri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...