EN 13892-1:2002

(Main)Methods of test for screed materials - Part 1: Sampling, making and curing specimens for test

Methods of test for screed materials - Part 1: Sampling, making and curing specimens for test

This European standard specifies a method for sampling of mixed screed materials, making and curing of specimens for subsequent testing. This method applies to dry material (bagged or bulk) or to freshly mixed screed materials (ready mixed or site mixed) or to products supplied in pre-packaged form or in packs ready for mixing. This method applies for mortars of cementitious-, calcium sulfate-, magnesite- and synthetic resin screed material. For mastic asphalt screed material see EN 12697-20 and EN 12697-21.

Prüfverfahren für Estrichmörtel und Estrichmassen - Teil 1: Probenahme, Herstellung und Lagerung der Prüfkörper

Diese Europäische Norm legt ein Verfahren für die Probenahme von Estrichmörteln und Estrichmassen, die Herstellung und Lagerung (Nachbehandlung) von Prüfkörpern für nachfolgende Prüfungen fest.

Dieses Verfahren gilt für trockene Estrichmörtel und -massen (in Säcken oder als Schüttgut), Frischestrichmörtel (fertiggemischt oder baustellengemischt) oder für Produkte, die als Fertigmörtel oder als mischfertige Packungen geliefert werden.

Diese Norm gilt

¾ für Proben von Fertigestrichmörteln und -massen, die vom Hersteller während der Produktion und/oder vor dem Ver-sand, vom Auftragnehmer oder Kunden vor oder während der Verwendung und nachträglich entnommen wurden, falls bei einer der interessierten Seiten Zweifel auftreten, und

¾ für Proben vom fertigen Mischgut vor dem Verlegen.

Dieses Verfahren ist auf Zement-, Calciumsulfat-, Magnesia- und Kunstharzestrichmörtel anwendbar. Gussasphalt-estrichmassen siehe prEN 12697-20 und prEN 12697-21. Bei speziellen Kunstharzestrichmörteln können bestimmte Verfahren nach Anweisungen des Herstellers erforderlich sein.

Méthodes d'essai des matériaux pour chapes - Partie 1: Echantillonnage, confection et cure des éprouvettes d'essai

La présente Norme européenne spécifie une méthode pour procéder à l'échantillonnage des matériaux pour chapes, à la confection et à la cure des éprouvettes destinées aux essais ultérieurs.

Cette méthode s'applique aux matériaux secs (ensachés ou en vrac) ou aux matériaux pour chapes fraîchement malaxés (pré-malaxés ou malaxés sur le chantier) ou aux produits fournis sous forme pré-conditionnée ou en sacs prêts au malaxage.

La présente norme s'applique aux :

échantillons des matériaux pour chape ensachés prélevés par le fabricant pendant la fabrication et/ou avant l'expédition, prélevés par le maître d'�uvre ou client avant ou pendant la durée de l'utilisation et par la suite en cas de litige par l'une des parties, ainsi que les échantillons du produit malaxé avant la pose.

Cette méthode s'applique aux mortiers préparés avec des matériaux pour chapes à base de ciment, de sulfate de calcium, de magnésie ou de résine synthétique. En ce qui concerne les matériaux pour chapes en asphalte coulé, se reporter au prEN 12697-20 et au prEN 12697-21. Certaines méthodes conformes aux instructions des fabricants peuvent être nécessaires pour certains matériaux spéciaux à base de résine synthétique.

Metode preskušanja za mešanice za estrih – 1. del: Vzorčenje, priprava in negovanje preskusnih vzorcev

General Information

- Status

- Published

- Publication Date

- 19-Nov-2002

- Withdrawal Date

- 30-May-2003

- Technical Committee

- CEN/TC 303 - Floor screeds and in-situ floorings in buildings

- Drafting Committee

- CEN/TC 303/WG 2 - Test methods

- Current Stage

- 9060 - Closure of 2 Year Review Enquiry - Review Enquiry

- Start Date

- 03-Jun-2024

- Completion Date

- 03-Jun-2024

- Directive

- 89/106/EEC - Construction products

Overview

EN 13892-1:2002 (CEN) specifies standardized procedures for the sampling, making and curing of specimens from screed materials to be used in subsequent laboratory testing. The method applies to dry (bagged or bulk) and freshly mixed screeds (ready-mixed or site-mixed) and to pre-packaged products. Covered screed types include cementitious, calcium sulphate, magnesite and synthetic resin materials. Mastic asphalt screeds are excluded (see EN 12697-20 / EN 12697-21).

This part of EN 13892 ensures that specimens are representative and prepared consistently so that test results for strength, wear, bond and other properties are reliable and comparable across laboratories and projects.

Key Topics

Sampling: Use a metal or rigid plastic receptacle (minimum ~1 L scoop) and clean airtight containers. Minimum sample mass is typically 5000 g; full packages (e.g. a 25 kg sack) should be included when required for representativity. Samples likely to change in air must be sealed immediately.

Mixing: Follow the manufacturer’s instructions and indicated liquid content. When an EN 196-1 mortar mixer is used, liquids are added over 15 s, mixed low speed for 45 s, the bowl is scraped, then mixed a further 1 min (or per manufacturer). When using a concrete mixer, water is added over 15 s and mixing is completed with an additional 120–180 s until uniform. Test room, materials and equipment temperature should be (20 ± 5) °C unless otherwise stated.

Specimen making: Moulds shall be non-reactive (steel or equivalent) and sized according to the test method (for example, 160 × 40 × 40 mm prisms for flexural/compressive tests). Mould filling and compaction methods vary by consistency: flowing mixes are poured in one operation; stiffer mixes may be compacted in layers using a tamper, shock table or vibration table in line with EN 196-1.

Curing and storage: Storage chambers must maintain (20 ± 2) °C or (23 ± 2) °C with controlled relative humidity options (e.g. 95%, 65% or 50% ±5%). Specific storage times and conditions are defined by material type and test (see Table 3 of the standard).

Test report requirements: Reports must record sampling method/time/place, product identification, batch references, mixing and curing details, who participated in sampling/preparation, and any manufacturer instructions followed.

Applications

- Provides a harmonized basis for specimen preparation used in strength, wear, bond, hardness and durability testing of screed materials.

- Supports quality control, acceptance testing on site, and objective resolution in supplier/contractor disputes.

- Useful for laboratory test protocols, product development and certification of screed materials.

Related Standards

- EN 13813 - Screed material properties and requirements

- EN 13892-2 to EN 13892-8 - Test methods for flexural/compressive strengths, wear, hardness and bond

- EN 196-1 / EN 196-7 - Cement mixing and sampling methods referenced for certain mixing/sampling procedures

- prEN 12697-20 / prEN 12697-21 - Mastic asphalt test methods (for mastic asphalt screeds)

For implementation, follow the full EN 13892-1:2002 text and the referenced parts for each specific test method and material type. The standard ensures consistent specimen preparation for reproducible and defensible test results in flooring projects.

Frequently Asked Questions

EN 13892-1:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Methods of test for screed materials - Part 1: Sampling, making and curing specimens for test". This standard covers: This European standard specifies a method for sampling of mixed screed materials, making and curing of specimens for subsequent testing. This method applies to dry material (bagged or bulk) or to freshly mixed screed materials (ready mixed or site mixed) or to products supplied in pre-packaged form or in packs ready for mixing. This method applies for mortars of cementitious-, calcium sulfate-, magnesite- and synthetic resin screed material. For mastic asphalt screed material see EN 12697-20 and EN 12697-21.

This European standard specifies a method for sampling of mixed screed materials, making and curing of specimens for subsequent testing. This method applies to dry material (bagged or bulk) or to freshly mixed screed materials (ready mixed or site mixed) or to products supplied in pre-packaged form or in packs ready for mixing. This method applies for mortars of cementitious-, calcium sulfate-, magnesite- and synthetic resin screed material. For mastic asphalt screed material see EN 12697-20 and EN 12697-21.

EN 13892-1:2002 is classified under the following ICS (International Classification for Standards) categories: 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13892-1:2002 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/EXP. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 13892-1:2002 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

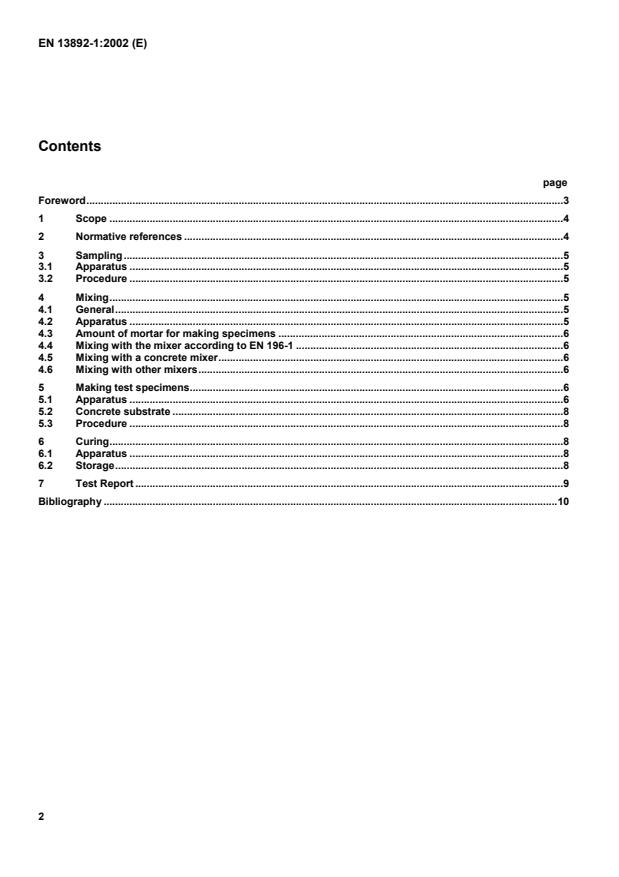

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Methods of test for screed materials - Part 1: Sampling, making and curing specimens for testMéthodes d'essai des matériaux pour chapes - Partie 1: Echantillonnage, confection et cure des éprouvettes d'essaiPrüfverfahren für Estrichmörtel und Estrichmassen - Teil 1: Probenahme, Herstellung und Lagerung der Prüfkörper91.100.10Cement. Mavec. Apno. MaltaCement. Gypsum. Lime. MortarICS:SIST EN 13892-1:2003enTa slovenski standard je istoveten z:EN 13892-1:200201-september-2003SIST EN 13892-1:2003SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13892-1November 2002ICS 91.100.10English versionMethods of test for screed materials - Part 1: Sampling, makingand curing specimens for testMéthodes d'essai des matériaux pour chapes - Partie 1:Echantillonnage, confection et cure des éprouvettes d'essaiPrüfverfahren für Estrichmörtel und Estrichmassen - Teil 1:Probenahme, Herstellung und Lagerung der PrüfkörperThis European Standard was approved by CEN on 9 October 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13892-1:2002 E

wear resistance-Böhme.EN 13892-4,Test Methods for screed materials – Part 4 : Determination of wear resistance-BCA.prEN 13892-5,Methods of test for screed materials – Part 5 : Determination of wear resistance to rolling wheel -Methods for screed material for wearing layer. EN 13892-6,Test Methods for screed materials –Part 6 : Determination of surface hardness.prEN 13892-7,Test Methods for screed materials – Part 7 : Determination of resistance to rolling wheel –Methods for screed material with floor coverings. EN 13892-8,Test Methods

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...