EN 14730-1:2006

(Main)Railway applications - Track - Aluminothermic welding of rails - Part 1: Approval of welding processes

Railway applications - Track - Aluminothermic welding of rails - Part 1: Approval of welding processes

This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions.

It applies to the joining of new, Vignole rails as described in EN 13674-1 of the same profile and steel grade.

Compliance with the requirements of this standard does not of itself ensure the suitability of a welding process for specific conditions of track and traffic.

The standard does not cover welds made between different rail sections, differently worn rails and different rail grades.

In addition to the definitive requirements this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied.

Bahnanwendungen - Oberbau - Aluminothermisches Schweißen von Schienen - Teil 1: Zulassung der Schweißverfahren

Diese Norm definiert Laborprüfungen und Anforderungen zur Zulassung eines aluminothermischen Schweißverfahrens an unter Werkstattbedingungen hergestellten Schweißungen.

Diese Norm umfasst die Verbindung von Vignolschienen, wie in EN 13674-1 beschrieben, des gleichen Profils und gleicher Stahlsorte.

Die Erfüllung der Anforderungen dieser Norm bedingt jedoch nicht notwendigerweise die Eignung des Schweißprozesses für spezifische Bedingungen im Oberbau und im Betrieb.

Die Norm berücksichtigt nicht die Schweißungen von unterschiedlichen Schienen-Querschnitten, unterschiedlich abgenutzten Schienen und unterschiedlichen Stahlsorten.

Zusätzlich zu den in dieser Norm definierten Anforderungen sind auch die in Abschnitt 4 beschriebenen Forderungen zu dokumentieren. Für die Übereinstimmung mit dieser Norm sind sowohl die definierten Anforderungen als auch die zu dokumentierenden Dinge zu erfüllen.

Applications ferroviaires - Soudage des rails par aluminothermie - Partie 1 : Approbation des procédés de soudage

La présente Norme définit ces essais de laboratoire et les exigences pour l’approbation d’un procédé de soudage des rails par aluminothermie.

Elle s’applique à l’assemblage de rails Vignole neufs tels que décrits dans l'EN 13674-1, de même profil et de même nuance d’acier.

La conformité aux exigences de la présente Norme n’assure pas par elle-même l’aptitude à l’emploi d’un procédé de soudage dans des conditions spécifiques de voie ferrée et de trafic.

La présente Norme ne s'applique pas au soudage des rails de profils, d'usures ou de nuances différentes.

Outre les exigences définitives, la présente Norme exige également que les éléments détaillés à l’article 4 soient documentés. Pour être conforme à la présente Norme, il est essentiel que les exigences définitives ainsi que les éléments à documenter soient remplis.

Železniške naprave – Zgornji ustroj – Aluminotermično varjenje tirnic – 1. del: Odobritev varilnega postopka

General Information

- Status

- Withdrawn

- Publication Date

- 01-Aug-2006

- Withdrawal Date

- 06-Jul-2010

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 4 - Rails

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 07-Jul-2010

- Completion Date

- 07-Jul-2010

Relations

- Effective Date

- 18-Jan-2023

Get Certified

Connect with accredited certification bodies for this standard

National Aerospace and Defense Contractors Accreditation Program (NADCAP)

Global cooperative program for special process quality in aerospace.

CARES (UK Certification Authority for Reinforcing Steels)

UK certification for reinforcing steels and construction.

DVS-ZERT GmbH

German welding certification society.

Sponsored listings

Frequently Asked Questions

EN 14730-1:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Aluminothermic welding of rails - Part 1: Approval of welding processes". This standard covers: This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions. It applies to the joining of new, Vignole rails as described in EN 13674-1 of the same profile and steel grade. Compliance with the requirements of this standard does not of itself ensure the suitability of a welding process for specific conditions of track and traffic. The standard does not cover welds made between different rail sections, differently worn rails and different rail grades. In addition to the definitive requirements this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied.

This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions. It applies to the joining of new, Vignole rails as described in EN 13674-1 of the same profile and steel grade. Compliance with the requirements of this standard does not of itself ensure the suitability of a welding process for specific conditions of track and traffic. The standard does not cover welds made between different rail sections, differently worn rails and different rail grades. In addition to the definitive requirements this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied.

EN 14730-1:2006 is classified under the following ICS (International Classification for Standards) categories: 25.160.10 - Welding processes; 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14730-1:2006 has the following relationships with other standards: It is inter standard links to EN 14730-1:2006+A1:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14730-1:2006 is associated with the following European legislation: EU Directives/Regulations: 93/38/EEC; Standardization Mandates: M/024. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 14730-1:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Railway applications - Track - Aluminothermic welding of rails - Part 1: Approval of welding processesApplications ferroviaires - Soudage des rails par aluminothermie - Partie 1 : Approbation des procédés de soudageBahnanwendungen - Oberbau - Aluminothermisches Schweißen von Schienen - Teil 1: Zulassung der SchweißverfahrenTa slovenski standard je istoveten z:EN 14730-1:2006SIST EN 14730-1:2007en45.080Rails and railway components25.160.10Varilni postopki in varjenjeWelding processesICS:SLOVENSKI

STANDARDSIST EN 14730-1:200701-januar-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14730-1August 2006ICS 25.160.10; 45.080 English VersionRailway applications - Track - Aluminothermic welding of rails -Part 1: Approval of welding processesApplications ferroviaires - Soudage des rails paraluminothermie - Partie 1 : Approbation des procédés desoudageBahnanwendungen - Oberbau - AluminothermischesSchweißen von Schienen - Teil 1: Zulassung derSchweißverfahrenThis European Standard was approved by CEN on 12 June 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14730-1:2006: E

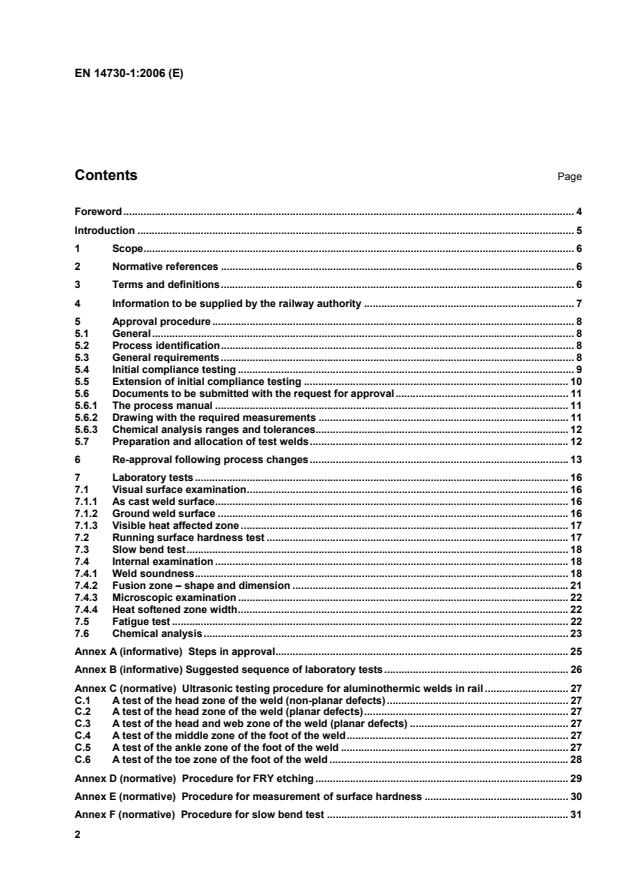

Steps in approval.25 Annex B (informative) Suggested sequence of laboratory tests.26 Annex C (normative)

Ultrasonic testing procedure for aluminothermic welds in rail.27 C.1 A test of the head zone of the weld (non-planar defects).27 C.2 A test of the head zone of the weld (planar defects).27 C.3 A test of the head and web zone of the weld (planar defects).27 C.4 A test of the middle zone of the foot of the weld.27 C.5 A test of the ankle zone of the foot of the weld.27 C.6 A test of the toe zone of the foot of the weld.28 Annex D (normative)

Procedure for FRY etching.29 Annex E (normative)

Procedure for measurement of surface hardness.30 Annex F (normative)

Procedure for slow bend test.31

Procedure for recording test weld fracture face defects.32 Annex H (normative)

Ultrasonic inspection procedure on aluminothermic welds to be sectioned.34 H.1 Principle.34 H.2 Apparatus.34 H.3 Preparation of samples.34 H.4 Calibration.34 H.5 Testing.35 H.6 Reporting.35 Annex I (normative)

Procedure for microscopic examination of the visible heat affected zone and fusion zone of welds.36 Annex J (normative)

Procedure for measurement of the heat softened zone width.37 J.1 Measurement of hardness.37 J.2 Evaluation of hardness data.38 J.2.1 General.38 J.2.2 Mean hardness of parent rail.38 J.2.3 Measurement hardness line.38 J.2.4 Heat softened zone width measurement.39 J.2.5 Parent rail hardness variation.39 Annex K (normative)

Fatigue test methods for aluminothermic welds.40 K.1 Scope.40 K.2 Test equipment.40 K.3 Calibration procedure.41 K.3.1 General.41 K.3.2 Test piece.41 K.3.3 Test piece preparation.41 K.3.4 Instrumentation.42 K.3.5 Procedure.42 K.4 Fatigue test method.45 K.4.1 General.45 K.4.2 Staircase testing method.45 K.4.3 Example of the data analysis of a fatigue strength determination by the staircase method.47 K.4.4 Past-the-post testing method.48 Annex L (informative)

A–deviations.49

1 Scope This standard defines the laboratory tests and requirements for approval of an aluminothermic welding process using welds produced in workshop conditions. It applies to the joining of new, Vignole rails as described in EN 13674-1 of the same profile and steel grade. Compliance with the requirements of this standard does not of itself ensure the suitability of a welding process for specific conditions of track and traffic. The standard does not cover welds made between different rail sections, differently worn rails and different rail grades. In addition to the definitive requirements this standard also requires the items detailed in Clause 4 to be documented. For compliance with this standard, it is important that both the definitive requirements and the documented items be satisfied. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 473, Non destructive testing – Qualification and certification of NDT personnel – General principles EN 13674-1, Railway applications – Track – Rail – Part 1: Vignole railway rails 46 kg/m and above EN ISO 6506-1, Metallic materials - Brinell hardness test - Part 1: Test method (ISO 6506-1:2005) EN ISO 6507-1, Metallic materials - Vickers hardness test - Part 1: Test method (ISO 6507-1:2005) EN ISO 7500-1:2004, Metallic materials – Verification of static uniaxial testing machines – Part 1: Tension/compression testing machines – Verification and calibration of the force-measuring system (ISO 7500-1:2004) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 fusion zone area of the weld which has been in a liquid state and which is revealed by etching sections cut through the weld 3.2 visible heat-affected zone HAZ areas on either side of the fusion zone within which rail steel microstructure has been visibly modified by the heat of the welding process as revealed by FRY macro-etching

b) Initial compliance with this standard shall be achieved by undertaking the tests specified in category 1 of Table 2 using either grade R220 or grade R260 rail of one profile in either group 1 or 2 of Table 1. Compliance with all the criteria specified and with the railway authority’s documented requirements specified in Clause 4 shall be demonstrated. A test sequence is outlined in informative Annex B. A test specimen can be used for several different tests.

Category 2b

Category 3c

Test Section Reference

R200/R220/ R260/R260Mn R320Cr R350HT R350LH T A Hardness Test 7.2 6 Nil 6 6 ____6_____ B Surface Examination - Visual 7.1.1 7.1.2 All All All All _____All_____ C Visible Heat Affected Zone 7.1.3 2 2 2 2 ______2_____ D Slow Bend Test 7.3

6 2 2 6 _____6______ E Ultrasonic Inspection - Annex H 7.4.1.1 5 2 Nil Nil Nil Nil F Fatigue Test 7.5 n* Nil Nil n* Nil n* 7.4.1 5 2 Nil Nil Nil Nil 7.3 (6) (2) (2) (2) ______2_____ G Fusion Zone -Weld Soundness 7.5.3 (n*) Nil Nil (n*) Nil n* H Fusion Zone

- Shape and Dimensions 7.4.2 5 2 Nil Nil Nil Nil I Chemical Analysis 7.6 3 Nil 3 3 ______3______ J Heat Softened Zone

- Hardness Distribution 7.4.4 2 2 2 2 ______2_______ 1 1 ______1_______ K Structure

- Fusion Zone

- Heat Affected Zone 7.4.3.3 7.4.3.2 1 1 Nil Nil 1 1 ______1_______ L Ultrasonic Inspection - Annex C 5.7 d) All All All All All All NOTE 1 n* indicates the number of welds required for one staircase or past the post evaluation. Typically 10 test pieces will be required for a staircase and 3 for a past the post evaluation. NOTE 2 ____X____ indicates that tests in one rail grade cover the other indicated grade NOTE 3 ( ) indicates weld soundness evaluation of the fracture face of the slow bend test or fatigue specimens a Category 1 Initial tests to be conducted using R220 or R260 grade rail and one profile from either of rail profile groups 1 or 2 (Table 1). b Category 2 Tests to be carried out on one profile from each of the remaining rail profile groups in order to extend approval to that group. c Category 3 Tests required extending approval to other rail grades. Tests on one rail profile cover all profile groups approved in categories 1 and 2.

5.5 Extension of initial compliance testing Initial compliance can be extended as follows: The relevant railway authority requirements defined in Clause 4 a) to k) shall be met for each of the items below: a) To other groups of rail profiles of Table 1 [subclause 5.4 a)] by the tests in category 2 of Table 2 [subclause 5.4 b)] to be conducted on one profile from each of the appropriate groups.

Failure of any test shall cause non-compliance for the group of rail profiles being tested. b) To other rail grades by the tests in category 3 of Table 2 [subclause 5.4 b)]. Failure of any test shall cause non-compliance for that rail grade. Tests on one rail profile cover all profiles in categories 1 and 2. c) To process changes as prescribed by the limits and tests of Clause 6. Failure of the relevant tests of Table 3 shall cause non-compliance of the process change.

Key 1 Figure showing the width of the weld collar around the weld 2 Riser cross section on the neutral axis mm² 3 25 % of the foot width 4 Riser cross section at the foot mm2 5 Longitudinal axis under the rail foot Figure 1 — Dimensions taken from mould pattern 5.6.3 Chemical analysis ranges and tolerances The chemical analysis ranges and tolerances according to 7.6.1. 5.7 Preparation and allocation of test welds a) Welds required for the tests shall be produced in accordance with the process manual (5.6.1) under the supervision of the approving authority recognised by the railway authority. Rails to be used for the production of test welds shall be new rails. Fifty percent of test welds shall be made with minimum gap and fifty percent at maximum gap. b) Welding gap shall be measured after weld alignment (peaking) on both sides of the rail head (or on the running surface), web mid point and both foot tips. The maximum gap is the maximum at any of the above points and minimum the minimum of any of the above points. c) The weld gap for all welds made for Table 2 tests shall be within the specified range. In the case of the welds required for test H in category 1 of Table 2, three welds shall be produced at the minimum gap and two at the maximum, and for category 2 of Table 2, one weld at the maximum gap and one weld at the minimum gap. Measurements shall be made to an accuracy of ± 0,5 mm. d) All welds shall be tested ultrasonically using the procedure given in Annex C and the results recorded.

(max.) 10 15 20 3 2 1

The number and dimensions of slag or sand inclusions shall not exceed the values specified in the information supplied by the railway authority [Clause 4 b)]: the condition of the surface left by riser removal (other than that on the ground rail head) shall conform with the requirements specified in the information supplied by the railway authority [(Clause 4 c)]. 7.1.2 Ground weld surface The head and the ground weld collar surface on either side of the rail head shall comply with the following: There shall be no cracks. Joints between weld collars and rail and flashing and rail are not cracks; There shall be no defects (pores, slag, sand inclusions, metal beads) with a dimension greater than 1 mm or limit fixed by the railway authority if the limit is less than 1 mm [Clause 4 d)]; A defect with a maximum dimension of 2 mm shall be accepted in the hatched zone 1 of Figure 2 for no more than 10 % of the test welds or one weld if fewer than 10 welds; Any additional non-destructive testing requirements specified in the information supplied by the railway authority [Clause 4, e)].

Key 1 Zone with a 2 mm radius 2 Rail head 3 Weld collar 4 Rail web Figure 2 — Ground collar surface 7.1.3 Visible heat affected zone Following FRY etching in accordance with Annex D the visible heat affected zones on each side of the weld shall be measured on the rail running surface centre line. Their widths shall not exceed 20 mm, 30 mm or 40 mm as specified in the information supplied by the railway authority [Clause 4 f)]. The visible heat affected zone shall be nominally symmetrical about the longitudinal axis of the rail and transverse axis of the weld. 7.2 Running surface hardness test Measurements shall be made in accordance with Annex E. The average of the three hardness measurements made on each weld shall fall within the range given in Table 5 for the appropriate parent rail grade. Table 5 — Ranges for running surface hardness tests Rail grade Hardness range HBW

Rail running surface on the unaffected parent rail Weld centre-line R200 200 to 240 230 ± 20 R220 220 to 260 250 ± 20 R260 260 to 300 280 ± 20 R260 260 to 300 300 ± 20 R260Mn 260 to 300 280 ± 20 R320Cr 320 to 360 330 ± 20 R350HT 350 to 390 350 ± 20 R350LHT 350 to 390 350 ± 20 NOTE 0,5 mm should be ground from the running surface before a hardness impression is made.

NOTE The centre-line hardness of the welds for the chromium alloyed and for the heat-treated grades is established below the hardness values of the rail running surface to ensure a fully pearlitic structure. The hardness profile along the rail crown centre-line of welds varies with the level of alloying element additions, with higher alloyed welds showing a relatively higher hardness at the weld edges. Therefore to achieve the correct average hardness a lower centre-line hardness is required. 7.3 Slow bend test Details of the slow bend test procedure are given in Annex F. The minimum fracture load (kN), rounded to the nearest 5 kN is defined by the equation F = 0,0032·S (equivalent to a minimum tensile bending strength of 800 MPa), where S (mm3) is the section modulus for the base of the rail, given in EN 13674-1. An alternative F = 0,003·S may be used for R320Cr rail grade when specified by the railway authority. The formula given shall be specified. The fracture face shall be subject to the soundness examination in accordance with 7.4.1.5 and a record made in accordance with Annex G. If the origin of any ultrasonic response is not revealed by slow bend testing, no further investigation is required. 7.4 Internal examination 7.4.1 Weld soundness 7.4.1.1 The head, web and foot of the rail containing the weld, (see Figure 3), shall be examined ultrasonically in accordance with Annex H. The positions of any apparent defects found by ultrasonic testing shall be recorded so that they may be revealed by sectioning.

Key 1 Head 2 Profile of rail 3 Profile of weld 4 Web 5 Foot Figure 3 — Head, web and foot of the rail

7.4.1.2 The rails containing the welds shall then be sectioned to give: longitudinal vertical section on the symmetry plane (cut 1 in Figure 4); longitudinal vertical sections in the rail foot (cuts 2 in Figure 4); cuts as appropriate at least 5 mm from any apparent defects located by the ultrasonic testing method specified in Annex H. For each defect, the size shall be determined by progressively grinding and measuring until the maximum dimension is found.

Key 1 Longitudinal vertical section on centre line 2 Longitudinal vertical section of foot tip Figure 4 — Sectioning of welds

7.4.1.3 Visual examination of the cut sections (polished to 220 grit) shall show no evidence of lack of fusion between the rail and fusion face. The weld collar's edge is permitted to be unfused to the rail surface for a maximum of 2 mm from the edge of the collar unless a lesser figure is specified in the information supplied by the railway authority [Clause 4, h)]. 7.4.1.4 The maximum dimension of any pores, slag inclusions, sand inclusions or metal beads shall be recorded. If multiple defects are revealed, they shall be counted and measured as a single defect if they are less than 1 mm apart. The maximum dimension of each defect shall be grouped in 1 mm size bands for the head, web and foot and summed for the number of sectioned welds examined in each test category of test G in Table 2 and Table 3. The size bands shall be as follows: Greater than 0 mm to 1 mm; Greater than 1 mm to 2 mm; Greater than 2 mm to 3 mm, etc. Per population of test welds in test G in Tables 2 and 3: no more than one defect with maximum dimension greater than 2 mm in the region of the head above the line A-A on Figure 3 shall be permitted.

Key * Datum marks on foot tip 1 Fusion line 2 Rail ends before welding 3 Rail head 4 Rail foot Figure 5 — Shape of fusion zone on the etched longitudinal vertical section

7.5 Fatigue test 7.5.1 Fatigue strength shall be evaluated by the staircase or past the post procedure in accordance with Annex K. 7.5.2 The fatigue strength in terms of the mean fatigue strength and standard deviation for the staircase method or the minimum value of upper stress in the rail foot for the past the post method shall comply with the information supplied by the railway authority [Clause 4 j)]. 7.5.3 All test pieces remaining unbroken after fatigue testing shall be broken by slow bending in order to examine the fracture faces. For staircase testing the fracture faces of those welds broken during fatigue testing shall be examined visually. If fatigue has initiated at a lack of fusion defect, the process shall be rejected.

Minimum Maximum

Carbon 0,30 0,35 0,40 0,50 0,55 0,70 0,75 0,85 ± 0,12 ± 0,12 ± 0,12 ± 0,12 R200 R220 R260, R260Mn R320Cr, R350HT, R350LHT Silicon 0,00 1,20 ±0,25 All Manganese 0,40 0,45 0,50 0,50 1,00 1,20 1,40 1,60 ± 0,20 ± 0,20 ± 0,20 ± 0,20 R200 R220 R260, R320Cr, R350HT, R350LHT R260Mn Phosphorous 0,00 0,035 All Sulphur 0,00 0,035 All Chromium 0,00 0,00 0,20 0,80 ± 0,20 R200, R220, R260, R260Mn R320Cr, R350HT, R350LHT Molybdenum 0,00 0,10 All Nickel 0,00 0,10 All Aluminium 0,02 0,60 ± 0,20 All Copper 0,00 0,20 All Tin 0,00 0,02 All Antimony 0,00 0,02 All Titanium 0,00 0,05 All Niobium 0,00 0,01 All Vanadium 0,00 0,00 0,00 0,25 0,45 0,65 R200, R220, R260, R260Mn R320Cr R350HT, R350LHT

Steps in approval

INITIAL APPROVAL One section from rail groups 1 or 2Rail Grade R220 or R260 TESTS: Table 2 Category 1

EXTENSIONOF APPROVAL

OTHER RAIL PROFILES (as required) One section of group 1 or 2 (as appropriate) 3 and 4 Tests: Table 1 Category 2

OTHER RAIL GRADES (as required) R200, R220, R260, R260Mn, R350HT, R350LHT Tests: Table 1 Category 3

PROCESS CHANGES Changes detailed in Clause 6Tests: Ta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...