EN 12101-1:2005

(Main)Smoke and heat control systems - Part 1: Specification for smoke barriers

Smoke and heat control systems - Part 1: Specification for smoke barriers

This part of EN 12101 specifies the product performance requirements, classifications and test methods for smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices, designed for use in smoke and heat control systems. It covers only barriers installed in buildings, i.e. it does not cover barriers made of part of the building's structure. This standard provides the test methods for, and evaluation of conformity of, the smoke barrier systems.

Rauch- und Wärmefreihaltung - Teil 1: Bestimmungen für Rauchschürzen

Diese Europäische Norm spezifiziert die Leistungsanforderungen an die Produkte sowie Klassifizierungs- und Prüfverfahren für Rauchschürzen, welche die Rauchschürze mit oder ohne zugehörige Antriebs- und Auslöseeinheiten umfasst, die für den Einsatz in Anlagen zur Rauchfreihaltung ausgelegt werden. Sie gilt nur für in Gebäuden installierte Rauchschürzen, d. h., diese Europäische Norm gilt nicht für als Rauchschürzen genutzte Bauteile des Bauwerks. Diese Norm beinhaltet die Prüfverfahren und die Vorgehensweise zur Beurteilung der Konformität für Rauchschürzensysteme..

Systèmes pour le contrôle des fumées et de la chaleur - Partie 1: Spécifications relatives aux écrans de cantonnement de fumée

Cette partie de norme européenne spécifie les exigences et donne les méthodes d d'essais pour les écrans de cantonnement de fumées qu'il est projeté d'installer en tant que composant d'un système d'évacuation de fumées et de la chaleur, conformément à prEN BKXF 4 et prEN BKXF 5.

Sistemi za nadzor dima in toplote – 1. del: Določila za ovire proti širjenju dima

General Information

- Status

- Published

- Publication Date

- 30-Aug-2005

- Withdrawal Date

- 30-Aug-2008

- Technical Committee

- CEN/TC 191 - Fixed firefighting systems

- Drafting Committee

- CEN/TC 191/SC 1/WG 1 - Smoke barriers

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 12-Oct-2010

- Completion Date

- 12-Oct-2010

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Amended By

EN 12101-1:2005/A1:2006 - Smoke and heat control systems - Part 1: Specification for smoke barriers - Effective Date

- 22-Dec-2008

- Effective Date

- 18-Jan-2023

Overview

EN 12101-1:2005 - “Smoke and heat control systems - Part 1: Specification for smoke barriers” is a CEN European Standard that defines product performance, classification and test methods for smoke barriers used in buildings as part of smoke and heat control systems (SHEVS). The standard covers both static and active smoke barriers (with or without activation/drive devices) and focuses on smoke containment, classification by performance, and procedures for evaluation of conformity and CE marking. It does not apply to barriers that form part of a building’s structural elements.

Key topics and technical requirements

- Product requirements and barrier types: definitions for static smoke barriers (SSB) and active smoke barriers (ASB), permitted materials and configurations.

- Performance classifications: temperature/time classifications and containment performance ranges for smoke barriers.

- Smoke leakage / containment efficiency: test methods for smoke (fire effluent) permeability and allowable leakage rates.

- Reliability, durability and response time: requirements and tests for service life, actuation reliability, response time of active systems and auxiliary power supply.

- Evaluation of conformity: procedures for initial type testing, Factory Production Control (FPC) and certification for CE marking.

- Installation, maintenance, marking: guidance on installation, ongoing maintenance and labelling to ensure in-service performance.

- Normative and informative annexes: include test procedures (temperature/time resistance, permeability, deflection), reporting formats and relationship to the EU Construction Products Directive.

Keywords: EN 12101-1:2005, smoke barriers, SHEVS, smoke leakage, response time, conformity assessment, CE marking.

Applications and who uses it

Practical uses of EN 12101-1:2005 include design, specification, testing and procurement of smoke containment elements in buildings. Typical applications:

- Smoke reservoir boundaries and channelling screens

- Void edge and void sealing screens

- Corridor, stairwell, escalator and elevator well containment

- Shop unit and compartment containment

Primary users:

- Manufacturers developing or certifying smoke barrier products

- Fire safety engineers and consultants specifying SHEVS components

- Test laboratories performing initial type testing and conformity assessments

- Installers and maintenance teams ensuring correct installation and serviceability

- Building owners, specifiers and authorities seeking compliance and CE-marked products

Related standards

EN 12101 is a multi-part series - relevant parts include:

- EN 12101-2 (natural ventilators), EN 12101-3 (powered ventilators), EN 12101-4 (kits), EN 12101-7 (smoke control ducts), EN 12101-8 (smoke control dampers), EN 12101-9 (control panels), EN 12101-10 (power supplies).

Normative references used: EN 1363‑1, EN 1363‑2, EN 1634‑3, prCEN/TR 12101‑4 and EN ISO 9001.

EN 12101-1:2005 is essential when specifying or verifying smoke barrier performance within comprehensive smoke and heat control strategies.

Get Certified

Connect with accredited certification bodies for this standard

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Kiwa BDA Testing

Building and construction product certification.

Sponsored listings

Frequently Asked Questions

EN 12101-1:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Smoke and heat control systems - Part 1: Specification for smoke barriers". This standard covers: This part of EN 12101 specifies the product performance requirements, classifications and test methods for smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices, designed for use in smoke and heat control systems. It covers only barriers installed in buildings, i.e. it does not cover barriers made of part of the building's structure. This standard provides the test methods for, and evaluation of conformity of, the smoke barrier systems.

This part of EN 12101 specifies the product performance requirements, classifications and test methods for smoke barriers, which comprise the barrier itself, with or without associated activation and drive devices, designed for use in smoke and heat control systems. It covers only barriers installed in buildings, i.e. it does not cover barriers made of part of the building's structure. This standard provides the test methods for, and evaluation of conformity of, the smoke barrier systems.

EN 12101-1:2005 is classified under the following ICS (International Classification for Standards) categories: 13.220.99 - Other standards related to protection against fire. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12101-1:2005 has the following relationships with other standards: It is inter standard links to CEN/TR 12101-4:2009, EN ISO 13943:2000, EN 1363-2:1999, EN 1634-3:2004, EN 1363-1:2020, EN ISO 9001:2015, EN 13501-4:2016, EN 13501-4:2007+A1:2009, CEN/TS 12101-11:2022, EN 15269-20:2020, EN 12101-1:2005/A1:2006, EN 12101-1:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12101-1:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/109. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12101-1:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Smoke and heat control systems - Part 1: Specification for smoke barriersSystemes pour le contrôle des fumées et de la chaleur - Partie 1: Spécifications relatives aux écrans de cantonnement de fuméeRauch- und Wärmefreihaltung - Teil 1: Bestimmungen für RauchschürzenTa slovenski standard je istoveten z:EN 12101-1:2005SIST EN 12101-1:2005en13.220.20ICS:SLOVENSKI

STANDARDSIST EN 12101-1:200501-december-2005

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12101-1August 2005ICS 13.220.99 English VersionSmoke and heat control systems - Part 1: Specification forsmoke barriersSystèmes pour le contrôle des fumées et de la chaleur -Partie 1: Spécifications relatives aux écrans decantonnement de fuméeRauch- und Wärmefreihaltung - Teil 1: Bestimmungen fürRauchschürzenThis European Standard was approved by CEN on 16 January 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2005 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12101-1:2005: E

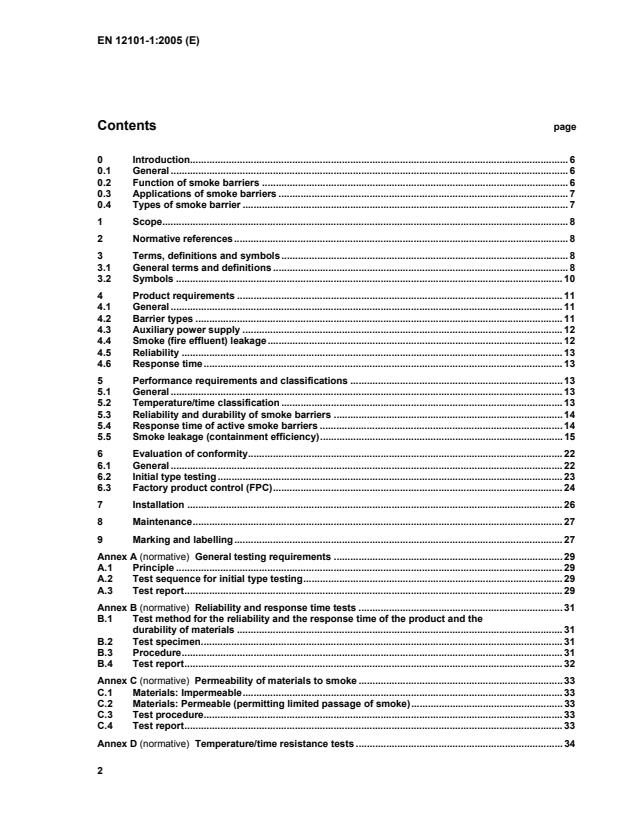

General testing requirements.29 A.1 Principle.29 A.2 Test sequence for initial type testing.29 A.3 Test report.29 Annex B (normative)

Reliability and response time tests.31 B.1 Test method for the reliability and the response time of the product and the durability of materials.31 B.2 Test specimen.31 B.3 Procedure.31 B.4 Test report.32 Annex C (normative)

Permeability of materials to smoke.33 C.1 Materials: Impermeable.33 C.2 Materials: Permeable (permitting limited passage of smoke).33 C.3 Test procedure.33 C.4 Test report.33 Annex D (normative)

Temperature/time resistance tests.34

Deflection of smoke barriers.40 E.1 General.40 E.2 Principle.42 E.3 Barriers not reaching the floor.44 E.4 Barriers closing an opening.45 E.5 Smoke leakage through gaps in barriers.46 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.47 ZA.0 Scope of this annex.47 ZA.1 Relationship between EU Directive and this European Standard.47 ZA.2 Procedure for the attestation of conformity of smoke barriers.48 ZA.3 CE marking.48 ZA.4 Certificate and declaration of conformity.49

which is an integral part of this document. This European Standard is one part of the European Standard EN 12101, which has the general title “Smoke and heat control systems” and consists of the following separate parts: Part 1: Specification for smoke barriers. Part 2: Specification for natural smoke and heat exhaust ventilators. Part 3: Specification for powered smoke and heat exhaust ventilators. Part 4: Fire and smoke control installations — Kits. Part 5: Guidelines on functional recommendations and calculation methods for smoke and heat exhaust ventilation systems (published as CR 12101-5) Part 6: Specification for pressure differential systems — Kits. Part 7: Smoke control ducts. Part 8: Specification for smoke control dampers. Part 9: Control panels. Part 10: Specification for power supplies. EN 12101 is included in a series of European Standards planned also to cover: a) CO2 systems (EN 12094 & EN ISO 14520); b) sprinkler systems (EN 12259); c) powder systems (EN 12416); d) explosion protection systems (EN 26184); e) foam systems (EN 13565); f) hose reel systems (EN 671);

shop unit containment; escalator containment; stairwell containment; elevator well containment. 0.4 Types of smoke barrier Construction works elements can be used to create static smoke barriers, and they can be augmented by smoke barriers covered by this standard. This European Standard applies to the following types of smoke barriers: static smoke barriers: (SSB), active smoke barriers: (ASB). A wide range of different materials may be used to create smoke barriers. Typical materials used for static smoke barriers include fabric, glass, metal, fire-resisting board, fibreglass and mineral wool or any impermeable material capable of resisting the smoke at temperatures required by the design. Typical examples of active smoke barriers include roller, pleated, folding, hinged or sliding, using the types of material as described for static smoke barriers. Static and active smoke barriers are categorized by type and performance in Clause 4. In addition an ASB product is deemed to include all controlling equipment etc. This does not include external controls, for example a fire alarm or a sprinkler flow switch.

3.1 General terms and definitions For the purposes of this European Standard, the terms and definitions given in EN ISO 13943:2000 and the following apply. 3.1.1 active smoke barrier smoke barrier which moves from its retracted position into its fire operational position automatically when called upon to do so 3.1.2 barrier movement travel distance (e.g. height, drop) of an active barrier from its retracted position to its fire operational position 3.1.3 channelling screen smoke barrier installed beneath a balcony or projecting canopy to direct the flow of smoke and hot gases from a room opening to the spill edge 3.1.4 consumable power supplies any form of power that when not available will prevent an active smoke barrier moving to the required fire operational position

The heat exposure at 600°C, designated D, represents the constant temperature of the smoke barrier test. The designations 30, 60, 90, 120 represent the period of the smoke barrier test. A smoke barrier which meets the requirements of D 60 also meets the requirements of D 30; equally, a D 90, or D120, smoke barrier also meets the requirements of D 60 and D 30, and D90, respectively. A DA smoke barrier meets all D requirements. If smoke barriers are to operate at higher time/temperature ranges, they shall be classified in accordance with the classification categories in Table 2. The testing shall meet the time temperature requirements of EN 1363-1.

The performance requirements of smoke barrier test specimens when tested in accordance with Annex D are as follows. a) Test specimens shall conform to A.1. b) Test specimens shall maintain integrity, without either: 1) permitting the penetration of a gap gauge (except for those free areas defined in 4.4.1 and 5.5); 2) resulting in sustained flaming; 3) collapsing. c) Test specimens shall not release flaming droplets or particles within the first 600 s when tested in accordance with this standard. NOTE Observation of any components or droplets falling during the test will be recorded in the test report. When selecting a barrier for a particular application where falling components would be considered a significant threat to occupants, for example where people are expected to escape beneath smoke barriers, the full test report should be obtained and checked. 5.3 Reliability and durability of smoke barriers 5.3.1 Reliability and durability of smoke barriers — Static smoke barriers The manufacturer/supplier shall provide verification that the materials used for static smoke barriers are fit for the purpose intended. For integrity and perforations see B.3, and for gaps see 5.5.3. NOTE This should be done taking into account, for example, breaking loads, tear strength, flexural strength and resistance to flexing requirements valid in the place of use. 5.3.2 Reliability of smoke barriers — Active smoke barriers Active smoke barrier specimens conforming to A.1 shall be tested in accordance with the reliability test in Annex B and shall complete the required number of cycles and shall then not allow the passage of either of the defined gap gauges (except for those free areas defined in 4.4.1 and 5.5). 5.4 Response time of active smoke barriers Active smoke barrier specimens conforming to A.1 shall be tested in accordance with the response time test in annex B and shall operate within the velocity ranges specified in this clause.

afebcd1 Key 1 Barrier NOTE Smoke flow through the head box is controlled by the smallest gap when the barrier is in the fire operational position. Gaps a - f are representative of the potential smallest gaps. It is recommended to use the gap a – f with the smallest value. Figure 1 — Potential gaps within a header box when barrier deployed gggWall111 Key g Gap 1 Barrier 2 Wall Figure 2 — Potential edge gaps between the barrier and surrounding construction

h Key h Gap NOTE The gap is measured with the barriers in their fire operational position. Figure 3 — Gaps between adjacent barriers when overlapped but not conjoined

iD Key i Maximum gap when barriers are in the fire operational condition h = i/2 Figure 4 — Gaps between adjacent barriers when overlapped and conjoined

Figure 5 — Barriers overlapped to have no gaps at the overlap Dh Key h Gap NOTE The gap shown is in the passive condition. Figure 6 — Adjacent barriers with no overlap

(a to f) (mm) Gap edge (g)

(mm) Gap joint (h)

(mm) Area head = W x Gap head (mm2) Area edge = D x Gap edge (mm2) Area joint = D x Gap joint (mm2) Area total = N1 . Area head + N2 . Area edge + N3 . Area joint NOTE 1 For functional reasons gaps can be required between the barrier and the construction works, and for angled and adjacent barriers. In these cases any gap, based on the maximum travel distance specified by the manufacturer should not exceed: a) 20 mm for barriers which travel up to and including 2 m; b) 40 mm for barriers which travel from 2 m up to and including 6 m;

AAA-A1 Key 1 Barrier Figure 8 — Example of static smoke barrier, flexible or rigid material 5.5.4 Deflection Static and active smoke barriers shall perform in accordance with the functional requirements of the system design, other SHEVS design requirements and construction works requirements, for the intended application.

In all tests, the smoke barrier shall be mounted as in practice, including the specified barrier mass and tensioning force, where required to reduce deflection. Deflection shall be assessed using a suitable method of calculating deflection to ensure that it is valid for the application. A method of calculating deflection is given in Annex E. Smoke barriers in continuous, overlapped and conjoined runs provide additional resistance to deflection and smoke leakage. The gaps between adjacent smoke barriers conforming to 5.5.3 will be

1 Key 1 Excessive gaps Figure 9 — Example of excess gap caused by deflection

5.5.5 Permeability of materials Smoke barriers shall be manufactured from materials conforming to Annex C with a maximum leakage rate of 25m³/h/m2 at 25 Pa at ambient temperature or 200 °C. 6 Evaluation of conformity 6.1 General The compliance of a smoke barrier with the requirements of this standard shall be demonstrated by: initial type testing; factory production control.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...