EN 16603-20-01:2020

(Main)Space engineering - Multipactor, design and test

Space engineering - Multipactor, design and test

This standard defines the requirements and recommendations for the design and test of RF components and equipment to achieve acceptable performance with respect to multipactor-free operation in service in space. The standard includes:

- verification planning requirements,

- definition of a route to conform to the requirements,

- design and test margin requirements,

- design and test requirements, and

- informative annexes that provide guidelines on the design and test processes.

This standard is intended to result in the effective design and verification of the multipactor performance of the equipment and consequently in a high confidence in achieving successful product operation.

This standard covers multipactor events occurring in all classes of RF satellite components and equipment at all frequency bands of interest. Operation in single carrier CW and pulse modulated mode are included, as well as multi-carrier operations. A detailed clause on secondary emission yield is also included.

This standard does not include breakdown processes caused by collisional processes, such as plasma formation.

This standard is applicable to all space missions.

This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

Raumfahrttechnik - Multipaction, Konzeption und Test

Ingénierie spatiale - Décharge auto-entretenue, conception et essai

La présente norme définit les exigences et recommandations applicables à la conception et aux essais des composants et équipements RF dans le but d’obtenir des performances acceptables pour un fonctionnement en service sans décharge auto-entretenue dans un environnement spatial. La présente norme couvre les aspects suivants :

- exigences relatives à la planification des activités de vérification ;

- définition d’un mode de mise en conformité aux exigences ;

- exigences relatives à la marge de conception et d'essai ;

- exigences de conception et d’essai ;

- annexes informatives contenant des recommandations sur les processus de conception et d’essai.

La présente norme vise à garantir une conception et une vérification efficaces des performances de décharge auto-entretenue des équipements et, par conséquent, à produire un haut degré de confiance quant au bon fonctionnement du produit.

La présente norme aborde les événements de décharge auto-entretenue survenant dans toutes les classes de composants et d’équipements RF à toutes les bandes de fréquences visées dans des conditions de vide poussé (pression inférieure à 10-5 hPa). Elle couvre également les opérations en mode onde entretenue à une seule porteuse et en mode modulation d’impulsions, ainsi que les opérations non modulées à plusieurs porteuses. Un paragraphe détaillé a également été ajouté sur le rendement d’émission secondaire.

La présente norme ne couvre pas les processus de claquage dus aux collisions, comme la plasmification.

La présente norme s’applique à toutes les missions spatiales.

La présente norme peut être adaptée aux caractéristiques et contraintes spécifiques d’un projet spatial, conformément à l’ECSS-S-ST-00.

Vesoljska tehnika - Multipaction, zasnova in preskušanje

General Information

- Status

- Published

- Publication Date

- 22-Sep-2020

- Withdrawal Date

- 30-Mar-2021

- Technical Committee

- CEN/CLC/TC 5 - Space

- Drafting Committee

- CEN/CLC/TC 5 - Space

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 23-Sep-2020

- Completion Date

- 23-Sep-2020

Relations

- Effective Date

- 30-Sep-2020

- Effective Date

- 09-Feb-2026

Overview

EN 16603-20-01:2020 - Space engineering: Multipaction, design and test is a European space standard that defines requirements and recommendations to ensure multipactor‑free operation of RF components and equipment in space. It covers design, analysis and verification (by test or by analysis) across all satellite RF component classes and frequency bands, including single‑carrier CW, pulsed, and multicarrier operation. The standard is intended to increase confidence in successful product operation and is applicable to all space missions. It may be tailored to project constraints in conformance with ECSS‑S‑ST‑00.

Key technical topics and requirements

This standard addresses the full verification lifecycle for preventing multipactor in vacuum RF systems. Key topics include:

- Verification planning: Requirements for a multipactor verification plan and verification routes (analysis, test, or combined).

- Design and test margins: Required margins to apply during analysis and testing to demonstrate safe operational envelopes.

- Design analysis: Field analysis, multipactor charts, frequency selection and levels of analysis for predicting multipactor susceptibility.

- Test requirements and procedures: Test bed configuration, validation, sequence, acceptance criteria, reporting and steps to follow on detected events.

- Test conditions: Environmental controls such as cleanliness, pressure and temperature; signal characteristics for single‑frequency, multi‑frequency and pulsed tests; electron seeding and seeding verification techniques.

- Detection methods: Recommended detection methods and parameters (sensitivity, rise time, verification).

- Secondary electron emission (SEY): Detailed clause on SEY measurements - procedures, worst‑case justification, sample conditions and selection of SEY data.

- Informative annexes: Guidance on document deliverables and the design/test process.

Important exclusion: the standard does not cover collisional breakdown processes (e.g., plasma formation).

Practical applications and who should use it

This standard is used by:

- Satellite payload and RF subsystem designers and engineers seeking to mitigate multipactor risks.

- Test laboratories and systems engineers developing multipactor test campaigns and facilities.

- Program managers, verification and quality assurance teams defining qualification routes and acceptance criteria.

- Contractors and procurement teams ensuring deliverables meet multipactor design and verification requirements.

Typical applications include high‑power satellite RF amplifiers, filters, waveguides, antennas and complex microwave assemblies used in telecommunications, navigation, Earth observation and science missions.

Related standards

- Originates from ECSS‑E‑ST‑20‑01C and supersedes EN 14777:2004.

- Can be tailored in line with ECSS‑S‑ST‑00 project tailoring rules.

Keywords: EN 16603-20-01:2020, multipactor, space engineering, RF components, multipactor‑free, verification, testing, SEY, multicarrier, CW, pulsed, space missions.

Get Certified

Connect with accredited certification bodies for this standard

DEKRA North America

DEKRA certification services in North America.

Eagle Registrations Inc.

American certification body for aerospace and defense.

Element Materials Technology

Materials testing and product certification.

Sponsored listings

Frequently Asked Questions

EN 16603-20-01:2020 is a standard published by the European Committee for Standardization (CEN). Its full title is "Space engineering - Multipactor, design and test". This standard covers: This standard defines the requirements and recommendations for the design and test of RF components and equipment to achieve acceptable performance with respect to multipactor-free operation in service in space. The standard includes: - verification planning requirements, - definition of a route to conform to the requirements, - design and test margin requirements, - design and test requirements, and - informative annexes that provide guidelines on the design and test processes. This standard is intended to result in the effective design and verification of the multipactor performance of the equipment and consequently in a high confidence in achieving successful product operation. This standard covers multipactor events occurring in all classes of RF satellite components and equipment at all frequency bands of interest. Operation in single carrier CW and pulse modulated mode are included, as well as multi-carrier operations. A detailed clause on secondary emission yield is also included. This standard does not include breakdown processes caused by collisional processes, such as plasma formation. This standard is applicable to all space missions. This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

This standard defines the requirements and recommendations for the design and test of RF components and equipment to achieve acceptable performance with respect to multipactor-free operation in service in space. The standard includes: - verification planning requirements, - definition of a route to conform to the requirements, - design and test margin requirements, - design and test requirements, and - informative annexes that provide guidelines on the design and test processes. This standard is intended to result in the effective design and verification of the multipactor performance of the equipment and consequently in a high confidence in achieving successful product operation. This standard covers multipactor events occurring in all classes of RF satellite components and equipment at all frequency bands of interest. Operation in single carrier CW and pulse modulated mode are included, as well as multi-carrier operations. A detailed clause on secondary emission yield is also included. This standard does not include breakdown processes caused by collisional processes, such as plasma formation. This standard is applicable to all space missions. This standard may be tailored for the specific characteristic and constrains of a space project in conformance with ECSS-S-ST-00.

EN 16603-20-01:2020 is classified under the following ICS (International Classification for Standards) categories: 49.140 - Space systems and operations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 16603-20-01:2020 has the following relationships with other standards: It is inter standard links to EN 14777:2004, ISO 14644-1:2015. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 16603-20-01:2020 is associated with the following European legislation: Standardization Mandates: M/496. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 16603-20-01:2020 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2020

Nadomešča:

SIST EN 14777:2005

Vesoljska tehnika - Multipaction, zasnova in preskušanje

Space engineering - Multipaction, design and test

Raumfahrttechnik - Multipaction-Konzeption und -Test

Systèmes sol et opérations - Conception et test prenant en compte l'effet Multipactor

Ta slovenski standard je istoveten z: EN 16603-20-01:2020

ICS:

49.140 Vesoljski sistemi in operacije Space systems and

operations

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 16603-20-01

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2020

ICS 49.140

Supersedes EN 14777:2004

English version

Space engineering - Multipactor, design and test

Ingénierie spatiale - Multipactor, conception et tests Raumfahrttechnik - Multipaction, Konzeption und Test

This European Standard was approved by CEN on 17 May 2020.

CEN and CENELEC members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for

giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical

references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to

any CEN and CENELEC member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN and CENELEC member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN and CENELEC members are the national standards bodies and national electrotechnical committees of Austria, Belgium,

Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy,

Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North Macedonia, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

CEN-CENELEC Management Centre:

Rue de la Science 23, B-1040 Brussels

© 2020 CEN/CENELEC All rights of exploitation in any form and by any means Ref. No. EN 16603-20-01:2020 E

reserved worldwide for CEN national Members and for

CENELEC Members.

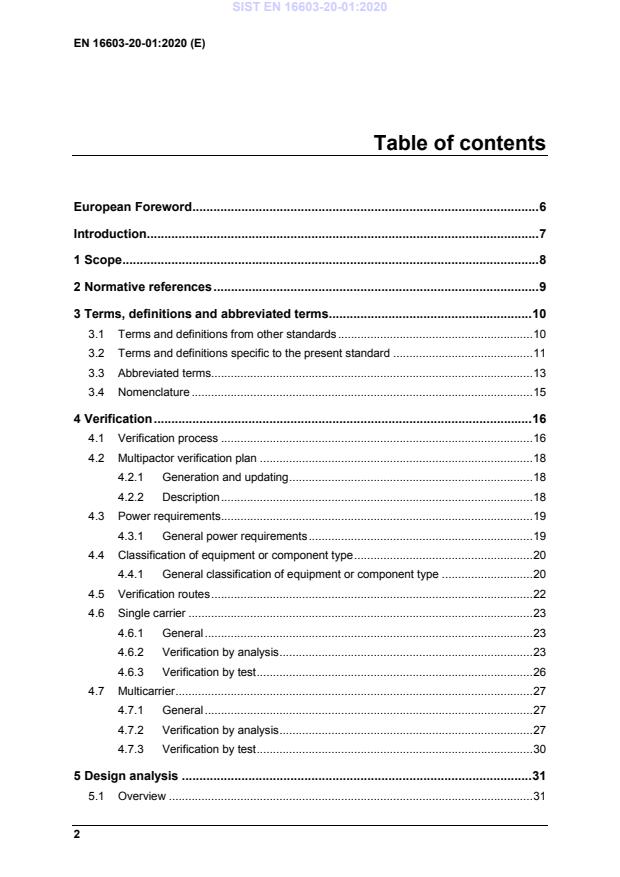

Table of contents

European Foreword . 6

Introduction . 7

1 Scope . 8

2 Normative references . 9

3 Terms, definitions and abbreviated terms . 10

3.1 Terms and definitions from other standards . 10

3.2 Terms and definitions specific to the present standard . 11

3.3 Abbreviated terms. 13

3.4 Nomenclature . 15

4 Verification . 16

4.1 Verification process . 16

4.2 Multipactor verification plan . 18

4.2.1 Generation and updating . 18

4.2.2 Description . 18

4.3 Power requirements . 19

4.3.1 General power requirements . 19

4.4 Classification of equipment or component type . 20

4.4.1 General classification of equipment or component type . 20

4.5 Verification routes . 22

4.6 Single carrier . 23

4.6.1 General . 23

4.6.2 Verification by analysis . 23

4.6.3 Verification by test . 26

4.7 Multicarrier . 27

4.7.1 General . 27

4.7.2 Verification by analysis . 27

4.7.3 Verification by test . 30

5 Design analysis . 31

5.1 Overview . 31

5.2 Field analysis . 31

5.3 Multipactor design analysis . 32

5.3.1 Frequency selection . 32

5.3.2 Design analysis levels . 32

5.3.3 Available data for Multipactor analysis . 37

6 Multipactor - Test conditions . 45

6.1 Cleanliness . 45

6.2 Pressure . 45

6.3 Temperature . 46

6.4 Signal characteristics . 47

6.4.1 Applicable bandwidth . 47

6.4.2 Single-frequency test case . 47

6.4.3 Multi-frequency test case . 47

6.4.4 Pulsed testing . 49

6.5 Electron seeding . 50

6.5.1 General . 50

6.5.2 Multipactor test in CW operation . 50

6.5.3 Multipactor test in pulsed operation . 50

6.5.4 Multipactor test in multi-carrier operation . 50

6.5.5 Seeding sources . 50

6.5.6 Seeding verification . 51

7 Multipactor - Methods of detection . 52

7.1 General . 52

7.2 Detection methods . 52

7.3 Detection method parameters . 53

7.3.1 Verification . 53

7.3.2 Sensitivity . 53

7.3.3 Rise time . 54

8 Multipactor - Test procedure . 55

8.1 General . 55

8.2 Test bed configuration . 55

8.3 Test bed validation. 56

8.4 Test sequence . 57

8.5 Acceptance criteria . 61

8.5.1 Definitions . 61

8.5.2 Multipactor Free Equipment or component . 61

8.5.3 Steps in case of Discharges or Events during test. 61

8.5.4 Investigation of Test Anomalies. 66

8.6 Test procedure . 66

8.7 Test reporting . 67

9 Secondary electron emission yield requirements . 68

9.1 General . 68

9.2 SEY measurements justification . 68

9.3 Worst case SEY measurement . 68

9.4 SEY measurements conditions . 69

9.4.1 Environmental conditions . 69

9.4.2 SEY test bed conditions . 69

9.4.3 SEY sample characteristics . 70

9.5 SEY measurements procedure . 70

9.5.1 SEY Measurements procedure documents . 70

9.5.2 SEY measurement calibration . 71

9.6 ECSS SEY data selection . 71

Annex A (informative) Multipactor document delivery per review . 72

Bibliography . 74

Figures

Figure 3-1: Minimum inflexion point for Silver multipactor chart. . 12

Figure 4-1: Verification routes per component/equipment type and qualification status

for multipactor conformance . 22

Figure 5-1: Multipactor chart for standard Aluminium obtained with parameters from

Table 9-1 . 42

Figure 5-2: Multipactor chart for standard Copper obtained with parameters from Table

9-1 . 42

Figure 5-3: Multipactor chart for standard Silver obtained with parameters from Table

9-1 . 43

Figure 5-4: Multipactor chart for standard Gold obtained with parameters from Table

9-1 . 43

Figure 5-5: Comparison of Multipactor charts for all standard materials obtained with

parameters from Table 9-1 . 44

Figure 8-1: Illustration of test sequence . 60

Figure 8-2: Illustration of test sequence following first Event . 63

Figure 8-3: Illustration of test sequence following first potential discharge . 65

Tables

Table 4-1: Classification of equipment or component type according to the qualification

status and heritage from a multipactor point of view (adapted from Table 5-

1 of ECSS-E-ST-10-02) . 17

Table 4-2: Classification of equipment or component type according to the material and

the geometry . 21

Table 4-3: Analysis margins w.r.t. nominal power applicable to P1 and P2 equipment or

components with Bm or Cm category verified by analysis . 24

Table 4-4: Analysis margins w.r.t. nominal power applicable to P1 and P2 equipment or

components with Dm category verified by analysis . 25

Table 4-5: Test margins w.r.t. nominal power applicable to P1, P2 and P3 equipment or

components verified by test . 26

Table 4-6: Analysis margins applicable to P1 and P2 equipment or components with

Bm or Cm category verified by analysis . 28

Table 4-7: Analysis margins applicable to P1 and P2 equipment or components with

Dm category verified by analysis . 29

Table 4-8: Test margins w.r.t. nominal power applicable to P1, P2 and P3 equipment or

components verified by test . 30

Table 5-1: Tabulated values of the lowest breakdown voltage threshold boundary of the

multipactor charts, computed with the SEY data of Table 9-1 . 38

Table 9-1: SEY parameters for Al, Cu, Au and Ag materials . 71

Table A-1 : Multipactor deliverable document per review . 73

European Foreword

This document (EN 16603-20-01:2020) has been prepared by Technical

Committee CEN-CENELEC/TC 5 “Space”, the secretariat of which is held by

DIN.

This standard (EN 16603-20-01:2020) originates from ECSS-E-ST-20-01C.

This European Standard shall be given the status of a national standard, either

by publication of an identical text or by endorsement, at the latest by March

2021, and conflicting national standards shall be withdrawn at the latest by

March 2021.

Attention is drawn to the possibility that some of the elements of this document

may be the subject of patent rights. CEN [and/or CENELEC] shall not be held

responsible for identifying any or all such patent rights.

This document supersedes EN 14777:2004.

This document has been prepared under a standardization request given to

CEN by the European Commission and the European Free Trade Association.

This document has been developed to cover specifically space systems and has

therefore precedence over any EN covering the same scope but with a wider

domain of applicability (e.g. : aerospace).

According to the CEN-CENELEC Internal Regulations, the national standards

organizations of the following countries are bound to implement this European

Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic,

Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia,

Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

In the context of increased RF power and equipment or component

miniaturization, more and more attention shall be paid to multipactor which is

critical for space missions based on satellite telecommunication or navigation

payloads, or active microwave instruments for Earth Observation or Science.

The multipactor phenomenon is an electron avalanche discharge occurring in

high vacuum initiated by primary electrons inside a RF component in presence

of a high local RF voltage or electric field.

In order to verify by analysis that a RF equipment or component is multipactor

free, accurate EM modelling tools are required. These tools need more and

more computation resources to cope with RF equipment or components with

complex geometries, advanced manufacturing techniques, new materials and

processes, and complex RF signals. The verification by test also requires some

up-to-date test facilities, that provide high power amplification, electron

seeding techniques, multiple and accurate detection methods, ability to

generate complex signals, and the ability to reproduce the space representative

environment conditions.

This standard is an update of previous version of ECSS-E-20-01A Rev.1, that

includes the state-of-art of new verification approaches, and associated

margins.

Scope

This standard defines the requirements and recommendations for the design

and test of RF components and equipment to achieve acceptable performance

with respect to multipactor-free operation in service in space. The standard

includes:

verification planning requirements,

definition of a route to conform to the requirements,

design and test margin requirements,

design and test requirements, and

informative annexes that provide guidelines on the design and test

processes.

This standard is intended to result in the effective design and verification of the

multipactor performance of the equipment and consequently in a high

confidence in achieving successful product operation.

This standard covers multipactor events occurring in all classes of RF satellite

components and equipment at all frequency bands of interest in high vacuum

-5

conditions (pressure lower than 10 hPa). Operation in single carrier CW and

pulse modulated mode are included, as well as unmodulated multi-carrier

operations. A detailed clause on secondary emission yield is also included.

This standard does not include breakdown processes caused by collisional

processes, such as plasma formation.

This standard is applicable to all space missions.

This standard may be tailored for the specific characteristic and constrains of a

space project in conformance with ECSS-S-ST-00.

Normative references

The following normative documents contain provisions which, through

reference in this text, constitute provisions of this ECSS Standard. For dated

references, subsequent amendments to, or revision of any of these publications

do not apply. However, parties to agreements based on this ECSS Standard are

encouraged to investigate the possibility of applying the more recent editions of

the normative documents indicated below. For undated references, the latest

edition of the publication referred to applies.

EN reference Reference in text Title

EN 16601-00 ECSS-S-ST-00-01 ECSS – Glossary of terms

EN 16603-10-02 ECSS-E-ST-10-02 Space engineering –Verification

EN 16603-10-03 ECSS-E-ST-10-03 Space engineering - Testing

EN 16602-20 ECSS-Q-ST-20 Space product assurance – Quality assurance

EN 16602-20-08 ECSS-Q-ST-20-08 Space product assurance – Storage, handling and

transportation of spacecraft hardware

EN 16602-70-01 ECSS-Q-ST-70-01 Space product assurance – Cleanliness and

contamination control

EN 16602-70-02 ECSS-Q-ST-70-02 Space product assurance – Thermal vacuum

outgassing test for the screening of space materials

ESCC-20600 Preservation, packaging and despatch of ESCC

component

ISO 14644–1:2015 Cleanrooms and associated controlled environments

– Part 1: Classification of air cleanliness by particle

concentration

Terms, definitions and abbreviated terms

3.1 Terms and definitions from other standards

a. For the purpose of this standard, the terms and definitions from ECSS-S-

ST-00-01 apply, in particular the following terms:

1. acceptance

2. assembly

3. bakeout

4. batch

5. component

6. development

7. equipment

8. integration

9. uncertainty

10. validation

11. verification

b. For the purpose of this standard, the terms and definitions from ECSS-E-

ST-10-02 apply, in particular the following terms:

1. acceptance stage

2. analysis

3. inspection

4. model philosophy

5. qualification stage

6. review of design

7. test

8. verification level

c. For the purpose of this standard, the terms and definitions from ECSS-E-

ST-10-03 apply, in particular the following terms:

1. acceptance margin

2. qualification margin

d. For the purpose of this standard, the terms and definitions from ECSS-Q-

ST-70-02 apply, in particular the following terms:

1. outgassing

3.2 Terms and definitions specific to the present

standard

3.2.1 analysis margin

required margin of the nominal power with respect to the theoretical threshold

power resulting from a Multipactor analysis

3.2.2 assembly

process of mechanical mating of hardware after the manufacturing process

3.2.3 backscattered electron

incident electron that was re-emitted from the material surface with or without

energy loss.

3.2.4 batch

group of equipment or component produced in a limited amount of time with

the same manufacturing tools, that originates from the same manufacturing lot,

and followed the same manufacturing processes

NOTE This definition is more specific than the one

from the ECSS Glossary ECSS-S-ST-00-01.

3.2.5 batch acceptance margin

allowance of the power level above the nominal power over the specified

equipment or component lifetime, excluding testing, to be applied to equipment

or component of the same batch

3.2.6 critical gap

Vacuum region within a component or equipment, surrounded by surfaces of

any material at which the discharge occurs at the lowest input power for a

given frequency within the operating frequency band.

NOTE Critical gap does not correspond necessarily to

the smallest gap.

3.2.7 discharge

simultaneous response on two or more

independent detection methods

NOTE The term "multipactor discharge" is

synonymous.

3.2.8 event

short time response on one detection method

3.2.9 ferromagnetic material

substances which have a large, positive susceptibility to an external magnetic

field, exhibit a strong attraction to magnetic fields and are able to retain their

magnetic properties after the external magnetic field has been removed.

3.2.10 gap voltage

voltage over the critical gap

3.2.11 heritage

status of verification based on previously verified reference component or

equipment including all relevant parameters

NOTE The relevant parameters are listed in Table 4-1.

3.2.12 multicarrier average power

sum of the average power of each carrier

𝑁

𝑃 =∑𝑃

𝑎𝑣𝑔 𝑖

𝑖=1

where:

Pi is the average power of each individual carrier

N is the number of carriers

3.2.13 minimum inflexion point

frequency times gap distance product, corresponding to multipactor order one,

at which there is a change in the slope of the breakdown voltage curve and the

breakdown voltage is minimized

NOTE Figure 3-1 is given as example. See for more

information the Multipactor handbook ECSS-E-

HB-20-01.

Figure 3-1: Minimum inflexion point for Silver multipactor chart.

3.2.14 multipactor discharge

see "discharge"

3.2.15 multipactor threshold

lowest power level for which a multipactor

discharge has occurred

3.2.16 multicarrier signal

signal composed of a number of independent

CW signals at different frequencies

3.2.17 qualification test

test performed on a single unit for establishing that a suitable margin exists in

the design and built standard

NOTE Such suitable margin is the qualification

margin.

3.2.18 RF boundary conditions

impedance matching conditions at all RF ports of the equipment or component

3.2.19 secondary electron emission yield (SEY)

see "total secondary electron emission coefficient"

3.2.20 total secondary electron emission coefficient

ratio of the number of all emitted electrons to the number of incident electrons

of defined incident kinetic energy and angle, specific of a material surface

under electron irradiation under high vacuum conditions

NOTE 1 The total secondary electron coefficient is the

sum of the true secondary electron coefficient

and the backscattered electron coefficient.

NOTE 2 The term "secondary electron emission yield"

is synonymous.

3.3 Abbreviated terms

For the purpose of this Standard, the abbreviated terms from ECSS-S-ST-00-01

and the following apply:

Abbreviation Meaning

alternating current/direct current

AC/DC

batch acceptance test

BAT

back-scattered electron emission

BSE

Critical Design Review

CDR

carbon-fibre-reinforced plastic

CFRP

continuous wave

CW

direct current

DC

Abbreviation Meaning

declared materials list

DML

declared processes list

DPL

documents requirements definition

DRD

device under test

DUT

equipment qualification status review

EQSR

European Cooperation for Space Standardization

ECSS

electromagnetic

EM

electromagnetic compatibility

EMC

European remote sensing satellite

ERS

European Space Components Coordination

ESCC

flight model

FM

high power amplifier

HPA

intermediate frequency

IF

low noise amplifier

LNA

output multiplexer

OMUX

preliminary design review

PDR

particle in cell

PIC

process identification document

PID

passive intermodulation product

PIMP

radio frequency

RF

secondary electron emission

SEE

system requirements review

SRR

regulated electron gun

REG

radioactive source

RS

secondary emission yield

SEY

TEM transverse electromagnetic mode

test review board

TRB

temperature reference point

TRP

test readiness review

TRR

thermal vacuum chamber

TVAC

travelling wave tube amplifier

TWTA

Abbreviation Meaning

unit acceptance test

UAT

ultraviolet

UV

voltage standing wave ratio

VSWR

wave guide

WG

worst case analysis

WOCA

3.4 Nomenclature

The following nomenclature applies throughout this document:

a. The word “shall” is used in this Standard to express requirements. All

the requirements are expressed with the word “shall”.

b. The word “should” is used in this Standard to express recommendations.

All the recommendations are expressed with the word “should”.

NOTE It is expected that, during tailoring,

recommendations in this document are either

converted into requirements or tailored out.

c. The words “may” and “need not” are used in this Standard to express

positive and negative permissions, respectively. All the positive

permissions are expressed with the word “may”. All the negative

permissions are expressed with the words “need not”.

d. The word “can” is used in this Standard to express capabilities or

possibilities, and therefore, if not accompanied by one of the previous

words, it implies descriptive text.

NOTE In ECSS “may” and “can” have completely

different meanings: “may” is normative

(permission), and “can” is descriptive.

e. The present and past tenses are used in this Standard to express

statements of fact, and therefore they imply descriptive text.

Verification

4.1 Verification process

a. The process of verification of the equipment with respect to multipactor

performance shall demonstrate conformance to the margin requirements

defined in clauses 4.6 and 4.7.

b. Verification of the equipment with respect to multipactor shall be

performed as part of the overall verification process specified in ECSS-E-

ST-10-02, by applying Table 4-1.

c. Each equipment shall have a dedicated multipactor verification plan as

specified in 4.2.2a.

NOTE It can involve a combination of design analyses,

inspections, development testing, qualification

testing, batch acceptance testing and equipment

or component acceptance testing.

d. Multipactor performance shall be verified at equipment level.

e. If multipactor performance cannot be verified at equipment level, as

specified in 4.1d, then verification may be performed at component level.

f. The process of verification of the component with respect to multipactor

performance shall demonstrate conformance to the margin requirements

defined in clauses 4.6 and 4.7.

g. Verification of the component with respect to multipactor shall be

performed as part of the overall verification process specified in ECSS-E-

ST-10-02, by applying Table 4-1.

h. Each component shall have a dedicated multipactor verification plan as

specified in 4.2.2a.

NOTE It can involve a combination of design analyses,

inspections, development testing, qualification

testing, batch acceptance testing and equipment

or component acceptance testing.

i. Multipactor performance shall be verified at component level.

Table 4-1: Classification of equipment or component type according to the qualification status and heritage from a multipactor

point of view (adapted from Table 5-1 of ECSS-E-ST-10-02)

Category Description Comments Verification type

Off the shelf equipment or component without modifications and:

subjected to a multipactor verification process (only analysis or

also test) with a power level and qualification environment at

Am Review of design

least as severe as that imposed by the actual mission

requirements, and

produced by the same manufacturer and using the same

manufacturing processes and procedures

Off the shelf equipment or component without modifications.

However:

It has been subjected to a multipactor verification process (only

For this document, modification of Review of design, analysis

analysis or also test) with a power level less severe as that

project specifications apply to power margin evaluation and if

Bm

imposed by the actual mission requirements, and qualification

only necessary test

environment at least as severe as that imposed by the actual

mission requirements, and

produced by the same manufacturer and using the same

manufacturing processes and procedures

Existing equipment or component with modifications. Modification

includes:

In case the equipment or component

minor changes to design

with modification includes a change of Review of design, analysis

change of parts

Cm materials and processes, the materials margin evaluation and if

change of materials, processes, manufacturer

and processes subject to change see necessary test

change to a more severe environment imposed by the actual

requirement 9.2a.

mission requirements

change of frequency

change of signal characteristics

Review of design, analysis

Newly designed and developed equipment or component or use of No analysis and test heritage for the

Dm

margin evaluation and if

non-already qualified material or process. new design or material and process

necessary test

4.2 Multipactor verification plan

4.2.1 Generation and updating

a. A multipactor verification plan shall be produced at EQSR and, if

necessary, updated at the PDR and the CDR at the latest.

b. The multipactor verification plan specified in 4.2.2a shall be kept up-to-

date and under configuration control.

NOTE The detailed verification plan adopted for any

particular project can depend on the

qualification status of the equipment and on the

model philosophy or production philosophy

adopted.

c. The inputs for the multipactor verification plan shall include as a

minimum:

1. equipment or component requirements specification,

2. proposed design,

3. equipment or the component qualification status as per Table 4-1,

4. equipment or component type as per Table 4-2.

4.2.2 Description

a. The multipactor verification plan shall be in conformance with the

Verification Plan DRD specified in Annex A of ECSS-E-ST-10-02 plus the

following items:

1. the verification route as per Figure 4-1,

2. list of the multipactor deliverable documents per review,

3. description of tests or analysis to be performed.

NOTE The list of Multipactor deliverable documents is

given in Table A-1.

b. The multipactor verification plan shall present a coherent sequence of

activities that are proposed in order to provide adequate evidence that

the requirement specifications for the product are achieved for each

delivered item.

c. The multipactor verification plan shall state the criteria for successful

completion of each of the verification activities.

4.3 Power requirements

4.3.1 General power requirements

4.3.1.1 Nominal power

a. The nominal power shall be the specified input power for which the

equipment or component is designed and verified to be multipactor free.

b. The nominal power shall be the RF power level to which the analysis

margin and test margin refers.

c. The nominal power specified at equipment or component level shall

exclude RF boundary conditions, neither from payload assembly nor

from test bed.

NOTE The nominal power for multicarrier signal can

be given as power per carrier, or a list of power

per carrier.

4.3.1.2 Increased power P due to payload mismatch

a. The increased power P of the Table 4-3, Table 4-4, Table 4-6 and Table

4-7 shall be calculated including the mismatch at the RF boundaries of

the equipment or the component.

NOTE Further details can be found in the Handbook

ECSS-E-HB-20-01.

4.3.1.3 Failure

a. At payload level, the design and the verification of the equipment or

component identified as critical shall include failure modes.

b. As a minimum, the failure modes shall include the following:

1. failed equipment

2. hot switching

3. overdrive scenario

4. unexpected thermal variations

5. unexpected full or partial RF power reflection

6. unexpected increase of input power

c. For multipactor design and verification, the failures modes shall be

included only if the equipment recovery is possible.

d. For multipactor design and verification, failure modes that are not

recoverable should not be taken.

e. At equipment or component level, the multipactor design and

verification shall include the impact of the applicable failure modes

identified at payload level.

f. The increased power P shall be determined by taking the change of RF

boundary conditions due to the failure mode that yields the worst case

among the ones defined in 4.3.1.3c.

4.4 Classification of equipment or component type

4.4.1 General classification of equipment or

component type

a. The classification of equipment or component types given in Table 4-1

and in Table 4-2 shall be used to determine the applicable multipactor

margin.

NOTE This requirement defines a classification of

equipment or component types according to the

materials employed in the construction and the

geometry and according to the qualification

status from a multipactor point of view.

b. In case of doubt when determining the classification of any particular

equipment or component, the type with a higher number and a lower

level of qualification status shall be used.

c. An equipment consisting of several components shall have the type of

the component with the highest number and the lowest level of

qualification status.

d. An RF equipment assembly consisting of equipment shall have the type

of the equipment with the highest number and the lowest level of

qualification status.

e. In case the equipment or component has multiple potential critical gaps

of different nature, each one shall be classified as P1 or P2 and follow the

verification approach as defined in 4.2.

NOTE Examples of potential critical gaps of different

nature are metal/metal, metal/dielectric or

dielectric/dielectric.

f. In case SEY characterization of materials present in an equipment or

component including dielectrics materials is not performed, it shall be

considered as P3 equipment or component.

Table 4-2: Classification of equipment or component type according to the material

and the geometry

Type Characteristics Parameters for equipment or component

knowledge

Minimum parameters:

P1 Equipment or component with metal

RF path dimensions of the equipment or

only in the critical gap area. Metal(s) and

component

geometry of equipment or component are

Tuning range of the equipment or

known.

component (if applicable)

SEY of the metal(s)

CTE of the material(s) (if applicable)

DC EM field (if applicable)

(1)

P2 Equipment or component with dielectric Minimum parameters:

and possibly metal in the critical gap

RF path dimensions of the equipment or

area. Dielectric material(s), metal(s) and

component

geometry of the equipment or component

Tuning range of the equipment or

are known.

component (if applicable)

SEY of the dielectrics and possibly metal(s)

CTE of the material(s) (if applicable)

DC EM field (if applicable)

Charging (if applicable)

(1)

P3 Any equipment or components not If any of the parameters needed for P1 or P2 is

classified as Type P1 or Type P2. unknown, the component or equipment is

classified as P3.

(1)

Any P2/P3 component/equipment with a geometry involving 3 media (dielectric, metal and vacuum) and with a

sharp edge in the metallic part exhibiting high RF field are prone to generate breakdown phenomena such as

“triple-point” discharge which are difficult to analyse and predict. (For more information, see the corresponding

clause of the Multipactor handbook ECSS-E-HB-20-01).

4.5 Verification routes

a. Verification shall be accomplished by one of the verification routes

shown in Figure 4-1.

Figure 4-1: Verification routes per component/equipment type and qualification

status for multipactor conformance

4.6 Single carrier

4.6.1 General

Clause 4.6 states the numerical values of the margins to be used for CW and

pulsed systems.

4.6.2 Verification by analysis

4.6.2.1 Analysis types

a. The Multipactor analysis shall be performed following one of the two

possible design analysis levels, L1 and L2, as per clause 5.3.2.

4.6.2.2 Analysis margins

a. The nominal margins shown in Table 4-3 and Table 4-4 for the different

contributions and equipment or component types according to the

heritage shall be applied.

b. The reduced margins, as indicated in Table 4-3 and Table 4-4, may be

used if justification is given by the supplier.

NOTE The nominal and reduced margins as indicated

in Table 4-3 and Table 4-4 include modelling

error.

Table 4-3: Analysis margins w.r.t. nominal power applicable to P1 and P2 equipment or components with Bm or Cm category

verified by analysis

L1 analysis L2 analysis L2 analysis L2 analysis

P1 equipment or P1 equipment or P1 equipment or P2 equipment or

(1)

component component component (other component

cases)

(no presence of

dielectrics or

Justification type

ferromagnetic

material in the

whole equipment)

Margin type Margin Margin Margin Margin

[dB] [dB] [dB] [dB]

Nominal dimension & ECSS SEY

Nominal margin 6+ΔP 7+ΔP 8+ΔP N/A

Manufacturing tolerance/thermal

Reduced margin 5+ΔP 6+ΔP 7+ΔP N/A

stability dimension & ECSS SEY

Nominal dimension & WOCA SEY

(ageing, temperature) justified by

(3)

Reduced margin 4+ΔP 5+ΔP 6+ΔP

8+ΔP

(2)

measurement

Manufacturing tolerance/thermal

stability dimension & WOCA SEY

(3)

Reduced margin 3+ΔP 4+ΔP 5+ΔP 7+ΔP

(ageing, temperature) justified by

(1) (2)

measurement

(1)

Worst case analysis combining both as-built/thermal stability dimension and real SEY characterized by measurement.

(2)

The SEY is characterized by measurement by the supplier as described in the clause 9.2.

(3)

Charging impact is considered as per 5.3.2.3.2c.

Table 4-4: Analysis margins w.r.t. nominal power applicable to P1 and P2 equipment or components with Dm category verified

by analysis

L1 analysis L2 analysis

P1 equipment or P1 equipment or P1 equipment or P2 equipment or

(1)

component component component (other component

cases)

(no presence of

dielectrics or

Justification type

ferromagnetic

material in the

whole equipment)

Margin type Margin Margin Margin Margin

[dB] [dB] [dB] [dB]

Manufacturing tolerance/thermal

stability dimension &

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...