EN 459-2:2010

(Main)Building lime - Part 2: Test methods

Building lime - Part 2: Test methods

This European Standard describes the test methods for all building limes covered by EN 459-1:2010.

This European Standard specifies the methods used for the chemical analyses and the determination of physical properties of building limes.

This document describes the reference methods and, in certain cases, an alternative method which can be considered to be equivalent. In the case of a dispute, only the reference methods are used.

Any other methods may be used provided they are calibrated, either against the reference methods or against internationally accepted reference materials, in order to demonstrate their equivalence.

Baukalk - Teil 2: Prüfverfahren

Diese Europäische Norm beschreibt Prüfverfahren für alle Baukalke, die in EN 459-1:2010 enthalten sind.

Diese Europäische Norm legt die Verfahren für die chemische Analyse und die Bestimmung der physikalischen

Eigenschaften von Baukalken fest.

Diese Europäische Norm beschreibt Referenzprüfverfahren und in einigen Fällen Alternativprüfverfahren, die

als gleichwertig angesehen werden können. Im Streitfall ist nur das Referenzverfahren maßgebend.

Werden andere Verfahren angewendet, so sind diese gegen die Referenzverfahren oder gegen international

anerkannte Referenzmaterialien zu kalibrieren, um ihre Eignung nachzuweisen.

Chaux de construction - Partie 2: Méthodes d’essai

La présente Norme européenne décrit les méthodes d'essai applicables à toutes les chaux de construction

faisant l'objet de I'EN 459-1:2010.

La présente norme européenne prescrit les méthodes utilisées pour les analyses chimiques et la

détermination des propriétés physiques des chaux de construction.

Le présent document décrit les méthodes de référence et, dans certains cas, une variante qui peut être

considérée comme équivalente. En cas de litige, seules les méthodes de référence sont utilisées.

II est possible d'utiliser d'autres méthodes à condition de démontrer qu'elles aient été étalonnées soit avec les

méthodes de référence, soit avec des matériaux de référence acceptés au niveau international pour

démontrer leur équivalence..

Gradbeno apno - 2. del: Metode preskušanja

Ta evropski standard opisuje preskusne metode za vsa gradbena apna, ki jih zajema EN 459-1:2010. Ta evropski standard določa metode, ki se uporabljajo za kemične analize in ugotavljanje fizikalnih lastnosti gradbenega apna. Ta dokument opisuje referenčne metode in v določenih primerih alternativno metodo, ki velja za enakovredno. V primeru spora se uporabljajo samo referenčne metode. Druge metode se lahko uporabljajo, če so kalibrirane glede na referenčne metode ali glede na mednarodno sprejete referenčne materiale, kar je dokaz njihove enakovrednosti.

General Information

- Status

- Withdrawn

- Publication Date

- 07-Sep-2010

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 51 - Cement and building limes

- Drafting Committee

- CEN/TC 51/WG 11 - Building lime

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 14-Jul-2021

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 13-Sep-2010

- Effective Date

- 21-Jul-2021

- Effective Date

- 28-Jan-2026

- Refers

EN 196-3:2016 - Methods of testing cement - Part 3: Determination of setting times and soundness - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 459-1:2015 - Building lime - Part 1: Definitions, specifications and conformity criteria - Effective Date

- 28-Jan-2026

- Referred By

EN 13454-2:2019 - Binders for floor screeds based on calcium sulphate - Part 2: Test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 459-2:2010 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building lime - Part 2: Test methods". This standard covers: This European Standard describes the test methods for all building limes covered by EN 459-1:2010. This European Standard specifies the methods used for the chemical analyses and the determination of physical properties of building limes. This document describes the reference methods and, in certain cases, an alternative method which can be considered to be equivalent. In the case of a dispute, only the reference methods are used. Any other methods may be used provided they are calibrated, either against the reference methods or against internationally accepted reference materials, in order to demonstrate their equivalence.

This European Standard describes the test methods for all building limes covered by EN 459-1:2010. This European Standard specifies the methods used for the chemical analyses and the determination of physical properties of building limes. This document describes the reference methods and, in certain cases, an alternative method which can be considered to be equivalent. In the case of a dispute, only the reference methods are used. Any other methods may be used provided they are calibrated, either against the reference methods or against internationally accepted reference materials, in order to demonstrate their equivalence.

EN 459-2:2010 is classified under the following ICS (International Classification for Standards) categories: 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 459-2:2010 has the following relationships with other standards: It is inter standard links to EN 459-2:2001, EN 459-2:2021, EN ISO 6506-1:2005, EN 196-3:2016, EN 196-7:2007, EN 196-1:2005, EN 932-1:1996, EN 459-1:2010, EN 15814:2011+A2:2014, EN 13279-2:2014, EN 15814:2011+A1:2012, EN 459-1:2015, EN 13454-2:2019, EN 413-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 459-2:2010 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/114. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 459-2:2010 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Gradbeno apno - 2. del: Metode preskušanjaBaukalk - Teil 2: PrüfverfahrenChaux de construction - Partie 2: Méthodes d’essaiBuilding lime - Part 2: Test methods91.100.10Cement. Mavec. Apno. MaltaCement. Gypsum. Lime. MortarICS:Ta slovenski standard je istoveten z:EN 459-2:2010SIST EN 459-2:2010en,de01-december-2010SIST EN 459-2:2010SLOVENSKI

STANDARDSIST EN 459-2:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 459-2

September 2010 ICS 91.100.10 Supersedes EN 459-2:2001English Version

Building lime - Part 2: Test methods

Chaux de construction - Partie 2: Méthodes d'essai

Baukalk - Teil 2: Prüfverfahren This European Standard was approved by CEN on 30 July 2010.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2010 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 459-2:2010: ESIST EN 459-2:2010

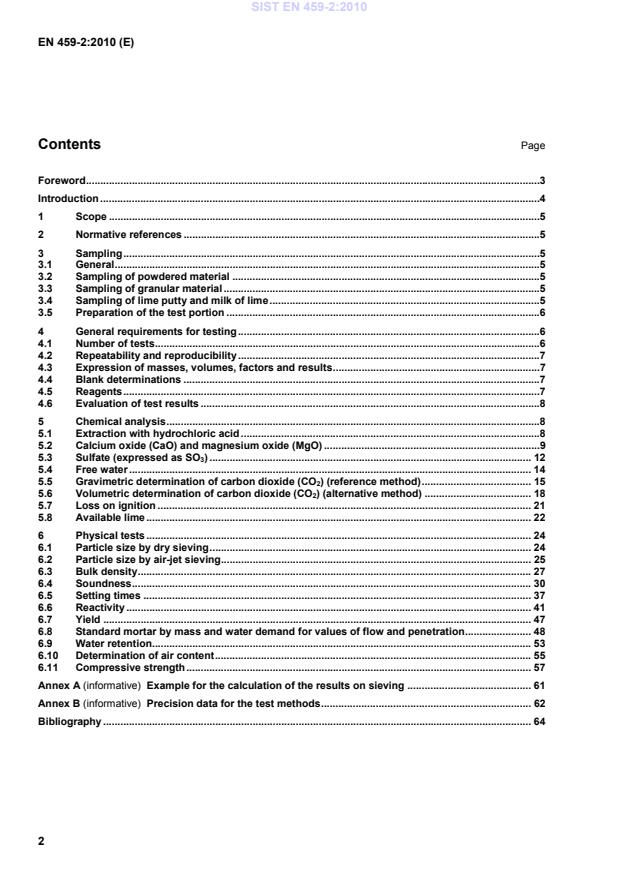

Example for the calculation of the results on sieving . 61Annex B (informative)

Precision data for the test methods . 62Bibliography . 64 SIST EN 459-2:2010

The sample preparation for the appropriate test is described in Table 1. Table 1

Sample preparation for the single tests Test Clause in this standard Type and form of the building lime Sample preparation Chemical analysis 5 All types of building lime The sample of granular material shall be crushed and ground. All tests shall be performed on materials of a grain size ≤ 0,2 mm Grain size distribution by sieving 6.1 and 6.2 Quicklime Material in the as-delivered state Grain size distribution by air-jet sieving 6.2 Hydrated lime, hydrated dolomitic lime, lime with hydraulic properties Material in the as-delivered state Bulk density 6.3 All types of building lime See 6.3.2 Soundness 6.4.2.1 and 6.4.2.2 Hydrated lime, lime with hydraulic properties Material in the as-delivered state 6.4.2.3 Hydraulic lime with an SO3 content of more than 3 % and up to 7 % Material in the as-delivered state 6.4.3 Hydrated lime, lime putty und hydrated dolomitic lime Material in the as-delivered state 6.4.4 Quicklime, lime putty, dolomitic quicklime, hydrated dolomitic lime See 6.4.4.3.1 Setting times 6.5 Lime with hydraulic propertiesMaterial in the as-delivered state Reactivity 6.6 Quicklime The test shall be performed on materials of a grain size ≤ 0,2 mm. If 100 % of the material pass the 5 mm sieve the product can alternatively be tested in the as-delivered state Yield 6.7 Quicklime See 6.7.2 Mortar tests 6.8 to 6.10 Hydrated lime, hydrated dolomitic lime, lime with hydraulic properties Material in the as-delivered state Compressive strength 6.11 Lime with hydraulic propertiesMaterial in the as-delivered state

4 General requirements for testing 4.1 Number of tests Analysis of a building lime may require the determination of a number of its chemical properties. For each determination one or more tests shall be carried out in which the number of measurements to be taken shall be as specified in the relevant clause of this standard. Where the analysis is one of a series subject to statistical control, determination of each chemical property by a single test shall be the minimum required. SIST EN 459-2:2010

5.2.3.8 Ethylenediaminetetra-acetic acid disodium salt dihydrate (EDTA), (C10H14N2Na2O8 ⋅ 2 H2O), dried to constant mass at 80 °C before weighing. 5.2.3.9 Calcium carbonate, c (CaCO3) = 99,9 % (dried at (200 ± 10) °C). 5.2.3.10 Buffer solution.

Make 70 g of ammonium chloride (5.2.3.7) and 570 ml of ammonium hydroxide solution (5.2.3.6) up to the mark with water in a 1 000 ml volumetric flask. 5.2.3.11 EDTA solution, c (EDTA) = 0,04 mol/l. a) Preparation: Dissolve 14,89 g of EDTA (5.2.3.8) in water and making up to 1 000 ml in a volumetric flask. b) Standardization: Pipette 50 ml of the calcium ion reference solution (5.2.3.12) into a 400 ml beaker and dilute with 100 ml of water. Adjust the pH value of the solution to (12,5 ± 0,5) with sodium hydroxide solution (5.2.3.5) using a pH meter. Add 0,1 g of calconcarboxylic indicator (5.2.3.13) and titrate with the EDTA solution being standardized until the colour changes to blue. The concentration of the EDTA solution is given by the following equation: 2222489,1204,009,10050VmVmc×=×××= (3) where m2 is the initial mass of calcium carbonate taken to prepare the calcium ion reference solution, in grams; V2 is the volume of the EDTA solution used in the titration, in millilitres. SIST EN 459-2:2010

Transfer (1 ± 0,002) g of calcium carbonate (5.2.3.9) (m2) and about 100 ml of water to a 400 ml beaker, cover the beaker with a watch glass and carefully add about 10 ml of hydrochloric acid (5.2.3.2). After the calcium carbonate has dissolved completely, remove the carbon dioxide by boiling, then allow the solution to cool and make it up to 1 000 ml in a volumetric flask. 5.2.3.13 Calconcarboxylic acid indicator.

Grind 0,2 g of calconcarboxylic acid intensively with 20 g of anhydrous sodium sulfate in a mortar. 5.2.3.14 Eriochrome Black T indicator.

Grind 1 g of Eriochrome Black T intensively with 100 g of sodium chloride in a mortar. 5.2.4 Apparatus 5.2.4.1 Ordinary laboratory equipment. 5.2.4.2 Magnetic stirrer with magnetic rod. 5.2.4.3 pH-meter with glass electrode, capable of measuring to an accuracy of 0,05. 5.2.5 Procedure 5.2.5.1 Determination of CaO To determine the calcium oxide content, transfer 25 ml (V3) of the solution prepared in accordance with 5.1.5 to a 400 ml beaker, dilute the solution with about 150 ml of water and add 5 ml of triethanolamine solution (5.2.3.4). Adjust the pH value of this solution to (12,5 ± 0,5) with sodium hydroxide solution (5.2.3.5) using a pH-meter. Add 0,1 g of calconcarboxylic acid indicator (5.2.3.13) and titrate with the EDTA solution while stirring constantly with a magnetic stirrer until the colour changes from wine red to blue, record the volume (V4) of the EDTA solution added. During titration the pH-value shall not fall below 12,0. 5.2.5.2 Determination of total CaO and MgO content Transfer about 150 ml of water and 25 ml (V5) of the solution prepared in accordance with 5.1.5 to a 400 ml beaker. Add 5 ml of triethanolamine solution (5.2.3.4) and adjust the pH value of the solution to (10,5 ± 0,5) with buffer solution (5.2.3.10) using a pH-meter. Then add about 90 % of the volume of EDTA solution used during the calcium oxide titration (as described in 5.2.5.1) and, after adding 0,1 g of Eriochrome Black T indicator (5.2.3.14), titrate the solution until the colour changes from wine red to blue. Record the total volume (V6) of EDTA solution added. 5.2.6 Evaluation and expression of results The calcium oxide content of the sample expressed as CaO in mass fraction in percent is given by the following equation: 1341000110008,5604,0mVVcVCaO×××××××= (4) where V1 is the volume of the digestion solution (5.1.5), in millilitres; SIST EN 459-2:2010

Dissolve 120 g of barium chloride in water and make up to 1 000 ml with water in a volumetric flask. 5.3.3.9 Silver nitrate, AgNO3. 5.3.3.10 Silver nitrate solution.

Dissolve 5 g of silver nitrate (5.3.3.9) in water, add 10 ml of nitric acid (5.3.3.4) and making up to 1 000 ml with water in a volumetric flask. 5.3.4 Apparatus 5.3.4.1 Ordinary laboratory equipment. 5.3.4.2 Analytical balance, accurate to 0,001 g. 5.3.4.3 Hot plate or sand bath. 5.3.4.4 Muffle furnace. 5.3.5 Procedure Weigh out (1 ± 0,1) g to the nearest 0,001 g of the sample (m3) into a 250 ml beaker, add 90 ml of cold water

and then add 10 ml of hydrochloric acid (5.3.3.1) while stirring vigorously. Carefully heat the solution in a fume cupboard on a hot plate or in a sand bath to just below boiling point and leave at this temperature for 15 min. Filter through a fine filter paper (mean pore diameter of approximately 2 µm, ash content < 0,01 %) into a 400 ml beaker and wash the residue several times with small portions of hot diluted hydrochloric acid (5.3.3.3). Dilute the filtrate to about 250 ml with water and, if necessary, adjust the pH value to 1 with hydrochloric acid (5.3.3.2) or ammonium hydroxide solution (5.3.3.6). Boil the solution for 5 min and then add 10 ml of hot barium chloride solution (5.3.3.8) dropwise to the still boiling solution while stirring continuously. Allow the solution to boil for a further 15 min to enable the precipitate to form satisfactorily. Leave the precipitation vessel on a hot plate at 60 °C overnight, ensuring that the solution will not evaporate down. Filter the precipitate through a fine filter paper (mean pore diameter of approximately 2 µm, ash content < 0,01 %) and wash the residue until chloride-free with boiling water, using silver nitrate solution (5.3.3.10) to test the filtrate (see below). After washing the precipitate, rinse the stem of the funnel with a few drops of water. Wash the filter paper and contents with a few millilitres of water, collect the wash water in a test tube and add a few drops of silver nitrate solution. If no cloudiness or precipitate appears in the solution, chloride is absent. If this is not the case, repeat the washing process until the silver nitrate test is negative. Transfer the filter paper and residue to a preweighed platinum crucible and incinerate to constant mass at (925 ± 25) °C in a muffle furnace. An incineration time of 15 min will generally be sufficient to achieve constant mass. Record the mass (m4). 5.3.6 Evaluation and expression of results The sulfate content expressed as SO3 in mass fraction in percent is given by the following equation: SIST EN 459-2:2010

5.4.2 Principle When heating a sample of hydrated lime or lime with hydraulic properties to (105 ± 5) °C, or for milk of lime or lime putty to (150 ± 5) °C the free water is driven off. The loss of mass at this temperature is referred to as free water in the case of hydrated lime and lime with hydraulic properties, and as the content of water in the suspension for milk of lime or lime putty. 5.4.3 Apparatus 5.4.3.1 Ordinary laboratory equipment. 5.4.3.2 Drying oven, thermostatically controlled to maintain a temperature of (105 ± 5) °C or (150 ± 5) °C (alternative equipment 1). 5.4.3.3 Automated moisture balance, being capable to be controlled between (105 ± 5) °C or (150 ± 5) °C (alternative equipment 2). 5.4.3.4 Analytical balance, accurate to 0,001 g. 5.4.3.5 Desiccator, containing drying agent. 5.4.3.6 Unglazed porcelain crucible. 5.4.3.7 Pipette. 5.4.4 Procedure 5.4.4.1 Hydrated lime and lime with hydraulic properties Weigh between (5 ± 0,1) g and (10 ± 0,1) g to the nearest 0,001 g (m5) of the sample in the as-delivered state in a pre-weighed crucible. Dry the sample until constant mass using the oven (5.4.3.2) or the balance (5.4.3.3). When using the oven limit the time of drying to approximately 2 h. Cover the crucible after removing it from the oven to prevent carbon dioxide and water vapour in the atmosphere from being absorbed. Cool in the desiccator and reweigh. SIST EN 459-2:2010

Key 1 Y-piece 2 Mohr clip 3 absorption tower containing carbon dioxide absorbent (5.5.2.7) 4 dropping funnel 5 dropping funnel connector 6 connecting tube connector 7 three-armed still head 8 condensor connector 9 condensor 10 wash bottle with concentrated sulfuric acid (5.5.2.1) 11 absorption tube with absorbent for hydrogen sulfide (5.5.2.5) 12 absorption tube with absorbent for water (5.5.2.6)13 absorption tubes with absorbents for carbon dioxide (5.5.2.7) and water (5.5.2.6) 14 100 ml distillation flask 15 absorption tube with absorbents for carbon dioxide (5.5.2.7) and water (5.5.2.6) Figure 1 — Typical apparatus for the determination of carbon dioxide (reference method) SIST EN 459-2:2010

45 mm; b) internal diameter:

20 mm; c) distance between the lower part of the tube and the upper part of the ground section: 75 mm; d) tube wall thickness:

1,5 mm. 5.5.4 Procedure The mass of the building lime sample used depends on the expected CO2 content and shall be chosen approximately as follows: a) 2 g

for 0 %

≤ CO2

≤ 2 %; b) 1 g

for 2 %

< CO2

≤ 5 %; c) 0,5 g for 5 %

< CO2

≤ 10 %; d) 0,3 g for 10 %

< CO2

≤ 15 %; e) 0,2 g for 15 %

< CO2

≤ 40 %; f) 0,1 g for 40 %

< CO2

≤ 50 %. Weigh out the sample to 0,001 g (m7) and place it in a dry 100 ml distillation flask. Connect the flask to the apparatus as shown in Figure 1, but without the two absorption tubes (13). Pass a current of carbon dioxide-free gas through the apparatus for 15 min at approximately three bubbles per second (bubble counter) via the connecting tube onto (6) (branch onto (5), Mohr clip closed). Release the Mohr clip and remove the gas supply from the funnel (4). Add 30 ml concentrated phosphoric acid (5.5.2.2) into the dropping funnel and reconnect the gas supply to fill the funnel (4). Condition the closed absorption tubes (13) for 15 min in the balance case in order to achieve temperature equilibrium. Then weigh each tube separately. Shut off the flow of gas and attach the tubes to the apparatus as shown in Figure 1. NOTE Care should be taken when handling the tubes to avoid affecting their weight, causing damage or sustaining injury. It is advisable to wear protective gloves when carrying out this operation. Reopen the gas flow. After 10 min close absorption tubes (13), remove them, place them in the balance case for 15 min and then weigh them separately. Repeat the passage of gas, removal and weighing of absorption tubes (13) for as long as is required for the results of two successive weighings of a tube not to differ by more than 0,000 5 g. If the change in mass of the absorption tubes (13) remains greater than 0,000 5 g, renew the absorbents in tubes (11) and (12). Attach the weighed absorption tubes (13) to the apparatus, as shown in Figure 1. Open the funnel tap and allow the phosphoric acid (5.5.2.2) to drop into the distillation flask (14). After the reaction has ceased, heat the contents of the flask to boiling and boil gently for 5 min. Maintain the gas flow through the apparatus until the flask has cooled to room temperature. Close absorption tubes (13), remove them and place them in the balance case for 15 min and then weigh them separately. The increase in mass of each tube is used for the calculation of the carbon dioxide content. SIST EN 459-2:2010

Dissolve 0,2 g of methyl red (5.6.2.5) in water and make up to 100 ml 5.6.2.7 Sodium sulfate, Na2SO4 5.6.2.8 Sealing liquid.

Add 20 g of sodium sulfate (5.6.2.7) and 5 ml of sulfuric acid (5.6.2.3) to water, make up to 100 ml and colour with a few drops of methyl red solution. The sealing liquid shall be saturated with CO2. 5.6.2.9 Potassium hydroxide solution, c (KOH) = 50 %. 5.6.2.10 Calcium carbonate, CaCO3, dried to constant mass at (200 ± 10) °C. 5.6.3 Apparatus 5.6.3.1 Analytical balance, accurate to 0,001 g. SIST EN 459-2:2010

Key 1 dropping funnel with a volume of 100 ml 2 stopcock 1 3 stopcock 2 4 capillary tubes 5 three-way tap 6 decomposition flask with a volume of 50 ml 7 absorption vessel with a volume of 100 ml containing potassium hydroxide solution (5.6.2.9) fitted with trap 8 burette with a volume of 100 ml 9 levelling vessel with a volume of 500 ml with sealing liquid (5.6.2.8) 10 jacketed tube filled with water Figure 2 — Typical apparatus for determination of carbon dioxide (alternative method) 5.6.4 Procedure The mass of the building lime sample used depends on the expected CO2 content and shall be chosen approximately as follows: a) 2 g

for 0 %

≤ CO2

≤ 2 %; b) 1 g

for 2 %

< CO2

≤ 5 %;

c) 0,5 g for 5 %

< CO2

≤ 10 %; d) 0,3 g for 10 %

< CO2

≤ 15 %; e) 0,2 g for 15 %

< CO2

≤ 40 %; f) 0,1 g for 40 %

< CO2

≤ 50 %. Weigh out the sample accurately to 0,001 g (m10) into the decomposition flask, add a spatula-tip of copper sulfate (5.6.2.4) to bind any hydrogen sulfide formed and suspend in a little water. SIST EN 459-2:2010

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...