prEN 13803-1

(Main)Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line

Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line

This European Standard specifies the track alignment design parameters, the rules and the values that shall be used to determine the maximum operating speed for both new and existing lines. Alternatively, for a given specified speed, it defines the track alignment design parameters either for a new line or an upgraded line.

Bahnanwendungen - Oberbau - Linienführung in Gleisen - Spurweiten 1 435 mm und größer - Teil 1: Durchgehendes Hauptgleis

Diese Europäische Norm legt die Regeln und Grenzen für die erlaubten Geschwindigkeiten für eine vorgegebene Linienführung fest. Alternativ für eine bestimmte erlaubte Geschwindigkeit, sind Grenzen für die Konstruktionsparameter für die Linienführung festgelegt.

Weitere restriktive Anforderungen nach den TSI und nach geeigneten lokalen Normen müssen angewendet werden.

Unnötige Anwendung der maximalen (oder minimalen) Grenzwerte nach dieser Europäischen Norm sollte vermieden werden. Eine umfangreiche Toleranz dieser sollte jedoch vorgesehen werden, entweder in Übereinstimmung mit den empfohlenen Grenzwerten oder bei Anwendung einer Toleranz im Hinblick auf die erlaubte Geschwindigkeit.

Diese Europäische Norm gilt für Hauptstrecken mit Spurweiten von 1 435 mm und größer, mit erlaubten Geschwindigkeiten von 80 km/h bis 300 km/h. Anhang C (informativ) beschreibt die Regeln für die Umrechnung, die bei Gleisen mit Spurweiten von mehr als 1 435 mm angewendet werden können. Anhang D besitzt eine verbindliche Bedeutung und ist bei den jeweiligen nationalen Regelungen zu beachten.

Die Werte und Bedingungen für den festgelegten Geschwindigkeitsbereich können auch für Linien mit erlaubten Geschwindigkeiten weniger als 80 km/h angewendet werden; aber in diesem Fall dürfen weiterer oder weniger restriktive Werte angewendet werden und sollten in einem Vertrag festgelegt werden.

Diese Europäische Norm gilt nicht für innerstädtische und Vorortbahnstrecken.

Diese Europäische Norm nimmt auch Bezug auf den Einsatz von Fahrzeugen, die für hohe Überhöhungs¬fehlbeträge ausgelegt sind.

In dieser Europäischen Norm sind bestimmte Anforderungen an Neigetechnikfahrzeuge festgelegt.

Applications ferroviaires - Voies - Paramètres de conception du tracé de la voie - Ecartement 1435 mm et plus large - Partie 1 : Voie courante

La présente Norme européenne définit les règles et limites qui déterminent la vitesse admissible pour un tracé de voie donnée. Réciproquement, elle définit les paramètres de conception du tracé de la voie pour une vitesse admissible donnée.

Des prescriptions plus restrictives faisant l’objet de Spécification Technique d’Intéropérabilité ou de normes nationales appropriées doivent s’appliquer.

Il convient d’éviter une utilisation sans nécessité des valeurs limites maximales (ou minimales) recommandées dans la présente Norme européenne. Il convient de prévoir une marge significative, soit en se conformant aux valeurs limites recommandées, soit en adoptant une marge par rapport à la vitesse admissible.

La présente Norme européenne est applicable aux voies principales d'écartement 1435 mm et plus large, dont les vitesses admissibles sont comprises entre 80 km/h et 300 km/h. L'Annexe C (informative) décrit les règles de conversion qui peuvent être appliquées pour les voies d'écartement supérieur à 1435 mm. L'Annexe D a un caractère normatif et est appliquée pour les conditions nationales particulières correspondantes.

Cependant, les valeurs et les conditions requises pour cette gamme de vitesse peuvent également être appliquées aux lignes dont les vitesses admissibles sont inférieures à 80 km/h, mais dans ce cas, il peut être nécessaire d’utiliser des valeurs plus ou moins restrictives, selon les indications du document contractuel.

Il n’est pas nécessaire d’appliquer la présente Norme européenne à certaines lignes de banlieue et de métro.

La présente Norme européenne prend également en considération la possibilité d’utiliser des véhicules ayant été homologuées pour des insuffisances de dévers élevées.

Pour les trains pendulaires, des exigences particulières sont définies dans la présente Norme européenne.

Železniške naprave – Zgornji ustroj – Parametri za projektiranje prog – Tirne širine 1435 mm in več – 1. del: Odprta proga

General Information

- Status

- Not Published

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 1/WG 15 - Track alignment design parameters

- Current Stage

- 4098 - Decision to abandon - Enquiry

- Start Date

- 25-Jul-2008

- Completion Date

- 25-Jul-2008

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

prEN 13803-1 - "Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line" is a CEN draft European Standard (2006) that specifies the track alignment design parameters and the rules and values used to determine maximum operating speed for new and existing plain-line railway routes. It also defines, for a given target speed, the alignment parameter values required when designing or upgrading a line. The document targets standard gauge (1435 mm) and includes rules and conversion guidance for wider track gauges.

Key Topics and Requirements

The standard covers technical parameters and recommended limiting values without prescribing construction methods. Major topics include:

- Horizontal alignment

- Radius of horizontal curve (R)

- Length of transition curves (L)

- Minimum lengths of alignment elements (circular curves and straights)

- Cant and running safety

- Cant (D), cant deficiency (I) and cant excess (E)

- Rates of change: dD/dt (rate of change of cant), dD/dℓ (cant gradient), dI/dt

- Vertical alignment

- Vertical curves, radius of vertical curve (Rv)

- Vertical acceleration limits

- Parameter classification and trade-offs

- Traffic categories and limiting values related to safety, comfort, and economy

- Supplementary and normative annexes

- Informative annexes on curve shapes, lateral track resistance, tilting trains and risks of using maximum/minimum limits

- Normative annexes and conversion rules for gauges wider than 1435 mm (Annexes F and G)

- Relationship to EU interoperability requirements (Annex ZA)

Practical Applications

This standard is intended to be used to:

- Calculate maximum permissible speeds based on existing or proposed track geometry

- Define alignment parameters when designing new lines or upgrading existing lines to achieve a specified speed

- Support safety and comfort assessment during alignment design, including effects on lateral forces and track resistance

- Provide conversion and parameter values for broader gauges (e.g., 1524 mm, 1668 mm) and for tilting train considerations

Who Uses It

- Railway infrastructure designers and track engineers

- Project planners and consultants responsible for upgrades and new-build lines

- Rolling stock engineers assessing vehicle-track interaction

- Infrastructure managers and safety assessors evaluating line classification and interoperability

- Standards bodies and regulatory authorities in Europe

Related standards

- Other parts of EN 13803 (if published) addressing specific track conditions or additional line types

- EU interoperability directives referenced in Annex ZA

Keywords: railway track alignment, track design parameters, cant deficiency, curve radius, track gauge 1435 mm, prEN 13803-1, CEN, maximum operating speed.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

prEN 13803-1 is a draft published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Track - Track alignment design parameters - Track gauges 1435 mm and wider - Part 1: Plain line". This standard covers: This European Standard specifies the track alignment design parameters, the rules and the values that shall be used to determine the maximum operating speed for both new and existing lines. Alternatively, for a given specified speed, it defines the track alignment design parameters either for a new line or an upgraded line.

This European Standard specifies the track alignment design parameters, the rules and the values that shall be used to determine the maximum operating speed for both new and existing lines. Alternatively, for a given specified speed, it defines the track alignment design parameters either for a new line or an upgraded line.

prEN 13803-1 is classified under the following ICS (International Classification for Standards) categories: 93.100 - Construction of railways. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 13803-1 has the following relationships with other standards: It is inter standard links to CEN/CLC/TR 17602-80-04:2021, EN 14969:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 13803-1 is associated with the following European legislation: EU Directives/Regulations: 2001/16/EC, 93/38/EEC, 96/48/EC; Standardization Mandates: M/275, M/334. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 13803-1 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI oSIST prEN 13803-1:2006

PREDSTANDARD

april 2006

Železniške naprave – Zgornji ustroj – Parametri za projektiranje prog – Tirne

širine 1435 mm in več – 1. del: Odprta proga

Railway applications - Track - Track alignment design parameters - Track gauges

1435 mm and wider - Part 1: Plain line

ICS 45.080 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

DRAFT

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2006

ICS

English Version

Railway applications - Track - Track alignment design

parameters - Track gauges 1435 mm and wider - Part 1: Plain

line

Applications ferroviaires - Paramètres de conception du Bahnnwendungen - Pberbau - Linienführung in Gleisen -

tracè de la voie - Ecartement 1435 mm et plus large - Spurweiten 1 435 mm und grösser - Teil 1: Durchgehendes

Partie 1: Voie courant Hauptgleis

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee CEN/TC 256.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations which

stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other language

made by translation under the responsibility of a CEN member into its own language and notified to the Management Centre has the same

status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are aware and to

provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without notice and

shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2006 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 13803-1:2006: E

worldwide for CEN national Members.

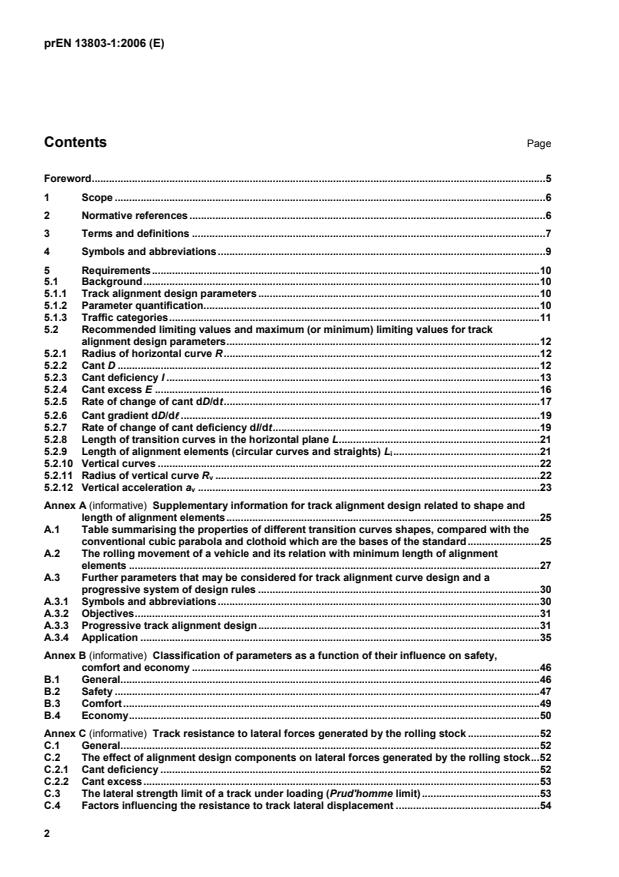

Contents Page

Foreword.5

1 Scope.6

2 Normative references.6

3 Terms and definitions .7

4 Symbols and abbreviations.9

5 Requirements.10

5.1 Background.10

5.1.1 Track alignment design parameters .10

5.1.2 Parameter quantification.10

5.1.3 Traffic categories.11

5.2 Recommended limiting values and maximum (or minimum) limiting values for track

alignment design parameters.12

5.2.1 Radius of horizontal curve R.12

5.2.2 Cant D .12

5.2.3 Cant deficiency I .13

5.2.4 Cant excess E .16

5.2.5 Rate of change of cant dD/dt.17

5.2.6 Cant gradient dD/dllll.19

5.2.7 Rate of change of cant deficiency dI/dt.19

5.2.8 Length of transition curves in the horizontal plane L.21

5.2.9 Length of alignment elements (circular curves and straights) L .21

i

5.2.10 Vertical curves.22

5.2.11 Radius of vertical curve R .22

v

5.2.12 Vertical acceleration a .23

v

Annex A (informative) Supplementary information for track alignment design related to shape and

length of alignment elements.25

A.1 Table summarising the properties of different transition curves shapes, compared with the

conventional cubic parabola and clothoid which are the bases of the standard.25

A.2 The rolling movement of a vehicle and its relation with minimum length of alignment

elements .27

A.3 Further parameters that may be considered for track alignment curve design and a

progressive system of design rules .30

A.3.1 Symbols and abbreviations.30

A.3.2 Objectives.31

A.3.3 Progressive track alignment design.31

A.3.4 Application.35

Annex B (informative) Classification of parameters as a function of their influence on safety,

comfort and economy .46

B.1 General.46

B.2 Safety.47

B.3 Comfort.49

B.4 Economy.50

Annex C (informative) Track resistance to lateral forces generated by the rolling stock .52

C.1 General.52

C.2 The effect of alignment design components on lateral forces generated by the rolling stock.52

C.2.1 Cant deficiency.52

C.2.2 Cant excess.53

C.3 The lateral strength limit of a track under loading (Prud'homme limit).53

C.4 Factors influencing the resistance to track lateral displacement .54

C.4.1 Rail profile.54

C.4.2 Type of sleeper .54

C.4.3 Type of fastening.54

C.4.4 Ballast characteristics.54

C.4.5 Running speed.54

C.4.6 Track consolidation after tamping.54

C.4.7 Thermal load in rails.55

C.4.8 Proximity of two axles.55

C.4.9 Oscillatory axle load variation (vehicle ride quality in the vertical plane).55

Annex D (informative) Other criteria to be considered for the description of a line classification

system .56

Annex E (informative) Consequences on track resistance, stress and fatigue resulting from tilting

body train systems.58

E.1 General.58

E.2 Basic principles applying to tilting body techniques .58

E.2.1 Safety requirements.59

E.2.2 Comfort requirements.61

E.2.3 Economic assessment of the system.62

Annex F (informative) Rules for converting parameter values for track gauges wider than 1435 mm.64

F.1 Scope.64

F.2 Symbols and abbreviations.64

F.3 Basic assumptions and equivalence rules .65

F.4 Detailed conversion rules.66

F.4.1 Radius of horizontal curve R (5.2.1 of the main body of the standard) .66

F.4.2 Cant D (5.2.2 of the main body of the standard).66

F.4.3 Cant deficiency I (5.2.3 of the main body of the standard) .67

F.4.4 Cant excess E (5.2.4 of the main body of the standard).68

F.4.5 Length of transition curves in the horizontal plane L (5.2.8 of the main body of the standard) .69

F.4.6 Rate of change of cant dD /dt (5.2.5 of the main body of the standard) .69

F.4.7 Cant gradient dD /dllll (5.2.6 of the main body of the standard) .70

F.4.8 Rate of change of cant deficiency dI /dt (5.2.7 of the main body of the standard).70

F.4.9 Length of the alignment elements (circular curves and straights) L (5.2.9 of the main body of

i

the standard).71

F.4.10 Other parameters.71

Annex G (normative) Track alignment design parameter values for track gauges wider than 1435

mm.72

G.1 Scope.72

G.2 Requirements for a gauge of 1668 mm .72

G.2.1 Cant D .72

G.2.2 Cant deficiency I .73

G.2.3 Rate of change of cant dD /dt [mm/s].74

G.2.4 Cant gradient dD /dℓ .74

G.2.5 Rate of change of cant deficiency dI /dt .74

G.2.6 Length of alignment elements (circular curves and straights) L .75

i1

G.2.7 Vertical curves.75

G.2.8 Radius of vertical curve R .76

v1

G.2.9 Vertical acceleration a .76

v1

G.3 Requirements for a gauge of 1524 mm .77

G.3.1 Cant D .77

G.3.2 Cant deficiency I .78

G.3.3 Rate of change of cant dD /dt [mm/s].79

G.3.4 Cant gradient dD /dℓ .79

G.3.5 Rate of change of cant deficiency dI /dt .79

G.3.6 Length of alignment elements (circular curves and straights) L .80

i1

G.3.7 Vertical curves.80

G.3.8 Radius of vertical curve R .81

v1

G.3.9 Vertical acceleration a .81

v1

Annex H (informative) Constraints and risks associated with the use of maximum (or minimum)

limiting values.82

Annex I (informative) Recapitulation of the work carried out by the ORE B 55 Committee - Maximum

permissible cant .83

I.1 Introduction.83

I.2 Criteria for safety against derailment at low speed through wheel-climbing .83

I.3 Limiting values for track twist.84

I.4 Rules applicable to the design of and checks performed on new vehicles with regard to

their capability of coping with track twist values.85

I.5 List of reports published by the ORE B 55 Committee.85

Annex ZA (informative) Relationship between this European Standard and the Essential

Requirements of EU Directive 96/48/EC on the interoperability of the trans-European

high-speed rail system.86

Foreword

This document (prEN 13803-1:2006) has been prepared by Technical Committee CEN/TC 256 “Railway

applications”, the secretariat of which is held by DIN.

This document is currently submitted to the CEN Enquiry.

This document has been prepared under a mandate given to CEN by the European Commission and the

European Free Trade Association, and supports essential requirements of the following EU Directives:

Council Directive 96/48/EC of 23 July 1996 on the interoperability of the European high-speed network

European Parliament and Council Directive 2004/17/EC of 31 March 2004 coordinating the procurement

procedures of entities operating in the water, energy, transport and postal services sectors

Council Directive 91/440/EEC of 29 July 1991 on the development of the Community's railways

For relationship with EU Directive 96/48/EC, see informative Annex ZA, which is an integral part of this

document.

EN 13803 "Railway applications – Track – Track alignment design parameters – Track gauges 1435 mm and

wider" consists of the following parts:

Part 1: Plain line

Part 2: Switches and crossings and comparable alignment design situations with abrupt changes of the

curvature

Official Journal of the European Communities N° L 235 of 1996-09-17

Official Journal of the European Communities N° L 134 of 2004-04-30

Official Journal of the European Communities N° L 237 of 1991-08-24

1 Scope

This European Standard specifies the track alignment design parameters, the rules and the values that shall be

used to determine the maximum operating speed for both new and existing lines. Alternatively, for a given

specified speed, it defines the track alignment design parameters either for a new line or an upgraded line.

The track alignment designer is free to specify the values most appropriate for the various parameters, when

considering safety, geographical, engineering, historical and economic constraints. These values are defined in

the contract document. However, the choice should be such that the selected values are no worse than the

maximum (or minimum) limiting values for the safety-related parameters.

Whenever necessary, the track alignment designer should take into account any specific requirements of the

appropriate national standards.

The designer should endeavour to comply with the recommended limiting values specified in this European

Standard and avoid unnecessary use of the maximum (or minimum) limiting values.

This European Standard applies to main lines with track gauges 1435 mm and wider with mixed or dedicated

passenger traffic, running at operating speeds between 80 km/h and 300 km/h. Annex F (informative) describes

the conversion rules which can be applied for tracks with gauges wider than 1435 mm. Annex G has a

normative character and is applied for corresponding specific national conditions.

However, the values and conditions stated for this speed range can also be applied to lines where operating

speeds are less than 80 km/h, but in this case, more or less restrictive values may need to be used and should

be defined in the contract.

This European Standard does not apply to urban and suburban lines.

This European Standard also considers the possibility of increasing the performance of line operation, without

major alignment modifications, by means of particular rail vehicle types, such as:

vehicles with a low axle mass;

vehicles with a low suspension roll coefficient;

vehicles equipped with tilting body systems to compensate for cant deficiency (active or passive systems).

For tilting trains, certain alignment parameters may prove to be sensitive, depending in particular on the tilt

control system used. Such special requirements and the corresponding limiting values are described, if

necessary, within this part of the European Standard. Annex E draws the attention of the designer to the

consequences of track resistance, stress and fatigue due to the operation of such vehicles.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced document

(including any amendments) applies.

prEN 13803-2, Railway applications – Track alignment design parameters – Track gauges 1435 mm and wider

– Part 2: Switches and crossings and comparable alignment design situations with abrupt changes of curvature

ISO 31-1, Quantities and units – Part 1: Space and time

UIC 505-5, Basic conditions common to Leaflets 505-1 and 505-4 – Notes on the preparation and provisions of

these leaflets

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply:

3.1

curves

this covers both horizontal and vertical curves and their related transitions. Unless otherwise stated, the curve

parameters are defined for the track centreline

31.1

circular curve

a curve of constant radius

3.1.2

transition curve

a curve of variable radius.

Transition curves may be found between two circular curves, each of a different radius, and between a circular

curve and a straight. The clothoid (or cubic parabola) is normally used for transition curves, giving a linear

variation of curvature and cant. In some cases, cant and or curvature is smoothed at the ends of the transition.

It is possible to use other forms of transition curve which show a non-linear variation of curvature and cant.

In principle, a transition curve is not used for the vertical alignment.

Annex A gives a detailed account of the alternative types of transitions that may be used in track alignment

design

3.1.3

compound curve

a curve formed by two circular curves of different radii which curve in the same direction.

The two adjacent curves may be joined by a transition curve

3.1.4

reverse curve

a curve formed by two circular curves which curve in the opposite direction.

The two adjacent curves may be joined by a transition curve

3.2

cant

the amount by which one gauge rail is raised above the other gauge rail.

Cant is positive when the outer rail on curved track is raised above the inner rail and is negative when the

inner rail on curved track is raised above the outer rail.

Negative cant is unavoidable at switches and crossings on a canted main line where the turnout is curving in

the opposite direction to the main line and, in certain cases, on the plain line immediately adjoining a turnout

(see prEN 13803-2).

When the speed of a vehicle negotiating a curve is such that the resultant of the gravitational force of the vehicle

and the effect of centrifugal force is perpendicular to the plane of the rails, the vehicle is not subjected to

unbalanced lateral force and is said to be in equilibrium. Obtaining this condition on curved track implies raising

one gauge rail above the level of the other gauge rail by a designed amount. This amount is known as the

equilibrium cant

3.3

cant excess

when the arranged cant is higher than equilibrium cant, there will be an unbalanced lateral force. The resultant

force will move towards the inner rail of the curve. The difference between arranged cant and equilibrium cant is

known as cant excess. Cant on a straight track results in cant excess, generating a force towards the low rail

3.4

cant deficiency

when the arranged cant is lower than equilibrium cant, there will be an unbalanced lateral force. The resultant

force will move towards the outer rail of the curve. The difference between equilibrium cant and arranged cant is

known as cant deficiency

3.5

cant gradient

the amount by which the cant is increased or decreased in a given transition length

3.6

rate of change of cant

the rate at which cant is increased or decreased relative to the speed of a vehicle negotiating a transition curve,

for example 35 mm per second means that a vehicle travelling at the specified speed will experience a change

in cant of 35 mm in each second

3.7

rate of change of cant deficiency

the rate at which cant deficiency is increased or decreased relative to the speed of a vehicle negotiating a

transition curve, for example 35 mm per second means that a vehicle travelling at the specified speed permitted

will experience a change in cant deficiency of 35 mm in each second

3.8

maximum permissible speed

maximum speed permitted on a curve with associated transitions when radius, cant, cant deficiency and rates of

change of cant and cant deficiency and other parameters have been taken into consideration

3.9

line speed

maximum speed at which vehicles are allowed to run on a line or branch or on sections of a line or branch.

The line speed limit is usually established after taking into consideration the incidence of permanent speed

restrictions on the line or branch. On mixed traffic lines, several different line speed limits may exist at the same

time due to the different types of traffic categories

3.10

recommended limiting values

values to be applied by the designer for the design of new railway lines or sections of such lines, or for the

upgrading of existing lines. Such values ensure maintenance costs of the track are kept at a reasonable level,

except where particular conditions of poor track stability may occur, without compromising passenger comfort

3.11

maximum (or minimum) limiting values

extreme but permissible values used at maximum speed for most railway vehicles. As these values are extreme,

it is essential that the use of maximum (or minimum) limiting values is as infrequent as possible on any given

line.

Annex H describes the constraints and risks associated with the use of maximum (or minimum) limiting values

4 Symbols and abbreviations

No. Symbol Designation Unit

1 a non-compensated lateral acceleration in the track plane m/s

q

da /dt

2 rate of change of non-compensated lateral acceleration m/s

q

3 a quasi-static lateral acceleration parallel to the vehicle floor m/s

i

4 da /dt rate of change of quasi-static lateral acceleration parallel to the vehicle floor m/s

i

5 a quasi-static vertical acceleration on vertical curve m/s

v

6 D cant mm

7 cant limit mm

D

l

8 dD/dt rate of change of cant mm/s

9 cant gradient mm/m

dD/dl

10 E cant excess mm

11 e distance between wheel treads of an axle (e.g. 1500 mm for gauge 1435 mm) mm

12 h height of the centre of gravity mm

g

13 I cant deficiency mm

14 dI/dt rate of change of cant deficiency mm/s

15 L length of transition curve and/or cant transition m

16 L length of alignment elements (circular curves and straights) m

i

17 R radius of horizontal curve m

18 R radius of vertical curve m

v

19 s roll flexibility coefficient according to UIC 505-5 -

20 t time s

21 V line speed km/h

22 V maximum curving speed of fast trains km/h

max

23 V minimum curving speed of slow trains km/h

min

2 2

24 g acceleration due to gravity: 9,81 m/s m/s

25 limiting value (index) -

lim

26 ∆a overall variation of non-compensated lateral acceleration along a transition curve m/s

q

between straight track and plain curve or between two adjacent curves of

different radii

27 overall cant deficiency variation along a transition curve, between straight track mm

∆I

and circular curve or between two adjacent circular curves of different radii

28 ∆D overall cant variation along a cant transition, between straight track and circular mm

curve or between two adjacent circular curves of different radii

Q

29 dynamic wheel load N

30 Q nominal wheel load N

N

31 overall wheel load variation N

∆Q

32 Y guiding force at the wheel rail contact N

5 Requirements

5.1 Background

The following technical normative rules assume that standards for acceptance of vehicle, track construction and

maintenance cover the conditions defined in the cited informative annexes.

A good compromise has to be found between train dynamic performance, maintenance of the vehicle and track

and construction costs. The choice of alignment elements depends upon the operation requirements, the

parameters specified (and their values) and on local conditions. The specified parameters and values within this

European Standard may have to be adjusted in consultation with the train operator.

5.1.1 Track alignment design parameters

The following parameters are specified in 5.2:

radius of horizontal curve R (m) (*S);

cant D (mm) (*S);

cant deficiency I (mm) (*S);

uncompensated (quasi-static) lateral acceleration at track level a (m/s ) (*S);

q

cant excess E (mm);

length of transition curves in the horizontal plane L (m);

rate of change of cant dD/dt (mm/s);

cant gradient dD/dl (mm/m) (*S);

rate of change of cant deficiency dI/dt (mm/s);

length of alignment elements (circular curves and straights ) L (m);

i

radius of vertical curve R (m);

v

vertical acceleration a (m/s );

v

speed V (km/h) (*S).

Parameters followed by the (*S) note indicate safety-related parameters.

Annex B describes an alternative means of classification for the above mentioned parameters, as a function of

their relative influence on safety, comfort and cost efficiency of the track/vehicle system.

5.1.2 Parameter quantification

For each of the parameters, two different types of limiting values are specified:

a recommended limiting value;

a maximum limiting value which may have two different meanings:

a) For safety-related parameters, it shall be considered as the absolute maximum limit of this parameter; this

maximum limit may depend upon the actual track mechanical and geometrical state. See annex B for

further information.

It should also be noted that the maximum limiting value is safety-related and may (for some

parameters) induce a reduced comfort level : most operators will reduce these values by at least 10%,

and refer to the proposed limits as "exceptional" values to be used only under special circumstances or

after a specific safety case analysis.

The attention of the operators is drawn to the fact that limiting values are defined with respect to a

commercial train operating pattern. If and when running trials are conducted, for example to ascertain

the vehicle dynamic behaviour (by continually monitoring of the vehicle responses), exceeding the

limiting values (particularly in terms of cant deficiency) shall be permitted and it shall be up to the

infrastructure manager to decide any appropriate arrangement. In this context, safety margins are

generally reinforced by taking additional steps such as ballast consolidation, monitoring of track

geometric quality, etc.

b) For non-safety related parameters, the values shall be considered as the limit above which passenger

comfort may be affected and track maintenance significantly increased; however, to cope with special

situations, operators may choose values in excess of these specified values, but they should not exceed

the safety limits.

NOTE The following parameters for interoperable high speed lines are specified by the Technical Specification for

Interoperability:

cant;

cant deficiency.

5.1.3 Traffic categories

A distinction is made between the following traffic categories:

I mixed traffic lines, with passenger train speeds from 80 km/h to 120 km/h maximum;

II mixed traffic lines, with passenger train speeds greater than 120 km/h and up to 200 km/h maximum;

III mixed traffic lines, designed for passenger train speed higher than 200 km/h to 300 km/h;

IV mixed traffic lines, with passenger train speeds up to 230 km/h (or 250 km/h on upgraded lines) with

vehicle incorporating special technical design characteristics (low axle mass, low roll flexibility coefficient,

etc.);

V dedicated passenger lines with speeds between 250 km/h and 300 km/h.

For the purposes of this European Standard, the reference speed is that for conventional trains.

The above classification uses speed as the most relevant criteria to be considered when defining operational

conditions for the different traffic categories.

Other criteria may be considered for the production of such a traffic classification, namely, aspects related to

safety, comfort and cost efficiency. Further information on such systems of classifications can be found in

annex D.

5.2 Recommended limiting values and maximum (or minimum) limiting values for track

alignment design parameters

5.2.1 Radius of horizontal curve R

The track alignment designer shall endeavour to use the largest curve radii and transition permitted by track

design constraints. This will cater for any future increase of speed. In any event, the track alignment designer

shall not use curve radii less than 180 m for new alignments.

The parameters that shall be considered in the determination of the minimum curve radius are:

the maximum and minimum operating speeds;

the applied cant;

the limiting values for cant deficiency and cant excess.

The minimum allowable curve radius for the maximum operating speed, usually with cant deficiency I, shall be

calculated using the following equation:

11,8

R = V [m]

max

D + I

The maximum allowable curve radius for the minimum operating speed, usually with cant excess E, shall be

calculated using the following equation:

11,8

R = V [m]

min

D − E

The curve radius shall be determined such that the values of D, I and E comply with the limits specified in this

European Standard and satisfy the following condition:

11,8 11,8

2 2

V ≥ R ≥ V [m]

min max

D − E D + I

NOTE 1 Sharp radius curves generally necessitate a widening of the track gauge in order to improve vehicle curving.

This widening of the track gauge can be used in conjunction with the installation of a check rail. The installed check rail

serves a dual purpose:

it increases stiffness of the track panel;

it provides better guidance of the inner face of the wheel and absorption of part of the curving force.

NOTE 2 It is recommended that the radius of tracks alongside platforms should not be less than 500 m. This is to restrict

the gap between platform and vehicles to facilitate safe vehicle access and egress by passengers.

5.2.2 Cant D

Cant shall be determined in relation to the following considerations:

high cant on small-radius curves increases the risk of low-speed freight wagons derailing. Under these

conditions, vertical wheel loading applied to the outer rail is much reduced, especially when track twist

causes additional reductions (see as reference [ORE B55/Rp 8]);

cant exceeding 160 mm may cause freight load displacement and the deterioration of passenger comfort

when a train makes an unscheduled stop at a location where high cant has been applied. Furthermore, with

such high cant, works vehicles and special loads with a high centre of gravity may become unstable;

high cant increases cant excess values on curves where there are large differences between the speeds of

fast trains and slow trains.

Table 1 — Cant D

lim

To avoid the risk of derailment of torsionally-stiff freight wagons on sharp radii curve, cant should be restricted to

the following limit (see as reference [ORE B 55/Rp 5 and 8]):

R − 50

D = [mm]

lim

1,5

I II III IV V

Traffic Mixed traffic Mixed traffic Mixed traffic lines Mixed traffic lines High-speed

categories lines lines designed for with passenger train lines

(speed in km/h) passenger train speeds with dedicated

80 ≤ V ≤ 120 120 < V ≤ 200

speed V ≤ 230 (or 250) passenger

traffic

200 < V ≤ 300 (with vehicles

incorporating special 250 ≤ V ≤ 300

technical design

characteristics)

Recommended

limiting value 160 160 160 160 160

[mm]

Maximum

limiting value 180 180 180 180 200

[mm]

NOTE It is recommended that cant should be restricted to 110 mm for tracks adjacent to passenger platforms. Some

other track features, such as level crossings, bridges and tunnels may also, in certain local circumstances, impose cant

restrictions.

5.2.3 Cant deficiency I

For given values of local radius R and cant D, the cant deficiency I shall determine the maximum speed through

a full curve such that:

V

max

I = 11,8 − D ≤ I [mm]

lim

R

I can be replaced with the value (a ) :

lim q lim

V I

g ⋅ D I

max lim

a = − = ≤()a = [m/s ]

q q

lim

12,96 ⋅R 1500 153 153

5.2.3.1 Cant deficiency for conventional trains

Table 2 — Cant deficiency l – Conventional trains

lim

a

Traffic categories Recommended limiting value Maximum limiting value

[mm] [mm]

(speed in km/h) Freight Passenger Freight Passenger

I - Mixed traffic lines R < 650 m 110 130 130 160

R ≥ 650 m 110 150 130 165

80 ≤ V ≤ 120

d

II - Mixed traffic lines

110 150 160 165

120 < V ≤ 200

d

III - Mixed traffic lines 100 100 150 150

200 < V ≤ 250

designed for passenger

c, d c

train speed 250 < V ≤ 300 80 80 130 130

200 < V ≤ 300

b d b

IV - Mixed traffic lines 110 160 160 180

V ≤ 160

with passenger train x 150 x 165

160 < V ≤ 200

speeds up to 230 km/h

(or 250 km/h on upgraded 200 < V ≤ 230 x 130 x 160

lines)

with vehicle incorporating

special technical design x 100 x 150

230 < V ≤ 250

characteristics

V - High-speed lines V = 250

x 100 x 150

with dedicated

c

passenger traffic V > 250 x 80 x 130

250 ≤ V ≤ 300

NOTE 1 The designer should endeavour to keep cant deficiency at least 20 mm below the recommended limiting

value.

NOTE 2 The previous table takes into consideration most of the maximum limiting values used by different

European Railways in commercial operation, for both new and existing lines (either for line speed upgrading or for

optimising speeds where both freight trains and passenger trains use the same tracks). Vehicle testing procedure for

dynamic vehicle behaviour is based on the values indicated.

NOTE 3 The preceding values apply only to progressive increases of cant deficiency for speeds above 80 km/h; in

the case of cant deficiency discontinuities (sudden application of a lateral acceleration) the specific rules for switches

and crossings for the diverging line (see prEN 13803-2) shall be taken into account.

a

For jointed tracks, cant deficiency values shall be as specified by the contract.

b

These cant deficiency limits shall only be applied to dedicated vehicle types with special mechanical characteristics

such as low axle load, reduced unsprung masses, low roll coefficient.

c

A cant deficiency of 150 mm can be used on non-ballasted tracks for speeds in excess of 250 km/h.

d

These values apply only to dedicated freight wagons with special mechanical characteristics whose performance is

similar to passenger vehicles.

NOTE The values of I and (a ) are based on the following considerations:

lim q lim

a) Track forces and safety

Cant deficiency affects the vertical and lateral forces on the outer rail and the lateral forces of the loaded track panel.

The magnitude of these forces depends, among other factors, upon:

type of track structure (welded or jointed track);

track maintenance condition;

track geometry;

type of vehicle running-gear and suspension;

axle-load and unsprung masses of vehicles;

vehicle maintenance condition.

Any authorisation of a higher I value would presuppose that the rail section, sleeper type, sleeper spacing, rail fastenings,

lim

ballast bed and carrying capacity of the infrastructure are suitable for this higher value.

Furthermore, it is assumed that the lateral forces exerted by the axles do not exceed the loaded track resistance to lateral

deformation. This resistance is not only a function of the track structure, especially the type of ballast material, but also of the

degree of ballast consolidation. After a tamping operation, for example, allowance is made for the minimum track lateral shift

value (see as a reference [ORE C 138/Rp 9 and DT 150]).

b) Economic aspects of track maintenance

Any increase in the value of I means extra cost for inspection and maintenance of track quality. There will also be a resultant

decrease in the service life of the track components.

c) Ride comfort and roll flexibility coefficient(s)

The quasi-static lateral acceleration parallel to the vehicle floor a, which is a measure of the acceleration felt by passengers

i

inside the vehicle, is greater than the lateral non-compensated acceleration at

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...