prEN 15011

(Main)Cranes - Bridge and gantry cranes

Cranes - Bridge and gantry cranes

This document applies to bridge and gantry cranes able to travel by wheels on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary position.

NOTE Light crane systems (assembly of lifting devices, crane bridges, trolleys and tracks; wall-mounted, pillar and workshop jib cranes) are covered by EN 16851.

This document specifies requirements for all significant hazards, hazardous situations and events relevant to bridge and gantry cranes when used as intended and under conditions foreseen by the manufacturer (see Clause 4).

This document does not include requirements for the lifting of persons.

The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in electromagnetic environment beyond the scope of EN 61000-6-2 are not covered by this document.

This document is applicable to bridge and gantry cranes manufactured after the date of its publication as a European standard.

Krane - Brücken- und Portalkrane

Dieses Dokument gilt für Brücken- und Portalkrane, einschließlich Halbportalkrane, die durch Laufräder auf Schienen, Fahrbahnen oder Fahrwegen bewegt werden können, sowie für Portalkrane ohne Laufräder, die in einer feststehenden Position montiert sind.

ANMERKUNG1 Leichtkransysteme (Baugruppe aus Hebevorrichtungen, Kranbrücken, Laufkatzen und Schienen; wandmontierte Auslegerkrane, Säulen-Auslegerkrane und Werkstatt-Auslegerkrane) werden in EN16851:2017+A1:2020 behandelt.

Dieses Dokument legt Anforderungen für alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse fest, die für Brücken- und Portalkrane maßgebend sind, wenn sie bestimmungsgemäß und unter den vom Hersteller vorgesehenen Bedingungen sowie bei vorhersehbarer Fehlanwendung verwendet werden (siehe AnhangA).

ANMERKUNG2 Der automatische Betrieb kann zusätzlichen Anforderungen unterliegen. Leitlinien sind in AnhangJ angegeben.

Dieses Dokument enthält keine Anforderungen an das Heben von Personen.

Die spezifischen Gefährdungen aufgrund von explosionsgefährdeten Bereichen, ionisierender Strahlung und Arbeiten in elektromagnetischen Umgebungen über den Anwendungsbereich der ENIEC61000-6-2 hinaus werden in diesem Dokument nicht behandelt.

Dieses Dokument gilt nicht für Brücken- und Portalkrane, die vor dem Veröffentlichungsdatum dieses Doku

ments hergestellt wurden.

Appareils de levage à charge suspendue - Ponts roulants et portiques de levage

Le présent document s’applique aux ponts roulants et portiques de levage, y compris les semi-portiques, pouvant se déplacer par l'intermédiaire de roues (galets) sur des rails, chemins de roulement ou routes et aux ponts roulants sans roues (galets) montés en position fixe.

NOTE 1 Les systèmes de grue légère (ensemble de dispositifs de levage, ponts, chariots et de roulement; grues à flèche murale, à colonne et d'atelier) sont couverts par l'EN 16851:2017+A1:2020.

Le présent document traite de l’ensemble des phénomènes dangereux significatifs, des situations et des événements dangereux liés aux ponts roulants et aux portiques de levage lorsque ceux-ci sont utilisés conformément à l’usage prévu, le mauvais usage prévisible et dans les conditions prévues par le fabricant (voir l’Annexe A).

NOTE 2 Le fonctionnement automatisé peut être soumis à des exigences supplémentaires. Des recommandations sont données à l’Annexe J.

Le présent document ne traite pas des exigences applicables au levage des personnes.

Les phénomènes dangereux spécifiques dus à des atmosphères potentiellement explosives, au rayonnement ionisant et à l’utilisation dans un environnement électromagnétique, qui sortent du domaine d’application de l’EN IEC 61000-6-2, ne sont pas couverts par le présent document.

Le présent document ne s’applique pas aux ponts roulants et aux portiques de levage fabriqués avant sa date de publication.

Žerjavi - Mostni in portalni (kozičasti) žerjavi

General Information

- Status

- Not Published

- Publication Date

- 14-Mar-2027

- Technical Committee

- CEN/TC 147 - Cranes - Safety

- Drafting Committee

- CEN/TC 147/WG 14 - Bridge and gantry cranes

- Current Stage

- 4060 - Closure of enquiry - Enquiry

- Start Date

- 02-Oct-2025

- Due Date

- 18-Jan-2026

- Completion Date

- 02-Oct-2025

Relations

- Effective Date

- 04-Dec-2024

Overview

prEN 15011:2025 - "Cranes - Bridge and gantry cranes" (CEN/TC 147) is the draft European standard that updates and will supersede EN 15011:2020. It specifies safety and performance requirements for bridge and gantry cranes that travel on wheels (rails, runways or roadway surfaces) and for stationary gantry cranes without wheels. The standard addresses significant hazards and protective measures for use as intended by the manufacturer and is intended as a harmonized standard supporting conformity with the EU Machinery Regulation.

Key exclusions: light crane systems (covered by EN 16851), lifting of persons, potentially explosive atmospheres, ionising radiation, and electromagnetic environments beyond EN 61000‑6‑2.

Key topics and requirements

prEN 15011:2025 covers the full lifecycle of crane design, manufacture, testing and information for use. Major technical topics include:

- Safety requirements and protective measures for all significant hazards (see Annex A)

- Strength and stability: load actions, limit states, proof of competence, and stability verification

- Electrotechnical requirements: electrical supply, protection against electric shock, control circuits, operator interfaces and batteries

- Mechanical systems: hoisting equipment, brakes, travelling/traversing, slewing, gear drives and tolerances

- Limiting and indicating devices: rated capacity limiters, indicators, motion and performance limiters

- Man–machine interface: control stations, mounted controls, guarding, access, lighting and noise reduction

- Warning and safety devices: visual/acoustic warnings, marking and cableless control

- Verification and testing: types of verification, fitness-for-purpose testing and installation checks

- Information for use: operator and user manuals, installation/maintenance instructions, marking and manufacturer’s plate

- Annexes covering noise test code, local wheel stresses, dynamic factors, skewing loads, actions on supporting structures, automated operation guidance and relationships to EU Regulation (Annex ZA)

Applications and who uses this standard

prEN 15011:2025 is essential for stakeholders involved with bridge and gantry cranes:

- Crane manufacturers and designers - to ensure safe design, structural verification and compliance

- Safety and standards engineers - to assess hazards, specify protective measures and prepare conformity documentation

- Test laboratories and notified bodies - for fitness-for-purpose testing and verification against the standard

- Plant owners, maintenance teams and integrators - for safe installation, commissioning, operation and maintenance

- Procurers and specifiers - to define technical requirements for cranes in tenders and contracts

Using this standard helps achieve crane safety, regulatory conformity and consistent technical specifications for industrial lifting equipment.

Related standards

- EN 16851 - Light crane systems (wall-mounted, pillar, jib)

- EN 13001-1 - Referenced for operating duty specification

- EN 61000-6-2 - Electromagnetic environment immunity limits

- EN 15011:2020 - Superseded by prEN 15011:2025

Keywords: prEN 15011:2025, bridge and gantry cranes standard, crane safety, CEN crane standard, load actions, stability, electrotechnical requirements, noise emission, crane verification.

Frequently Asked Questions

prEN 15011 is a draft published by the European Committee for Standardization (CEN). Its full title is "Cranes - Bridge and gantry cranes". This standard covers: This document applies to bridge and gantry cranes able to travel by wheels on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary position. NOTE Light crane systems (assembly of lifting devices, crane bridges, trolleys and tracks; wall-mounted, pillar and workshop jib cranes) are covered by EN 16851. This document specifies requirements for all significant hazards, hazardous situations and events relevant to bridge and gantry cranes when used as intended and under conditions foreseen by the manufacturer (see Clause 4). This document does not include requirements for the lifting of persons. The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in electromagnetic environment beyond the scope of EN 61000-6-2 are not covered by this document. This document is applicable to bridge and gantry cranes manufactured after the date of its publication as a European standard.

This document applies to bridge and gantry cranes able to travel by wheels on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary position. NOTE Light crane systems (assembly of lifting devices, crane bridges, trolleys and tracks; wall-mounted, pillar and workshop jib cranes) are covered by EN 16851. This document specifies requirements for all significant hazards, hazardous situations and events relevant to bridge and gantry cranes when used as intended and under conditions foreseen by the manufacturer (see Clause 4). This document does not include requirements for the lifting of persons. The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in electromagnetic environment beyond the scope of EN 61000-6-2 are not covered by this document. This document is applicable to bridge and gantry cranes manufactured after the date of its publication as a European standard.

prEN 15011 is classified under the following ICS (International Classification for Standards) categories: 53.020.20 - Cranes. The ICS classification helps identify the subject area and facilitates finding related standards.

prEN 15011 has the following relationships with other standards: It is inter standard links to EN 15011:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

prEN 15011 is associated with the following European legislation: EU Directives/Regulations: 2023/1230; Standardization Mandates: M/605. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

prEN 15011 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2025

Žerjavi - Mostni in portalni (kozičasti) žerjavi

Cranes - Bridge and gantry cranes

Krane - Brücken- und Portalkrane

Appareils de levage à charge suspendue - Ponts roulants et portiques de levage

Ta slovenski standard je istoveten z: prEN 15011

ICS:

53.020.20 Dvigala Cranes

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

July 2025

ICS 53.020.20 Will supersede EN 15011:2020

English Version

Cranes - Bridge and gantry cranes

Appareils de levage à charge suspendue - Ponts Krane - Brücken- und Portalkrane

roulants et portiques de levage

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 147.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 15011:2025 E

worldwide for CEN national Members.

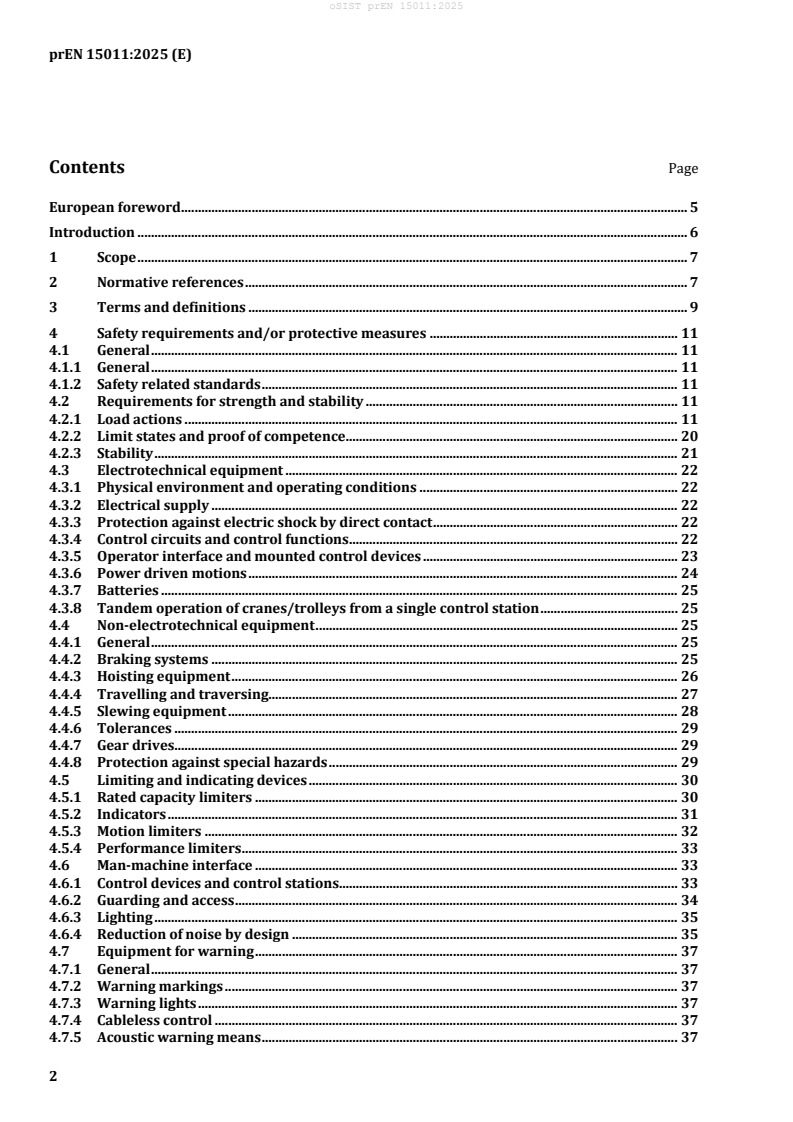

Contents Page

European foreword . 5

Introduction . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 9

4 Safety requirements and/or protective measures . 11

4.1 General . 11

4.1.1 General . 11

4.1.2 Safety related standards . 11

4.2 Requirements for strength and stability . 11

4.2.1 Load actions . 11

4.2.2 Limit states and proof of competence . 20

4.2.3 Stability . 21

4.3 Electrotechnical equipment . 22

4.3.1 Physical environment and operating conditions . 22

4.3.2 Electrical supply . 22

4.3.3 Protection against electric shock by direct contact . 22

4.3.4 Control circuits and control functions . 22

4.3.5 Operator interface and mounted control devices . 23

4.3.6 Power driven motions . 24

4.3.7 Batteries . 25

4.3.8 Tandem operation of cranes/trolleys from a single control station . 25

4.4 Non-electrotechnical equipment . 25

4.4.1 General . 25

4.4.2 Braking systems . 25

4.4.3 Hoisting equipment . 26

4.4.4 Travelling and traversing. 27

4.4.5 Slewing equipment . 28

4.4.6 Tolerances . 29

4.4.7 Gear drives. 29

4.4.8 Protection against special hazards . 29

4.5 Limiting and indicating devices . 30

4.5.1 Rated capacity limiters . 30

4.5.2 Indicators . 31

4.5.3 Motion limiters . 32

4.5.4 Performance limiters . 33

4.6 Man-machine interface . 33

4.6.1 Control devices and control stations. 33

4.6.2 Guarding and access . 34

4.6.3 Lighting . 35

4.6.4 Reduction of noise by design . 35

4.7 Equipment for warning . 37

4.7.1 General . 37

4.7.2 Warning markings . 37

4.7.3 Warning lights . 37

4.7.4 Cableless control . 37

4.7.5 Acoustic warning means . 37

4.7.6 Location of the visual display unit . 37

5 Verification of safety requirements and/or protective measures . 37

5.1 General . 37

5.2 Types of verification . 38

5.3 Fitness for purpose testing. 41

5.3.1 General . 41

5.3.2 Tests . 42

6 Information for use . 44

6.1 General . 44

6.2 Operator’s manual . 44

6.3 User’s manual . 45

6.3.1 General . 45

6.3.2 Instructions for installation . 45

6.3.3 Instructions for maintenance . 45

6.4 Marking of rated capacities . 46

6.5 Manufacturer´s plate . 47

Annex A (informative) List of significant hazards . 48

Annex B (informative) Guidance for specifying the operating duty in accordance with

EN 13001-1:2015 . 52

B.1 Total number of working cycles . 52

B.2 Load spectrum factor kQ . 52

B.3 Average motion displacements . 54

Annex C (informative) Guidance for specifying the classes P of average number of accelerations

in accordance with EN 13001-1:2015 . 57

Annex D (informative) Calculation of dynamic coefficient ϕ . 58

Annex E (informative) Loads caused by skewing . 61

E.1 Assumptions for simplified calculating methods. 61

E.2 Calculation of skewing forces by method RIGID . 61

E.3 Calculation of skewing forces by method FLEXIBLE . 64

Annex F (normative) Local stresses in wheel supporting flanges . 69

F.1 General . 69

F.2 Local stresses in wheel supporting flanges (main girder as I-beam) . 69

F.3 Local stresses of a box girder with the wheel loads on the bottom flange . 72

Annex G (normative) Noise test code . 74

G.1 General . 74

G.2 Description of machinery family . 75

G.3 Determination of an emission sound pressure level by calculation . 75

G.4 Determination of emission sound pressure level at control stations and other specified

positions and determination of sound power level by measurement . 76

G.5 Uncertainties . 81

G.6 Information to be recorded . 81

G.7 Information to be reported . 81

G.8 Declaration and verification of noise emission values . 81

Annex H (normative) Actions on crane supporting structures induced by cranes . 83

H.1 General . 83

H.2 Actions induced by cranes . 83

H.3 Dynamic factors . 84

Annex I (informative) Selection of a suitable set of crane standards for a given application . 86

Annex J (informative) Guidance for automated operation . 88

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of Regulation (EU) 2023/1230 aimed to be covered . 89

Bibliography . 93

European foreword

This document (prEN 15011:2025) has been prepared by Technical Committee CEN/TC 147

“Cranes - Safety”, the secretariat of which is held by SFS.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 15011:2020.

The main changes compared with EN 15011:2020 are as follows:

— Clause 4, List of significant hazards was moved to Annex A. Tables, annexes and references were

renumbered accordingly;

— updated reference documents;

— revised subclauses 4.1, 4.2.1.3.1;

— added new subclause 6.5;

— deleted Clause A.4;

— added new subclause 4.3.4.4;

— added new Annex J.

This document has been prepared under a standardization request addressed to CEN by the European

Commission. The Standing Committee of the EFTA States subsequently approves these requests for its

Member States.

For the relationship with EU Legislation, see informative Annex ZA, which is an integral part of this

document.

For the relationship with other European Standards for cranes, see Annex I.

Introduction

This document has been prepared to be a harmonized standard to provide one means for bridge and

gantry cranes to conform with the essential health and safety requirements of the Machinery Regulation,

as mentioned in Annex ZA.

As many of the hazards related to bridge and gantry cranes relate to their operating environment and

use, it is assumed in the preparation of this document that all the relevant information relating to the use

and operating environment of the crane has been exchanged between the manufacturer and the user,

covering such issues as, for example:

— clearances;

— requirements concerning protection against hazardous environments;

— processed materials, such as potentially flammable or explosive material (e.g. coal, powder type

materials).

This document is a type C standard as stated in EN ISO 12100:2010.

This document is of relevance, in particular, for the following stakeholder groups representing the market

players with regard to machinery safety:

— machine manufacturers (small, medium and large enterprises);

— health and safety bodies (regulators, accident prevention organizations, market surveillance, etc.).

Others can be affected by the level of machinery safety achieved with the means of the document by the

above-mentioned stakeholder groups:

— machine users/employers (small, medium and large enterprises);

— machine users/employees (e.g. trade unions, organizations for people with special needs);

— service providers, e.g. for maintenance (small, medium and large enterprises); — consumers (in case

of machinery intended for use by consumers).

The above-mentioned stakeholder groups have been given the possibility to participate at the drafting

process of this document.

The machinery concerned and the extent to which hazards, hazardous situations and hazardous events

are covered, are indicated in the scope of this document.

When requirements of this type C standard are different from those which are stated in type A or B

standards, the requirements of this type C standard take precedence over the requirements of the other

standards, for machines that have been designed and built according to the requirements of this type C

standard.

1 Scope

This document applies to bridge and gantry cranes, including semi-gantry cranes, able to travel by wheels

on rails, runways or roadway surfaces, and to gantry cranes without wheels mounted in a stationary

position.

NOTE 1 Light crane systems (assembly of lifting devices, crane bridges, trolleys and tracks; wall-mounted, pillar

and workshop jib cranes) are covered by EN 16851:2017+A1:2020.

This document specifies requirements for all significant hazards, hazardous situations and events

relevant to bridge and gantry cranes when used as intended, foreseeable misuse and under conditions

foreseen by the manufacturer (see Annex A).

NOTE 2 Automated operation can be subject to additional requirements. Guidance is given in Annex J.

This document does not include requirements for the lifting of persons.

The specific hazards due to potentially explosive atmospheres, ionising radiation and operation in

electromagnetic environment beyond the scope of EN IEC 61000-6-2 are not covered by this document.

This document is not applicable to bridge and gantry cranes manufactured before the date of its

publication.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 81-43:2025, Safety rules for the construction and installation of lifts - Special lifts for the transport of

persons and goods - Part 43: Lifts for cranes

EN 894-1:1997+A1:2008, Safety of machinery - Ergonomics requirements for the design of displays and

control actuators - Part 1: General principles for human interactions with displays and control actuators

EN 894-2:1997+A1:2008, Safety of machinery - Ergonomics requirements for the design of displays and

control actuators - Part 2: Displays

EN 12077-2:2024, Cranes safety - Requirements for health and safety - Part 2: Limiting and indicating

devices

EN 13001-1:2015, Cranes - General design - Part 1: General principles and requirements

EN 13001-2:2021, Crane safety - General design - Part 2: Load actions

EN 13001-3-1:2025, Cranes - General Design - Part 3-1: Limit states and proof competence of steel structure

EN 13001-3-2:2014, Cranes - General design - Part 3-2: Limit states and proof of competence of wire ropes

in reeving systems

EN 13001-3-3:2014, Cranes - General design - Part 3-3: Limit states and proof of competence of wheel/rail

contacts

EN 13001-3-4:2018, Cranes - General design - Part 3-4: Limit states and proof of competence of machinery

- Bearings

EN 13001-3-5:2016+A1:2021, Cranes - General design - Part 3-5: Limit states and proof of competence of

forged and cast hooks

EN 13001-3-6:2018+A1:2021, Cranes - General design - Part 3-6: Limit states and proof of competence of

machinery - Hydraulic cylinders

EN 13135:2013+A1:2018, Cranes - Safety - Design - Requirements for equipment

EN 13157:2004+A1:2009, Cranes - Safety - Hand powered cranes

EN 13557:2024, Cranes – Control devices and control stations

EN 13586:2020, Cranes - Access

EN 14492-2:2019, Cranes - Power driven winches and hoists - Part 2: Power driven hoists

EN 50742:—, Safety of machinery - Protection against corruption

EN IEC 60204-11:2019, Safety of machinery - Electrical equipment of machines - Part 11: Requirements for

equipment for voltages above 1 000 V AC or 1 500 V DC and not exceeding 36 kV (IEC 60204-11:2018)

EN 60204-32:2008, Safety of machinery - Electrical equipment of machines - Part 32: Requirements for

hoisting machines (IEC 60204-32:2008)

HD 60364-4-41:2017, Low voltage electrical installations - Part 4-41: Protection for safety - Protection

against electric shock (IEC 60364-4-41:2005/A1:2017, modified)

EN 60825-1:2014, Safety of laser products - Part 1: Equipment classification and requirements

(IEC 60825-1:2014)

Low-voltage switchgear and controlgear - Part 5-5: Control circuit devices and

EN 60947-5-5:1997,

switching elements - Electrical emergency stop device with mechanical latching function

(IEC 60947-5-5:1997, IEC 60947-5-5:1997/A2:2016)

EN 62745:2017, Safety of machinery - Requirements for cableless control systems of machinery

(IEC 62745:2017)

EN ISO 20607:2019, Safety of machinery - Instruction handbook - General drafting principles (ISO

20607:2019)

EN ISO 3744:2010, Acoustics - Determination of sound power levels and sound energy levels of noise sources

using sound pressure - Engineering methods for an essentially free field over a reflecting plane (ISO

3744:2010)

EN ISO 4871:2009, Acoustics - Declaration and verification of noise emission values of machinery and

equipment (ISO 4871:1996)

EN ISO 11201:2010, Acoustics - Noise emitted by machinery and equipment - Determination of emission

sound pressure levels at a work station and at other specified positions in an essentially free field over a

reflecting plane with negligible environmental corrections (ISO 11201:2010)

Under preparation with CLC/TC 44X/WG 2. Stage 10.99 realized on 2023-12-13.

As impacted by HD 60364-4-41:2017/A11:2017 and HD 60364-4-41:2017/A12:2019.

As impacted by EN 60825-1:2014/A11:2021 and by two Corrigenda EN 60825-1:2014/A11:2021/AC:2022-03 and EN 60825-

1:2014/AC:2017-06

As impacted by EN 60947-5-5:1997/A1:2005, EN 60947-5-5:1997/A11:2013 and EN 60947-5-5:1997/A2:2017

As impacted by EN 62745:2017/A11:2020

EN ISO 11688-1:2009, Acoustics - Recommended practice for the design of low-noise machinery and

equipment - Part 1: Planning (ISO/TR 11688-1:1995)

EN ISO 12100:2010, Safety of machinery - General principles for design - Risk assessment and risk reduction

(ISO 12100:2010)

EN ISO 13849-1:2023, Safety of machinery - Safety-related parts of control systems - Part 1: General

principles for design (ISO 13849-1:2023)

EN ISO 13854:2019, Safety of machinery - Minimum gaps to avoid crushing of parts of the human body (ISO

13854:2017)

EN ISO 13857:2019, Safety of machinery - Safety distances to prevent hazard zones being reached by upper

and lower limbs (ISO 13857:2019)

EN ISO 14120:2015, Safety of machinery - Guards - General requirements for the design and construction

of fixed and movable guards (ISO 14120:2015)

ISO 2631-1:1997, Mechanical vibration and shock - Evaluation of human exposure to whole-body

vibration - Part 1: General requirements

ISO 3864-1:2011, Graphical symbols - Safety colours and safety signs - Part 1: Design principles for safety

signs and safety markings

ISO 3864-2:2016, Graphical symbols - Safety colours and safety signs - Part 2: Design principles for product

safety labels

ISO 3864-3:2024, Graphical symbols - Safety colours and safety signs - Part 3: Design principles for

graphical symbols for use in safety signs

ISO 3864-4:2011, Graphical symbols - Safety colours and safety signs - Part 4: Colorimetric and photometric

properties of safety sign materials

ISO 4306-1:2007, Cranes - Vocabulary - Part 1: General

ISO 6336-1:2019, Calculation of load capacity of spur and helical gears - Part 1: Basic principles,

introduction and general influence factors

ISO 7752-5:2021, Cranes - Control layout and characteristics - Part 5: Bridge and gantry cranes

ISO 12488-1:2012, Cranes - Tolerances for wheels and travel and traversing tracks - Part 1: General

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN ISO 12100:2010,

EN ISO 3744:2010, EN ISO 11201:2010, ISO 4306-1:2007 and the following apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at http://www.electropedia.org/

As impacted by ISO 2631-1:1997/Amd1:2010A

3.1

bridge crane

crane with its bridge girders directly supported on rail tracks by travelling (end) carriages

Note 1 to entry: Light crane systems are defined in EN 16851.

Note 2 to entry: Building structures, where hoists are mounted, are not regarded as bridge cranes.

[SOURCE: ISO/DIS 4306-1:2023, 1.1.1.1]

3.2

gantry crane

crane with the bridge girders supported either on rail tracks or on flat surface by legs

Note 1 to entry: Building structures, where hoists are mounted, are not regarded as gantry cranes.

Note 2 to entry: See ISO 4306-5, e.g. RTG cranes.

[SOURCE: ISO/DIS 4306-1:2023, 1.1.1.2]

3.3

rated capacity

m

RC

maximum net load (the sum of the payload and non-fixed load-lifting attachment) that the crane is

designed to lift for a given crane configuration and load location during normal operation

Note 1 to entry: The term Safe Working Load (SWL) can differ from rated capacity.

[SOURCE: ISO 4306-1:2007, 6.1.8, modified]

3.4

hoist load

m

H

sum of the masses of the load equal to the rated capacity, the fixed lifting attachment and the hoist

medium

Note 1 to entry: This is equivalent to gross load defined in ISO 4306-1:2007.

3.6

underhung crane

crane travelling suspended on the bottom of the track beams

[SOURCE: ISO/DIS 4306-1:2023, 1.6.2, modified]

3.7

directly acting lifting force limiter

limiter acting directly in the chain of drive elements and limiting the transmitted force

Note 1 to entry: Those limiters can be, for example, friction torque limiters, pressure limiting valves. Directing

acting rated capacity limiters generally have no response delay.

3.8

indirectly acting lifting force limiter

limiter determining the transmitted force by measured signals and switching off the energy supply for

the operation and, if required, triggering application of the brake torque

4 Safety requirements and/or protective measures

4.1 General

4.1.1 General

Bridge and gantry cranes shall comply with the safety requirements and/or protective measures of

Clause 4. In addition, these cranes shall be designed in accordance with the principles of

EN ISO 12100:2010 for relevant but not significant hazards, which are not dealt with by this document.

4.1.2 Safety related standards

Bridge and gantry cranes shall be designed and constructed in such a way as to prevent failure from

fatigue and wear, taking due account of their intended use and any reasonably foreseeable misuse.

Cranes shall be in accordance with the following standards, except as otherwise required in this

document:

— EN 13001-1:2015, Cranes — General design — Part 1: General principles and requirements;

— EN 13001-2:2021, Cranes — General design — Part 2: Load actions;

— EN 13135:2013+A1:2018, Cranes — Safety — Design — Requirements for equipment;

— EN 12077-2:2024, Cranes safety — Requirements for health and safety — Part 2: Limiting and

indicating devices;

— EN 13586:2020, Cranes — Access;

— EN 60204-32:2008, Safety of machinery — Electrical equipment of machines — Part 32: Requirements

for hoisting machines (IEC 60204-32:2008).

Cranes designed for high-risk applications, e.g. handling hot molten metal, shall meet the relevant

requirements given in EN 13135:2013+A1:2018, 5.9 and EN 13001-2:2021, 4.3.2.

The requirements of this document are not applied to power driven hoist units, designed in accordance

with EN 14492-2:2019, and incorporated in a bridge or gantry cranes.

4.2 Requirements for strength and stability

4.2.1 Load actions

4.2.1.1 Selection of operating conditions

The operating conditions and the design duty (classification) that are selected and used as the basis of

design, in accordance with EN 13001-1:2015, 4.3 and EN 13001-2:2021, Clause 4, shall be specified in the

technical file of the crane. Examples of the operating conditions are:

— operational temperature limits;

— in-service wind speed limit;

— the wind characteristics, as defined in EN 13001-2:2021, 4.2.4.2, for out-of-service condition;

— high risk provisions (if any) taken in-to account;

— displacement limits for the crane runway in the loaded condition.

For cranes located outdoors, the recurrence period in accordance with EN 13001-2:2021, 4.2.4.2 for out

of service wind shall be not less than:

— 25 years for cranes located permanently outdoors;

— 5 years for indoor cranes which can occasionally be parked outdoors.

Guidance for specifying the operation duty is given in Annex B.

NOTE For information needed for the derivation of classification parameters, see also ISO 9374-5.

4.2.1.2 Selection of loads and load combinations

The basic load combinations for the load calculation shall be selected in accordance with

EN 13001-2:2021, 4.3.

4.2.1.3 Determination of dynamic factors

4.2.1.3.1 Dynamic effect on mass of the crane

The masses of the crane shall be multiplied with factor ϕ = 1 + δ when calculating the stresses in load

combinations in accordance with EN 13001-2:2021, 4.3.

For masses with unfavourable gravitational load effect the factors shall be taken as δ = 0,10 and ϕ = 1,10,

and for masses with favourable gravitational load effect as δ = −0,05 and ϕ = 0,95. Factor ϕ for

1 1

unfavourable gravitational load effect need not be taken greater than factor ϕ of 4.2.1.3.2. Alternatively,

ϕ may be determined by dynamic analysis.

4.2.1.3.2 Dynamic effects when hoisting a grounded load

Dynamic effects and the related load actions shall be taken into account as specified in EN 13001-2:2021,

4.2.2.2.1.

The dynamic factor ϕ shall be determined by one of the following methods, which shall not be mixed or

cross referenced with each other in any way:

a) applying the method given in EN 13001-2:2021, 4.2.2.2.1, where stiffness class HC and the hoist drive

class HD are specified for the crane;

b) using analytic modelling, where the crane and trolley structures, hoisting mechanism and the hoist

drive system are taken into account. Design value of the hoisting speed shall be selected in

accordance with the HD class (EN 13001-2:2021, 4.2.2.2.2) for each relevant load combination.

Annex D gives an analytic solution for a particular type of bridge crane to determine the factor ϕ

and can be used where applicable;

c) measuring of the hoist rope force. Hoisting shall be assumed to commence from a rope tightness

condition at a maximum hoisting speed, which can be attained by taking into account the

characteristics of the hoist drive system.

4.2.1.3.3 Load caused by travelling on uneven surfaces

The dynamic actions on the crane by travelling, with or without hoist load, on roadway or on rail tracks

shall be considered by the specific factor ϕ .

For continuous rail tracks or welded rail tracks with finished ground joints without notches (steps or

gaps) the specific factor ϕ 4 = 1.

For roadways or rail tracks with notches (steps or gaps) the specific factor ϕ shall be calculated in

accordance with EN 13001-2:2021, 4.2.2.4. For rubber tyred cranes the flexibility of tyres shall be taken

into account.

The factor ϕ for steps may be set equal to 1,0, separately in any of the following cases:

— the step is 1 mm or less and the natural frequency of a single mass model of the crane, including the

masses of the trolley and the hoist load, is 4 Hz or less;

— the wheel subject to the step is arranged in a hinged, multi-wheel bogie system;

— rubber tyred cranes.

The factor ϕ for gaps may be set equal to 1,0, separately in any of the following cases:

— the gap is 5 mm or less and the natural frequency of a single mass model of the crane, including the

masses of the trolley and the hoist load, is 8 Hz or less;

— the wheel subject to the gap is arranged in a hinged, multi-wheel bogie system;

— rubber tyred cranes.

Where the factor ϕ is set to 1,0 both for steps and for gaps, the corresponding load combination of

EN 13001-2:2021, 4.3 may be omitted.

4.2.1.3.4 Loads caused by acceleration of drives

For crane drive motions, the change in load effect, ΔS, caused by acceleration or deceleration is presented

by the following equation:

∆S S− S (1)

f i

( ) ()

where

S is the final load effect;

(f)

S is the initial load effect.

(i)

The change in load effects, ΔS, is caused by the change of drive force, ΔF, given by the equation:

(2)

∆F F− F

fi

( ) ()

where

F is the final drive force; and

(f)

F is the initial drive force.

(i)

Loads induced in a crane by acceleration or deceleration caused by drive forces may be calculated using

rigid body kinetic models. The load effect S shall be applied to the components exposed to the drive forces

and where applicable to the crane and the hoist load as well. As a rigid body analysis does not directly

reflect elastic effects, the load effect S shall be calculated by using a dynamic factor ϕ5 defined in

EN 13001-2:2021, 4.2.2.5 as follows:

(3)

S S+φ××am

i

()

and

φ φ×φ (4)

5 p A

where

=

=

=

=

S is the initial load effect caused by F ;

(i) (i)

ϕ is the amplification factor;

A

ϕ is the factor for effect of sequential positioning movements;

p

a is the acceleration or deceleration value;

m is the mass for which applies.

The factor ϕ shall be taken from Tables 1 and 2 unless more accurate factors are available from elastic

A

model calculations or measurements. The factor ϕ shall be taken from Table 3.

p

Where the force S is limited by friction or by the nature of the drive mechanism, this frictional force shall

be used instead of calculated force S.

for travel, traverse and slewing mechanism

Table 1 — Factor ϕA

Factor ϕ

A

Dead weight of moved masses Weight of

Drive type

freely

Typical Considerable

suspended

backlash for backlash, e.g.

load

gearbox open gears

Stepless speed control (e.g. frequency control) 1,2 1,5 2,0

Multi step speed control (e.g. slip ring motor with 2,0

1,6 2,0

rotor resistors)

Two step speed control (e.g. pole changeable 2,0

1,8 2,2

squirrel cage motor with creep speed)

Single speed control (e.g. squirrel cage motor 2,0

2,0 2,4

without creep speed)

Table 2 — Factor ϕ for hoist mechanism

A

Factor ϕ Factor ϕ

A A

Drive type

lifting lowering

Stepless speed control 1,05 1,10

Multi step speed control 1,15 1,20

Two step speed control 1,20 1,35

Single speed control 1,20 1,30

Factors in Tables 1 and 2 take account for switching on/off the speed and speed change.

Table 3 — Factor ϕ

P

Class of load positioning in

accordance with ϕP

EN 13001-1:2015

P and P 1,0

0 1

P 1,15

P 1,3

For freely suspended load the factor ϕ is set to 1,0.

P

Positioning movements can increase the total load effects, when made in non-optimal manner. This is

taken into account by factor ϕ dependent upon the class P. Guidance for determining the class P is given

P

in Annex C.

4.2.1.4 Loads caused by skewing

4.2.1.4.1 General

Skewing forces for top running cranes and trolleys shall be calculated in accordance with 4.2.1.4.2 to

4.2.1.4.4. More guidance and examples are given in Annex E, which provides a simplified method for

calculating the forces generated when considering both RIGID and FLEXIBLE crane structures. Skewing

forces for underhung cranes shall be calculated in accordance with 4.2.1.4.5.

The skewing forces shall be addressed to load combination B. Where the crane is provided with

continuously active anti-skew devices, the forces, without the benefit of anti-skew devices (e.g. failure of

the device), shall be addressed to load combination C.

Where two bridge or gantry cranes are linked by articulated connection beams, they shall be considered

as a single crane.

NOTE 1 The method given in EN 13001-2:2021, 4.2.3.4 is applicable to rigid structures. Cranes can possess both

rigid and flexible characteristics; therefore, a more general method is required as given here. With this method also

flexible structures, uneven number of wheels, unequally distributed wheel loads as well as different types of guide

means and anti-skewing devices can be considered.

NOTE 2 Forces arising from skewing are generated when the resultant direction of rolling movement of the

travelling crane no longer coincides with the direction of the runway rail, and when the front positive guiding means

come to contact with the rail. This is caused by tolerances and inaccuracies, which arise in the manufacture of the

crane (bores of track wheels) and that of the runway's rail (bends, kinks). The values and distribution of these forces

depend chiefly upon the clearances between the runway rail and the wheel flanges or guide rollers and the latter's

location, also on the number, arrangement, bearing arrangement and rotational speed synchronisation of the track

wheels and structural flexibility.

NOTE 3 Anti-skew device is a mechanical or electrical system to reduce skewing forces. The use of anti-skew

devices with travel motions reduces the guiding forces between the rail and guiding means. It also reduces the

lateral slip forces of the wheels, but some lateral slip remains due to wheel alignment tolerances and lateral

deformations of structures.

4.2.1.4.2 Skew angle

The skew angle shall be calculated as follows in Figure 1:

Figure 1 — Parameters of skew angle

The total skew angle to be considered in design is

α= α+α+α

gw t

where

α is the skew angle to be considered in design;

α is the skew component s /w ;

g g b

α is the component due to wear - rail and wheel flange/guide roller;

w

α is the component due to alignment tolerances of rail/wheel.

t

The values for skew angles shall be determined in accordance with Table 4.

Table 4 — Skew angle computation

Skew Skew angle resulting from Flanged wheels Guide rollers

component

α = (sW/ )

rad;

g g min b

when

ss≤

g g min

α

Track clearance

s

g

g

α 0, 75× rad;

g

W

b

when ss>

g g min

Crane travelling; Recommended

s = 10 mm s = 5 mm

gmin gmin

minimum track clearances

Trolley traversing; Recommended

s = 4 mm s = 2 mm

gmin gmin

minimum track clearances

Tolerances (wheel alignment and

α α = 0,001 rad

t

t

straightness of the rail)

b

h

α 0,03× rad

b

Wear of wheel flanges/rollers and w

h

α α 0,10× rad

W

w w

b

rails

W

b

For underhung cranes b , shall be taken as the sum of the wheel contact widths on the same axis.

h

The ske

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...