EN 10250-4:2021

(Main)Open die steel forgings for general engineering purposes - Part 4: Stainless steels

Open die steel forgings for general engineering purposes - Part 4: Stainless steels

This document specifies the technical delivery requirements for open die forgings, forged bars and products pre-forged and finished in ring rolling mills, manufactured from stainless steels with ferritic, martensitic, austenitic and austenitic-ferritic structures.

NOTE The majority of steels listed in this part of EN 10250 are identical to steels specified EN 10088-3 and EN 10028-7, and more extensive information on properties is given in these European Standards.

General information on technical delivery conditions is given in EN 10021.

Freiformschmiedestücke aus Stahl für allgemeine Verwendung - Teil 4: Nichtrostende Stähle

Dieses Dokument legt die technischen Lieferbedingungen für Freiformschmiedestücke, geschmiedete Stäbe sowie vorgeschmiedete und in Ringwalzwerken fertigumgeformte Erzeugnisse fest, die aus nichtrostenden Stählen mit ferritischem, martensitischem, austenitischem oder austenitisch-ferritischem Gefüge gefertigt werden.

ANMERKUNG Die meisten Stähle, die in diesem Teil der EN 10250 aufgeführt sind, sind mit Stählen identisch, die in EN 10088-3 und EN 10088-7 festgelegt sind. Umfassende Angaben über deren Eigenschaften werden in jenen Europäischen Normen gemacht.

Allgemeine Angaben über die technischen Lieferbedingungen enthält EN 10021.

Pièces forgées en acier pour usage général - Partie 4 : Aciers inoxydables

Le présent document spécifie les conditions techniques de livraison des pièces obtenues par forgeage libre, des barres forgées et des produits préforgés et finis par laminage circulaire, fabriqués en aciers inoxydables à structure ferritique, martensitique, austénitique et austéno-ferritique.

NOTE La majorité des aciers énumérés dans la présente partie de l'EN 10250 sont identiques à ceux spécifiés dans l'EN 10088-3 et l’EN 10028-7, et des informations plus complètes quant aux caractéristiques de ces aciers sont fournies dans ces Normes européennes.

Les informations générales sur les conditions techniques de livraison sont données dans l'EN 10021.

Prosto kovani jekleni izkovki za splošno tehnično uporabo - 4. del: Nerjavna jekla

General Information

- Status

- Published

- Publication Date

- 18-May-2021

- Withdrawal Date

- 29-Nov-2021

- Technical Committee

- ECISS/TC 111 - Steel castings and forgings

- Drafting Committee

- CEN/TC 459/SC 11/WG 2 - Steel forgings

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 19-May-2021

- Completion Date

- 19-May-2021

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 10250-4:2021 - Open die steel forgings for general engineering purposes (Part 4: Stainless steels) is a CEN European Standard that defines the technical delivery requirements for open-die forgings, forged bars and products pre-forged or finished in ring-rolling mills manufactured from stainless steels. It covers stainless grades with ferritic, martensitic, austenitic and austenitic‑ferritic (duplex) microstructures and provides requirements for chemical composition, corrosion characteristics, heat treatment and mechanical properties.

Key topics and technical requirements

- Scope and product types: Applies to open die forgings, forged bars and ring-rolled products made from stainless steels for general engineering use.

- Chemical composition: Cast analysis and product analysis requirements are given in tabulated form (Tables 1–3), with permissible deviations between cast and product analysis specified (Table 4). Intentional additions of elements not listed require purchaser agreement.

- Corrosion resistance: Resistance to intergranular corrosion for austenitic, austenitic‑ferritic and ferritic grades is addressed by reference to EN ISO 3651-2; note that EN ISO 3651-2 is not applicable to martensitic and precipitation‑hardening steels.

- Heat treatment: Guidance for heat treatment conditions is provided in Annex A (Tables A.1–A.3). Grain size is at manufacturer’s discretion. If post‑heat‑treatment straightening is performed, procedures must avoid harmful residual stresses; thermal stress relief applied to forgings must also be applied to test specimens.

- Mechanical properties: Room temperature mechanical properties and testing requirements are in Tables 5–7; low temperature properties are shown in Annex B. Elevated temperature proof strength references are given to EN 10088‑3.

- Testing and delivery: Test-piece preparation, sampling and test methods are aligned with EN 10250‑1 requirements and relevant normative references.

Practical applications

- Specification benchmark for manufacturers and purchasers when ordering stainless steel forgings for pumps, valves, shafts, rings and general engineering components.

- Basis for quality control, inspection and acceptance testing of forged stainless steel components used in chemical, petrochemical, power generation and marine industries.

- Reference for material selection where corrosion resistance, mechanical performance at room and low temperature, and heat‑treatability are critical.

Who uses this standard

- Forging manufacturers, heat‑treaters and ring‑rolling mills

- Design and procurement engineers specifying forged stainless components

- Quality assurance, inspection and testing laboratories

- Project managers and fabricators in oil & gas, chemical processing, power and marine sectors

Related standards

- EN 10250‑1:1999 (General requirements for open die forgings)

- EN 10088‑3 and EN 10028‑7 (more extensive information on stainless steel grades and properties)

- EN 10021 (technical delivery conditions - general guidance)

- EN ISO 3651‑2 (intergranular corrosion testing)

Keywords: EN 10250-4:2021, stainless steel forgings, open die forgings, technical delivery requirements, corrosion resistance, heat treatment, mechanical properties, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Element Materials Technology

Materials testing and product certification.

Inštitut za kovinske materiale in tehnologije

Institute of Metals and Technology. Materials testing, metallurgical analysis, NDT.

Sponsored listings

Frequently Asked Questions

EN 10250-4:2021 is a standard published by the European Committee for Standardization (CEN). Its full title is "Open die steel forgings for general engineering purposes - Part 4: Stainless steels". This standard covers: This document specifies the technical delivery requirements for open die forgings, forged bars and products pre-forged and finished in ring rolling mills, manufactured from stainless steels with ferritic, martensitic, austenitic and austenitic-ferritic structures. NOTE The majority of steels listed in this part of EN 10250 are identical to steels specified EN 10088-3 and EN 10028-7, and more extensive information on properties is given in these European Standards. General information on technical delivery conditions is given in EN 10021.

This document specifies the technical delivery requirements for open die forgings, forged bars and products pre-forged and finished in ring rolling mills, manufactured from stainless steels with ferritic, martensitic, austenitic and austenitic-ferritic structures. NOTE The majority of steels listed in this part of EN 10250 are identical to steels specified EN 10088-3 and EN 10028-7, and more extensive information on properties is given in these European Standards. General information on technical delivery conditions is given in EN 10021.

EN 10250-4:2021 is classified under the following ICS (International Classification for Standards) categories: 77.140.20 - Stainless steels; 77.140.85 - Iron and steel forgings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 10250-4:2021 has the following relationships with other standards: It is inter standard links to EN 10250-4:1999, EN 10250-1:1999, EN 14015:2004, EN 10250-1:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 10250-4:2021 is associated with the following European legislation: Standardization Mandates: M/005. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 10250-4:2021 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-julij-2021

Nadomešča:

SIST EN 10250-4:2000

Prosto kovani jekleni izkovki za splošno tehnično uporabo - 4. del: Nerjavna jekla

Open die steel forgings for general engineering purposes - Part 4: Stainless steels

Freiformschmiedestücke aus Stahl für allgemeine Verwendung - Teil 4:Nichtrostende

Stähle

Pièces forgées en acier pour usage général - Partie 4: Aciers inoxydables

Ta slovenski standard je istoveten z: EN 10250-4:2021

ICS:

77.140.20 Visokokakovostna jekla Stainless steels

77.140.85 Železni in jekleni kovani Iron and steel forgings

izdelki

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 10250-4

EUROPEAN STANDARD

NORME EUROPÉENNE

May 2021

EUROPÄISCHE NORM

ICS 77.140.20; 77.140.85 Supersedes EN 10250-4:1999

English Version

Open die steel forgings for general engineering purposes -

Part 4: Stainless steels

Pièces forgées en acier pour usage général - Partie 4 : Freiformschmiedestücke aus Stahl für allgemeine

Aciers inoxydables Verwendung - Teil 4: Nichtrostende Stähle

This European Standard was approved by CEN on 12 April 2021.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 10250-4:2021 E

worldwide for CEN national Members.

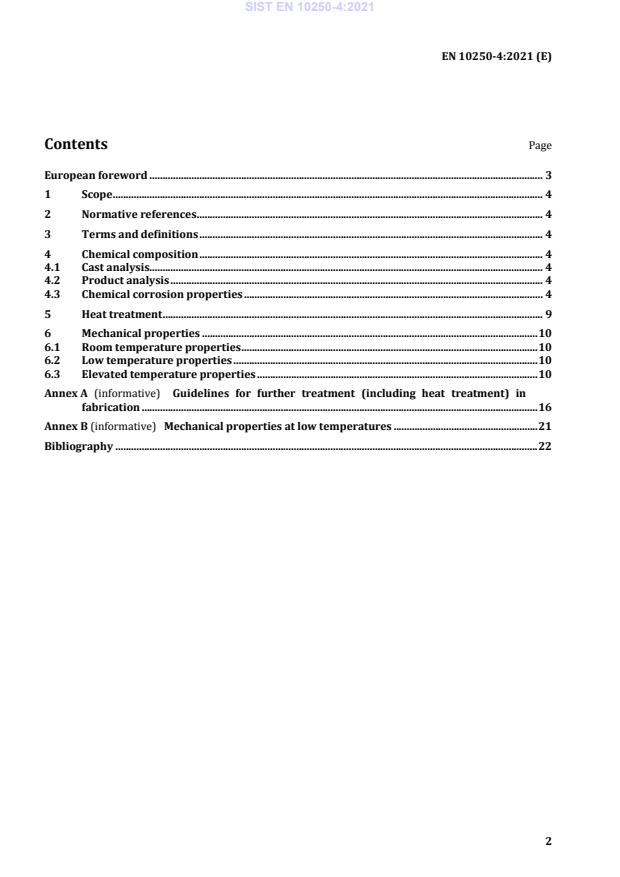

Contents Page

European foreword . 3

1 Scope . 4

2 Normative references . 4

3 Terms and definitions . 4

4 Chemical composition . 4

4.1 Cast analysis . 4

4.2 Product analysis . 4

4.3 Chemical corrosion properties . 4

5 Heat treatment . 9

6 Mechanical properties . 10

6.1 Room temperature properties . 10

6.2 Low temperature properties . 10

6.3 Elevated temperature properties . 10

Annex A (informative) Guidelines for further treatment (including heat treatment) in

fabrication . 16

Annex B (informative) Mechanical properties at low temperatures . 21

Bibliography . 22

European foreword

This document (EN 10250-4:2021) has been prepared by Technical Committee CEN/TC 459/SC 11

“Steel castings and forgings”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by November 2021, and conflicting national standards

shall be withdrawn at the latest by November 2021.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 10250-4:1999.

In comparison with the previous edition, the following technical modifications have been made:

— addition of EN 10028-7 after EN 10088-3 in the note of the Scope;

— removal of EN 10021 and EN 10088-3 from the Normative references;

— addition of Clause 3, Terms and definitions;

— restructuration of Clause 4, Chemical composition;

— introduction of three steel grades in Table 2: X1CrNi25-21, X1CrNiSi18–15–4 and

X2CrNiMnMoN25–18–6-5;

— alignment of silicon characteristics with EN 10088-3 in Table 4;

— addition of 2 columns on resistance to intergranular corrosion in Tables 6 and 7;

— introduction of footnotes in Tables of Annex A;

— deletion of Annex C, Elevated temperature proof strength.

The EN 10250 series, Open die steel forgings for general engineering purposes, consists of the following

parts:

— Part 1: General requirements;

— Part 2: Non-alloy quality and special steels;

— Part 3: Alloy special steels;

— Part 4: Stainless steels.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the

United Kingdom.

1 Scope

This document specifies the technical delivery requirements for open die forgings, forged bars and

products pre-forged and finished in ring rolling mills, manufactured from stainless steels with ferritic,

martensitic, austenitic and austenitic-ferritic structures.

NOTE The majority of steels listed in this part of EN 10250 are identical to steels specified EN 10088-3 and

EN 10028-7, and more extensive information on properties is given in these European Standards.

General information on technical delivery conditions is given in EN 10021.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 10250-1:1999, Open die steel forgings for general engineering purposes - Part 1: General requirements

3 Terms and definitions

No terms and definitions are listed in this document.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• ISO Online browsing platform: available at https://www.iso.org/obp

• IEC Electropedia: available at https://www.electropedia.org/

4 Chemical composition

4.1 Cast analysis

The chemical composition of the steel shall be determined by cast analysis and shall conform to the

analysis given in Tables 1, 2 and 3 (see A.7, A.8, and A.11 of EN 10250-1:1999).

Elements not quoted in Tables 1, 2, and 3 shall not be added intentionally to the steel without the

agreement of the purchaser, except for the purpose of finishing the heat. All reasonable measures

should also be taken to prevent the addition from the scrap, or other material used in the manufacture

of the steel, of such elements which affect the corrosion resistance, mechanical properties and

applicability of the steel.

4.2 Product analysis

The product analysis shall not deviate from the specified cast analysis (see Tables 1, 2 and 3) by more

than the values specified in Table 4 (see 9.2 of EN 10250-1:1999).

4.3 Chemical corrosion properties

Referring to resistance to intergranular corrosion as defined in EN ISO 3651-2, for austenitic, austenitic-

ferritic and ferritic stainless steels the specifications in Tables 6 and 7 apply.

NOTE 1 EN ISO 3651-2 is not applicable for testing martensitic and precipitation hardening steels.

NOTE 2 The corrosion resistance of stainless steels is very dependent on the type of environment and can

therefore not always be clearly ascertained through laboratory tests. It is therefore advisable to draw on the

available experience of the use of the steels.

Table 1 — Steel grades and chemical composition - Ferritic and martensitic grades

Steel designation

C Si max Mn max P max S max Cr Mo Ni Others

% % % % % % % % %

Name Number

a

X6CrAl13 1.4002 ≤ 0,08 1,00 1,00 0,040 12,00 to 14,00 – – Al 0,10 to 0,30

0,030

a

X6Cr17 1.4016 ≤ 0,08 1,00 1,00 0,040 16,00 to 18,00 – – –

0,030

a

X12Cr13 1.4006 0,08 to 0,15 1,00 1,50 0,040 11,50 to 13,50 – ≤ 0,75 –

0,030

a

X20Cr13 1.4021 0,16 to 0,25 1,00 1,50 0,040 12,00 to 14,00 – – –

0,030

a

X30Cr13 1.4028 0,26 to 0,35 1,00 1,50 0,040 12,00 to 14,00 – – –

0,030

a

X17CrNi16–2 1.4057 0,12 to 0,22 1,00 1,50 0,040 15,00 to 17,00 – 1,50 to 2,50 –

0,030

X3CrNiMo13–4 1.4313 ≤ 0,05 0,70 1,50 0,040 0,015 12,00 to 14,00 0,30 to 0,70 3,50 to 4,50 N ≥ 0,020

a

X4CrNiMo16–5-1 1.4418 ≤ 0,06 0,70 1,50 0,040 15,00 to 17,00 0,80 to 1,50 4,00 to 6,00 N ≥ 0,020

0,030

Nb = 5xC to 0,45

a

X5CrNiCuNb16–4 1.4542 ≤ 0,07 0,70 1,50 0,040 15,00 to 17,00 ≤ 0,60 3,00 to 5,00 Cu = 3,00 to 5,00

0,030

a

For products to be machined a controlled sulfur content of 0,015 % to 0,030 % is recommended.

Table 2 — Steel grades and chemical composition - Austenitic grades

Steel designation C P

Si max Mn max S max N Cr Mo Ni Nb Ti Others

max max

% % % % % % % % % %

Name Number

% %

17,50 to

a

X2CrNi18–9 1.4307 0,030 1,00 2,00 0,045 ≤ 0,11 – 8,00 to 10,00 – – –

≤ 0,030

19,50

10,00 to

18,00 to

a

X2CrNi19–11 1.4306 0,030 1,00 2,00 0,045 ≤ 0,11 – – – –

0,030

b

20,00

12,00

0,12 to 17,00 to – – –

a

X2CrNiN18–10 1.4311 0,030 1,00 2,00 0,045 – 8,50 to 11,50

0,030

0,22 19,50

17,00 to – – –

a

X5CrNi18–10 1.4301 0,07 1,00 2,00 0,045 ≤ 0,11 – 8,00 to 10,50

0,030

19,50

9,00 to

17,00 to 5xC to

a

X6CrNiTi18–10 1.4541 0,08 1,00 2,00 0,045 – – – –

0,030

b

19,00 0,70

12,00

10,00 to

16,50 to 2,00 to

a

X2CrNiMo17–12–2 1.4404 0,030 1,00 2,00 0,045 ≤ 0,11 – – –

0,030

b

18,50 2,50

13,00

0,12 to 16,50 to 2,00 to 10,00 to

a

X2CrNiMoN17–11–2 1.4406 0,030 1,00 2,00 0,045 – – –

0,030

0,22 18,50 2,50 12,00

16,50 to 2,00 to 10,00 to

a

X5CrNiMo17–12–2 1.4401 0,07 1,00 2,00 0,045 ≤ 0,11 – – –

0,030

18,50 2,50 13,00

10,50 to

16,50 to 2,00 to 5xC to

a

X6CrNiMoTi17–12–2 1.4571 0,08 1,00 2,00 0,045 – – –

0,030

b

18,50 2,50 0,70

13,50

0,12 to 16,50 to 2,50 to 11,00 to

X2CrNiMoN17–13–3 1.4429 0,030 1,00 2,00 0,045 0,015 – – –

0,22 18,50 3,00 14,00b

10,50 to

16,50 to 2,50 to

a

X3CrNiMo17–13–3 1.4436 0,05 1,00 2,00 0,045 ≤ 0,11 – – –

0,030

b

18,50 3,00

13,00

17,00 to 2,50 to 12,50 to

a

X2CrNiMo18–14–3 1.4435 0,030 1,00 2,00 0,045 ≤ 0,11 – – –

0,030

19,00 3,00 15,00

Steel designation C P

Si max Mn max S max N Cr Mo Ni Nb Ti Others

max max

% % % % % % % % % %

Name Number

% %

19,00 to 4,00 to 24,00 to Cu 1,20 to

X1NiCrMoCu25–20–5 1.4539 0,020 0,70 2,00 0,030 0,010 ≤ 0,15 – –

21,00 5,00 26,00 2,00

20,00 to

24,00 to

X1CrNi25-21 1.4335 0,020 0,25 2,00 0,025 0,010 ≤ 0,11 0,20 – – –

26,00

22,00

9,00 to

17,00 to 10xC to

X6CrNiNb18–10 1.4550 0,08 1,00 2,00 0,045 0,015 – – – –

b

19,00 1,00

12,00

3,7 to 16,5 to

X1CrNiSi18–15–4 1.4361 0,015 2,00 0,025 0,010 ≤ 0,10 0,20 14,0 to 16,0 – – –

4,5 18,5

26,00 to 3,00 to 30,00 to Cu 0,70 to

X1NiCrMoCu31–27–4 1.4563 0,020 0,70 2,00 0,030 ≤ 0,010 ≤ 0,11 – –

28,00 4,00 32,00 1,50

0,18 to 19,50 to 6,00 to 17,500 to Cu 0,50 to

X1CrNiMoCuN20–18–7 1.4547 0,020 0,70 1,00 0,030 0,010 – –

0,25 20,50 7,00 18,50 1,00

5,00 to 0,30 to 24,00 to 4,00 to 16,00 to

X2CrNiMnMoN25–18–6-5 1.4565 0,030 1,00 0,030 0,015 ≤ 0,15 – –

7,00 0,60 26,00 5,00 19,00

0,15 to 19,00 to 6,00 to 24,00 to

X1NiMoCuN25–20–7 1.4529 0,020 0,50 1,00 0,030 0,010 – – –

0,25 21,00 7,00 26,00

a

For products to be machined a controlled sulfur content of 0,015 % to 0,030 % is recommended.

b

Where for special reasons, e.g. hot workability for fabrication where it is necessary to minimize the delta ferrite content, or with the aim of low permeability, the maximum Ni

content may be increased by the following amounts:

– 0,50 %: 1.4571

– 1,00 %: 1.4306, 1.4429, 1.4436, 1.4541, 1.4550

– 1,50 %: 1.4404

Table 3 — Steel grades and chemical composition - Austenitic-ferritic grades

C Si Mn P S

Steel designation N Cr Mo Ni Others

max max max max max

Name Number % % % % % % % % % %

Cu 0,10 to

X2CrNiN23–4 1.4362 0,030 1,00 2,00 0,035 0,015 0,05 to 0,20 22,00 to 24,00 0,10 to 0,60 3,50 to 5,50

0,60

a

X3CrNiMoN27–5-2 1.4460 0,05 1,00 2,00 0,035 0,05 to 0,20 25,00 to 28,00 1,30 to 2,00 4,50 to 6,50 –

0,030

X2CrNiMoN22–5-3 1.4462 0,030 1,00 2,00 0,035 0,015 0,10 to 0,22 21,00 to 23,00 2,50 to 3,50 4,50 to 6,50 –

Cu 1,00 to

X2CrNiMoCuN25–6-3 1.4507 0,030 0,70 2,00 0,035 0,015 0,15 to 0,30 24,00 to 26,00 2,70 to 4,00 5,50 to 7,50

2,50

X2CrNiMoN25–7-4 1.4410 0,030 1,00 2,00 0,035 0,015 0,20 to 0,35 24,00 to 26,00 3,00 to 4,50 6,00 to 8,00 –

W 0,50 to

1,00

X2CrNiMoCuWN25–7-4 1.4501 0,030 1,00 1,00 0,035 0,015 0,20 to 0,30 24,00 to 26,00 3,00 to 4,00 6,00 to 8,00

Cu 0,50

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...