EN 13941:2003

(Main)Design and installation of preinsulated bonded pipe systems for district heating

Design and installation of preinsulated bonded pipe systems for district heating

This European Standard specifies rules for design, calculation and installation for preinsulated bonded pipe systems for buried hot water distribution and transmission networks, see. Figure 2, with pipe assemblies in accordance with prEN 253, for continuous operation with hot water at various temperatures up to 120 °C and occasionally with peak temperatures up to 140 °C and maximum internal pressure 25 bar (overpressure).

Application rule:

For larger pipe dimensions and pressures below 25 bar wall thickness bigger than specified in prEN 253 can be required for straight pipes, bends and tees.

The principles of the standard can be applied to preinsulated pipe systems with pressures higher than 25 bar, provided that special attention is paid to the effects of pressure. Adjacent pipes belonging to the network (e.g. pipes in ducts, valve chambers, road crossings above ground etc.) can be designed and installed according to this standard.

The standard assumes use of treated water, which by softening, demineralisation, deaeration, adding of chemicals, or otherwise has been treated to prevent internal corrosion and deposits in the pipes.

This standard is not applicable for such units as

- pumps,

- exchangers,

- boiler installations, tank installations,

- consumer installations.

However, the full functional ability and durability of such units should be ensured in consideration of the impacts from the district heating system and other impacts occurring from the conditions under which they have been installed.

Guidelines for product quality inspection and in situ tests of joints are given in annex A of prEN 448:2002, annex D of prEN 253:2002, annex A of prEN 488:2002 and annex B of prEN 489:2002.

Guidelines for welding of polyethylene casing are given in annex B of prEN 448:2002.

The estimation of expected life with continuous operation at various temperatures is outlined in annex B of prEN 253:2002

Berechnung und Verlegung von werkmäßig gedämmten Verbundmantelrohren für die Fernwärme

Diese Europäische Norm legt Regeln für den Entwurf, die Berechnung und die Verlegung von werkmäßig gedämmten Verbundrohrsystemen für erdverlegte Heißwasserverteilungs und Transportnetze (siehe Bild 2) fest, mit Verbundrohren nach EN 253, für einen kontinuierlichen Betrieb mit Heißwasser bei schwankenden Temperaturen bis 120 °C, zeitweise Spitzentemperaturen bis 140 °C und mit einem maximalen Betriebsdruck von 25 bar (Überdruck).

Anwendungsregel:

Für größere Rohrdurchmesser und Betriebsdrücke unter 25 bar kann für gerade Rohre, Bögen und T Stücke eine höhere Wanddicke als die in EN 253 festgelegte erforderlich sein.

Die Grundsätze der vorliegenden Norm können auch auf werkmäßig gedämmte Rohrsysteme mit Betriebsdrücken über 25 bar angewandt werden, vorausgesetzt, die Auswirkungen der höheren Drücke werden besonders beachtet. Angrenzende Rohre, die dem Netz angehören (z. B. Rohre in Kanälen, Armaturenschächten, oberirdische Straßenüberquerungen usw.), können entsprechend dieser Norm ausgelegt und verlegt werden.

Die Norm setzt die Benutzung von aufbereitetem Wasser voraus, das durch Enthärtung, Entsalzung, Entlüftung, Zusatz von Chemikalien oder auf andere Art und Weise so behandelt worden ist, dass innere Korrosion und Ablagerungen in den Leitungen vermieden werden.

Diese Norm gilt nicht für Geräte bzw. Anlagen, wie z. B.

Pumpen;

Wärmetauscher;

Kesselanlagen, Behälteranlagen;

Einrichtungen der angeschlossenen Kundenanlagen.

Diese Norm setzt voraus, dass die betreffenden Geräte bzw. Anlagen hinsichtlich der Einwirkungen, die vom Fernwärmenetz verursacht werden, und anderen von den baulichen Verhältnissen ausgehenden Belastungen voll funktionsfähig und dauerhaft sind.

Für Produktqualitätskontrolle und Vor Ort Prüfungen von Verbindungen gilt Anhang A von EN 448:2003, Anhang D von EN 253:2003, Anhang A von EN 488:2003 und Anhang B von EN 489:2003.

Für das Schweißen des Polyethylenmantelrohres gilt Anhang B von EN 448:2003.

Die Einschätzung der

Conception et installation des systèmes bloqués de tuyaux pré-isolés pour les réseaux enterrés d'eau chaude

Načrtovanje in vgradnja izoliranih vezanih cevnih sistemov za daljinsko ogrevanje

General Information

- Status

- Withdrawn

- Publication Date

- 18-Mar-2003

- Withdrawal Date

- 30-Jun-2009

- Technical Committee

- CEN/TC 107 - Pre-fabricated district heating pipe systems

- Drafting Committee

- CEN/TC 107 - Pre-fabricated district heating pipe systems

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Jul-2009

- Completion Date

- 01-Jul-2009

Relations

- Replaced By

EN 13941:2009 - Design and installation of preinsulated bonded pipe systems for district heating - Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

TÜV Rheinland

TÜV Rheinland is a leading international provider of technical services.

TÜV SÜD

TÜV SÜD is a trusted partner of choice for safety, security and sustainability solutions.

Sponsored listings

Frequently Asked Questions

EN 13941:2003 is a standard published by the European Committee for Standardization (CEN). Its full title is "Design and installation of preinsulated bonded pipe systems for district heating". This standard covers: This European Standard specifies rules for design, calculation and installation for preinsulated bonded pipe systems for buried hot water distribution and transmission networks, see. Figure 2, with pipe assemblies in accordance with prEN 253, for continuous operation with hot water at various temperatures up to 120 °C and occasionally with peak temperatures up to 140 °C and maximum internal pressure 25 bar (overpressure). Application rule: For larger pipe dimensions and pressures below 25 bar wall thickness bigger than specified in prEN 253 can be required for straight pipes, bends and tees. The principles of the standard can be applied to preinsulated pipe systems with pressures higher than 25 bar, provided that special attention is paid to the effects of pressure. Adjacent pipes belonging to the network (e.g. pipes in ducts, valve chambers, road crossings above ground etc.) can be designed and installed according to this standard. The standard assumes use of treated water, which by softening, demineralisation, deaeration, adding of chemicals, or otherwise has been treated to prevent internal corrosion and deposits in the pipes. This standard is not applicable for such units as - pumps, - exchangers, - boiler installations, tank installations, - consumer installations. However, the full functional ability and durability of such units should be ensured in consideration of the impacts from the district heating system and other impacts occurring from the conditions under which they have been installed. Guidelines for product quality inspection and in situ tests of joints are given in annex A of prEN 448:2002, annex D of prEN 253:2002, annex A of prEN 488:2002 and annex B of prEN 489:2002. Guidelines for welding of polyethylene casing are given in annex B of prEN 448:2002. The estimation of expected life with continuous operation at various temperatures is outlined in annex B of prEN 253:2002

This European Standard specifies rules for design, calculation and installation for preinsulated bonded pipe systems for buried hot water distribution and transmission networks, see. Figure 2, with pipe assemblies in accordance with prEN 253, for continuous operation with hot water at various temperatures up to 120 °C and occasionally with peak temperatures up to 140 °C and maximum internal pressure 25 bar (overpressure). Application rule: For larger pipe dimensions and pressures below 25 bar wall thickness bigger than specified in prEN 253 can be required for straight pipes, bends and tees. The principles of the standard can be applied to preinsulated pipe systems with pressures higher than 25 bar, provided that special attention is paid to the effects of pressure. Adjacent pipes belonging to the network (e.g. pipes in ducts, valve chambers, road crossings above ground etc.) can be designed and installed according to this standard. The standard assumes use of treated water, which by softening, demineralisation, deaeration, adding of chemicals, or otherwise has been treated to prevent internal corrosion and deposits in the pipes. This standard is not applicable for such units as - pumps, - exchangers, - boiler installations, tank installations, - consumer installations. However, the full functional ability and durability of such units should be ensured in consideration of the impacts from the district heating system and other impacts occurring from the conditions under which they have been installed. Guidelines for product quality inspection and in situ tests of joints are given in annex A of prEN 448:2002, annex D of prEN 253:2002, annex A of prEN 488:2002 and annex B of prEN 489:2002. Guidelines for welding of polyethylene casing are given in annex B of prEN 448:2002. The estimation of expected life with continuous operation at various temperatures is outlined in annex B of prEN 253:2002

EN 13941:2003 is classified under the following ICS (International Classification for Standards) categories: 11.060.20 - Dental equipment; 23.040.07 - Pipeline and its parts for district heat; 23.040.10 - Iron and steel pipes; 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13941:2003 has the following relationships with other standards: It is inter standard links to EN 13941:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13941:2003 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Berechnung und Verlegung von werkmäßig gedämmten Verbundmantelrohren für die FernwärmeConception et installation des systemes bloqués de tuyaux pré-isolés pour les réseaux enterrés d'eau chaudeDesign and installation of preinsulated bonded pipe systems for district heating91.140.10Sistemi centralnega ogrevanjaCentral heating systemsICS:Ta slovenski standard je istoveten z:EN 13941:2003SIST EN 13941:2004en01-oktober-2004SIST EN 13941:2004SLOVENSKI

STANDARD

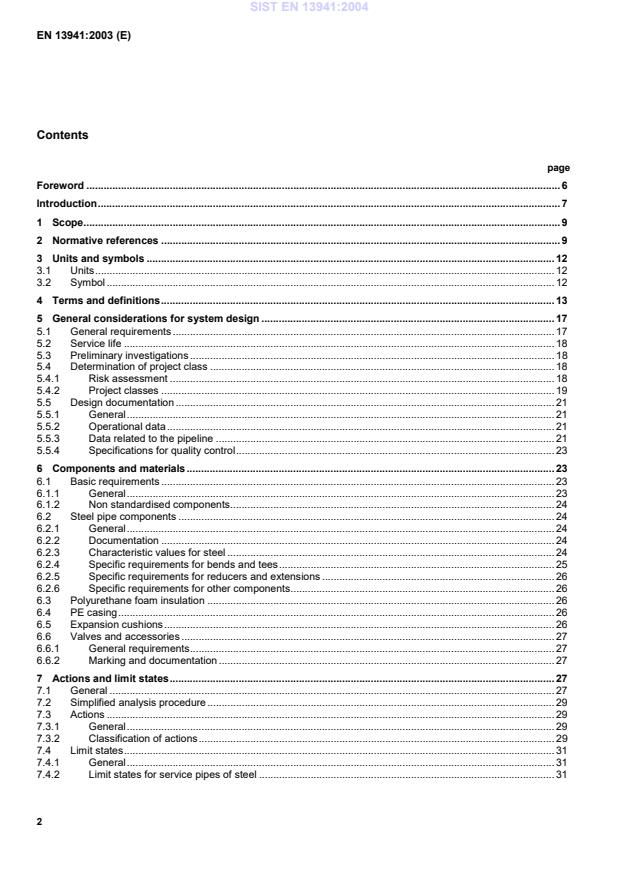

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13941March 2003ICS 91.140.10English versionDesign and installation of preinsulated bonded pipe systems fordistrict heatingConception et installation des systèmes bloqués de tuyauxpré-isolés pour les réseaux enterrés d'eau chaudeBerechnung und Verlegung von werkmäßig gedämmtenVerbundmantelrohren für die FernwärmeThis European Standard was approved by CEN on 27 December 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Hungary, Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Slovakia, Spain, Sweden, Switzerland and UnitedKingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2003 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13941:2003 ESIST EN 13941:2004

(normative)

Design of piping components under internal pressure.55A.1General.55A.2Symbols.55A.3Straight pipe and bends.56A.3.1Straight pipes.56A.3.2Bends.56A.4Tees and branch connections.56A.4.1General aspects and limitations.56A.4.2Reinforcement.56A.5Reducers and extensions.59A.5.1Minimum wall thickness of the cone.59A.5.2Offset reducers.60A.6Dished ends.60Annex B

(informative)

Geotechnics and pipe-soil interaction.61SIST EN 13941:2004

(informative)

Global- and cross sectional analysis.77C.1General.77C.2Symbols.77C.3Survey of limit states for steel.79C.4Locations to be assessed.81C.4.1Components to be considered.81C.4.2Areas to be considered.83C.5Actions.83C.5.1General.83C.5.2Action cycles.84C.6Global analysis.85C.6.1General.85C.6.2Flexibility.85C.6.3Boundary conditions.87C.7Calculation of stresses.90C.7.1Simplified procedure.91C.7.2Cross section analyses, steel.91C.7.3Straight pipes.93SIST EN 13941:2004

(informative)

Calculation of heat losses.108D.1General.108D.2Heat loss per pipe pair.108D.3Insulance of the soil.109D.4Insulance of the insulation material.109D.5Insulance of the heat exchange between flow and return pipe.109Bibliography.110SIST EN 13941:2004

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...