EN 438-2:2005

(Main)High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (usually called Laminates) - Part 2: Determination of properties

High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (usually called Laminates) - Part 2: Determination of properties

This part of EN 438 specifies the methods of test for determination of the properties of high-pressure decorative laminates as defined in Clause 3. These methods are primarily intended for testing the sheets specified in EN 438-3, 4, 5 and 6.

The precision of the test methods specified in Clauses 5, 6, 7, 8, 9, 12, 17, 18, 32 and 33 of this part of EN 438 is not known because inter-laboratory data are not available. When inter-laboratory data are obtained, precision statements will be added to the test methods at the following revision. As all the other test methods have an end point determination based on subjective judgement, it is not meaningful to make a statement of precision in these cases.

Dekorative Hochdruck-Schichtpressstoffplatten (HPL) - Platten auf Basis härtbarer Harze (Schichtpressstoffe) - Teil 2: Bestimmung der Eigenschaften

Dieser Teil von prEN 438 legt die Prüfverfahren für die Bestimmung der Eigenschaften der im Abschnitt 3 beschriebenen dekorativen Hochdruck-Schichtpressstoffplatten (HPL) fest. Diese Prüfungen sind vorzugsweise zur Prüfung der Schichtpressstoffe bestimmt, die in den Teilen 3, 4, 5 und 6 von prEN 438 beschrieben werden.

Die Präzision der in den Abschnitten 5, 6, 7, 8, 9, 12, 17, 18, 32 und 33 der vorliegenden Norm festgelegten Prüfverfahren ist nicht bekannt, da Daten von Ringversuchen nicht vorliegen. Sobald Daten aus Ringversuchen vorliegen, werden bei der folgenden Überarbeitung den Prüfverfahren Angaben zur Präzision hinzugefügt. Weil sämtliche weiteren Prüfverfahren eine Endpunktbestimmung haben, die auf einer subjektiven Beurteilung beruht, ist es in diesen Fällen nicht sinnvoll, Angaben zur Präzision zu machen.

Stratifiés décoratifs haute pression (HPL) - Plaques à base de résines thermodurcissables (communément appelées stratifiés) - Partie 2 : Détermination des caractéristiques

La présente partie de l'EN 438 spécifie les méthodes d'essai pour la détermination des caractéristiques des plaques de stratifiés décoratifs haute pression définies à l'Article 3. Ces méthodes sont principalement destinées pour la réalisation des essais sur les plaques spécifiées dans les EN 438-3, 4, 5 et 6.

La précision des méthodes d'essai spécifiées dans les Articles 5, 6, 7, 8, 9, 12, 17, 18, 32 et 33 de la présente partie de l'EN 438 est inconnue par manque de résultats interlaboratoires. Quand ceux-ci seront connus, les données de précision seront ajoutées aux méthodes d'essai correspondantes lors d'une prochaine révision. Toutes les autres méthodes d'essai étant fondées sur une appréciation subjective du résultat final, il n'est pas possible d'établir une tolérance de précision dans ces cas

Dekorativni visokotlačni laminati (HPL) - Plošče na osnovi duromernih smol - 2. del: Ugotavljanje lastnosti

General Information

- Status

- Withdrawn

- Publication Date

- 25-Jan-2005

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 249 - Plastics

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 17-Feb-2016

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 22-Dec-2008

- Effective Date

- 24-Feb-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 438-2:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (usually called Laminates) - Part 2: Determination of properties". This standard covers: This part of EN 438 specifies the methods of test for determination of the properties of high-pressure decorative laminates as defined in Clause 3. These methods are primarily intended for testing the sheets specified in EN 438-3, 4, 5 and 6. The precision of the test methods specified in Clauses 5, 6, 7, 8, 9, 12, 17, 18, 32 and 33 of this part of EN 438 is not known because inter-laboratory data are not available. When inter-laboratory data are obtained, precision statements will be added to the test methods at the following revision. As all the other test methods have an end point determination based on subjective judgement, it is not meaningful to make a statement of precision in these cases.

This part of EN 438 specifies the methods of test for determination of the properties of high-pressure decorative laminates as defined in Clause 3. These methods are primarily intended for testing the sheets specified in EN 438-3, 4, 5 and 6. The precision of the test methods specified in Clauses 5, 6, 7, 8, 9, 12, 17, 18, 32 and 33 of this part of EN 438 is not known because inter-laboratory data are not available. When inter-laboratory data are obtained, precision statements will be added to the test methods at the following revision. As all the other test methods have an end point determination based on subjective judgement, it is not meaningful to make a statement of precision in these cases.

EN 438-2:2005 is classified under the following ICS (International Classification for Standards) categories: 83.140.20 - Laminated sheets. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 438-2:2005 has the following relationships with other standards: It is inter standard links to EN 438-2:1991, EN 438-2:2016, EN ISO 62:2008, EN ISO 6506-1:2014, EN 20105-A02:1994, EN ISO 4892-3:2024, EN ISO 4892-1:2024, EN ISO 291:2008, EN ISO 4892-2:1999, EN ISO 105-B02:2014, EN 316:2009, EN ISO 178:2019, EN 3332:2005, EN 12174:2013, EN 12122:2005. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 438-2:2005 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/121. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 438-2:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Dekorative Hochdruck-Schichtpressstoffplatten (HPL) - Platten auf Basis härtbarer Harze (Schichtpressstoffe) - Teil 2: Bestimmung der EigenschaftenStratifiés décoratifs haute pression (HPL) - Plaques a base de résines thermodurcissables (communément appelées stratifiés) - Partie 2 : Détermination des caractéristiquesHigh-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (usually called Laminates) - Part 2: Determination of properties83.140.20Laminated sheetsICS:Ta slovenski standard je istoveten z:EN 438-2:2005SIST EN 438-2:2005en01-maj-2005SIST EN 438-2:2005SLOVENSKI

STANDARDSIST EN 438-2:19991DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 438-2

January 2005 ICS 83.140.20

Supersedes EN 438-2:1991

English version

High-pressure decorative laminates (HPL) - Sheets based on thermosetting resins (usually called Laminates) - Part 2: Determination of properties

Stratifiés décoratifs haute pression (HPL) - Plaques à base de résines thermodurcissables (communément appelées stratifiés) - Partie 2 : Détermination des caractéristiques

Dekorative Hochdruck-Schichtpressstoffplatten (HPL) - Platten auf Basis härtbarer Harze (Schichtpressstoffe) - Teil 2: Bestimmung der Eigenschaften This European Standard was approved by CEN on 10 December 2004.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2005 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 438-2:2005: ESIST EN 438-2:2005

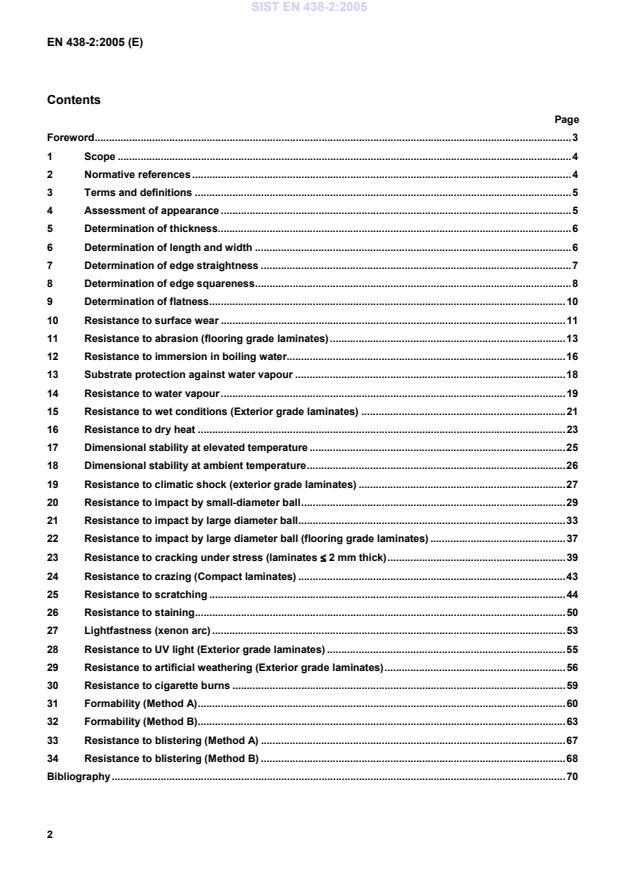

Page Foreword.3 1 Scope.4 2 Normative references.4 3 Terms and definitions.5 4 Assessment of appearance.5 5 Determination of thickness.6 6 Determination of length and width.6 7 Determination of edge straightness.7 8 Determination of edge squareness.8 9 Determination of flatness.10 10 Resistance to surface wear.11 11 Resistance to abrasion (flooring grade laminates).13 12 Resistance to immersion in boiling water.16 13 Substrate protection against water vapour.18 14 Resistance to water vapour.19 15 Resistance to wet conditions (Exterior grade laminates).21 16 Resistance to dry heat.23 17 Dimensional stability at elevated temperature.25 18 Dimensional stability at ambient temperature.26 19 Resistance to climatic shock (exterior grade laminates).27 20 Resistance to impact by small-diameter ball.29 21 Resistance to impact by large diameter ball.33 22 Resistance to impact by large diameter ball (flooring grade laminates).37 23 Resistance to cracking under stress (laminates ≤≤≤≤ 2 mm thick).39 24 Resistance to crazing (Compact laminates).43 25 Resistance to scratching.44 26 Resistance to staining.50 27 Lightfastness (xenon arc).53 28 Resistance to UV light (Exterior grade laminates).55 29 Resistance to artificial weathering (Exterior grade laminates).56 30 Resistance to cigarette burns.59 31 Formability (Method A).60 32 Formability (Method B).63 33 Resistance to blistering (Method A).67 34 Resistance to blistering (Method B).68 Bibliography.70

1 Scope This part of EN 438 specifies the methods of test for determination of the properties of high-pressure decorative laminates as defined in Clause 3. These methods are primarily intended for testing the sheets specified in EN 438-3, 4, 5 and 6.

The precision of the test methods specified in Clauses 5, 6, 7, 8, 9, 12, 17, 18, 32 and 33 of this part of EN 438 is not known because inter-laboratory data are not available.

When inter-laboratory data are obtained, precision statements will be added to the test methods at the following revision. As all the other test methods have an end point determination based on subjective judgement, it is not meaningful to make a statement of precision in these cases. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 312, Particleboards — Specifications EN 316, Wood fibreboards — Definition, classification and symbols EN 20105-A02, Textiles — Tests for colour fastness — Part A02: Grey scale for assessing change in colour (ISO 105-A02:1993) EN ISO 62, Plastics — Determination of water absorption (ISO 62:1999) EN ISO 105-B02, Textiles — Tests for colour fastness — Part B02: Colour fastness to artificial light: Xenon arc fading lamp test (ISO 105-B02:1994, including amendment 1:1998) EN ISO 178, Plastics - Determination of flexural properties (ISO 178:2001) EN ISO 291, Plastics — Standard atmospheres for conditioning and testing (ISO 291:1995) EN ISO 4892-1, Plastics - Methods of exposure to laboratory light sources - Part 1: General guidance (ISO 4892-1:1999). EN ISO 4892-2:1999, Plastics - Methods of exposure to laboratory light sources - Part 2: Xenon-arc sources (ISO 4892-2:1994). EN ISO 4892-3, Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps (ISO 4892-3:1994). EN ISO 6506-1, Metallic materials — Brinell hardness test - Part 1: Test method (ISO 6506-1:1999) ISO 9352, Plastics — Determination of resistance to wear by abrasive wheels ISO 9370, Plastics — Instrumental determination of radiant exposure in weathering tests —

General guidance and basic test method SIST EN 438-2:2005

3 Terms and definitions For the purposes of this document, the following term and definition applies:

3.1 high-pressure decorative laminate(s) (HPL) sheet(s) consisting of layers of cellulosic fibrous material (normally paper) impregnated with thermosetting resins and bonded together by the high pressure process described below The high pressure process is defined as the simultaneous application of heat (temperature ≥ 120 °C) and high specific pressure (≥ 5 MPa), to provide flowing and subsequent curing of the thermosetting resins to obtain a homogeneous non-porous material with increased density (≥ 1,35 g/cm³), and with the required surface finish. 4 Assessment of appearance 4.1 Principle Laminates shall be inspected for surface appearance under standardised conditions of lighting and viewing. 4.2 Apparatus 4.2.1 Horizontal inspection table, of height approximately 700 mm and large enough to accommodate the largest sheets to be inspected. 4.2.2 Overhead white fluorescent lights, of colour temperature approximately 5000 K and giving an intensity of 800 to 1000 lux over the whole area of the largest sheets to be inspected. A convenient distance of the lights from the inspection table is approximately 1,5 m. 4.3 Test specimen The specimen shall be the laminate under test, as supplied by the manufacturer. 4.4 Procedure Place the laminate, decorative face uppermost, on the inspection table. Wipe it free of any loose contamination with a soft cloth, using a suitable cleaning agent if necessary. Inspect it from the distance required by the relevant part of EN 438 for defects such as smudges, smears, fingerprints, scratches, foreign particles, damage or any other form of blemish evident within the decorative surface. The inspector shall use normal vision, corrected if necessary. 4.5 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) size of the laminate under test; d) viewing distance; e) total area of spot-type defects in square millimetres; f) total length of hair-like defects in millimetres;

g) any deviation from the specified test method; SIST EN 438-2:2005

5.5 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) all values measured; d) any deviation from the specified test method; e) date of the test. 6 Determination of length and width 6.1 Principle Measuring the length and width of the laminate using a metal tape or rule. 6.2 Apparatus Steel tape or rule, of sufficient length to measure the greatest dimension of the laminate, and graduated to allow a reading accuracy of 1 mm. 6.3 Test specimen The specimen shall be the laminate under test, as supplied by the manufacturer. 6.4 Procedure Apply the steel tape or rule (see 6.2) to each edge of the laminate in turn, on a line approximately 25 mm from and parallel to the edge. Measure the length on each edge to the nearest 1 mm. SIST EN 438-2:2005

7.2.1 Metal straightedge, of 1000 mm length. 7.2.2 Steel rule, graduated in 0,5 mm divisions. 7.3 Test specimen The specimen shall be the laminate under test, as supplied by the manufacturer. 7.4 Procedure Apply the metal straightedge (see 7.2.1) to each edge of the laminate in turn, and use the steel rule (see 7.2.2) to measure the maximum deviation of the edge of the laminate from the metal straightedge (x in Figure 1) to the nearest 0,5 mm. SIST EN 438-2:2005

Key 1 Metal straightedge 2 Laminate Figure 1 — Edge straightness measurement 7.5 Expression of results The maximum deviation from the metal straightedge shall be recorded for each of the four edges. Results shall be designated (+) if the edge is convex, and (-) if the edge is concave. 7.6 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) test result for each of the four edges; d) any deviation from the specified test method; e) date of the test. 8 Determination of edge squareness 8.1 Principle Applying a right-angled square to the corner of the laminate and measuring the deviation of the edge from the square using a steel rule. 8.2 Apparatus 8.2.1 Right-angled square, with two arms of at least 1000 mm long (see Figure 2). SIST EN 438-2:2005

211 00090ºx

Key 1 Right-angled square 2 Laminate

Figure 2 — Edge squareness measurement 8.5 Expression of results The maximum deviation from the square shall be recorded for the two diagonally opposite corners (x in Figure 2). 8.6 Test report The test report shall include the following information: a)

reference to this part of EN 438; b) name, type and nominal thickness of the product; c) test result; d) any deviation from the specified test method; e) date of the test. SIST EN 438-2:2005

Dimensions in millimetres AA1 000A - A

Figure 3 — Bow gauge for measuring flatness 9.3 Test specimens The specimen shall be the laminate as supplied by the manufacturer. In cases of dispute the laminate must be pre-conditioned in accordance with the manufacturer’s recommendations until equilibrium is reached. 9.4 Procedure Place the laminate concave side up without restraint on a flat horizontal surface. SIST EN 438-2:2005

reference to this part of EN 438; b) name, type and nominal thickness of the product; c) maximum flatness deviation; d) any deviation from the specified test method; e) date of the test. 10 Resistance to surface wear 10.1 Principle The test measures the ability of the decorative surface of the laminate under test to resist abrasive wear-through to the sub-layer. Abrasion is achieved by rotating a specimen in contact with a pair of loaded cylindrical wheels covered with abrasive paper. The wheels are positioned so that their cylindrical faces are equidistant from the specimen's axis of rotation but not tangential to it. As they are turned by the rotating specimen they abrade an annular track on the specimen's surface. The numbers of revolutions of the specimen required to cause defined degrees of abrasion are used as measures of resistance to surface wear. This test is not applicable to flooring grade laminates. 10.2 Materials

10.2.1 Calibration plates of rolled zinc sheet, (Taber S-34 or equivalent), having a thickness of (0,8 ± 0,1) mm and a Brinell hardness of (48 ± 2) when tested in accordance with ISO 6506, except that the ball diameter shall be 5 mm and the load 360 N. 10.2.2 Abrasive paper strips, (Taber S-42 or equivalent), of width 12,7 mm and length about 160 mm, having the following composition: a) paper of grammage 70 g/m2 to 100 g/m2; b) open coated 180 grit powdered aluminium oxide (Al2O3) having a particle size such that it will pass through a sieve of aperture 100 µm and remain on a sieve having an aperture of 63 µm; c) adhesive backing (optional). 10.2.3 Double-sided adhesive tape, required only if the abrasive paper has no adhesive backing. 10.3 Apparatus 10.3.1 Test machine, as specified in ISO 9352. NOTE A suitable machine is available from Taber Acquisition Corp., Taber Industries, 455 Bryant St, P.O. Box 164, North Tonawanda, NY 14120, USA. (This test machine is an example of a suitable machine available SIST EN 438-2:2005

This information is given for the convenience of users of this part of EN 438 and does not constitute an endorsement by CEN of the machine.) 10.3.2 Conditioning chamber, in accordance with EN ISO 291, with a standard atmosphere of (23 ± 2) °C, relative humidity (50 ± 5) %. 10.4 Test specimens Each specimen shall be a piece of the laminate under test, shaped to fit the type of clamping device used. It will usually be a disc of diameter about 130 mm, or a square of about 100 mm with its corners rounded to give a diagonal of about 130 mm, and it will usually have a hole of diameter 6 mm in its centre. Three specimens shall be prepared. 10.5 Preparation of specimens and abrasive paper Clean the surface of the specimens with a non-hazardous organic solvent which is immiscible with water. Using a suitable marker pen, mark the surface of each specimen with two lines mutually at right angles so that the surface area is divided into quadrants.

Precondition the specimens and the abrasive strips for at least 72 h in the conditioning atmosphere (see 10.3.2) before testing. After preconditioning seal the paper strips in suitable polythene bags (maximum 10 strips per bag) until required for immediate use. 10.6 Procedure 10.6.1 Preparation of abrasive wheels Bond a strip of preconditioned unused abrasive paper (see 10.2.2) to each of the rubber covered wheels, using either the adhesive backing, if present, or the double-sided adhesive tape (see 10.2.3). Ensure that the cylindrical surface is completely covered, but without any overlapping of the abrasive paper. 10.6.2 Calibration of abrasive paper Prepare two abrasive wheels with preconditioned unused strips of abrasive paper from the batch to be used for testing (see 10.6.1). Clamp a zinc plate (see 10.2.1) in the specimen holder, start the suction device, set the revolution-counter to zero, lower the wheels and abrade the zinc plate for 500 revolutions. Wipe the zinc plate clean and weigh to the nearest 1 mg. Replace the abrasive paper on the wheels with preconditioned unused strips from the same batch, clamp the same zinc plate in the specimen holder, lower the abrasive wheels and operate the suction device. Abrade the zinc plate for an additional 500 revolutions, then wipe it clean and reweigh it to the nearest 1 mg. Its loss in mass shall be (130 ± 20) mg. Any batch of abrasive paper which causes a loss in mass of the zinc plate outside this permitted range shall not be used for testing. 10.6.3 Abrasion of specimen Perform the test immediately after removal of the specimen and calibrated abrasive paper from the preconditioning atmosphere. Prepare two wheels with preconditioned unused abrasive paper from the same batch previously approved by calibration. Fit the wheels to the machine and set the revolution counter to zero. Clamp the specimen in the holder, ensuring that the surface of the specimen is flat. Lower the abrasive wheels on to the specimen, start the suction device and begin abrading the specimen.

Examine the specimen for wear after each 25 revolutions and examine the abrasive paper for clogging with abraded particles. Replace the abrasive paper if it becomes clogged, or after 500 revolutions, whichever happens first.

Continue the test in this way until the initial wear point (IP) is reached. Record the number of revolutions and resume the test until the final wear point (FP) is reached. Record the number of revolutions again. SIST EN 438-2:2005

The sub-layer for printed patterns is the background on which the pattern is printed; for plain colours it is the first sub-layer of different colour 1) 2). The final wear point (FP) occurs in the case of a patterned laminate when about 95 % of the pattern is removed in the abraded area, and in the case of a plain-colour laminate when an underlayer of a different colour is exposed over about 95 % of the abraded area. 10.7 Expression of results Calculate the wear resistance, expressed as a number of revolutions, for each specimen using the following equation: Wear resistance = 2FPIP+ The initial wear point (IP) for the sample under test shall be the average of the IP values obtained on the three specimens. The resistance to surface wear of the laminate under test shall be the average of the wear resistance values obtained on the three specimens, rounded to the nearest 50 revolutions. 10.8 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) initial wear point (IP) for the sample under test, in revolutions; d) resistance to surface wear of the sample under test, in revolutions; e) any deviation from the specified test method; f)

date of the test. 11 Resistance to abrasion (flooring grade laminates) 11.1 Principle The test measures the ability of the decorative surface of the laminate under test to resist abrasive wear-through to the sub-layer. Abrasion is achieved by rotating a specimen in contact with a pair of loaded cylindrical wheels covered with abrasive paper. The wheels are positioned so that their cylindrical faces are equidistant from the specimen's axis of rotation but not tangential to it. As they are turned by the rotating specimen they abrade an annular track on the specimen's surface. The number of revolutions of the

1) IP-poster. This is a full-colour photographic visual aid with text in the three CEN languages, to assist correct interpretation, and increase repeatability and reproducibility in the determination of the initial wear point (IP). The poster has been developed by CEN/TC134/SC2, and is available from SIS Förlag AB, Box 6455, SE-113 82 STOCKHOLM, Sweden; Tel. 00 46 8 610 30 60, Fax 00 46 8 30 18 50 (order reference 21824 IP-poster). 2) Dirt size estimation chart. The use of this chart is recommended to precisely determine the size in mm2 of the wear-through area. It is available from TAPPI, Technology Park/Atlanta, P.O. Box 105 113, Atlanta, GA 30348-5113, USA; Tel. 00 1 770 446 1400, Fax. 00 1 770 446 6947 (order reference TAPPI - Dirt size estimation chart). SIST EN 438-2:2005

11.2.1 Calibration plates of rolled zinc sheet, (Taber S-34 or equivalent), having a thickness of (0,8 ± 0,1) mm and a Brinell hardness of (48 ± 2) when tested in accordance with EN ISO 6506-1, except that the ball diameter shall be 5 mm and the load 360 N. 11.2.2 Abrasive paper strips, (Taber S-42 or equivalent) of width 12,7 mm and length about 160 mm, having the following composition: a) paper of grammage 70 g/m2 to 100 g/m2; b) open coated 180 grit powdered aluminium oxide (Al2O3) having a particle size such that it will pass through a sieve of aperture 100 µm and remain on a sieve having an aperture of 63 µm; c) adhesive backing (optional). 11.2.3 Double-sided adhesive tape, required only if the abrasive paper has no adhesive backing. 11.3 Apparatus 11.3.1 Test machine, as specified in ISO 9352. NOTE A suitable machine3 is available from Taber Acquisition Corp., Taber Industries, 455 Bryant St, P.O. Box 164, North Tonawanda, NY 14120, USA.

11.3.2 Conditioning chamber, in accordance with EN ISO 291, with a standard atmosphere of (23 ± 2) °C, relative humidity (50 ± 5) %. 11.4 Test specimens Each specimen shall be a piece of the laminate under test, shaped to fit the type of clamping device used. It will usually be a disc of diameter about 130 mm, or a square of about 100 mm with its corners rounded to give a diagonal of about 130 mm, and it will usually have a hole of diameter 6 mm in its centre. Three specimens shall be prepared. 11.5 Preparation of specimens and abrasive paper Clean the surface of the specimens with a non-hazardous organic solvent which is immiscible with water. Using a suitable marker pen, mark the surface of each specimen with two lines mutually at right angles so that the surface area is divided into quadrants. Precondition the specimens and the abrasive strips for at least 72 h in the conditioning atmosphere (see 11.3.2) before testing. After preconditioning seal the paper strips in suitable polythene bags (maximum 10 strips per bag) until required for immediate use.

3 This test machine is an example of a suitable machine available commercially. This information is given for the convenience of users of this part of EN 438 and does not constitute an endorsement by CEN of the machine.

Continue the test in this way until the initial wear point (IP) is reached. The initial wear point (IP) is that point at which the first clearly recognisable wear-through of the print, pattern or plain colour appears and the sub-layer becomes exposed in three quadrants. The initial wear point is reached when there are areas of at least 0,60 mm2

wear-through

in two quadrants and an area of 0,60 mm2 wear-through becomes visible in a third quadrant. The sub-layer for printed patterns is the background on which the pattern is printed; for plain colours it is the first sub-layer of different colour (see Footnotes 1 and 2). Record the number of revolutions as the IP-value. Repeat the test immediately using the two remaining test specimens. 11.7 Expression of results The resistance to abrasion of the laminate under test shall be the average of the initial wear-point (IP) values obtained on the three specimens, rounded to the nearest 100 revolutions. 11.8 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) resistance to abrasion for the sample under test, in revolutions; d) any deviation from the specified test method; SIST EN 438-2:2005

m1

is the mass of the specimen before immersion; m2

is the mass of the specimen after immersion. The percentage increase in thickness at the measuring points of each specimen is given by the formulae:

100115×−ttt .,100226etcttt×−

where t1, t2, t3

and t4

are the thicknesses measured before immersion; t5, t6, t7

and t8

are the thicknesses measured after immersion. The percentage by mass of boiling water absorbed by the laminate under test shall be the average of the values obtained on the three specimens. The percentage increase in thickness of the laminate under test shall be the average of the twelve values obtained at the four measuring points on all three specimens. The result of the examination for change in appearance shall be the lowest rating of the three specimens assessed in accordance with the following rating scale: Rating 5:

No visible change. Rating 4:

Slight change of gloss and/or colour, only visible at certain viewing angles.

Rating 3:

Moderate change of gloss and/or colour. Rating 2:

Marked change of gloss and/or colour. Rating 1:

Blistering and/or delamination. 12.6 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) average percentage increase in mass; d) average percentage increase in thickness; e) result of the examination for change in appearance; f) any deviation from the specified test method; g) date of the test. SIST EN 438-2:2005

(35,7 ± 0,1) mm and an outside diameter of (42,0 ± 0,1) mm.

13.2.2 Thickness gauge, as specified in 5.2. 13.2.3 Wide-necked Erlenmeyer flask, of capacity 250 ml and mouth diameter 50 mm. 13.2.4 Electric hot-plate, or other suitable heat source. 13.3 Test specimens Each specimen shall be a square of side approximately 100 mm, cut from the laminate under test. Two specimens shall be tested. 13.4 Procedure Using the milling tool (see 13.2.1) cut a circular groove in the centre of the specimen as shown in Figure 4, to a depth which is just sufficient to expose the first sub-layer (i.e. the layer immediately beneath the decorative surface). Using the thickness gauge (see 13.2.2) measure the thickness in a position adjacent to the inner edge of the groove to the nearest 0,1 mm and record it as value t1. Place approximately 200 ml of water in the flask (see 13.2.3) and bring it to the boil on the hot-plate (see 13.2.4).

Place the specimen, with the cut decorative surface face down, centrally over the mouth of the flask. After 1 h, remove the specimen and remove excess water from the surfaces and edges using absorbent paper. Re-measure the thickness in the same position as measurement t1, and record it as value t2. Repeat the procedure using the second specimen. 13.5 Expression of results The substrate protection against water vapour shall be expressed as the difference between the final thickness and the corresponding initial thickness (t2 - t1). SIST EN 438-2:2005

Dimensions in millimetres

Key 1

Circular groove 2

Test specimen

Figure 4 — Specimen for substrate protection test 13.6 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) higher of the two test values; d) any deviations from the specified test method; e) date of the test. 14 Resistance to water vapour 14.1 Principle A specimen from the laminate under test is held in place over the neck of a flask containing boiling water, so that the decorative surface of the specimen is exposed to the water vapour. After 1 h, the specimen is removed and allowed to recover for 24 h in normal ambient conditions before examination for any change in appearance. SIST EN 438-2:2005

No visible change. Rating 4:

Slight change of gloss and/or colour, only visible at certain viewing angles. Rating 3:

Moderate change of gloss and/or colour. Rating 2:

Marked change of gloss and/or colour. Rating 1:

Blistering and/or delamination. 14.6 Test report The test report shall include the following information: a) reference to this part of EN 438; b) name, type and nominal thickness of the product; c) effect on the surface of the specimen, expressed in accordance with the rating scale: d) any deviation from the specified test method; e) date of the test.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...