EN 13914-2:2016

(Main)Design, preparation and application of external rendering and internal plastering - Part 2: Internal plastering

Design, preparation and application of external rendering and internal plastering - Part 2: Internal plastering

This European Standard deals with the design considerations and essential principles for internal plastering systems and application of plastering systems.

The different parts of the EN 13914 series of standards specify requirements and recommendations for detailing, design and material considerations, the selection of mixes and the application of gypsum plasters, gypsum/lime plasters, lightweight plasters, lime/gypsum-, cement- and cement/lime-based plasters, lime-based plasters, clay plasters, silicate plasters, organic plasters, polymer-modified plasters, etc.

This standard does not deal with the following:

- external finishes;

- painting and/or preparation;

- impregnations;

- structural repair of concrete;

- prefabricated fibre-reinforced plaster elements.

Owing to the many and varied materials and practices and different climatic conditions in Europe it is not possible for certain aspects of the standard to enter into sufficient detail to be fully usable to practitioners in each country. Such guidance to complement, but not alter, any basic European recommendations is given in documentation prepared by each country. Aspects of this European Standard, the basic recommendations of which may need to be complemented, are indicated where they occur by a footnote referencing this clause.

Planung, Zubereitung und Ausführung von Außen- und Innenputzen - Teil 2: Innenputze

Diese Europäische Norm behandelt die Planung und wesentliche Grundsätze für Innenputzsysteme sowie für die Ausführung von Innenputzsystemen.

Die einzelnen Abschnitte der Normenreihe EN 13914 legen Anforderungen an und Empfehlungen für die Detailausführung, für die Planung und die Auswahl der Materialien, für die Auswahl von Putzmischungen sowie für das Auftragen von Gipsputz, Gipskalkputz, Leichtputz, Putzen auf Kalkgips , Kalk , Zement und Kalkzementbasis, Lehmputze, Silikatputze, organisch gebundene Putze, polymermodifizierte Putze, usw., fest.

Diese Norm gilt nicht für:

außen liegende Oberflächen;

Anstriche und/oder ihre Vorbereitung;

Imprägnierungen;

die konstruktive Instandsetzung von Beton;

vorgefertigte faserverstärkte Innenputzelemente.

Aufgrund der zahlreichen und unterschiedlichen Materialien und Arbeitsweisen und unterschiedlicher klimatischer Bedingungen in Europa ist es nicht möglich, zu bestimmten Gesichtspunkten dieser Norm genügend Einzelheiten anzugeben, um den Anwendern in jedem Land umfassende Verwendbarkeit zu bieten. Eine geeignete Anleitung für die Ergänzung grundsätzlicher europäischer Empfehlungen, nicht jedoch für deren Änderung, gibt es in den von den einzelnen Ländern ausgearbeiteten Dokumentationen. Gesichtspunkte dieser Europäischen Norm, deren grundlegende Empfehlungen einer Ergänzung bedürfen, sind jeweils mit einer auf diesen Abschnitt verweisenden Fußnote versehen.

Conception, préparation et mise en oeuvre des enduits extérieurs et intérieurs - Partie 2: Enduits intérieurs

La présente norme traite des aspects liés à la conception ainsi que des principes essentiels des systèmes d'enduit interne et de la mise en oeuvre de ces systèmes.

Les différentes parties de la présente norme spécifient les exigences et recommandations relatives à la construction, à la conception et aux matériaux utilisés, au choix des mélanges et à la mise en oeuvre des plâtres pour enduit ; des enduits à base de plâtre/chaux ; des enduits allégés pré-mélangés ; des enduits d'anhydrite ; de la chaux/du plâtre ; des enduits à base de ciment et de ciment/chaux ; des enduits à la chaux, aux silicates, aux polymères et modifiés avec des polymères.

La présente norme ne traite pas :

- des finitions extérieures ;

- de la mise en peinture et/ou de la préparation ;

- des imprégnations ;

- de la remise en état des structures en béton ;

- des ouvrages en staff.

Sous certains aspects, la présente norme ne permet pas d’entrer suffisamment dans le détail pour être pleinement utilisable dans chaque pays en raison de la grande variété de matériaux et de méthodes mis en oeuvre en Europe. Des orientations sont alors données dans des documents préparés par chaque pays et viennent compléter mais non remplacer les recommandations européennes de base. Une note de bas de page renvoyant au présent article le signalera aux endroits opportuns de la présente Norme européenne.

Projektiranje, priprava in uporaba zunanjih in notranjih ometov - 2. del: Notranji ometi

Ta standard obravnava smernice za projektiranje in osnovna načela za sisteme notranjih ometov ter njihovo uporabo. Standard v različnih delih podaja zahteve in priporočila za podrobnosti glede gradnje, projektiranja in materialov, izbiro mešanic in uporabo ometov iz mavca; omete iz mavca/apna; vnaprej zmešane lahke omete; anhidridne omete; apno/mavec; cement in omete na osnovi cementa/apna; omete na osnovi apna, silikatne omete; polimerne omete in omete, spremenjene s polimeri. Ta standard ne obravnava naslednjega:

– zunanje obloge:

– barvanje in/ali priprava;

– impregnacija;

– popravilo betonskih konstrukcij;

– obdelava z vlakneno sadro.

General Information

- Status

- Published

- Publication Date

- 08-Mar-2016

- Technical Committee

- CEN/TC 125 - Masonry

- Drafting Committee

- CEN/TC 125/WG 5 - Application of external rendering in masonry

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 22-Mar-2022

- Completion Date

- 11-Feb-2026

Not Harmonized89/106/EEC - Construction products

Relations

- Effective Date

- 16-Mar-2016

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 998-1:2010 - Specification for mortar for masonry - Part 1: Rendering and plastering mortar - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

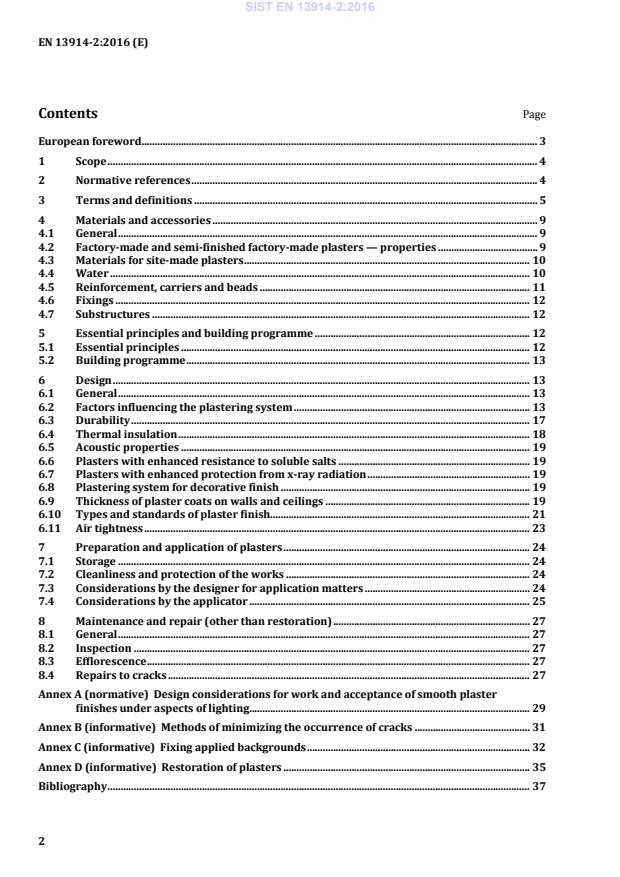

Overview - EN 13914-2:2016 (Internal plastering)

EN 13914-2:2016 is the CEN European standard that sets out essential design principles, material considerations and application guidance for internal plastering systems. It forms Part 2 of the EN 13914 series (with Part 1 covering external rendering) and applies to plasters based on gypsum, lime, cement, polymer modification and other mineral or organic binders used on internal vertical and soffit surfaces. The standard updates and supersedes EN 13914-2:2005 and is intended for use across CEN member states while allowing for national complementary guidance where climatic or practice differences exist.

Key topics and technical requirements

- Scope and terminology: Definitions for plaster types (gypsum plaster, mineral-based, organic, designed vs prescribed plasters), coats, layers, systems, reinforcement and related terms.

- Materials and accessories: Requirements for factory-made and site-made plasters, aggregates, water quality, reinforcement (meshes, fibres), fixings, carriers and beads.

- Design principles: Factors influencing choice of plastering system including substrate, exposure, durability, thermal and acoustic properties, salt resistance and radiation protection where applicable.

- Plaster system composition: Selection of mixes, use of lightweight and specialised plasters (gypsum, lime/gypsum, cement, clay, silicate, polymer-modified), and layering strategies (one-coat, thin coat, skim/filler).

- Noted coat thickness ranges: thin coat (1–6 mm), skim/filler (0.1–5 mm).

- Preparation and application: Guidance on storage, substrate preparation (cleanliness, pre-treatment, spatterdash, primers), workmanship considerations and sequencing (building programme).

- Durability, maintenance and repair: Inspection, efflorescence control, crack minimization and repair methods; annexes provide practical guidance (lighting/finish, crack minimising methods, fixing backgrounds, restoration).

- Exclusions: Does not cover external finishes, painting/preparation, impregnations, structural concrete repair or prefabricated fibre‑reinforced plaster elements.

Applications - who uses EN 13914-2:2016

- Architects and building designers specifying internal plaster systems and finishes.

- Contractors and applicators implementing plastering works (gypsum, lime, cement and polymer plasters).

- Material manufacturers developing or certifying factory-made plasters and reinforcement accessories.

- Specifiers and facility managers responsible for maintenance, repair and durability assessment of internal plaster finishes.

- National standards bodies and consultants using the standard together with local guidance to adapt recommendations to climate and practice.

Related standards

- EN 13914-1 (External rendering)

- EN 998-1 (Mortar for rendering and plastering)

- EN 13279-1 (Gypsum binders and plasters)

- EN 13658-1 (Metal lath and beads)

- EN 15824 (External renders/internal plasters based on organic binders) These referenced EN standards provide product and test requirements that complement the design and application guidance in EN 13914-2:2016.

Keywords: EN 13914-2:2016, internal plastering, internal plaster, plastering systems, gypsum plaster, lime plaster, cement plaster, plaster design, CEN standard.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13914-2:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Design, preparation and application of external rendering and internal plastering - Part 2: Internal plastering". This standard covers: This European Standard deals with the design considerations and essential principles for internal plastering systems and application of plastering systems. The different parts of the EN 13914 series of standards specify requirements and recommendations for detailing, design and material considerations, the selection of mixes and the application of gypsum plasters, gypsum/lime plasters, lightweight plasters, lime/gypsum-, cement- and cement/lime-based plasters, lime-based plasters, clay plasters, silicate plasters, organic plasters, polymer-modified plasters, etc. This standard does not deal with the following: - external finishes; - painting and/or preparation; - impregnations; - structural repair of concrete; - prefabricated fibre-reinforced plaster elements. Owing to the many and varied materials and practices and different climatic conditions in Europe it is not possible for certain aspects of the standard to enter into sufficient detail to be fully usable to practitioners in each country. Such guidance to complement, but not alter, any basic European recommendations is given in documentation prepared by each country. Aspects of this European Standard, the basic recommendations of which may need to be complemented, are indicated where they occur by a footnote referencing this clause.

This European Standard deals with the design considerations and essential principles for internal plastering systems and application of plastering systems. The different parts of the EN 13914 series of standards specify requirements and recommendations for detailing, design and material considerations, the selection of mixes and the application of gypsum plasters, gypsum/lime plasters, lightweight plasters, lime/gypsum-, cement- and cement/lime-based plasters, lime-based plasters, clay plasters, silicate plasters, organic plasters, polymer-modified plasters, etc. This standard does not deal with the following: - external finishes; - painting and/or preparation; - impregnations; - structural repair of concrete; - prefabricated fibre-reinforced plaster elements. Owing to the many and varied materials and practices and different climatic conditions in Europe it is not possible for certain aspects of the standard to enter into sufficient detail to be fully usable to practitioners in each country. Such guidance to complement, but not alter, any basic European recommendations is given in documentation prepared by each country. Aspects of this European Standard, the basic recommendations of which may need to be complemented, are indicated where they occur by a footnote referencing this clause.

EN 13914-2:2016 is classified under the following ICS (International Classification for Standards) categories: 91.100.10 - Cement. Gypsum. Lime. Mortar. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13914-2:2016 has the following relationships with other standards: It is inter standard links to EN 13914-2:2005, EN ISO 16120-2:2017, EN 13055:2016, EN 10346:2015, EN 10088-1:2023, EN 13658-1:2005, EN 13139:2002, EN 459-1:2015, EN 998-1:2010, EN 413-1:2011, EN 13139:2013, EN 13914-1:2016, EN 10244-2:2023, EN 13279-1:2008, EN 1008:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13914-2:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13914-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Projektiranje, priprava in uporaba zunanjih in notranjih ometov - 2. del: Notranji ometiPlanung, Zubereitung und Ausführung von Außen- und Innenputzen - Teil 2: InnenputzeConception, préparation et mise en oeuvre des enduits extérieurs et intérieurs - Partie 2: Enduits intérieursDesign, preparation and application of external rendering and internal plastering - Part 2: Internal plastering91.100.10Cement. Mavec. Apno. MaltaCement. Gypsum. Lime. MortarICS:Ta slovenski standard je istoveten z:EN 13914-2:2016SIST EN 13914-2:2016en,fr,de01-junij-2016SIST EN 13914-2:2016SLOVENSKI

STANDARDSIST EN 13914-2:20051DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13914-2

March

t r s x ICS

{ sä s r rä s r Supersedes EN

s u { s væ tã t r r wEnglish Version

Designá preparation and application of external rendering and internal plastering æ Part

tã Internal plastering Conceptioná prßparation et mise en oeuvre des enduits extßrieurs et intßrieurs æ Partie

tã Enduits intßrieurs

Planungá Zubereitung und Ausführung von Außenæ und Innenputzen æ Teil

tã Innenputze This European Standard was approved by CEN on

t January

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u { s væ tã t r s x ESIST EN 13914-2:2016

Design considerations for work and acceptance of smooth plaster finishes under aspects of lighting . 29 Annex B (informative)

Methods of minimizing the occurrence of cracks . 31 Annex C (informative)

Fixing applied backgrounds . 32 Annex D (informative)

Restoration of plasters . 35 Bibliography . 37 SIST EN 13914-2:2016

European foreword This document (EN 13914-2:2016) has been prepared by Technical Committee CEN/TC 125 “Masonry”, the secretariat of which is held by BSI. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by September 2016, and conflicting national standards shall be withdrawn at the latest by September 2016. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document supersedes EN 13914-2:2005. The initial draft of this document was prepared by the European section of International Union of Contractors of Plastering, Dry Lining, Stucco and Related Activities (UIEP) at the request of the CEN Technical Sector Board (Resolution No.BTS1/56/1991). It has been revised by CEN/TC 125/WG 5 in conjunction with experts of CEN/TC 241. Relevant data are summarized in a series of tables. This part of EN 13914 applies to the design of plaster made of mortars containing inorganic and organic binders and mineral aggregate1) which is applied to internal vertical and soffit surfaces of structures. As this standard is a code-like document as opposed to the more conventional European product standard, it is appropriate to mention that, as with product standards, the use of the verbal form 'shall' denotes a requirement for which verification of compliance has to be able to be demonstrated. Recommendations are denoted by the verbal form 'should' and should be followed unless there is a justifiable reason for not doing so. It is not the function of this standard to assign responsibility for the design and application of any work or actions mentioned herein to any specific party. Such responsibility is a matter for other documentation associated with the work, e.g. the contract. It has been assumed in the drafting of this document that the application of its provisions is entrusted to appropriately qualified and experienced persons, for whose guidance it has been prepared. The content of CEN Technical Reports containing guidance relating to the design, preparation and application of plaster and plastering systems for gypsum (CEN/TR 15124), cement and/or lime (CEN/TR 15125) and polymer plasters (CEN/TR 15123) has been included. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom.

1) The aggregate can be omitted from mortars made from gypsum plaster or anhydrite binders. SIST EN 13914-2:2016

Masonry cements EN 413-1 Building lime EN 459-1 Gypsum binder EN 13279-1 a Refer to final paragraph of Clause 1 for further information. 4.3.3 Aggregates Aggregates shall conform to EN 13139 for dense aggregates or EN 13055-1 for light aggregates, as appropriate. 4.3.4 Admixtures for cement- and/or lime-based plasters The admixtures used should conform to EN 934-3. However, admixtures falling outside the scope of EN 934-3 can be used in accordance with the manufacturer's instructions. 4.3.5 Colouring agents Colouring agents (e.g. inorganic and organic pigments or pigment preparations, dyes, natural minerals) should not have any influence on the behaviour of the fresh or hardened render. They shall be stable, unaffected by alkalinity or exposure to light and shall not easily be leached out by water. The use of colouring agents on the construction site shall always be subject to prior tests. Pigments shall conform to EN 12878. A uniform shade of the finishing coat is not generally ensured. 4.3.6 Fibres Natural and synthetic fibres, that do not affect the chemical or physical stability of the plaster, may be used either added on site or in premixed or factory made plasters. Fibres shall be dry, clean and free from oil or grease. 4.4 Water Water used for plasters shall fulfil the requirements of EN 1008. Drinking or potable water is suitable. SIST EN 13914-2:2016

Expanded metal (stainless steel or zinc-coated steel) Stainless steel in accordance with EN 10088-1 (austenitic steel) Zinc-coated steel in accordance with EN ISO 16120-2 and EN 10346 Profiled welded wire mesh (stainless steel or zinc-coated)

Beads (e.g. corner beads) Stainless steel and zinc coated steel EN 13658-1 Stainless steel in accordance with EN 10088-1 (austenitic steel) Zinc-coated steel in accordance with EN ISO 16120-2 and EN 10346 Plastic and plastic coated steel products

Other products and/or techniques may be used and defined at national level.a a Refer to final paragraph of Clause 1 for further information. SIST EN 13914-2:2016

Background Pre-treatmenta 1. Clay masonry A special pre-treatment of the background is normally not necessary when the background demonstrates uniform normal suction. 2. Concrete and calcium silicate brick- or blockwork Depending on suction and bond; may require use of a spatterdash pre-treatment or bond with polymer-modified cement mortar or metal lathing. 3. Lightweight clay blockwork The suction should be checked to ensure that it is similar to that of normal clay bricks. If not, special precautions may be necessary. 4. Lightweight blockwork: lightweight aggregate concrete Ordinary suction: no pre-treatment necessary High-suction: use a spatterdash treatment or metal lathing 5. Large lightweight concrete elements Special precautions in accordance with the recommendations of the manufacturer of the element or plaster. Gypsum plasters are not recommended. 6. Lightweight blockwork: autoclaved aerated concrete Depending on the absorption characteristics, may require use of a suction-reducing treatment. 7. Lightweight concrete blockwork A polymer-modified spatterdash or a bonding agent is recommended, depending on the plaster and the smoothness and suction of the blockwork. 8. Normal weight and dense aggregate concrete blockwork Depending on suction and bond; may require use of a spatterdash treatment or bond with polymer-modified cement plaster or carrier. Bonding agent recommended for gypsum plaster. 9. Sandstone blockwork Use a spatterdash or a dubbing-out coat if necessary 10. Dense or poured concrete with a smooth surface Use a pre-treatment. Bonding agent recommended for gypsum plaster. Certain polymer-modified lime cement, cement and organic plasters may be applied without pre-treatment. 11. Formwork blocks — cement/aggregate based Use a special pre-treatment as recommended by the block manufacturer 12. Cement/wood based blockwork a) lime/cement plaster: none, but use glass fibre mesh b) lime/cement lightweight plaster: none, but use glass fibre mesh c) lime/cement thermal insulating plaster: none, but use glass fibre mesh. A metal carrier is recommended depending on the thickness of the coat d) gypsum plaster: none, but use glass fibre mesh Spatterdash can be used. 13. Wood wool boards (with or without thermal insulation) b c a) lime/cement plaster: none, but use glass fibre mesh b) lime/cement lightweight plaster: no pre-treatment necessary. The undercoat is unreinforced: apply a reinforcing coat after sufficient drying time. c) lime/cement thermal insulating plaster: none, but use glass fibre mesh or metal carrier d) gypsum plaster: none, but use glass fibre mesh Spatterdash can be used. SIST EN 13914-2:2016

Background Pre-treatmenta 14. Old plaster surfaces Old plaster surfaces can be reworked using bonding and renovation mortar suitable for this purpose. It is recommended that any cracks present in the old plaster be repaired. Alternatively, a special plastering mortar with a reinforcement mesh can be applied over the whole surface. Gypsum plaster is not recommended on organic based plaster. A bonding agent or polymer-modified cement or cement lime plaster is necessary on cement-based plaster. 15. Multi-coat plaster — plaster surfaces A primer may be necessary prior to application of the final coat. 16. Extruded and expanded polystyrene boards c a) on small XPS-areas (up to 60 cm width) for lightweight lime/cement plasters: pre-treatment with bonding agent (premixed polymer-modified plaster) necessary, but use glass fibre mesh in the undercoat. b) on large XPS-areas: lightweight lime/cement plasters: pre-treatment with bonding agent (premixed polymer-modified plaster) necessary. The undercoat is unreinforced. Apply a reinforcing coat after sufficient drying time. c) Gypsum plasters: smooth XPS-boards should be roughened and plastered with plaster containing glass fibre or wire mesh. d) lime or lime/cement plasters do not provide enough adhesion on smooth XPS-boards so that special precautions need to be taken. e) EPS-boards can be plastered directly with a reinforcing coat. Special pre-treatment required. 17. Mineral wool Depending on the type of mineral wool and the thickness of the plaster, an additional carrier may be required, e.g. metal or fibre mesh. 18. Timber framework Use of a carrier system is required. 19. Areas containing more than one type of background, e.g. mixed masonry, timber framework with infill (masonry, loam, etc.) Depending on the type of plaster being applied, either a carrier system or reinforced undercoat will be required. 20. Gypsum plaster boards A bonding agent/primer may be required depending on the type of plasterboard and the thickness and type of plaster. a The manufacturer of the background material/product may recommend special pre-treatments. b Wood wool should be dry and should not be exposed to wet conditions. c Board joints should be tight. Methods of preparing board surfaces are:

— overlaying with reinforcement;

— for boards made of polystyrene and polyurethane that have rough surfaces, proprietary pre-treatment systems

are available using thin layers of polymer-modified cement-based plasters. Such products should be left for at least

one day before application of the plastering system. 6.2.3 Service conduits Service conduits and similar items that are to be built into a wall should be positioned within the thickness of the background wherever possible. Generally speaking, lathing or reinforcement may be required where service conduits are plastered over. If it is necessary to plaster behind service conduits additional work will be required. SIST EN 13914-2:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...