EN 15180:2014

(Main)Food processing machinery - Food depositors - Safety and hygiene requirements

Food processing machinery - Food depositors - Safety and hygiene requirements

1.1 General

This European Standard deals with all significant hazards, hazardous situations and events relevant to food depositors as defined in Subclauses 1.2.2 to 1.2.6 and the equipment typically integrated into them, i.e. product pumps, product elevators, conveyors and indexing mechanisms, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

This document deals with the significant hazards, hazardous situations and events during transport, assembly and installation, commissioning, use and decommissioning as defined in EN ISO 12100.

NOTE 1 According to the clause which is referred to, "use" includes "setting, teaching/programming or process changeover, operation, cleaning, fault finding and maintenance".

NOTE 2 Although this standard is intended to apply to depositors used in the food industry, many of its requirements can also be used for similar machines used in other industries.

This standard is not applicable to the following machines:

- auger depositors or auger fillers and gravimetric filling machines, safety requirements for these machines are contained in EN 415 3;

- automatic dough dividers, safety requirements for these machines are contained in EN 12042;

- filling machines for sausages, safety requirements for these machines are contained in EN 12463;

- mincing machines, safety requirements for these machines are contained in EN 12331;

- food depositors that are powered exclusively by manual effort.

This document does not deal with the hazards related to the use of food depositors in a potentially explosive atmosphere.

This document is not applicable to food depositors that were manufactured before the date of its publication as a European Standard.

1.2 Types of food depositors

1.2.1 General

This European Standard deals with five different types of food depositors. These machines can be free standing machines or be assemblies incorporated into other machines e.g. pie and tart machines. Food depositors may work fully automatically integrated with a product conveyor or product indexing mechanism or semi-automatically discharging a deposit when required by an operator.

1.2.2 Piston depositor

A piston depositor typically comprises a hopper, a rotary valve, a product measuring chamber in the form of a piston and a product dispensing valve. Some piston depositors incorporate several product measuring chambers and dispensing valves. Some designs dispense the product directly from the rotary valve without the use of a separate product dispensing valve. The volume of product dispensed is varied by altering the stroke of the product measuring chamber piston. Piston depositors are used to fill liquids, liquids containing solids in suspension and pastes. The product dispensing valve may be attached rigidly to the depositor or using a flexible pipe and in some cases is held by the operator. Figure 1 shows the typical cross section of a piston depositor.

(...)

1.2.3 Chamber depositor

A chamber depositor comprises a hopper feeding one or more product measuring chambers that are filled under gravity from the top. When the chamber has been filled with product the flow of product is stopped either by moving the chamber or using a product cutting device. The chamber is then discharged through the bottom of the chamber either by moving the chamber or by moving a plate in the base of the chamber. The volume of product dispensed is varied by altering the volume of the chamber. Chamber depositors are typically used to deposit free-flowing products like cooked rice or pasta. Figure 2 shows the typical cross section of a chamber depositor.

(...)

1.2.4 Roller depositor

A roller depositor typically comprises a hopper that feeds product to two or more fluted contra-rotating rollers. These rollers force the product through one or more dies that shape the product. (....)

Nahrungsmittelmaschinen - Nahrungsmittelportioniermaschinen - Sicherheits- und Hygieneanforderungen

1.1 Allgemeines

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefähr-dungsereignisse, die auf Nahrungsmittelportioniermaschinen, wie in 1.2.2 bis 1.2.6 definiert, zutreffen, sowie auf die typischerweise in sie integrierten Geräte, d. h. Produktpumpen, Produkthebevorrichtungen, Förder-einrichtungen und Taktgeber, wenn sie bestimmungsgemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen verwendet werden (siehe Abschnitt 4).

Diese Europäische Norm behandelt die signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungs-ereignisse während des Transports, der Montage und der Installation, der Inbetriebnahme, der Verwendung und der Außerbetriebnahme wie in EN ISO 12100 festgelegt.

ANMERKUNG 1 Entsprechend der vorstehend genannten Verweisung umfasst „Verwendung“ das „Einrichten, das Einlernen (Teachen)/Programmieren oder das Umrüsten, den Betrieb, die Reinigung, die Fehlersuche und die Instand¬haltung“.

ANMERKUNG 2 Obwohl diese Norm für Portioniermaschinen anzuwenden ist, die in der Nahrungsmittelindustrie eingesetzt werden, können viele der Anforderungen auch für ähnliche Maschinen angewendet werden, die in anderen Industriezweigen zum Einsatz kommen.

Diese Europäische Norm gilt nicht für die folgenden Maschinen:

Schneckenportionierer oder Schnecken-Füllmaschinen und gravimetrische Dosierer, Sicherheitsanfor-derungen für diese Maschinen sind in EN 415 3 enthalten;

automatische Teigteilmaschinen, Sicherheitsanforderungen für diese Maschinen sind in enthalten EN 12042;

Füllmaschinen für Wurstwaren. Sicherheitsanforderungen für diese Maschinen sind in EN 12463 enthalten;

Wölfe, Sicherheitsanforderungen für diese Maschinen sind in EN 12331 enthalten;

Nahrungsmittelportioniermaschinen, die ausschließlich von Hand betrieben werden.

Dieses Dokument behandelt nicht die Gefährdungen in Bezug auf den Einsatz von Portioniermaschinen in einer potentiell explosionsfähigen Atmosphäre.

Diese Europäische Norm gilt nicht für Nahrungsmittelportioniermaschinen, die vor dem Tag der Veröffentlichung als Europäische Norm gebaut wurden.

1.2 Typen von Nahrungsmittelportioniermaschinen

1.2.1 Allgemeines

Diese Europäische Norm behandelt fünf verschiedene Typen von Nahrungsmittelportioniermaschinen. Diese Maschinen können freistehende Maschinen sein oder in andere Maschinen eingebaute Baugruppen, wie z. B. Tortelettmaschinen. Nahrungsmittelportioniermaschinen können vollautomatisch mit integrierter Produkt-fördereinrichtung oder integriertem Produkttaktgeber bzw. halbautomatisch arbeiten, wobei sie eine Portion ableiten, wenn dies vom Bediener verlangt wird.

1.2.2 Kolbenportionierer

Ein Kolbenportionierer besteht üblicherweise aus einem Produkttrichter, einem Drehschieber, einer Produktdosierkammer in Form eines Kolbens und einem Produktausgabeventil. Bei einigen Kolben¬portionierern sind mehrere Produktdosierkammern und Produktausgabeventile eingebaut. Bei einigen Konstruktionen wird das Produkt ohne ein separates Produktausgabeventil direkt durch den Drehschieber ausgegeben. Die Menge des ausgegebenen Produkts wird durch die Hubhöhe des Kolbens in der Produkt¬dosierkammer verändert. Kolbenportionierer werden zum Abfüllen von Flüssigkeiten und flüssigkeitshaltigen Feststoffen in Suspensionen und Pasten eingesetzt. Das Produktausgabeventil kann fest am Portionierer angebaut sein oder eine flexible Leitung verwenden und in einigen Fällen vom Bediener gehalten werden. Bild 1 zeigt den typischen Querschnitt eines Kolbenportionierers.

Machines pour les produits alimentaires - Doseuses alimentaires - Prescriptions relatives à la sécurité et l'hygiène

1.1 Généralités

La présente Normes européenne traite de tous les phénomènes dangereux, situations et événements dangereux significatifs spécifiques aux doseuses alimentaires tel que définies aux 1.2.2 et 1.2.6 et aux équipements qui leurs sont spécifiquement associés, c’est à dire : les pompes, les ascendeurs, les tapis et les mécanismes à encliquetage, lorsqu’elles sont utilisées normalement et dans des conditions de mauvaise utilisation raisonnablement prévisibles par le fabricant (voir Article 4).

La présente Norme européenne traite de tous les phénomènes dangereux, situations et événements dangereux significatifs relatifs au transport, à l’assemblage et à l’installation, à la mise en service, à l’utilisation et à la mise hors service tel que définis dans l’EN ISO EN ISO 12100.

NOTE 1 Selon l'article auquel il est fait référence, l'utilisation" implique le "réglage, l'apprentissage/la programmation, le changement de processus, le fonctionnement, le nettoyage, la recherche de défauts et la maintenance".

NOTE 2 Bien que la présente norme soit destinée à s'appliquer aux doseuses utilisées dans l'industrie agroalimentaire, un grand nombre de ses prescriptions peut également s'appliquer à des machines similaires utilisées dans d'autres secteurs.

La présente Norme européenne ne s’applique pas aux machines suivantes :

- machines à former, remplir et sceller ; les prescriptions de sécurité applicables à ces machines figurent dans l’EN 415 3 ;

- diviseuses automatiques, les prescriptions de sécurité applicables à ces machines figurent dans l’EN 12042;

- machines à remplir les saucisses, les prescriptions de sécurité applicables à ces machines sont contenues dans l’EN 12463 ;

- hachoirs, les prescriptions de sécurité applicables à ces machines figurent dans l’EN 12331 ;

- doseuses alimentaires actionnées uniquement par un effort manuel.

La présente Norme européenne ne traite pas des phénomènes dangereux liés à l'utilisation de doseuses alimentaires dans une atmosphère potentiellement explosible.

Le présent document ne s'applique pas aux doseuses alimentaires qui ont été fabriquées avant sa date de publication comme Norme européenne.

1.2 Types de doseuses alimentaires

1.2.1 Généralités

La présente Norme européenne traite de cinq différents types de doseuses alimentaires. Ces machines peuvent être non scellées ou être incorporées dans un ensemble incorporant d’autres machines, par exemple : les fonceuses à tarte. Les doseuses alimentaires peuvent fonctionner de manière totalement automatique en étant reliées à un convoyeur de produit ou un mécanisme à indexage, ou de manière semi-automatique lorsque cela est demandé par un opérateur.

1.2.2 Doseuses à piston

Une doseuse à piston comprenant généralement une trémie, une vanne rotative, une chambre de mesurage du produit en forme de piston ainsi qu’une vanne de distribution du produit. Certaines doseuses à piston comportent plusieurs chambres de mesurage et vannes de distribution du produit. Dans le cas de certaines conceptions, le produit peut être directement diffusé par la vanne rotative sans qu’aucune vanne distincte de distribution de produit ne soit utilisée. La modification de la course du piston de la chambre de mesurage permet de faire varier le volume de produit déversé. Les doseuses à piston sont utilisées pour le remplissage de liquides, de liquides contenant des solides en suspension et de préparation pâteuses. La vanne de distribution du produit peut être attachée de manière rigide à la doseuses ou en utilisant un tuyau flexible et dans certains cas tenue par l’utilisateur. La Figure 1 illustre la section transversale type d'une doseuse à piston.

Stroji za predelavo hrane - Dodajalne naprave - Varnostne in higienske zahteve

Ta evropski standard opisuje vsa večja tveganja, nevarne situacije in nevarne dogodke v zvezi z dodajalnimi napravami, kot je določeno v točki 3, ter opremo, običajno povezano z njimi, tj. s črpalkami izdelka, dvigali izdelka, transporterji in mehanizmi za indeksiranje, kadar se uporabljajo v skladu z njihovim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določa proizvajalec.

Ta dokument opisuje večja tveganja, nevarne situacije in nevarne dogodke, ki se pojavijo med transportom, sestavljanjem in nameščanjem, začetkom obratovanja ter uporabo, kot je opredeljeno v točki 5.3 standarda EN ISO 12100-1.

Ta evropski standard se ne uporablja za naslednje stroje:

– dodajalne naprave s svedrom ali polnilce s svedrom in gravimetrične polnilne naprave; varnostne zahteve za te stroje so navedene v standardu EN 415-3:2000;

– polnilnike za klobase; varnostne naprave za te stroje so navedene v standardu EN 12463:2004;

– dodajalne naprave, ki se napajajo izključno z ročno silo.

Ta dokument se ne uporablja za dodajalne naprave, ki so bile izdelane pred datumom objave dokumenta kot evropskega standarda.

General Information

- Status

- Withdrawn

- Publication Date

- 04-Nov-2014

- Withdrawal Date

- 20-Jan-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 12 - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 26-Mar-2025

- Completion Date

- 28-Jan-2026

Relations

- Replaced By

EN 15180:2025 - Food processing machinery - Food depositors - Safety and hygiene requirements - Effective Date

- 28-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 15180:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Food depositors - Safety and hygiene requirements". This standard covers: 1.1 General This European Standard deals with all significant hazards, hazardous situations and events relevant to food depositors as defined in Subclauses 1.2.2 to 1.2.6 and the equipment typically integrated into them, i.e. product pumps, product elevators, conveyors and indexing mechanisms, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This document deals with the significant hazards, hazardous situations and events during transport, assembly and installation, commissioning, use and decommissioning as defined in EN ISO 12100. NOTE 1 According to the clause which is referred to, "use" includes "setting, teaching/programming or process changeover, operation, cleaning, fault finding and maintenance". NOTE 2 Although this standard is intended to apply to depositors used in the food industry, many of its requirements can also be used for similar machines used in other industries. This standard is not applicable to the following machines: - auger depositors or auger fillers and gravimetric filling machines, safety requirements for these machines are contained in EN 415 3; - automatic dough dividers, safety requirements for these machines are contained in EN 12042; - filling machines for sausages, safety requirements for these machines are contained in EN 12463; - mincing machines, safety requirements for these machines are contained in EN 12331; - food depositors that are powered exclusively by manual effort. This document does not deal with the hazards related to the use of food depositors in a potentially explosive atmosphere. This document is not applicable to food depositors that were manufactured before the date of its publication as a European Standard. 1.2 Types of food depositors 1.2.1 General This European Standard deals with five different types of food depositors. These machines can be free standing machines or be assemblies incorporated into other machines e.g. pie and tart machines. Food depositors may work fully automatically integrated with a product conveyor or product indexing mechanism or semi-automatically discharging a deposit when required by an operator. 1.2.2 Piston depositor A piston depositor typically comprises a hopper, a rotary valve, a product measuring chamber in the form of a piston and a product dispensing valve. Some piston depositors incorporate several product measuring chambers and dispensing valves. Some designs dispense the product directly from the rotary valve without the use of a separate product dispensing valve. The volume of product dispensed is varied by altering the stroke of the product measuring chamber piston. Piston depositors are used to fill liquids, liquids containing solids in suspension and pastes. The product dispensing valve may be attached rigidly to the depositor or using a flexible pipe and in some cases is held by the operator. Figure 1 shows the typical cross section of a piston depositor. (...) 1.2.3 Chamber depositor A chamber depositor comprises a hopper feeding one or more product measuring chambers that are filled under gravity from the top. When the chamber has been filled with product the flow of product is stopped either by moving the chamber or using a product cutting device. The chamber is then discharged through the bottom of the chamber either by moving the chamber or by moving a plate in the base of the chamber. The volume of product dispensed is varied by altering the volume of the chamber. Chamber depositors are typically used to deposit free-flowing products like cooked rice or pasta. Figure 2 shows the typical cross section of a chamber depositor. (...) 1.2.4 Roller depositor A roller depositor typically comprises a hopper that feeds product to two or more fluted contra-rotating rollers. These rollers force the product through one or more dies that shape the product. (....)

1.1 General This European Standard deals with all significant hazards, hazardous situations and events relevant to food depositors as defined in Subclauses 1.2.2 to 1.2.6 and the equipment typically integrated into them, i.e. product pumps, product elevators, conveyors and indexing mechanisms, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). This document deals with the significant hazards, hazardous situations and events during transport, assembly and installation, commissioning, use and decommissioning as defined in EN ISO 12100. NOTE 1 According to the clause which is referred to, "use" includes "setting, teaching/programming or process changeover, operation, cleaning, fault finding and maintenance". NOTE 2 Although this standard is intended to apply to depositors used in the food industry, many of its requirements can also be used for similar machines used in other industries. This standard is not applicable to the following machines: - auger depositors or auger fillers and gravimetric filling machines, safety requirements for these machines are contained in EN 415 3; - automatic dough dividers, safety requirements for these machines are contained in EN 12042; - filling machines for sausages, safety requirements for these machines are contained in EN 12463; - mincing machines, safety requirements for these machines are contained in EN 12331; - food depositors that are powered exclusively by manual effort. This document does not deal with the hazards related to the use of food depositors in a potentially explosive atmosphere. This document is not applicable to food depositors that were manufactured before the date of its publication as a European Standard. 1.2 Types of food depositors 1.2.1 General This European Standard deals with five different types of food depositors. These machines can be free standing machines or be assemblies incorporated into other machines e.g. pie and tart machines. Food depositors may work fully automatically integrated with a product conveyor or product indexing mechanism or semi-automatically discharging a deposit when required by an operator. 1.2.2 Piston depositor A piston depositor typically comprises a hopper, a rotary valve, a product measuring chamber in the form of a piston and a product dispensing valve. Some piston depositors incorporate several product measuring chambers and dispensing valves. Some designs dispense the product directly from the rotary valve without the use of a separate product dispensing valve. The volume of product dispensed is varied by altering the stroke of the product measuring chamber piston. Piston depositors are used to fill liquids, liquids containing solids in suspension and pastes. The product dispensing valve may be attached rigidly to the depositor or using a flexible pipe and in some cases is held by the operator. Figure 1 shows the typical cross section of a piston depositor. (...) 1.2.3 Chamber depositor A chamber depositor comprises a hopper feeding one or more product measuring chambers that are filled under gravity from the top. When the chamber has been filled with product the flow of product is stopped either by moving the chamber or using a product cutting device. The chamber is then discharged through the bottom of the chamber either by moving the chamber or by moving a plate in the base of the chamber. The volume of product dispensed is varied by altering the volume of the chamber. Chamber depositors are typically used to deposit free-flowing products like cooked rice or pasta. Figure 2 shows the typical cross section of a chamber depositor. (...) 1.2.4 Roller depositor A roller depositor typically comprises a hopper that feeds product to two or more fluted contra-rotating rollers. These rollers force the product through one or more dies that shape the product. (....)

EN 15180:2014 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15180:2014 has the following relationships with other standards: It is inter standard links to EN 15180:2025, EN 894-1:1997+A1:2008, EN ISO 4871:2009, EN ISO 11202:2010, EN ISO 12001:2009, EN ISO 4414:2010, EN 618:2002+A1:2010, EN ISO 11201:2010, EN ISO 13857:2008, EN 2286:1989, EN ISO 13854:2019, EN 894-2:1997+A1:2008, EN ISO 14118:2018, EN 614-1:2006+A1:2009, EN 1005-3:2002+A1:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15180:2014 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15180:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo hrane - Dodajalne naprave - Varnostne in higienske zahteveNahrungsmittelmaschinen - Nahrungsmittelportioniermaschinen - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Doseuses alimentaires - Prescriptions relatives à la sécurité et l'hygièneFood processing machinery - Food depositors - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 15180:2014SIST EN 15180:2015en,fr,de01-januar-2015SIST EN 15180:2015SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15180

November 2014 ICS 67.260 English Version

Food processing machinery - Food depositors - Safety and hygiene requirements

Machines pour les produits alimentaires - Doseuses alimentaires - Prescriptions relatives à la sécurité et l'hygiène

Nahrungsmittelmaschinen - Nahrungsmittelportioniermaschinen - Sicherheits- und Hygieneanforderungen This European Standard was approved by CEN on 13 September 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15180:2014 ESIST EN 15180:2015

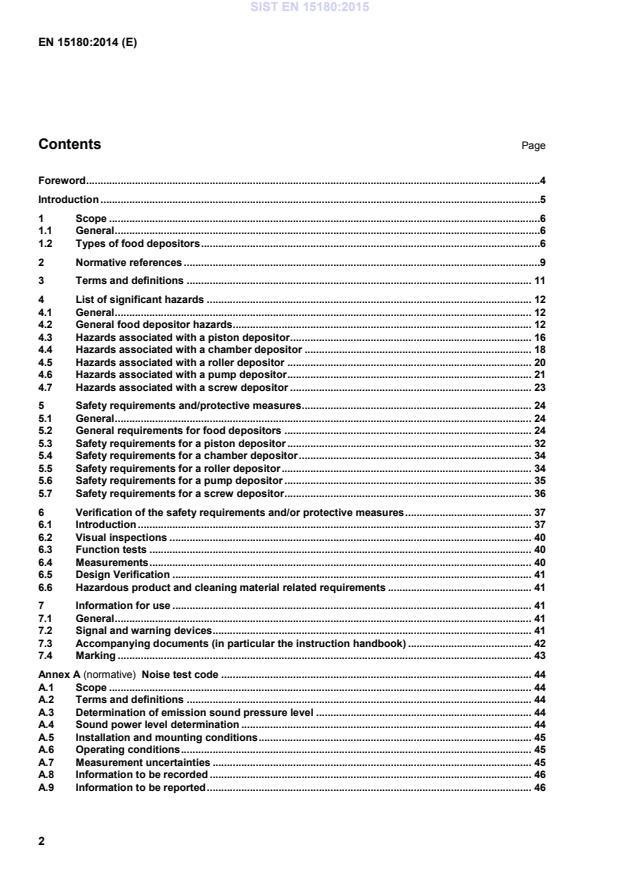

Noise test code . 44 A.1 Scope . 44 A.2 Terms and definitions . 44 A.3 Determination of emission sound pressure level . 44 A.4 Sound power level determination . 44 A.5 Installation and mounting conditions . 45 A.6 Operating conditions . 45 A.7 Measurement uncertainties . 45 A.8 Information to be recorded . 46 A.9 Information to be reported . 46 SIST EN 15180:2015

Correlation between Clauses 4, 5 and 7 . 48 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC on Machinery . 51 Bibliography . 52

Figure 1 — Piston depositor 1.2.3 Chamber depositor A chamber depositor comprises a hopper feeding one or more product measuring chambers that are filled under gravity from the top. When the chamber has been filled with product the flow of product is stopped either by moving the chamber or using a product cutting device. The chamber is then discharged through the bottom of the chamber either by moving the chamber or by moving a plate in the base of the chamber. The volume of product dispensed is varied by altering the volume of the chamber. Chamber depositors are typically used to deposit free-flowing products like cooked rice or pasta. Figure 2 shows the typical cross section of a chamber depositor.

Figure 2 — Chamber depositor SIST EN 15180:2015

Figure 3 — Roller depositor 1.2.5 Pump depositor A pump depositor comprises a hopper that feeds a pump which in turn feeds pipe-work on which are mounted one or more product dispensing valves. The dispensing valves may remain fixed, move up and down or from side to side in synchronization with a product conveyor. The volume of product dispensed is varied by altering the length of time that the dispensing valves are open. Pump depositors are typically used to deposit liquids or liquids containing finely divided solids Figure 4 shows the typical cross section of a pump depositor.

Figure 4 —Pump depositor SIST EN 15180:2015

Figure 5 — Screw depositor 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 349, Safety of machinery — Minimum gaps to avoid crushing of parts of the human body EN 574:1996+A1:2008, Safety of machinery — Two-hand control devices — Functional aspects — Principles for design EN 614 (all parts), Safety of machinery — Ergonomic design principles EN 618, Continuous handling equipment and systems — Safety and EMC requirements for equipment for mechanical handling of bulk materials except fixed belt conveyors EN 619, Continuous handling equipment and systems — Safety and EMC requirements for equipment for mechanical handling of unit loads EN 620, Continuous handling equipment and systems — Safety and EMC requirements for fixed belt conveyors for bulk materials EN 894-1, Safety of machinery — Ergonomics requirements for the design of displays and control — Part 1: General principles for human interactions with displays and control actuators EN 894-2, Safety of machinery — Ergonomics requirements for the design of displays and control — Part 2: Displays SIST EN 15180:2015

Figure 6 — Food depositor equipped with wheels 4.2.14 Slip, trip and fall hazards resulting from the design of the machine Slip accidents can occur if the product being deposited or cleaning media is spilt on the floor. Trip accidents may occur if power cables or compressed air pipes powering the food depositor are left on the floor. Falls may occur if people stand on parts of the depositor e.g. for hopper loading, size changing, maintenance or cleaning. 4.2.15 Hygienic design hazards The product being deposited can become contaminated, e.g. by the following causes: — incorrect choice of contact materials; — inappropriate construction methods; — non-food grade lubricants which are allowed to come into contact with the product, e.g. from gearboxes or compressed air exhausts. 4.3 Hazards associated with a piston depositor 4.3.1 General The hazards described in 4.2 and those detailed below are specifically associated with a piston depositor. Figure 7 illustrates the components that typically present hazards on piston depositors. SIST EN 15180:2015

Key 1 hopper 2 D-valve 3 product measuring chamber 4 measuring chamber drive mechanism 5 product dispensing valve Figure 7 — Typical components on a piston depositor 4.3.2 Hopper The product hopper will usually be mounted over product feeding devices that present crushing, shearing and drawing-in hazards and may be equipped with stirring devices that present entanglement hazards. On some machines the hopper is removed for cleaning and excessive effort may be required to remove or replace the hopper. Excessive effort and a risk of falling may occur if the hopper cannot easily be loaded with product from floor level. 4.3.3 D-valve The D-valve presents a shearing hazard if it can be reached when operating under power either during normal operation, trouble-shooting or cleaning, e.g. by partly dismantling the machine. 4.3.4 Product measuring chamber The product measuring chamber presents crushing and shearing hazards if it can be reached when operating under power either during normal operation, trouble-shooting or cleaning, e.g. by partly dismantling the machine. 4.3.5 Measuring chamber drive mechanism Measuring chamber drive mechanisms are typically pneumatic cylinders that can present crushing and shearing hazards. Other drive mechanisms, e.g. electric motors, driving rack and pinion mechanisms will present crushing and drawing-in hazards. SIST EN 15180:2015

Key 1 hopper 2 product measuring chamber 3 chamber drive mechanism 4 product discharge 5 product cutting device Figure 8 — Typical components on a chamber depositor 4.4.2 Hopper See 4.3.2. 4.4.3 Product feeding mechanism Chamber depositors may be fitted with a variety of product feeding mechanisms including vibrating trays, rotating brushes or rotating fingers. These mechanisms present crushing and entanglement hazards. On some machines the flow of product into the chamber may be regulated by a product cutting device in the form of a brush or shear blade. These mechanisms present crushing and shearing hazards. 4.4.4 Product measuring chamber Product measuring chambers will typically incorporate a mechanism to vary the volume of the chamber and a discharging flap. These mechanisms present crushing and shearing hazards. On machines where the product measuring chamber moves there is a shearing hazard between the measuring chamber and fixed assemblies on the machine. 4.4.5 Container or materials handling mechanisms See 4.3.7. SIST EN 15180:2015

Key 1 rollers 2 product cutting mechanism 3 extruding die 4 rise and fall mechanism 5 conveyor Figure 9 — Typical components on a roller depositor 4.5.2 Hopper See 4.3.2. 4.5.3 Roller product feeder The roller product feeder normally comprises a pair of contra rotating fluted rollers that are a significant drawing-in hazard. The drive mechanism powering the rollers is also a drawing in hazard. The hopper and roller assembly may move backwards and forwards causing a crushing hazard between the assembly and the supporting frame. 4.5.4 Product extruding die Product extruding dies may be equipped with mechanisms to rotate the die as the product is extruded. These mechanisms can present crushing and drawing-in hazards. It is typical for the die assembly to be withdrawn SIST EN 15180:2015

Key 1 hopper 2 pump 3 product pipe 4 product dispensing valve 5 rise and fall mechanism 6 conveyor Figure 10 — Typical components on a pump depositor 4.6.2 Product pump The hazards presented by the pump will vary depending on the type of pump used. However, most designs of pump present shearing or drawing-in hazards if the moving parts can be reached, e.g. by reaching into the hopper or by partly disassembling the pump. 4.6.3 Manifold Some pump depositors incorporate a manifold that supports several dispensing valves. The manifold may be fixed or attached to a mechanism that moves the manifold forwards and backwards and up and down in synchronization with the product conveyor. These mechanisms will normally present crushing hazards when they lower the valves and may also present crushing and shearing hazards when the mechanism moves up, forwards or backwards. If the product being filled is hot the manifold can become a burning hazard. 4.6.4 Product dispensing valves See 4.3.6. 4.6.5 Rise and fall mechanism See 4.5.6. 4.6.6 Container and materials handling equipment See 4.3.7.1. SIST EN 15180:2015

Key 1 hopper 2 screw 3 product dispensing valve 4 conveyor 5 product measuring chamber Figure 11 — Typical components on a screw depositor 4.7.2 Hopper See 4.3.2. 4.7.3 Screw The screw presents a drawing-in hazard if it can be reached when operating under power either during normal operation, troubleshooting or cleaning. 4.7.4 Product measuring chamber Screw depositors may be fitted with one or a number of product measuring chambers. The product measuring chamber presents a crushing hazard if it can be reached when operating under power either during normal operation, troubleshooting or cleaning, e.g. by partly dismantling the machine. 4.7.5 Measuring chamber drive mechanism See 4.3.5. SIST EN 15180:2015

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...