EN 13197:2011+A1:2014

(Main + Amendment)Road marking materials - Wear simulator Turntable

Road marking materials - Wear simulator Turntable

This European Standard specifies the requirements for wear simulator test for road marking materials intended for use in both permanent and temporary road markings including those with increased retroreflection under wet and rain conditions, without road studs.

It gives description for the equipment and for test plate’s characteristics; it also gives description for the test method involving road marking materials application, test conditions during wear test, parameters to be measured, frequency of the measurements and expression of the results as a test report.

This document gives also the requirements to be followed when the test is to be used for CE marking purposes.

Straßenmarkierungsmaterialien - Verschleißsimulator

Diese Europäische Norm legt die Anforderungen an Verschleißsimulator-Prüfung für Straßenmarkierungsmaterialien fest, die sowohl für die Verwendung als ständige als auch vorübergehende Straßenmarkierungen vorgesehen sind, einschließlich solcher mit verbesserter Retroreflexion bei Nässe und Regen, nicht jedoch für Markierungsknöpfe.

Sie enthält eine Beschreibung der Einrichtung und der Prüfkörper-Merkmale; sie beschreibt außerdem das Prüfverfahren mittels Applikation der Straßenmarkierungsmaterialien, die Prüfbedingungen während der Verschleißprüfung, die zu messenden Parameter, die Messintervalle und die Angabe der Ergebnisse als Prüf-bericht.

Dieses Dokument legt außerdem die zu befolgenden Anforderungen fest, wenn die Prüfung zur Anbringung der CE Kennzeichnung dient.

Produits de marquage routier - Simulateur d’usure tournant

La présente Norme européenne spécifie les exigences pour les essais sur simulateur d’usure pour les produits de marquage routier destinés à une utilisation aussi bien permanente que temporaire, y compris ceux présentant une rétroréflexion accrue en conditions humides et de pluie, et à l’exclusion des plots routiers.

Elle fournit la description des équipements, des caractéristiques des plaques d’essai, des méthodes d’essai impliquant l’application de produits de marquage routier, des conditions pendant l’essai d’usure, des paramètres à mesurer, de la fréquence des mesurages et de l’expression des résultats sous forme d’un rapport d’essai.

La présente Norme européenne spécifie également les exigences à satisfaire lorsque l’essai est utilisé à des fins de marquage CE.

Materiali za označevanje vozišča - Vrtljiva plošča za simulacijo obrabe

Standard EN 13197+A1 določa zahteve za preskus simulacije obrabe materialov za označevanje vozišča, ki so namenjeni uporabi za stalno in začasno označevanje vozišča, vključno s takimi s povečano retrorefleksijo v mokrih in deževnih razmerah, brez odsevnikov. Podaja opis za opremo in za lastnosti preskusne plošče; prav tako podaja opis preskusne metode, ki zadeva nanos materialov za označevanje vozišča, preskusne razmere med preskusom obrabe, parametre, ki jih je treba meriti, frekvenco meritev in izražanje rezultatov v obliki preskusnega poročila. Ta dokument podaja tudi zahteve, ki jim je treba slediti, kadar se preskus uporablja za označevanje CE.

General Information

- Status

- Published

- Publication Date

- 15-Apr-2014

- Technical Committee

- CEN/TC 226 - Road equipment

- Drafting Committee

- CEN/TC 226/WG 2 - Horizontal road signs

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 29-Jul-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 28-Jan-2026

- Refers

EN 1436:2018 - Road marking materials - Road marking performance for road users and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

CEN/TR 16958:2017 - Road marking materials - Conditions for removing/masking road markings - Effective Date

- 28-Jan-2026

Overview - EN 13197:2011+A1:2014 (Wear simulator Turntable)

EN 13197:2011+A1:2014 is a CEN European standard that specifies a laboratory wear-simulator (turntable) test method for evaluating road marking materials. It covers permanent and temporary markings, including products designed for increased retroreflection under wet and rain conditions (without road studs). The standard defines the simulator equipment, test-plate characteristics, application and conditioning of samples, test operation, measured parameters, reporting and the specific requirements when the test is used for CE marking.

Key topics and technical requirements

- Wear simulator (turntable): mobile turntable with external diameter 6.4 m, wheel stations and drive capable of bi-directional rotation at tangential speeds up to 120 km/h. Rolling line location is specified (diameter ~585 cm ± 5 cm).

- Test plates and substrate: rigid plates resistant up to 50 °C; bitumen coating (≈50 g/m²) when non-bituminous substrates are used. Minimum parallel dimension for housings is 190 mm. Measurement area per product ≥ 800 cm².

- Surface roughness classes: texture depth measured per EN 13036‑1 and classified RG1–RG4; for CE marking only RG1 and RG2 are used.

- Wheels, tyres and loads: reference stress created by two pairs of wheels; wheel load 0–4 000 N; inflation pressure 0–0.3 MPa. Tyres must be approved against a control plate; new tyres used for each test.

- Test environment & ancillary systems: air‑conditioned test room, cleaning systems (brushes, air jets, vacuum, water atomizers) to remove loose drop‑on particles, and a water dispenser for wet-test conditions.

- Measurements and records: control of turntable speed, direction, room and plate temperatures, wheel load, number of wheel passages (wp), steering/support angles, inflation. Annexes include procedures for no-pickup determination, layer thickness, drop‑on consumption and example test reports.

- Control plate: at least one reference plate/material included in each run to verify correct procedure and comparability.

Applications and users

- Manufacturers of road marking paints, thermoplastics, and drop-on materials use the method to validate durability and wet-night retroreflective performance.

- Test laboratories and conformity assessment bodies performing type testing and supporting CE marking of road marking systems.

- Road authorities and procurement teams specifying performance criteria for markings exposed to traffic abrasion and wet conditions.

- R&D departments evaluating new formulations, binder performance and aggregate retention under simulated wheel abrasion.

Related standards

- Normative references: EN 13036‑1 (texture depth measurement) and EN 1436 (road marking materials - related performance aspects). These standards are complementary when assessing surface texture and overall marking performance.

Keywords: EN 13197, wear simulator, turntable, road marking materials, wet retroreflection, test plates, wheel passages, CE marking, EN 13036-1.

Get Certified

Connect with accredited certification bodies for this standard

Zavod za gradbeništvo Slovenije (ZAG) - Inšpekcija

ZAG inspection body for construction products, structures, and materials.

Sponsored listings

Frequently Asked Questions

EN 13197:2011+A1:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Road marking materials - Wear simulator Turntable". This standard covers: This European Standard specifies the requirements for wear simulator test for road marking materials intended for use in both permanent and temporary road markings including those with increased retroreflection under wet and rain conditions, without road studs. It gives description for the equipment and for test plate’s characteristics; it also gives description for the test method involving road marking materials application, test conditions during wear test, parameters to be measured, frequency of the measurements and expression of the results as a test report. This document gives also the requirements to be followed when the test is to be used for CE marking purposes.

This European Standard specifies the requirements for wear simulator test for road marking materials intended for use in both permanent and temporary road markings including those with increased retroreflection under wet and rain conditions, without road studs. It gives description for the equipment and for test plate’s characteristics; it also gives description for the test method involving road marking materials application, test conditions during wear test, parameters to be measured, frequency of the measurements and expression of the results as a test report. This document gives also the requirements to be followed when the test is to be used for CE marking purposes.

EN 13197:2011+A1:2014 is classified under the following ICS (International Classification for Standards) categories: 93.080.20 - Road construction materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13197:2011+A1:2014 has the following relationships with other standards: It is inter standard links to EN 13197:2011/FprA1, EN 13197:2011, EN 13036-1:2010, EN 1436:2018, EN 18124:2025, CEN/TR 16958:2017. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13197:2011+A1:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.REUDEHStraßenmarkierungsmaterialien - VerschleißsimulatorProduits de marquage routier - Simulateur d’usure tournantRoad marking materials - Wear simulator Turntable93.080.20Materiali za gradnjo cestRoad construction materialsICS:Ta slovenski standard je istoveten z:EN 13197:2011+A1:2014SIST EN 13197:2011+A1:2014en,fr,de01-julij-2014SIST EN 13197:2011+A1:2014SLOVENSKI

STANDARDSIST EN 13197:20111DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13197:2011+A1

April 2014 ICS 93.080.20 Supersedes EN 13197:2011English Version

Road marking materials - Wear simulator Turntable

Produits de marquage routier - Simulateur d'usure tournant Straßenmarkierungsmaterialien - Verschleißsimulator This European Standard was approved by CEN on 22 April 2011 and includes Amendment 1 approved by CEN on 13 March 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13197:2011+A1:2014 ESIST EN 13197:2011+A1:2014

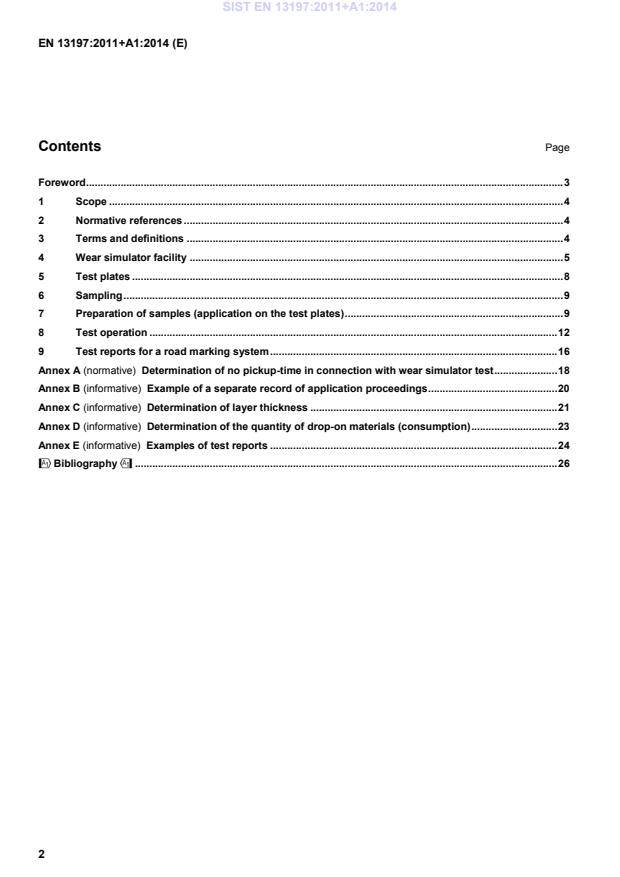

Determination of no pickup-time in connection with wear simulator test . 18 Annex B (informative)

Example of a separate record of application proceedings . 20 Annex C (informative)

Determination of layer thickness . 21 Annex D (informative)

Determination of the quantity of drop-on materials (consumption) . 23 Annex E (informative)

Examples of test reports . 24 !Bibliography" . 26

— EN 13212, , — EN 13459, . According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 13197:2011+A1:2014

!deleted text" EN 13036-1, Road and airfield surface characteristics

1: Measurement of pavement surface macrotexture depth using a volumetric patch technique 3 Terms and definitions For the purpose of this document, the following terms and definitions apply. 3.1 support angle angle between a plane perpendicular to the axle of the loading wheel and the vertical 3.2 steering angle angle between a plane perpendicular to the axle of the loading wheel and a plane tangential to the movement of the loaded wheel relative to the test plates 3.3 wheel passages (wp) number of loading wheels that have passed over a test plate 3.4 measurement area summary of those areas of all the test plates of one tested product that are subject to wheel passages, which makes it possible to determine the required measurements 3.5 control plate test plate of a standard material and with a standard road marking material included in each test run for indication of correct procedure 3.6 rolling line circumferential line characterised by the central line of the contact area of loading tyre SIST EN 13197:2011+A1:2014

Key 1 wheel stations 6 wheel suspension 2 test tyre 7 bearing 3 road marking samples 8 electric/hydraulic engine 4 turnable diameter 6,40 9 samples, test surface 5 turntable bearing assembly

Figure 1 — Scheme of the wear simulator SIST EN 13197:2011+A1:2014

NOTE 1 For practical purposes a value in the middle of the classes should be chosen. A sample of test plates shall be submitted periodically to the test process in order to determine if after the test process they are still in the same class of roughness. NOTE 2 Sometimes, to stabilise the texture of the test plates it is convenient to submit them to a preparatory wheel passages process. 5.4 Size (useful surface) The size of the test plates shall to be sufficient both for the complete contact area of the tyre to roll over and for the necessary measurements to be performed allowing the use of the appropriate measurement equipment. For testing a road marking material, the necessary number of test plates to complete a measurement area of, at least, 800 cm² shall be used. NOTE The longer are the test plates (in one piece) the more reliable are the photometric measurements particularly for night-time visibility under wet and rain conditions. Test plates of 45 cm have shown good performance in these cases. 6 Sampling When samples are required for identification purposes, each road markind material, all components of a multiple component material, and drop-on materials shall be taken into account. NOTE 1 For certification purposes sampling shall be done by the test laboratory. NOTE 2 The participants can agree to include further specifications for sampling, such as quantities to sample. 7 Preparation of samples (application on the test plates) 7.1 General The test results depend on various factors related to the application of the road marking materials, mainly on the application instructions (type of application and quantities applied) on the direction of application (in relation to the wearing process and the direction of measurements) and on the drying or hardening conditions (conditioning). A particular case is the preparation of a sample as a reference or control plate. SIST EN 13197:2011+A1:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...