EN 15655-1:2018

(Main)Ductile iron pipes, fittings and accessories - Requirements and test methods for organic linings of ductile iron pipes and fittings - Part 1: Polyurethane lining of pipes and fittings

Ductile iron pipes, fittings and accessories - Requirements and test methods for organic linings of ductile iron pipes and fittings - Part 1: Polyurethane lining of pipes and fittings

This European Standard defines the requirements and test methods applicable to factory applied internal polyurethane high duty corrosion protection of buried ductile iron pipes and fittings conforming to EN 545, EN 598 and EN 969 for use at permanent operating temperatures up to 45 °C

Rohre, Formstücke und Zubehörteile aus duktilem Gusseisen - Anforderungen und Prüfverfahren für organische Auskleidungen von Rohren und Formstücken aus duktilem Gusseisen - Teil 1: Polyurethan-Auskleidung von Rohren und Formstücken

Diese Europäische Norm legt die Anforderungen und Prüfverfahren fest für werksseitig aufgebrachte Aus-kleidungen aus Polyurethan für den Korrosionsschutz bei starker Beanspruchung von beschichteten Rohren und Formstücken aus duktilem Gusseisen nach EN 545, EN 598 und EN 969 für den Einsatz bei Betriebs-temperaturen bis 45 °C.

Tuyaux, raccords et accessoires en fonte ductile - Prescriptions et méthodes d’essai relatives aux revêtements organiques des tuyaux et raccords en fonte ductile - Partie 1 : Revêtement en polyuréthane des tuyaux et raccords

La présente Norme européenne établit les exigences et les méthodes d'essais applicables aux revêtements intérieurs en polyuréthane, appliqués en usine, et destinés à fournir une protection renforcée contre la corrosion pour les tuyaux et raccords en fonte ductile conformes à l'EN 545, l'EN 598 et l'EN 969, utilisables à des températures de service permanentes allant jusqu'à 45 °C.

Cevi, fitingi in pribor iz duktilne železove litine - Zahteve in preskusne metode za notranje organske prevleke cevi in fitingov iz duktilne železove litine - 1. del: Poliuretanska prevleka cevi in fitingov

Ta evropski standard določa zahteve in preskusne metode, ki veljajo za tovarniško naneseno notranjo poliuretansko visoko odporno protikorozijsko prevleko zakopanih cevi iz duktilne železove litine in fitingov v skladu s standardi EN 545, EN 598 in EN 969 za uporabo pri stalnih delovnih temperaturah do 45 °C.

General Information

- Status

- Published

- Publication Date

- 18-Dec-2018

- Withdrawal Date

- 29-Jun-2019

- Technical Committee

- CEN/TC 203 - Cast iron pipes, fittings and their joints

- Drafting Committee

- CEN/TC 203/WG 8 - Coatings for pipes, fittings and accessories

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 04-Jun-2024

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN 12842:2012 - Ductile iron fittings for PVC-U or PE piping systems - Requirements and test methods - Effective Date

- 28-Jan-2026

Overview

EN 15655-1:2018 is a CEN European Standard that specifies requirements and test methods for factory-applied internal polyurethane (PU) linings on buried ductile iron pipes, fittings and accessories. It covers heavy‑duty corrosion protection for items conforming to EN 545 (water), EN 598 (sewerage) and EN 969 (gas) for permanent operating temperatures up to 45 °C. The standard defines production controls, routine and performance tests, and quality assurance measures for polyurethane lining systems.

Key Topics

- Scope and applicability

- Internal polyurethane lining of ductile iron pipes and fittings for buried service (water, wastewater, gas networks).

- Designed for permanent operating temperatures up to 45 °C.

- Surface preparation

- Blast cleaning and surface roughness requirements prior to lining application; substrate temperature control relative to dew point.

- Finished lining requirements

- Appearance and continuity, minimum lining thickness (specified in tables within the standard), non‑porosity (holiday testing), pipe end protection, repairs and marking.

- Mechanical and physical properties

- Adhesion (pull‑off), indirect impact strength, resistance to ovalization, elongation at break, glass transition temperature, specific electrical resistance of the lining.

- Chemical and abrasion resistance

- Chemical resistance performance tests; abrasion resistance required where applicable (notably wastewater applications).

- Testing framework

- Routine production tests and more extensive performance tests (e.g., Differential Scanning Calorimetry (DSC), adhesion per EN ISO 4624, and other referenced ISO/CEN test methods).

- Quality assurance and documentation

- Informative annexes cover QA, lining process and materials, DN grouping for tests, and packaging.

Applications and Users

- Who uses it

- Pipe and fitting manufacturers, coating applicators, utilities (water, wastewater, gas), civil/mechanical engineers, procurement/specification professionals, and testing laboratories.

- Practical uses

- Specifying and verifying internal polyurethane corrosion protection for new ductile iron pipelines and fittings used in potable water, sewerage and gas distribution networks.

- Setting acceptance criteria for factory linings, production controls, and supplier quality assessment.

Related Standards

- EN 545, EN 598, EN 969 (ductile iron pipes/fittings for water, sewerage, gas)

- EN 14901 (epoxy coating of fittings)

- EN ISO 4624, EN ISO 62, EN ISO 527-3, EN ISO 868, EN ISO 8501-1, EN ISO 8503-1 (test methods referenced)

Keywords: EN 15655-1:2018, polyurethane lining, ductile iron pipes, corrosion protection, test methods, factory-applied lining, potable water, wastewater, pipe lining standard.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 15655-1:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ductile iron pipes, fittings and accessories - Requirements and test methods for organic linings of ductile iron pipes and fittings - Part 1: Polyurethane lining of pipes and fittings". This standard covers: This European Standard defines the requirements and test methods applicable to factory applied internal polyurethane high duty corrosion protection of buried ductile iron pipes and fittings conforming to EN 545, EN 598 and EN 969 for use at permanent operating temperatures up to 45 °C

This European Standard defines the requirements and test methods applicable to factory applied internal polyurethane high duty corrosion protection of buried ductile iron pipes and fittings conforming to EN 545, EN 598 and EN 969 for use at permanent operating temperatures up to 45 °C

EN 15655-1:2018 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15655-1:2018 has the following relationships with other standards: It is inter standard links to EN 15655:2009, EN ISO 8501-1:2007, EN ISO 868:2003, EN 14901-1:2014+A1:2019, EN ISO 4624:2023, EN ISO 527-3:2018, EN 545:2010, EN 598:2007+A1:2009, EN 969:2009, EN ISO 8503-1:2012, EN ISO 62:2008, EN 14525:2022, EN 12842:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15655-1:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Cevi, fitingi in pribor iz duktilne železove litine - Zahteve in preskusne metode za notranje organske prevleke cevi in fitingov iz duktilne železove litine - 1. del: Poliuretanska prevleka cevi in fitingovRohre, Formstücke und Zubehörteile aus duktilem Gusseisen - Anforderungen und Prüfverfahren für organische Auskleidungen von Rohren und Formstücken aus duktilem Gusseisen - Teil 1: Polyurethan-Auskleidung von Rohren und FormstückenTuyaux, raccords et accessoires en fonte ductile - Exigences et méthodes d'essais relatives aux revêtements organiques des tuyaux et raccords en fonte ductile - Partie 1 : Revêtement en polyuréthane des tuyaux et raccordsDuctile iron pipes, fittings and accessories - Requirements and test methods for organic linings of ductile iron pipes and fittings - Part 1: Polyurethane lining of pipes and fittings23.040.40Kovinski fitingiMetal fittings23.040.10Železne in jeklene ceviIron and steel pipesICS:Ta slovenski standard je istoveten z:EN 15655-1:2018SIST EN 15655-1:2019en,fr,de01-marec-2019SIST EN 15655-1:2019SLOVENSKI

STANDARDSIST EN 15655:20091DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15655-1

December

t r s z ICS

t uä r v rä s râ

t uä r v rä v r Supersedes EN

s w x w wã t r r {English Version

Ductile iron pipesá fittings and accessories æ Requirements and test methods for organic linings of ductile iron pipes and fittings æ Part

sã Polyurethane lining of pipes and fittings Tuyauxá raccords et accessoires en fonte ductile æ Prescriptions et méthodes d 5essai relatives aux revêtements organiques des tuyaux et raccords en fonte ductile æ Partie

s ã Revêtement en polyuréthane des tuyaux et raccords

Rohreá Formstücke und Zubehörteile aus duktilem Gusseisen æ PolyurethanæAuskleidung von Rohren und Formstücken æ Anforderungen und Prüfverfahren This European Standard was approved by CEN on

{ November

t r s zä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s w x w wæ sã t r s z ESIST EN 15655-1:2019

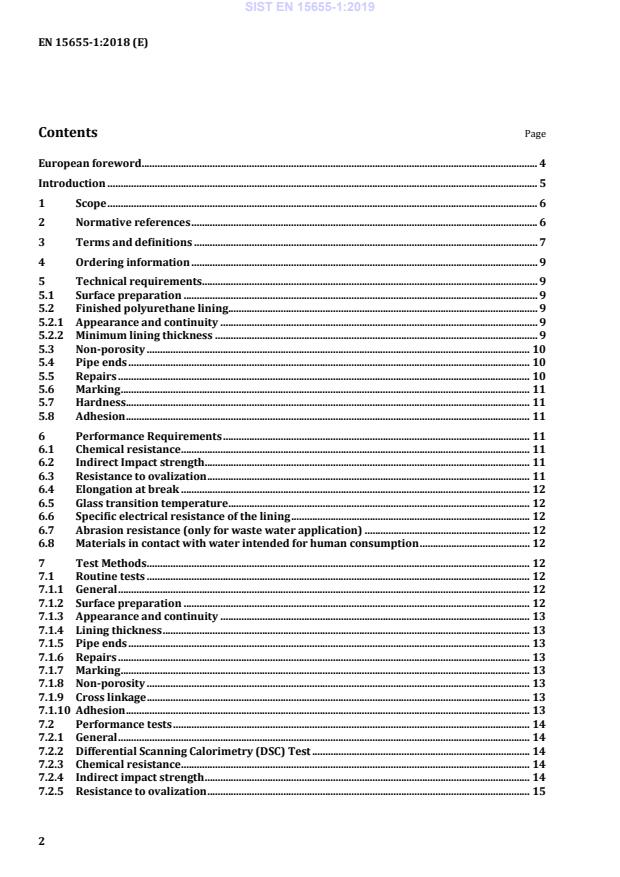

Quality assurance . 17 A.1 General . 17 A.2 Performance test - DN grouping . 19 A.3 Quality assessment system . 19 Annex B (informative)

Lining process and materials . 20 B.1 Lining application process . 20 B.2 Material properties . 20 B.2.1 General . 20 B.2.2 Polyurethane . 20 B.2.3 Epoxy resin . 21 B.3 Field of use, characteristics of transported waters . 21 B.4 Jet cleaning . 21 Annex C (informative)

Packaging. 22 Bibliography . 23

addition to informative annex that the manufacturer should provide infrared scans. According to the CEN-CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 15655-1:2019

IEC Electropedia: available at http://www.electropedia.org/

ISO Online browsing platform: available at http://www.iso.org/obp 3.1 ductile iron cast iron used for pipes, fittings and accessories in which graphite is present substantially in spheroidal form 3.2 adhesion force per unit area, applied perpendicular to the surface, which is necessary to separate the lining from its substrate 3.3 indirect impact strength impact energy applied from outside of the pipe with deformation to which a lining can withstand without damage under defined test conditions 3.4 hardness resistance of the lining to the penetration of a ball under defined test conditions 3.5 minimum lining thickness minimum value of the lining thickness measured at the lined item 3.6 non-porosity absence of holidays in a high voltage test under defined test conditions 3.7 polyurethane lining factory applied lining which consists of polyurethane on the inside of the pipe or fitting SIST EN 15655-1:2019

Key 1 gasket seat 2 pipe barrel 3 spigot end 4 lining 5 internal socket profile Figure 1 — Location of the defined pipe areas

Key 1 lining 2 internal socket profile Figure 2 — Location of the defined fitting areas 3.8 protection of pipe ends factory applied coating/lining of PU or Epoxy on ends of pipes or fittings 3.9 specific lining resistance surface related electric resistance of the lining perpendicular to the pipe wall 3.10 performance test test which is done once and is repeated according to a schedule or after relevant change of lining material and/or material supplier or change in process application 3.11 routine test test carried out to control the manufacturing process with a frequency defined by the manufacturer SIST EN 15655-1:2019

minimum lining thickness the test tension shall be 4 kV. For 1000

minimum lining thickness the test tension shall be 5 kV. The scanning electrode shall be passed over the surface of the lining being inspected with a continuous, relative movement not exceeding 300 mm/s. The electrode shall not be damaged and shall be in constant touch with the lining. For thicker linings, a higher test voltage may be used by agreement between the manufacturer and the purchaser. 5.4 Pipe ends Spigot end and internal socket profile (see Figure 1) shall be coated with one of the following: — epoxy lining in accordance with EN 14901; — polyurethane in accordance with this standard with a minimum lining thickness of 150 m; — zinc + bituminous finishing layer according to EN 545; — multilayer, e.g. of epoxy, PUR-Epoxy; — zinc-rich paint and epoxy. The manufacturer shall ensure that the joint can be assembled. The coating thickness shall be checked according to 7.1.5. 5.5 Re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...