EN 598:2007+A1:2009

(Main)Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Requirements and test methods

Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Requirements and test methods

This European Standard specifies the requirements and associated test methods applicable to ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings:

- operating without pressure (gravity sewerage), or with positive or negative pressure (see Table 5);

- to be installed below or above ground;

- to convey surface water, domestic waste water and certain types of industrial effluents, either in separate systems or in combined systems.

This European Standard applies to pipes, fittings and accessories which are:

- manufactured with socketed, flanged or spigot ends;

- normally delivered externally and internally coated;

- suitable for continuous fluid temperatures between 0 °C excluding frost, and 45 °C for DN - 200 or 35 °C for

DN - 200, according to EN 476;

- not intended for use in areas subject to reaction to fire regulations.

NOTE 1 This does not preclude special arrangements for the products to be used at higher temperatures.

This European Standard covers pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, of a size range extending from DN 80 to DN 2000 inclusive.

This European Standard specifies requirements for materials, dimensions and tolerances, mechanical properties and standard coatings of ductile iron pipes and fittings. It also gives performance requirements for all components including joints. Joint design and gasket shapes are outside the scope of this European Standard.

NOTE 2 In this European Standard, all pressures are relative pressures, expressed in bars (100 kPa = 1 bar).

Rohre, Formstücke, Zuberhörteile aus duktilem Gusseisen und ihre Verbindungen für die Abwasser-Entsorgung - Anforderungen und Prüfverfahren

Diese Europäische Norm legt die Anforderungen und die entsprechenden Prüfverfahren für duktile Gussrohre,

Formstücke, Zubehörteile und deren Verbindungen fest, die für die Errichtung von Abwasserleitungen

und -kanälen außerhalb von Gebäuden verwendet werden, und

- als Freispiegelleitungen (Schwerkraftentwässerungssysteme) oder mit positivem oder negativem Druck

(siehe Tabelle 5) betrieben werden,

- erdüberdeckt oder oberirdisch eingebaut werden,

- zum Transport von Oberflächenwasser, häuslichem Abwasser und bestimmten Arten von Industrieabwässern,

entweder in Trenn- oder in Mischwassersystemen betrieben werden.

Diese Europäische Norm gilt für Rohre, Formstücke und Zubehörteile, die:

- mit Muffen, Flanschen oder Einsteckenden hergestellt werden;

- normalerweise mit einem Innen- und Außenschutz geliefert werden;

- für Flüssigkeitstemperaturen zwischen 0 °C, Frost ausgenommen, und 45 °C für DN ≤ 200 oder 35 °C für

DN > 200 geeignet sind, nach EN 476;

- nicht vorgesehen sind für die Anwendung in Bereichen, die Bestimmungen zum Brandverhalten

unterliegen.

ANMERKUNG 1 Dies schließt besondere Vereinbarungen für die Verwendung dieser Produkte bei höheren

Temperaturen nicht aus.

Diese Europäische Norm gilt für Rohre, Formstücke und Zubehörteile, die nach einem beliebigen Gießverfahren

oder aus gegossenen Einzelteilen hergestellt werden, sowie für die entsprechenden Verbindungen

für den Nennweitenbereich von DN 80 bis einschließlich DN 2 000.

Diese Europäische Norm legt Anforderungen an Werkstoffe, Abmessungen und Grenzabmaße, mechanische

Eigenschaften und die Standardüberzüge und Auskleidungen von Rohren und Formstücken aus duktilem

Gusseisen fest. Sie enthält ebenfalls Anforderungen an die Funktion aller Rohrleitungsteile, einschließlich der

Verbindungen. Gestaltung der Verbindungen und Form der Dichtungen liegen außerhalb des Anwendungsbereiches

dieser Europäischen Norm.

Tuyaux, raccords et accessoires en fonte ductile et leurs assemblages pour l'assainissement - Prescriptions et méthodes d'essai

La présente Norme européenne spécifie les prescriptions et les méthodes d’essai associées applicables aux tuyaux,

raccords et accessoires en fonte ductile et à leurs assemblages, destinés à la construction de collecteurs et de

branchements d’assainissement à l’extérieur des bâtiments :

— fonctionnant sans pression (assainissement à écoulement libre) ou sous pression positive ou négative

(voir Tableau 5) ;

— mis en oeuvre dans le sol ou en élévation ;

— pour transporter les eaux de surface, les eaux usées domestiques et certains types d’effluents industriels,

en système séparatif ou en système unitaire.

La présente norme s’applique aux tuyaux, raccords et accessoires qui sont :

— fabriqués avec des extrémités à emboîture, à bride ou à bout uni ;

— normalement livrés revêtus extérieurement et intérieurement ;

— utilisables pour des températures de fluide en régime continu comprises entre 0 °C, gel exclu, et 45 °C pour

DN ≤ 200 ou 35 °C pour DN > 200, conformément à l’EN 476 ;

— non prévus pour être utilisés dans des zones soumises à une réglementation sur la réaction au feu.

NOTE Ceci n’exclut pas des modalités spéciales pour les produits utilisables à des températures supérieures.

La présente norme traite des tuyaux, raccords et accessoires moulés par tout procédé de fonderie ou fabriqués

à partir de composants moulés, ainsi que les assemblages correspondants, pour la gamme des DN 80

à DN 2 000 inclus.

La présente norme spécifie les prescriptions relatives aux matériaux, aux dimensions et aux tolérances, aux

propriétés mécaniques et aux revêtements normalisés des tuyaux et raccords en fonte ductile. Elle indique aussi les

prescriptions de performance de tous les composants y compris les assemblages. La conception des assemblages

et la forme des garnitures de joints sortent du domaine d’application de la présente norme.

NOTE Dans la présente norme, toutes les pressions sont des pressions relatives exprimées en bars (100 kPa = 1 bar).

Cevi, fitingi in dodatni deli iz nodularne litine za kanalizacijo - Zahteve in preskusne metode

General Information

- Status

- Published

- Publication Date

- 23-Jun-2009

- Withdrawal Date

- 30-Dec-2009

- Technical Committee

- CEN/TC 203 - Cast iron pipes, fittings and their joints

- Drafting Committee

- CEN/TC 203/WG 9 - Revision of EN 545, EN 598 and EN 969

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 24-Jun-2009

- Completion Date

- 24-Jun-2009

- Directive

- Harmonized Standard305/2011 - Regulation (eu) No 305/2011 of the European Parliament and of the Council of 9 march 2011 laying down harmonised conditions for the marketing of construction products and repealing council directive 89/106/eecOJ Ref: C 259, C 259, C 259, C 259, C 259, C 259, C 259, C OJ Date: 08-Aug-2014

Not Harmonized89/106/EEC - Construction productsOJ Ref: C 309, C 309, C 309, C 309, C 309, C 309, C 309, C OJ Date: 18-Dec-2009

Relations

- Effective Date

- 06-May-2009

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 598:2007+A1:2009 - Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Requirements and test methods (CEN) sets European requirements and associated test methods for ductile iron products used in external sewer and drain systems. The standard covers socketed, flanged and spigot pipes, fittings and accessories (normally internally and externally coated) across a size range DN 80 to DN 2000. It applies to gravity sewerage and pressure (positive/negative) sewer systems, for installation below or above ground, conveying surface water, domestic wastewater and some industrial effluents. The document supports CE marking and conformity assessment under the Construction Products Directive.

Key Topics and Requirements

- Scope and application: products for drains and sewers outside buildings, including gravity, pressure and vacuum sewers; temperature limits referenced to EN 476.

- Materials and mechanical properties: specifications for ductile iron material characteristics, tensile and hardness testing.

- Dimensions and tolerances: standardized dimensions, lengths and allowable deviations for sockets, spigots and flanged ends.

- Coatings and linings: requirements for standard zinc and paint coatings and cement mortar linings; thickness and adhesion checks.

- Joint and component performance: performance criteria for joints (leak tightness to internal and external pressure, dynamic and static loads); note that detailed gasket and joint design are outside scope.

- Structural performance tests: longitudinal bending, diametral stiffness, abrasion resistance, chemical resistance to effluents, and strength of cement mortar lining.

- Testing methods: detailed test procedures for dimensional checks, tensile tests, Brinell hardness, leak tightness (positive/negative pressure), coating thickness, and performance testing.

- Conformity and quality control: requirements for Initial Type Testing (ITT), Factory Production Control (FPC), sampling, and documentation supporting CE marking.

- Informative annexes: allowable pressures, field of use vs. soil/effluent characteristics, buried pipeline design, and resistance to cleaning/root penetration.

Applications and Who Uses This Standard

- Manufacturers of ductile iron pipes, fittings and accessories - for product design, production control and type testing.

- Design engineers and specifiers - to select compliant components for gravity, pressure and vacuum sewer systems.

- Contractors and utilities - for installation acceptance testing, procurement specifications and quality assurance.

- Testing laboratories and certification bodies - to perform prescribed test methods and conformity assessment.

- Regulators and procurement teams - to reference harmonized European requirements for CE marking and safety compliance.

Related Standards

- EN 476 (temperature classification) and other CEN documents on sewerage systems and piping materials are referenced for complementary requirements and limits.

Keywords: EN 598:2007+A1:2009, ductile iron pipes, sewerage, test methods, leak tightness, diametral stiffness, coatings, cement mortar lining, CE marking, factory production control.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 598:2007+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Requirements and test methods". This standard covers: This European Standard specifies the requirements and associated test methods applicable to ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings: - operating without pressure (gravity sewerage), or with positive or negative pressure (see Table 5); - to be installed below or above ground; - to convey surface water, domestic waste water and certain types of industrial effluents, either in separate systems or in combined systems. This European Standard applies to pipes, fittings and accessories which are: - manufactured with socketed, flanged or spigot ends; - normally delivered externally and internally coated; - suitable for continuous fluid temperatures between 0 °C excluding frost, and 45 °C for DN - 200 or 35 °C for DN - 200, according to EN 476; - not intended for use in areas subject to reaction to fire regulations. NOTE 1 This does not preclude special arrangements for the products to be used at higher temperatures. This European Standard covers pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, of a size range extending from DN 80 to DN 2000 inclusive. This European Standard specifies requirements for materials, dimensions and tolerances, mechanical properties and standard coatings of ductile iron pipes and fittings. It also gives performance requirements for all components including joints. Joint design and gasket shapes are outside the scope of this European Standard. NOTE 2 In this European Standard, all pressures are relative pressures, expressed in bars (100 kPa = 1 bar).

This European Standard specifies the requirements and associated test methods applicable to ductile iron pipes, fittings, accessories and their joints for the construction of drains and sewers outside buildings: - operating without pressure (gravity sewerage), or with positive or negative pressure (see Table 5); - to be installed below or above ground; - to convey surface water, domestic waste water and certain types of industrial effluents, either in separate systems or in combined systems. This European Standard applies to pipes, fittings and accessories which are: - manufactured with socketed, flanged or spigot ends; - normally delivered externally and internally coated; - suitable for continuous fluid temperatures between 0 °C excluding frost, and 45 °C for DN - 200 or 35 °C for DN - 200, according to EN 476; - not intended for use in areas subject to reaction to fire regulations. NOTE 1 This does not preclude special arrangements for the products to be used at higher temperatures. This European Standard covers pipes, fittings and accessories cast by any type of foundry process or manufactured by fabrication of cast components, as well as corresponding joints, of a size range extending from DN 80 to DN 2000 inclusive. This European Standard specifies requirements for materials, dimensions and tolerances, mechanical properties and standard coatings of ductile iron pipes and fittings. It also gives performance requirements for all components including joints. Joint design and gasket shapes are outside the scope of this European Standard. NOTE 2 In this European Standard, all pressures are relative pressures, expressed in bars (100 kPa = 1 bar).

EN 598:2007+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 23.040.05 - Pipeline and its parts for external sewage systems; 23.040.10 - Iron and steel pipes; 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 598:2007+A1:2009 has the following relationships with other standards: It is inter standard links to EN 598:2007, EN ISO 4034:2012, EN 196-1:2016, EN 681-1:1996, EN ISO 7091:2000, EN 1092-2:2023, EN ISO 9001:2000, EN ISO 6506-1:2014, EN ISO 6892-1:2019, EN ISO 4016:2022, EN 545:2010, EN 14628:2005, EN 14901-2:2019, EN 15655-2:2020, EN 877:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 598:2007+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, 93/38/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 598:2007+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-september-2009

Cevi, fitingi in dodatni deli iz nodularne litine za kanalizacijo - Zahteve in

preskusne metode

Ductile iron pipes, fittings, accessories and their joints for sewerage applications -

Requirements and test methods

Rohre, Formstücke, Zuberhörteile aus duktilem Gusseisen und ihre Verbindungen für die

Abwasser-Entsorgung - Anforderungen und Prüfverfahren

Tuyaux, raccords et accessoires en fonte ductile et leurs assemblages pour

l'assainissement - Prescriptions et méthodes d'essai

Ta slovenski standard je istoveten z: EN 598:2007+A1:2009

ICS:

23.040.10 Železne in jeklene cevi Iron and steel pipes

23.040.40 Kovinski fitingi Metal fittings

93.030 Zunanji sistemi za odpadno External sewage systems

vodo

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EUROPEAN STANDARD

EN 598:2007+A1

NORME EUROPÉENNE

EUROPÄISCHE NORM

June 2009

ICS 23.040.10; 23.040.40 Supersedes EN 598:2007

English Version

Ductile iron pipes, fittings, accessories and their joints for

sewerage applications - Requirements and test methods

Tuyaux, raccords et accessoires en fonte ductile et leurs Rohre, Formstücke, Zuberhörteile aus duktilem Gusseisen

assemblages pour l'assainissement - Prescriptions et und ihre Verbindungen für die Abwasser-Entsorgung -

méthodes d'essai Anforderungen und Prüfverfahren

This European Standard was approved by CEN on 11 August 2007 and includes Amendment 1 approved by CEN on 23 May 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the

official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland,

France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal,

Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2009 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 598:2007+A1:2009: E

worldwide for CEN national Members.

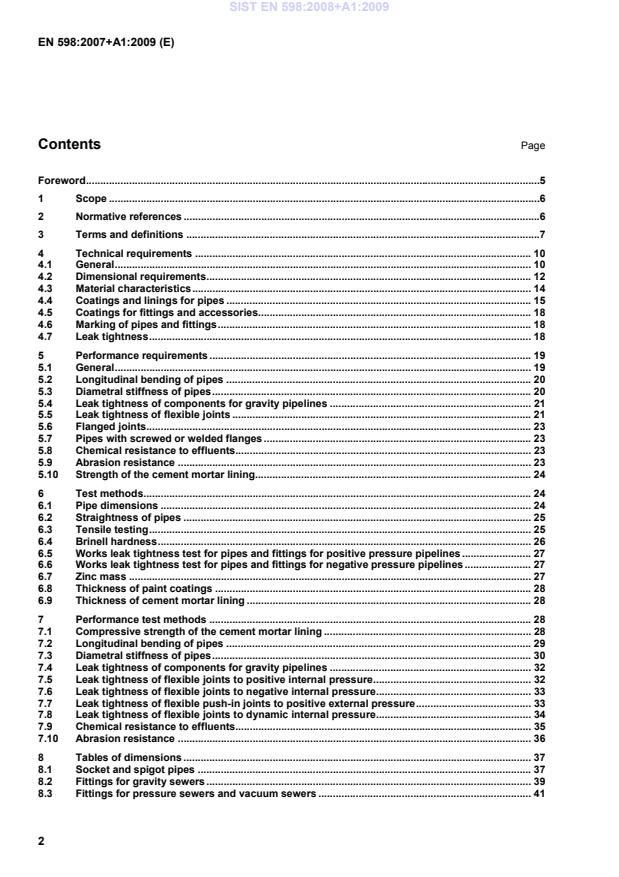

Contents Page

Foreword .5

1 Scope .6

2 Normative references .6

3 Terms and definitions .7

4 Technical requirements . 10

4.1 General . 10

4.2 Dimensional requirements . 12

4.3 Material characteristics . 14

4.4 Coatings and linings for pipes . 15

4.5 Coatings for fittings and accessories. 18

4.6 Marking of pipes and fittings . 18

4.7 Leak tightness . 18

5 Performance requirements . 19

5.1 General . 19

5.2 Longitudinal bending of pipes . 20

5.3 Diametral stiffness of pipes . 20

5.4 Leak tightness of components for gravity pipelines . 21

5.5 Leak tightness of flexible joints . 21

5.6 Flanged joints . 23

5.7 Pipes with screwed or welded flanges . 23

5.8 Chemical resistance to effluents . 23

5.9 Abrasion resistance . 23

5.10 Strength of the cement mortar lining. 24

6 Test methods . 24

6.1 Pipe dimensions . 24

6.2 Straightness of pipes . 25

6.3 Tensile testing . 25

6.4 Brinell hardness . 26

6.5 Works leak tightness test for pipes and fittings for positive pressure pipelines . 27

6.6 Works leak tightness test for pipes and fittings for negative pressure pipelines . 27

6.7 Zinc mass . 27

6.8 Thickness of paint coatings . 28

6.9 Thickness of cement mortar lining . 28

7 Performance test methods . 28

7.1 Compressive strength of the cement mortar lining . 28

7.2 Longitudinal bending of pipes . 29

7.3 Diametral stiffness of pipes . 30

7.4 Leak tightness of components for gravity pipelines . 32

7.5 Leak tightness of flexible joints to positive internal pressure . 32

7.6 Leak tightness of flexible joints to negative internal pressure . 33

7.7 Leak tightness of flexible push-in joints to positive external pressure . 33

7.8 Leak tightness of flexible joints to dynamic internal pressure . 34

7.9 Chemical resistance to effluents . 35

7.10 Abrasion resistance . 36

8 Tables of dimensions . 37

8.1 Socket and spigot pipes . 37

8.2 Fittings for gravity sewers . 39

8.3 Fittings for pressure sewers and vacuum sewers . 41

9 Evaluation of conformity . 42

9.1 General . 42

9.2 Initial type testing . 42

9.3 Factory production control (FPC) . 44

Annex A (normative) Allowable pressures for pressure sewers . 49

Annex B (informative) Alternative coatings and field of use in relation to characteristics of soils . 51

Annex C (informative) Field of use in relation to characteristics of effluents . 54

Annex D (informative) Calculation method for buried pipelines, permissible heights of cover . 55

Annex E (informative) Resistance to jet cleaning and to root penetration . 60

Annex ZA (informative) Clauses of this European Standard addressing essential requirements or other

provisions of EU Directives . 61

Bibliography . 66

Tables

Table 1 — Limit deviation on internal diameter . 13

Table 2 — Standardized length of socket and spigot pipes . 13

Table 3 — Tensile properties . 15

Table 4 — Thickness of cement mortar lining . 17

Table 5 — Pressure . 19

Table 6 — DN groupings for performance tests . 20

Table 7 — Performance tests for joints . 22

Table 8 — Dimensions of test bar . 26

Table 9 — Test bending moments . 29

Table 10 — Diametral stiffness test requirements . 31

Table 11 — Dimensions of pipes . 38

Table 12 — Number of test samples for initial type testing . 44

Table 13 — Minimum frequency of product testing as part of FPC . 46

Table 14 — Maximum batch sizes for tensile testing . 47

Table A.1 — Allowable pressures . 50

Table D.1 — Pressure pipes . 58

Table D.2 — Gravity pipes . 59

Table ZA.1 — Relevant clauses for ductile iron pipes, fittings, accessories and their joints for sewerage

applications . 62

Table ZA.2 — System of attestation of conformity . 63

Table ZA.3 — Assignment of evaluation of conformity tasks for ductile iron pipes, fittings, accessories

and their joints for sewerage applications under system 4 . 63

Figures

Figure 1 — Longitudinal bending test . 29

Figure 2 — Diametral stiffness test . 30

Figure 3 — Leak tightness test of joints (internal pressure) . 33

Figure 4 — Leak tightness test of joints (external pressure) . 34

Figure 5 — Chemical resistance test . 37

Figure 6 — Socket and spigot pipes . 37

Figure 7 — Collars . 39

Figure 8 — Manhole connectors . 39

Figure 9 — Double socket bends . 39

Figure 10 — Angle branches . 40

Figure 11 — Connection branches . 40

Figure 12 — Inspection tees . 41

Figure 13 — Access traps . 41

Figure ZA.1 — Example of CE marking information for marking on the product . 65

Figure ZA.2 — Example of information on the accompanying documents . 65

Foreword

This document (EN 598:2007+A1:2009) has been prepared by Technical Committee CEN/TC 203 “Cast iron pipes,

fittings and their joints”, the secretariat of which is held by AFNOR.

This European Standard shall be given the status of a national standard, either by publication of an identical text or by

endorsement, at the latest by December 2009, and conflicting national standards shall be withdrawn at the latest by

December 2009.

This document includes Amendment 1, approved by CEN on 2009-05-23.

This document supersedes !EN 598:2007".

The start and finish of text introduced or altered by amendment is indicated in the text by tags !".

This document has been prepared under a mandate given to CEN by the European Commission and the European

Free Trade Association, and supports essential requirements of EU Construction Products Directive (89/106/EEC).

For relationship with EU Construction Products Directive, see informative Annex ZA, which is an integral part of this

document.

This European Standard is in conformity with the general requirements already established by CEN/TC 165 in the field

of sewerage.

Annex ZA includes the requirements of the mandate given under the EU Construction Products Directive

(89/106/EEC). Only if the requirements specified in Annex ZA are met, the CE marking will be effected.

For reasons of conformity with mandate M/131 “Pipes, tanks and ancillaries not in contact with water intended for

human consumption”, EN 598:1994 has been revised by extension with Annex ZA (see Resolution CEN/BT 113/1994

and CEN/BT 63/1996) and Clause 9 for the evaluation of conformity.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries

are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark,

Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta,

Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United

Kingdom.

1 Scope

This European Standard specifies the requirements and associated test methods applicable to ductile iron pipes,

fittings, accessories and their joints for the construction of drains and sewers outside buildings:

operating without pressure (gravity sewerage), or with positive or negative pressure (see Table 5);

to be installed below or above ground;

to convey surface water, domestic waste water and certain types of industrial effluents, either in separate systems

or in combined systems.

This European Standard applies to pipes, fittings and accessories which are:

manufactured with socketed, flanged or spigot ends;

normally delivered externally and internally coated;

suitable for continuous fluid temperatures between 0 °C excluding frost, and 45 °C for DN ≤ 200 or 35 °C for

DN > 200, according to EN 476;

not intended for use in areas subject to reaction to fire regulations.

NOTE 1 This does not preclude special arrangements for the products to be used at higher temperatures.

This European Standard covers pipes, fittings and accessories cast by any type of foundry process or manufactured

by fabrication of cast components, as well as corresponding joints, of a size range extending from DN 80 to DN 2000

inclusive.

This European Standard specifies requirements for materials, dimensions and tolerances, mechanical properties and

standard coatings of ductile iron pipes and fittings. It also gives performance requirements for all components

including joints. Joint design and gasket shapes are outside the scope of this European Standard.

NOTE 2 In this European Standard, all pressures are relative pressures, expressed in bars (100 kPa = 1 bar).

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only

the edition cited applies. For undated references, the latest edition of the referenced document applies (including any

amendments).

EN 196-1, Methods of testing cement — Part 1: Determination of strength

EN 545, Ductile iron pipes, fittings, accessories and their joints for water pipelines — Requirements and test methods

EN 681-1, Elastomeric seals — Materials requirements for pipe joint seals used in water and drainage applications —

Part 1: Vulcanised rubber

EN 1092-2, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN designated —

Part 2: Cast iron flanges

EN 10002-1, Metallic materials — Tensile testing — Part 1: Method of test at ambient temperature

EN 14901, Ductile iron pipes, fittings and accessories — Epoxy coating (heavy duty) of ductile iron fittings and

accessories — Requirements and test methods

EN ISO 4016, Hexagon head bolts — Product grade C (ISO 4016:1999)

EN ISO 4034, Hexagon nuts — Product grade C (ISO 4034:1999)

EN ISO 6506-1, Metallic materials — Brinell hardness test — Part 1: Test method (ISO 6506-1:2005)

EN ISO 9001:2000, Quality management systems — Requirements (ISO 9001:2000)

EN ISO 7091, Plain washers — Normal series — Product grade C (ISO 7091:2000)

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

ductile iron

cast iron used for pipes, fittings and accessories in which graphite is present substantially in spheroidal form

3.2

pipe

casting of uniform bore, straight in axis, having either socket, spigot or flanged ends, except for flanged-socket pieces,

flanged-spigot pieces and collars which are classified as fittings

3.3

fitting

casting other than a pipe which allows pipeline deviation, change of direction or bore. In addition flanged-socket

pieces, flanged-spigot pieces and collars are also classified as fittings

3.4

accessory

any casting other than a pipe or fitting which is used in a pipeline, for example:

inspection chambers (see 3.5);

manholes (see 3.6);

glands and bolts for mechanical flexible joints (sec 3.15);

glands, bolts and locking rings for restrained flexible joints (see 3.16);

adjustable flanges and flanges to be welded or screwed

NOTE Valves of all types are not covered by the term accessory.

3.5

inspection chamber

component of a discharge system, of a drain or of a sewer providing access from the ground surface for inspection

and maintenance equipment

[EN 476:1997]

3.6

manhole

component of a sewer of sufficient size to provide access from the ground surface for inspection and maintenance

operations by personnel and equipment

[EN 476:1997]

3.7

flange

flat circular end of a pipe or fitting extending perpendicular to its axis, with bolt holes equally spaced on a circle

NOTE A flange is either fixed (e.g. integrally cast or welded-on) or adjustable; an adjustable flange comprises a ring, in one or

several parts assembled together, which bears on an end joint hub and can be freely rotated around the pipe axis before jointing.

3.8

spigot

male end of a pipe or fitting

3.9

spigot end length

spigot over a length equal to maximum insertion depth plus 50 mm

3.10

socket

female end of a pipe or fitting to make the connection with the spigot of the next component

3.11

gasket

sealing component of a joint

3.12

joint

connection between the ends of two pipes and/or fittings in which a gasket is used to effect a seal

3.13

flexible joint

joint which permits significant angular deflection both during and after installation and which can accept a slight offset

of the centreline

3.14

push-in flexible joint

flexible joint assembled by pushing the spigot through the gasket in the socket of the mating component

3.15

mechanical flexible joint

flexible joint in which sealing is obtained by applying pressure to the gasket by mechanical means, e.g. a gland

3.16

restrained flexible joint

flexible joint in which a means is provided to prevent separation of the assembled joint

3.17

flanged joint

joint between two flanged ends

3.18

nominal size (DN)

alphanumerical designation of size for components of a pipework system, which is used for reference purposes. It

comprises the letters DN followed by a dimensionless whole number which is indirectly related to the physical size, in

millimetres, of the bore or outside diameter of the end connections

[EN ISO 6708:1995]

3.19

nominal pressure (PN)

alphanumerical designation used for reference purposes related to a combination of mechanical and dimensional

characteristics of a component of a pipework system. It comprises the letters PN followed by a dimensionless number

[EN 1333:2006]

NOTE All equipment of the same nominal size DN designated by the same PN number have compatible mating dimensions.

3.20

leak tightness test pressure

pressure applied to a component during manufacture in order to ensure its leak tightness

3.21

allowable operating pressure (PFA)

maximum hydrostatic pressure that a component can withstand continuously in service

[EN 773:1999]

3.22

allowable maximum operating pressure (PMA)

maximum hydrostatic pressure, including surge, that a component can withstand from time to time in service

[EN 773:1999]

3.23

allowable test pressure (PEA)

maximum hydrostatic pressure that a newly installed component can withstand for a relatively short duration, when

either fixed above ground level or laid and backfilled underground, in order to ensure the integrity and tightness of the

pipeline

[EN 773:1999]

NOTE This test pressure is different from the system test pressure (STP), which is related to the design pressure of the

pipeline and is intended to ensure its integrity and leak tightness.

3.24

diametral stiffness of a pipe

characteristic of a pipe which allows it to resist ovalization under loading when installed

3.25

discharge system

system of pipes, fittings, accessories and joints used to collect and drain waste water and rainwater of a building

NOTE It comprises discharge pipes, stack ventilation pipes and rainwater downpipes, installed within the limits of a building or

attached to the building.

3.26

drain

system of pipes, fittings, accessories and joints installed outside the limits of a building in order to connect the

discharge system of this building to a sewer or a septic tank

3.27

sewer

pipeline designed to collect waste water and rainwater from buildings and surface water and to convey them to the

point of disposal or treatment

3.28

gravity sewer

sewer operating normally under free flowing conditions (see Table 5)

3.29

pressure sewer; pumping sewer

sewer (or section of a sewer) operating under positive pressure (see Table 5)

3.30

vacuum sewer

sewer operating under negative pressure (see Table 5)

3.31

combined system

sewerage system collecting together rainwater, surface water and waste water

3.32

separate system

sewerage system which collects waste water separately from rainwater and surface water

3.33

performance test (initial type test – ITT)

test which is done once and is repeated only after change of design, material or process

3.34

length

effective length of a pipe or fitting as shown on Figure 6 for socket and spigot pipes and as given in 4.2.3.2 for flanged

pipes and 4.2.3.3 for fittings

3.35

deviation

design length allowance with respect to the standardised length of a pipe

3.36

ovality

A − A

1 2

out of roundness of a pipe section; it is equal to : 100

A + A

1 2

where

A is the maximum axis in millimetres;

A is the minimum axis, in millimetres

4 Technical requirements

4.1 General

4.1.1 Ductile iron pipes and fittings

Nominal sizes, thicknesses, lengths and coatings are specified in 4.1.1, 4.2.1, 4.2.3, 4.4 and 4.5 respectively. When,

by agreement between manufacturer and purchaser, pipes and fittings with different wall thicknesses, lengths and/or

coatings and other types of fittings than those given in 8.1, 8.2 and 8.3 are supplied with reference to this European

Standard, they shall comply with all the other requirements of this European Standard.

NOTE 1 Other types of fittings include tees and tapers with other combinations DN × dn, draining tees etc.

The standardized nominal sizes, DN of pipes and fittings are as follows: 80, 100, 125, 150, 200, 250, 300, 350, 400,

450, 500, 600, 700, 800, 900, 1000, 1100, 1200, 1400, 1500, 1600, 1800, 2000. These DN values are DN/ID

according to EN 476.

The functional properties of ductile iron pipes and fittings shall be as given in Clause 5.

NOTE 2 When installed and operated under the conditions for which they are designed (see Annexes A to E) ductile iron pipes,

fittings, accessories and their joints maintain all their functional characteristics over their reasonable economic operating life, due to

the constant material properties, to the stability of their cross section and to their design with high safety factors.

4.1.2 Surface condition and repairs

Pipes, fittings and accessories shall be free from defects and surface imperfections which could lead to

non-compliance with Clauses 4 and 5.

When necessary, pipes and fittings may be repaired, for example by welding, in order to remove surface imperfections

and localized defects which do not affect the entire wall thickness, provided that:

the repairs are carried out according to the manufacturer's written procedure;

the repaired pipes and fittings shall comply with all the requirements of Clause 4 and of Clause 5.

4.1.3 Types of joints and interconnection

4.1.3.1 Gasket materials

Rubber gasket materials shall comply with the requirements of EN 681-1 for the type WC or WG. When materials

other than rubber are necessary (e.g. for high temperature flanged joints), they shall comply with the appropriate

European Technical Specification or where no European Technical Specification exists, the appropriate International

Standard.

4.1.3.2 Flanged joints

Flanged joints shall be designed such that they can be attached to flanges whose dimensions and tolerances comply

with EN 1092-2. This ensures interconnection between all flanged components (pipes, fittings, valves etc.) of the

same PN and DN and adequate joint performance.

Bolts and nuts shall comply as a minimum with the requirements of EN ISO 4016 and EN ISO 4034, grade 4.6. Where

washers are required they shall comply with EN ISO 7091.

Although it does not affect interconnection, the manufacturer shall make the information available as to whether his

products are normally delivered with fixed flanges or adjustable flanges.

Flange gaskets may be one of any type given in EN 1514.

4.1.3.3 Flexible joints

Pipes and fittings with flexible joints shall comply with 4.2.2.1 for their spigot external diameters DE and their

tolerances. This offers the possibility of interconnection between components equipped with different types of flexible

joints. In addition, each type of flexible joint shall be designed to fulfil the performance requirements of Clause 5.

NOTE 1 For interconnection with certain types of joints operating within a tighter tolerance range on DE, the manufacturer’s

guidance should be followed as to the means of ensuring adequate joint performance at high pressures (e.g. measurement and

selection of external diameter).

NOTE 2 For interconnection with existing pipelines having external diameters not in compliance with 4.2.2.1, the manufacturer’s

guidance should be followed as to the appropriate means of interconnection (e.g. adaptors).

4.1.4 Colour identification

Pipes for sewers and drains shall be identified externally by one of the following colours: brown, red or grey. This is to

allow easy identification of installed sewers and drains. Pipes specifically intended for rain water or surface water

sewers (separate systems) may be identified by a different colour other than those used for potable water pipes.

4.2 Dimensional requirements

4.2.1 Wall thickness

For pipes the standardised thicknesses and limit deviations are given in Table 11. They are such that the diametral

stiffnesses of pipes are not less than the values shown in Table 10. The measurement of the wall thickness shall be in

accordance with 6.1.1.

The iron thickness of fittings used for pressure sewers shall be in accordance with EN 545.

The iron thickness of fittings used for gravity sewers shall be equal to or higher than those of pipes of the same DN.

4.2.2 Diameter

4.2.2.1 External diameter

8.1 specifies the values of the external diameter DE of the coated spigot end length of pipes and fittings and their

maximum allowable tolerances, when measured using a circumferential tape in accordance with 6.1.2.

NOTE 1 Certain types of flexible joints operate within a tighter range of tolerance (see 4.1.3.3).

NOTE 2 Thick external coatings should be removed, according to the manufacturer's guidance, in order to comply with the

specified external diameter DE, when the pipe needs to be cut on site.

For DN ≤ 300, the external diameter of the pipe barrel measured with a circumferential tape shall be such as to allow

the assembly of the joint over at least two thirds of the pipe length from the spigot end when the pipe needs to be cut

on site.

In addition, the ovality (see 3.9) of the spigot end of pipes and fittings shall

remain within the tolerance on DE (see Table 11) for DN 80 to DN 200 and

not exceed 1 % for DN 250 to DN 600 or 2 % for DN > 600.

NOTE 3 The manufacturer’s guidance should be followed as to the necessity and means of ovality correction; certain types of

flexible joints can accept the maximum ovality without a need for spigot re-rounding prior to jointing.

4.2.2.2 Internal diameter

The nominal values of the internal diameters of pipes, expressed in millimetres, are equal to the numbers indicating

their nominal size, DN, and the tolerances shall be as given in Table 1 which applies to cement mortar lined pipes.

These tolerances apply only to the pipe with iron thickness as given in Table 11 and cement mortar lining thickness as

given in Table 4.

NOTE Due to the manufacturing process of the ductile iron pipes and their internal linings, internal diameters with the lower limit

deviation will only appear locally along the pipe length.

Compliance shall be demonstrated according to 6.1.3 or by calculation from the measurements taken for pipe external

diameter, iron wall thickness and lining thickness.

Table 1 — Limit deviation on internal diameter

a

Limit deviation

DN

mm

80 to 1000

− 10

1100 to 2000 − 0,01 DN

a

The lower limit only is given.

4.2.3 Length

4.2.3.1 Standardized lengths of socket and spigot pipes

Pipes shall be supplied to the standardized lengths given in Table 2.

Table 2 — Standardized length of socket and spigot pipes

a

Standardized length L

u

DN

m

80 to 600 3 or 5 or 5,5 or 6

700 to 800 5,5 or 6 or 7

900 to 1400 6 or 7 or 8,15

1500 to 2000 8,15

a

See 3.34.

The permissible deviations (see 3.35) on the standardized length L of pipes shall be as follows:

u

for standardized length 8,15 m ± 150 mm;

for all other standardized lengths ± 100 mm.

Pipes shall be designed to a length taken in the range: standardized length plus or minus the permissible deviation;

they shall be manufactured to this design length plus or minus the limit deviation given in 4.2.3.4.

The manufacturer shall make the information available as to his design lengths.

The length shall be measured according to 6.1.4 and shall be within the limit deviations given in 4.2.3.4.

Of the total number of socket and spigot pipes to be supplied in each diameter, the percentage of shorter pipes shall

not exceed 10 %, in which case the length reduction shall be:

up to 0,15 m for the pipes in which samples have been cut for testing (see 4.3);

up to 2 m by increments of 0,5 m for DN < 700;

up to 3 m by increments of 0,1 m for DN ≥ 700.

4.2.3.2 Standardized lengths of flanged pipes

The length of flanged pipes shall comply with EN 545.

4.2.3.3 Standardized lengths of fittings

The length of the fittings used for pressure sewers shall be in accordance with EN 545 (see 8.3).

The length of fittings used for gravity sewers shall be made available by the manufacturer (see 8.2 for usual types of

fittings).

4.2.3.4 Limit deviations on lengths

The limit deviations on lengths of the socket and spigot pipes shall be within − 30 mm, + 70 mm.

The limit deviations on lengths of flanged pipes and of fittings shall be in accordance with EN 545.

The limit deviations on lengths of fittings used for gravity sewers shall be made available by the manufacturer.

4.2.4 Straightness of pipes

Pipes shall be straight, with a maximum deviation of 0,125 % of their length.

The verification of this requirement is usually carried out by visual inspection, but in case of doubt or in dispute the

deviation shall be measured in accordance with 6.2.

4.2.5 Inspection chambers

Inspection chambers (see 3.5) shall be manufactured either as an integral item or by site assembly of a bottom part

(inspection tee) and a vertical part.

Opening dimensions shall be as follows: 250 mm, 300 mm, 400 mm, 600 mm.

4.2.6 Manholes

Manholes (see 3.6) shall comprise a vertical part of DN ≥ 800, a bottom plate, a top plate capable of receiving a frame

and a manhole cover, and two or more inlets/outlets fixed to the vertical part.

The number and location of inlets/outlets shall preserve the hydraulic continuity of the manhole.

4.3 Material characteristics

4.3.1 Tensile properties

Pipes, fittings and accessories of ductile iron shall have the tensile properties given in Table 3.

The tensile strength shall be tested in accordance with 6.3.

Table 3 — Tensile properties

Minimum tensile Minimum elongation after fracture, A

strength, R

m

MPa %

DN 80 to DN 2000 DN 80 to DN 1000 DN 1100 to DN 2000

Pipes centrifugally cast 420 10 7

Pipes not centrifugally cast, fittings and

420 5 5

accessories

By agreement between manufacturer and purchaser, the 0,2 % proof stress (R ) may be measured. It shall be not less

p0,2

than:

270 MPa when A ≥ 12 % for DN 80 to DN 1000 or A ≥10 % for DN > 1000;

300 MPa in other cases.

4.3.2 Hardness

The hardness of the various components shall be such that they can be cut, drilled, tapped and/or machined with

normal tools. The reference test for hardness shall be the Brinell hardness test in accordance with 6.4.

The Brinell hardness shall not exceed 230 HBW for pipes and 250 HBW for fittings and accessories. For components

manufactured by welding, a higher Brinell hardness is allowed in the heat affected zone of the weld.

4.4 Coatings and linings for pipes

4.4.1 General

All pipes conforming to this document shall be delivered with an external coating of zinc with finishing layer in

accordance with 4.4.2, and an internal lining of high alumina cement mortar in accordance with 4.4.3.

This shall not preclude special coating arrangements for products which deviate from the requirements of this

document for specific design reasons. Annex B indicates possible alternative coatings.

Except for pipes intended only for the transport of rainwater, the surfaces which can come into contact with the

effluents (internal surface of the socket and external surface of the spigot end) shall be coated with a synthetic resin

(epoxy, polyurethane etc.) in accordance with 4.4.4.

NOTE 1 This does not preclude the possibility that for special design reasons the upper limit deviation on the external diameter

DE of the coated spigot can be greater than that specified in 8.1, provided that the interconnection of the products is ensured by the

joint design.

Pipes with cast flanges may be coated as fittings (see 4.5).

The maximum fluid temperature may be limited to 35 °C for some polymeric coatings. If such coatings are to be used

at higher temperatures, additional performance testing should be carried out.

NOTE 2 Annexes B and C give advice on the field of intended use for pipes with coatings and linings according to this document.

4.4.2 External coating of zinc with finishing layer

4.4.2.1 General

The external coating of centrifugally cast ductile iron pipes shall comprise a layer of metallic zinc, covered by a

finishing layer of a synthetic resin (epoxy, polyurethane etc.) compatible with zinc. Both layers shall be works applied.

The zinc is normally applied on oxide-surfaced pipes after heat treatment; at the manufacturer’s option, it may also be

applied on blast-cleaned pipes. Prior to application of the zinc, the pipe surface shall be dry and free from rust or non-

adhering particles or foreign matter such as oil or grease.

4.4.2.2 Coating characteristics

The metallic zinc coating shall cover the external surface of the pipe and provide a dense, continuous, uniform layer. It

shall be free from such defects as bare patches or lack of adhesion. The uniformity of the coating shall be checked by

visual inspection. When measured in accordance with 6.7, the mean mass of zinc per unit area shall be not less than

130 g/m . The purity of the zinc used shall be at least 99,99 %.

The finishing layer shall uniformly cover the whole surface of the metallic zinc layer and be free from such defects as

bare patches or lack of adhesion. The uniformity of the finishing layer shall be checked by visual inspection. When

measured in accordance with 6.8, the mean thickness of the finishing layer shall be not less than 70 µm and the local

minimum thickness not less than 50 µm.

4.4.2.3 Repairs

Damage to coatings where the area of total removal of zinc and finishing layer has a width exceeding 5 mm and areas

left uncoated (e.g. under test token, see 6.7) shall be repaired.

Repairs shall be carried out by:

metallic zinc spray complying with 4.4.2.2, or application of zinc-rich paint containing at least 90 % zinc by mass

of dry film and with a mean mass of applied paint not less than 150 g/m and

application of a finishing layer complying with 4.4.2.2.

4.4.3 Internal lining of high alumina cement mortar

4.4.3.1 General

Unless otherwise specified in the corresponding European Standard, the internal cement morta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...