CEN/TR 17996:2024

(Main)Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Guidelines for Pipelines Installation

Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Guidelines for Pipelines Installation

This European Standard is a complementary document for the installation of ductile iron pipes, fittings, accessories and their joints, covered by EN 598:2009 harmonized standard. It is intended to describe, in a wider perspective, installation technologies, tools and pipelines particular examples, applicable for the construction, outside buildings, of:

- Drainage pipeline systems;

- Raw water pipeline systems;

- Sewage pipeline systems;

- Pipeline systems conveying surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents, either in separate systems or in combined systems;

- Operating without pressure (gravity sewers) or with positive or negative pressure;

- Below or above ground installation types.

It also gives some site operation/site instructions for the application of fittings, intended to be used for the connection of ductile iron drains and sewers to other materials as plastic, concrete, vitrified clay, etc.

This European Standard is not intended to cover:

- Hydraulic design of drains and sewers systems outside buildings. For this purpose, EN 16933-2 applies.

- Construction and site testing of drains and sewers. For this purpose, EN 1610 applies.

- Trenchless construction and testing of drains and sewers. For this purpose, EN 12889:2000 applies

Rohre, Formstücke, Zubehörteile aus duktilem Gusseisen und ihre Verbindungen für Wasserleitungen - Richtlinien für die Installation von Rohrleitungen

Tuyaux, raccords et accessoires en fonte ductile et leurs assemblages pour les applications en assainissement - Lignes directrices pour l’installation des canalisations

Le présent document est un document complémentaire pour l’installation de tuyaux, raccords et accessoires en fonte ductile et leurs assemblages, couverts par la norme harmonisée EN 598:2009. Il est destiné à décrire, dans une perspective plus large, des technologies d’installation, des exemples spécifiques d’outils et de canalisations, applicables à la construction, à l’extérieur des bâtiments, des éléments suivants :

— systèmes de canalisations de drainage ;

— systèmes de canalisations d’eaux brutes ;

— systèmes de canalisations d’eaux usées ;

— systèmes de canalisations de réutilisation des eaux usées, traitées ;

— systèmes de canalisations transportant des eaux de surface (par exemple, des eaux pluviales), des eaux usées domestiques et/ou certains types d’effluents industriels, en système séparatif ou en système unitaire ;

— fonctionnant sans pression (assainissement gravitaire) ou sous pression positive ou négative ;

— types d’installations dans le sol ou en élévation.

Il fournit également quelques instructions d’exploitation/de chantier pour l’application de raccords, destinés à être utilisés pour le raccordement des branchements et collecteurs d’assainissement en fonte ductile à d’autres matériaux tels que le plastique, le béton, le grès vernissé, etc.

Le présent document n’est pas destiné à couvrir :

— la conception hydraulique des systèmes de branchements et de collecteurs d’assainissement situés à l’extérieur de bâtiments. À cette fin, l’EN 16933 2 s’applique ;

— la construction et les essais sur site de branchements et collecteurs d’assainissement. À cette fin, l’EN 1610 s’applique ;

— la mise en œuvre sans tranchée et les essais des branchements et collecteurs d’assainissement. À cette fin, l’EN 12889 s’applique.

Cevi, fitingi, pribor in spoji iz duktilne železove litine za kanalizacijo - Smernice za vgradnjo cevovodov

Ta evropski standard je dopolnilni dokument za nameščanje cevi, fitingov, pribora in spojev iz duktilne železove litine, ki so zajeti v usklajeni standard EN 598:2009. Namenjen je širšemu opisu tehnologij nameščanja, orodja in določenih primerov cevovodov, ki se uporabljajo za gradnjo, zunanje stavbe:

– drenažni cevovodni sistemi;

– cevovodni sistemi za neobdelano vodo;

– komunalni cevovodni sistemi;

– cevovodni sistemi za odvod površinske vode (npr. padavinske vode), odpadne vode iz gospodinjstev in/ali določenih vrst industrijskih odplak, v ločene ali združene sisteme;

– delovanje brez tlaka (gravitacijska kanalizacija) ali z nadtlakom ali podtlakom;

– za podzemno ali nadzemno nameščanje.

Prav tako podaja nekaj navodil za upravljanje delovišča v zvezi z uporabo fitingov, ki so namenjeni za povezovanje odvodov in kanalizacije iz duktilne železove litine z drugimi materiali, kot so plastika, beton, keramika itd.

Ta evropski standard ne zajema:

– hidravlične zasnove sistemov odvodov odpadne vode in kanalizacije zunaj stavb. Za ta namen se uporablja standard EN 16933- 2.

– gradnje in preskušanja odvodov odpadne vode in kanalizacije na mestu samem. Za ta namen se uporablja standard EN 1610.

– Izvedbe in preskušanja odvodov odpadne vode in kanalizacije brez izkopa. Za ta namen se uporablja standard EN 12889:2000.

General Information

- Status

- Published

- Publication Date

- 20-Feb-2024

- Technical Committee

- CEN/TC 203 - Cast iron pipes, fittings and their joints

- Drafting Committee

- CEN/TC 203/WG 9 - Revision of EN 545, EN 598 and EN 969

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 21-Feb-2024

- Due Date

- 11-Jan-2024

- Completion Date

- 21-Feb-2024

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

CEN/TR 17996:2024 provides comprehensive guidelines for the installation of ductile iron pipes, fittings, accessories and their joints in sewerage and related pipeline applications. Published by CEN (Technical Committee CEN/TC 203) in February 2024, this Technical Report complements the harmonized product standard EN 598:2009 and describes practical installation methods, tools, site operations and typical pipeline examples for systems installed outside buildings - including gravity and pressure sewers, raw water, surface water, domestic wastewater, water reuse and certain industrial effluent pipelines. The document also covers above- and below-ground installations and procedures for connecting ductile iron to other materials (plastic, concrete, vitrified clay).

Key Topics

The report focuses on practical, installation-related topics rather than product specifications or hydraulic design. Major areas include:

- Assembling and jointing methods: recommended techniques and mechanical aids (crowbars, winches, lever tackle, excavator-assisted methods).

- Laying in trench and above-ground: trench preparation, bedding, working in shored trenches, and temporary/interim installations.

- Special installation conditions: unstable soils, steep inclines, and shoring/safety rules.

- Connections and fittings: manhole and inspection chamber connections, branch and saddle connections, and fittings for pressure or vacuum sewers.

- Trenchless technologies: guidance on HDD, pipe bursting, casing methods, pipe jacking, press/pull, ploughing-in, and microtunnelling.

- Testing procedures: recommended approaches for gravity pipeline testing (air and water methods) and detailed pressure testing steps for pressure pipelines, including safety, filling, anchorage and recording test results.

- Site instructions: handling, disassembly/reuse, and on-site application of fittings to join ductile iron to other materials.

Applications

CEN/TR 17996:2024 is aimed at practical implementation and is useful for:

- Utility owners and municipal engineers planning sewerage and drainage works

- Design engineers and specifiers preparing installation requirements

- Contractors and site supervisors executing ductile iron pipeline installation

- Inspectors, commissioning teams and maintenance personnel

- Manufacturers and suppliers providing installation guidance and accessories

Use cases include construction of gravity sewers, pressured water mains, stormwater drains, sewer rehabilitation using trenchless methods, and transitions between ductile iron and other pipe materials.

Related Standards

This Technical Report is complementary to product and procedural standards and explicitly references:

- EN 598:2009 (ductile iron for sewerage)

- EN 545:2010, EN 476:2011 (components and requirements)

- EN 1610 (construction and site testing of drains and sewers)

- EN 12889 (trenchless construction/testing)

- EN 16933-2 (hydraulic design for drains and sewers) Referencing these ensures installations meet both product and procedural regulatory expectations.

Keywords: CEN/TR 17996:2024, ductile iron pipes, sewerage installation, EN 598, pipeline installation, trenchless technologies, pressure testing, gravity sewers.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

CEN/TR 17996:2024 is a technical report published by the European Committee for Standardization (CEN). Its full title is "Ductile iron pipes, fittings, accessories and their joints for sewerage applications - Guidelines for Pipelines Installation". This standard covers: This European Standard is a complementary document for the installation of ductile iron pipes, fittings, accessories and their joints, covered by EN 598:2009 harmonized standard. It is intended to describe, in a wider perspective, installation technologies, tools and pipelines particular examples, applicable for the construction, outside buildings, of: - Drainage pipeline systems; - Raw water pipeline systems; - Sewage pipeline systems; - Pipeline systems conveying surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents, either in separate systems or in combined systems; - Operating without pressure (gravity sewers) or with positive or negative pressure; - Below or above ground installation types. It also gives some site operation/site instructions for the application of fittings, intended to be used for the connection of ductile iron drains and sewers to other materials as plastic, concrete, vitrified clay, etc. This European Standard is not intended to cover: - Hydraulic design of drains and sewers systems outside buildings. For this purpose, EN 16933-2 applies. - Construction and site testing of drains and sewers. For this purpose, EN 1610 applies. - Trenchless construction and testing of drains and sewers. For this purpose, EN 12889:2000 applies

This European Standard is a complementary document for the installation of ductile iron pipes, fittings, accessories and their joints, covered by EN 598:2009 harmonized standard. It is intended to describe, in a wider perspective, installation technologies, tools and pipelines particular examples, applicable for the construction, outside buildings, of: - Drainage pipeline systems; - Raw water pipeline systems; - Sewage pipeline systems; - Pipeline systems conveying surface water (e.g. rainwater), domestic waste water and/or certain types of industrial effluents, either in separate systems or in combined systems; - Operating without pressure (gravity sewers) or with positive or negative pressure; - Below or above ground installation types. It also gives some site operation/site instructions for the application of fittings, intended to be used for the connection of ductile iron drains and sewers to other materials as plastic, concrete, vitrified clay, etc. This European Standard is not intended to cover: - Hydraulic design of drains and sewers systems outside buildings. For this purpose, EN 16933-2 applies. - Construction and site testing of drains and sewers. For this purpose, EN 1610 applies. - Trenchless construction and testing of drains and sewers. For this purpose, EN 12889:2000 applies

CEN/TR 17996:2024 is classified under the following ICS (International Classification for Standards) categories: 23.040.10 - Iron and steel pipes; 23.040.40 - Metal fittings. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TR 17996:2024 has the following relationships with other standards: It is inter standard links to EN 476:2022, EN 805:2000, EN 598:2007+A1:2009, EN 1610:2015, EN 752:2017, EN 545:2010. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TR 17996:2024 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-maj-2024

Cevi, fitingi, pribor in spoji iz duktilne železove litine za kanalizacijo - Smernice za

vgradnjo cevovodov

Ductile iron pipes, fittings, accessories and their joints for sewerage applications -

Guidelines for Pipelines Installation

Rohre, Formstücke, Zubehörteile aus duktilem Gusseisen und ihre Verbindungen für

Wasserleitungen - Richtlinien für die Installation von Rohrleitungen

Ta slovenski standard je istoveten z: CEN/TR 17996:2024

ICS:

23.040.10 Železne in jeklene cevi Iron and steel pipes

23.040.40 Kovinski fitingi Metal fittings

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TR 17996

TECHNICAL REPORT

RAPPORT TECHNIQUE

February 2024

TECHNISCHER REPORT

ICS 23.040.10; 23.040.40

English Version

Ductile iron pipes, fittings, accessories and their joints for

sewerage applications - Guidelines for Pipelines

Installation

Rohre, Formstücke, Zubehörteile aus duktilem

Gusseisen und ihre Verbindungen für Wasserleitungen

- Richtlinien für die Installation von Rohrleitungen

This Technical Report was approved by CEN on 12 February 2024. It has been drawn up by the Technical Committee CEN/TC

203.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TR 17996:2024 E

worldwide for CEN national Members.

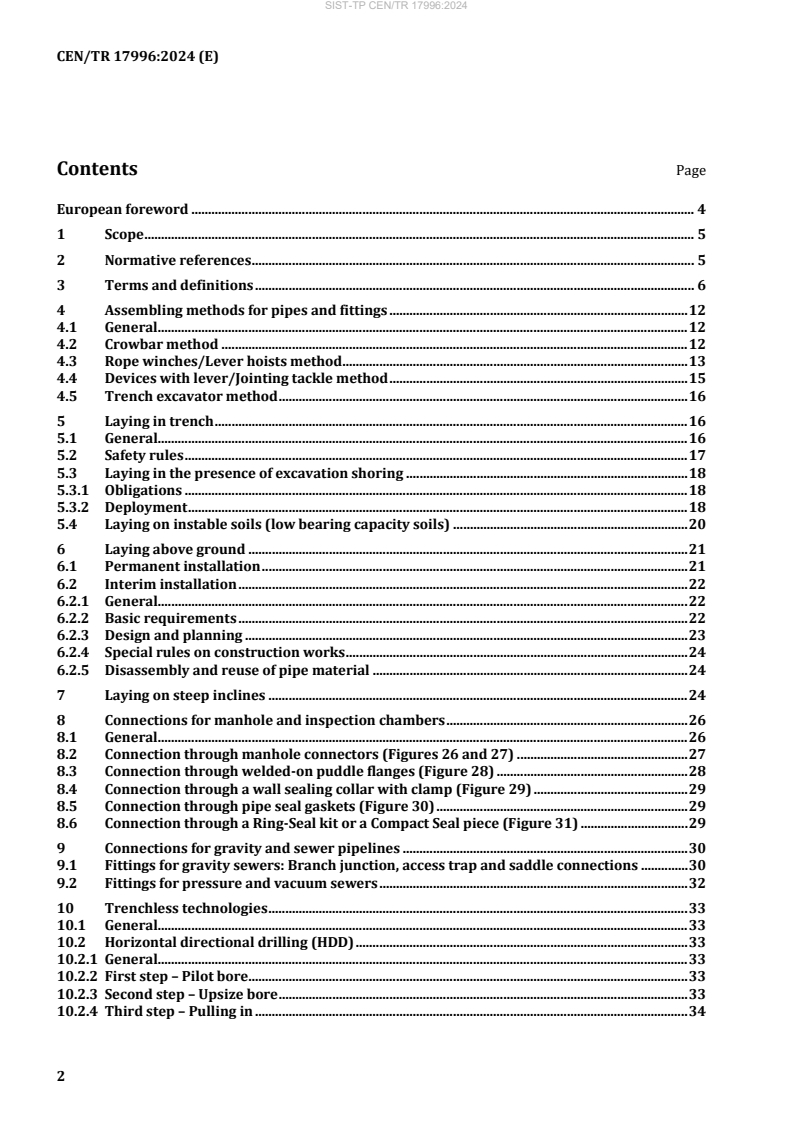

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 6

4 Assembling methods for pipes and fittings . 12

4.1 General. 12

4.2 Crowbar method . 12

4.3 Rope winches/Lever hoists method . 13

4.4 Devices with lever/Jointing tackle method . 15

4.5 Trench excavator method . 16

5 Laying in trench . 16

5.1 General. 16

5.2 Safety rules . 17

5.3 Laying in the presence of excavation shoring . 18

5.3.1 Obligations . 18

5.3.2 Deployment . 18

5.4 Laying on instable soils (low bearing capacity soils) . 20

6 Laying above ground . 21

6.1 Permanent installation . 21

6.2 Interim installation . 22

6.2.1 General. 22

6.2.2 Basic requirements . 22

6.2.3 Design and planning . 23

6.2.4 Special rules on construction works . 24

6.2.5 Disassembly and reuse of pipe material . 24

7 Laying on steep inclines . 24

8 Connections for manhole and inspection chambers . 26

8.1 General. 26

8.2 Connection through manhole connectors (Figures 26 and 27) . 27

8.3 Connection through welded-on puddle flanges (Figure 28) . 28

8.4 Connection through a wall sealing collar with clamp (Figure 29) . 29

8.5 Connection through pipe seal gaskets (Figure 30) . 29

8.6 Connection through a Ring-Seal kit or a Compact Seal piece (Figure 31) . 29

9 Connections for gravity and sewer pipelines . 30

9.1 Fittings for gravity sewers: Branch junction, access trap and saddle connections . 30

9.2 Fittings for pressure and vacuum sewers . 32

10 Trenchless technologies . 33

10.1 General. 33

10.2 Horizontal directional drilling (HDD) . 33

10.2.1 General. 33

10.2.2 First step – Pilot bore. 33

10.2.3 Second step – Upsize bore . 33

10.2.4 Third step – Pulling in . 34

10.3 Pipe Bursting . 34

10.4 Casing method (CM) . 35

10.4.1 General . 35

10.4.2 Casing installation . 35

10.4.3 Service Pipeline installation . 35

10.5 Pipe jacking (PJ) . 36

10.6 Press/Pull Technique . 36

10.6.1 Press/Pull Requirements . 37

10.6.2 Description of technique . 37

10.7 Ploughing-in Technique . 38

10.7.1 General . 38

10.7.2 Description of technique . 38

10.8 Microtunnelling . 39

11 Procedures and requirements for testing gravity pipelines . 40

11.1 General . 40

11.2 Testing with air (method “L”). 40

11.3 Testing with water (method “W”) . 43

11.3.1 Test pressure. 43

11.3.2 Conditioning time . 44

11.3.3 Test requirements . 44

11.3.4 Testing time . 44

11.3.5 Testing individual joints . 44

12 Testing of pressure pipelines . 45

12.1 General . 45

12.2 Safety . 45

12.3 Backfilling and Anchorage . 46

12.4 Filling with water and release of air/gas . 47

12.5 Pressure testing procedure . 49

12.5.1 General requirements . 49

12.5.2 Preliminary operations . 51

12.5.3 Preliminary test . 51

12.5.4 Pressure drop test . 52

12.5.5 Main pressure test . 52

12.5.6 Test evaluation . 55

12.5.7 Final system test (complete pipeline) . 55

12.5.8 Recording test results . 55

Bibliography . 56

European foreword

This document (CEN/TR 17996:2024) has been prepared by Technical Committee CEN/TC 203 “Cast

iron pipes, fittings and their joints”, the secretariat of which is held by AFNOR.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of

EU Directive(s)/Regulation(s).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

1 Scope

This document is a complementary document for the installation of ductile iron pipes, fittings,

accessories and their joints, covered by EN 598:2009 harmonized standard. It is intended to describe, in

a wider perspective, installation technologies, tools and pipelines particular examples, applicable for

the construction, outside buildings, of:

— drainage pipeline systems;

— raw water pipeline systems;

— sewage pipeline systems;

— water reuse pipeline systems;

— pipeline systems conveying surface water (e.g. rainwater), domestic wastewater and/or certain

types of industrial effluents, either in separate systems or in combined systems;

— operating without pressure (gravity sewers) or with positive or negative pressure;

— below or above ground installation types.

It also gives some site operation/site instructions for the application of fittings, intended to be used for

the connection of ductile iron drains and sewers to other materials as plastic, concrete, vitrified

clay, etc.

This document is not intended to cover:

— hydraulic design of drains and sewers systems outside buildings. For this purpose, EN 16933-2

applies;

— construction and site testing of drains and sewers. For this purpose, EN 1610 applies;

— trenchless construction and testing of drains and sewers. For this purpose, EN 12889 applies.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 476:2011, General requirements for components used in drains and sewers

EN 545:2010, Ductile iron pipes, fittings, accessories and their joints for water pipelines - Requirements

and test methods

EN 598:2009, Ductile iron pipes, fittings, accessories and their joints for sewerage applications –

Requirements and test methods

EN 752:2017, Drain and sewer systems outside buildings - Sewer system management

EN 805:2000, Water supply - Requirements for systems and components outside buildings

EN 1610:2015, Construction and testing of drains and sewers

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 598:2009, EN 476:2011,

EN 1333:2006, EN 773:1999 and EN 1610:2015 apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp/

— IEC Electropedia: available at https://www.electropedia.org/

3.1

ductile iron

cast iron used for pipes, fittings and accessories in which graphite is present substantially in spheroidal

form

3.2

pipe

casting of uniform bore, straight in axis, having either socket, spigot or flanged ends, except for flanged-

socket pieces, flanged-spigot pieces and collars which are classified as fittings

3.3

fitting

casting other than a pipe which allows pipeline deviation, change of direction or bore. In addition,

flanged-socket pieces, flanged-spigot pieces and collars are also classified as fittings

3.4

accessory

any casting/fabrication other than a pipe or fitting which is intended for the use in a ductile iron

pipeline including:

— inspection chambers (see 3.5);

— manholes (see 3.6);

— glands and bolts for mechanical flexible joints (sec 3.16);

— glands, bolts and locking rings for restrained flexible joints (see 3.17);

— adjustable flanges and flanges to be welded or screwed;

— pipe saddles for service pipe connections;

— flange adaptors for use with ductile iron pipes and fittings;

— couplings for use with ductile iron pipes and fittings;

— valves for use with ductile iron pipes and fittings

3.5

inspection chamber

structure with a removable cover, constructed on a drain or sewer that permits the introduction of

cleaning and inspection equipment from surface level, but does not provide access for personnel

[SOURCE EN 16323:2014]

3.6

manhole

structure with a removable cover, constructed on a drain or sewer to permit entry by personnel

[SOURCE EN 16323:2014]

3.7

access chamber

component of a sewer, with one or two side inlets set at a variety of angles, ideal for making single

connections

3.8

flange

flat circular end of a pipe or fitting extending perpendicular to its axis, with bolt holes equally spaced on

a circle

Note 1 to entry: A flange is either fixed (e.g. integrally cast or welded-on) or adjustable; an adjustable flange

comprises a ring, in one or several parts assembled together, which bears on an end joint hub and can be freely

rotated around the pipe axis before jointing.

3.9

spigot

male end of a pipe or fitting

3.10

spigot end length

spigot over a length equal to maximum insertion depth plus 50 mm

3.11

socket

female end of a pipe or fitting to make the connection with the spigot of the next component

3.12

gasket

sealing component of a joint

3.13

joint

connection between the ends of two pipes and/or fittings in which a gasket is used to effect a seal

3.14

flexible joint

joint which permits significant angular deflection both during and after installation and which can

accept a slight offset of the centreline

3.15

push-in flexible joint

flexible joint assembled by pushing the spigot through the gasket in the socket of the mating component

3.16

mechanical flexible joint

flexible joint in which sealing is obtained by applying pressure to the gasket by mechanical means, e.g. a

gland

3.17

restrained flexible joint

flexible joint in which a means is provided to prevent separation of the assembled joint

3.18

flanged joint

joint between two flanged ends

3.19

nominal size (DN)

alphanumerical designation of size for components of a pipework system, which is used for reference

purposes

Note 1 to entry: It comprises the letters DN followed by a dimensionless whole number which is indirectly

related to the physical size, in millimetres, of the bore or outside diameter of the end connections

[SOURCE EN ISO 6708:1995]

3.20

nominal pressure (PN)

alphanumerical designation used for reference purposes related to a combination of mechanical and

dimensional characteristics of a component of a pipework system

Note 1 to entry: It comprises the letters PN followed by a dimensionless number

Note 2 to entry: All equipment of the same nominal size DN designated by the same PN number have

compatible mating dimensions.

[SOURCE EN 1333:2006]

3.21

leak tightness test pressure

pressure applied to a component during manufacture in order to ensure its leak tightness

3.22

allowable operating pressure (PFA)

maximum hydrostatic pressure that a component can withstand continuously in service

[SOURCE EN 773:1999]

3.23

allowable maximum operating pressure (PMA)

maximum hydrostatic pressure, including surge, that a component can withstand from time to time in

service

[SOURCE EN 773:1999]

3.24

allowable test pressure (PEA)

maximum hydrostatic pressure that a newly installed component can withstand for a relatively short

duration, when either fixed above ground level or laid and backfilled underground, in order to ensure

the integrity and tightness of the pipeline

Note 1 to entry: This test pressure is different from the system test pressure (STP), which is related to the

design pressure of the pipeline and is intended to ensure its integrity and leak tightness.

[SOURCE EN 773:1999]

3.25

working pressure

WP

P

W

highest pressure that occurs at a time and a point in the pipeline when operating continuously under

stable conditions, without surge

[SOURCE ISO 10802:2020]

3.26

maximum working pressure

MWP

P

MW

maximum pressure to which a pipeline is subjected under surge conditions

[SOURCE ISO 10802:2020]

3.27

maximum design pressure

MDP

P

MD

maximum operating pressure of the system or of the pressure zone fixed by the designer considering

future developments and including surge to which a pipeline is subjected under surge conditions

Note 1 to entry: It is the maximum pressure considering the design pressure and surge together, where:

— MDP is designated MDPa, PMDa, fixed allowance for surge (secondary distribution networks);

, surge is calculated (pumping and water mains).

— MDP is designated MDPc, PMDc

[SOURCE ISO 10802:2020]

3.28

system test pressure

STP

P

ST

pressure to which a pipeline or a pipeline section is subjected for testing purposes

[SOURCE ISO 10802:2020]

3.29

diametral stiffness of a pipe

characteristic of a pipe which allows it to resist ovalization under loading when installed

3.30

discharge system

system of pipes, fittings, accessories and joints used to collect and drain wastewater and rainwater of a

building

Note 1 to entry: It comprises discharge pipes, stack ventilation pipes and rainwater downpipes, installed within

the limits of a building or attached to the building.

3.31

drain

system of pipes, fittings, accessories and joints installed outside the limits of a building in order to

connect the discharge system of this building to a sewer or a septic tank

3.32

sewer

pipeline designed to collect wastewater and rainwater from buildings and surface water and to convey

them to the point of disposal or treatment

3.33

gravity sewer

sewer operating normally under free flowing conditions

3.34

pressure sewer; pumping sewer

sewer (or section of a sewer) operating under positive pressure

3.35

vacuum sewer

sewer operating under negative pressure

3.36

combined system

sewerage system collecting together rainwater, surface water and wastewater

3.37

separate system

sewerage system which collects wastewater separately from rainwater and surface water

3.38

length

effective length of a pipe or fitting

Note 1 to entry: Lengths are:

— as shown on Figure 6 and given in table 2 of the EN 598:2009, for socket and spigot pipes;

— as given by EN 545:2010, clause 4.3.3.2, for flanged pipes;

— as given by EN 545:2010, clauses 8.3, 8.4, and 4.3.3.3, for pressure fittings

Note 2 to entry: the length of fittings used for gravity sewers are available by the manufacturer.

3.39

deviation

design length allowance with respect to the standardized length of a pipe

3.40

ovality

out of roundness of a pipe section

AA−

Note 1 to entry: It is equal to:

A + A

1 2

where

A is the maximum axis in millimetres

A2 is the minimum axis, in millimetres

3.41

bentonite

clay mineral, primarily montmorillonite, with high swelling properties, which forms the primary

component in drilling muds used in horizontal directional drilling technology

[SOURCE ISO 13470:2012]

3.42

bore

cavity that is created to receive a pipe or conduit

[SOURCE ISO 13470:2012]

3.43

casing

continuous structural shell that acts as an envelope and support for the service pipeline during

construction and service

[SOURCE ISO 13470:2012]

3.44

casing method

method in which a casing is put into place and then a pipe is inserted into the casing

[SOURCE ISO 13470:2012]

3.45

horizontal directional drilling

steerable method for the underground installation of pipes using a surface launched drilling rig

[SOURCE ISO 13470:2012]

3.46

pilot bore

initial hole drilled along the drill path

3.47

pipe bursting method

method for replacement of an existing pipe by longitudinal splitting

[SOURCE ISO 13470:2012]

3.48

pipe jacking method

system of directly installing pipes behind a cutting head and/or shield, by hydraulic thrust

[SOURCE ISO 13470:2012]

3.49

microtunnelling

trenchless steerable remote-control method for drain and sewage pipelines installation, using

microtunnel boring machines

3.50

pulling head

reusable component mounted at the beginning of the pipe string, which transmits the pulling force from

the drilling rod to the pipes

[SOURCE ISO 13470:2012]

3.51

service pipeline

ductile iron pipeline intended to carry water or wastewater, operated with or without pressure

[SOURCE ISO 13470:2012]

3.52

overcut

the annular space around the pipe deliberately created by using a cutting head or shield of greater

dimension than the outside dimension of the pipe

[SOURCE EN 12889:2000]

3.53

water reuse

wastewater that has been treated to meet specific water quality for intended beneficial use

[SOURCE ISO 20678:2018]

4 Assembling methods for pipes and fittings

4.1 General

The assembling can be done by several different methods as given below:

4.2 Crowbar method

For small diameter pipes, usually up to DN 125, the assembling of pipes can be achieved by pushing the

pipe with a crowbar against a timber held against the face of the socket of the entering pipe. The

crowbar takes support on the ground. In case of the assembly of fittings, the crowbar pushes the fitting

in the direction of the spigot, keeping the socket of the fitting centred and perpendicular with the spigot

end (see Figures 1 and 2).

Figure 2 — Crowbar assembling

Figure 1 – Crowbar assembling method for pipes

method for fittings

4.3 Rope winches/Lever hoists method

Either due to some site constraints, associated to a lower control over the insertion of the spigot in the

socket or a major concern over the alignment between pipes to joint, the rope winches/lever hoists

method is the most recommendable method. In general terms, this method is used for bigger diameter

pipes and fittings and wherever the excavator bucket pushing is not possible or recommended.

For the assembly of pipes or fittings externally coated with polymeric coatings, such as epoxy,

polyurethane, it is strictly forbidden to use metallic rope or chains in direct contact with the coating. In

this specific case, it is recommended to use flat textile slings.

For the bigger diameter to be assembled below ground (directly in the trench), it is necessary to have at

least 60 cm extra space, between the pipe barrel and the trench walls, to allow either the manual

operation of the wire rope winches or the levers (lever hoists).

If it is used the rope winches method, the wire rope or the flat textile sling should be looped and

positioned behind the socket, the free end should then be attached to the pulley block. The second wire

rope can then be threaded through the winch and, using snatch block with hook, the assembling is then

possible by operating the winch. The number of rope winches, wire ropes/flat textile slings depend on

the size of pipes and fittings. For the number and capacity of the rope winches, the producer’s

recommendations should be followed (see Figures 3 and 4).

Whether it is used the lever hoists method (see Figure 5), the wire rope or flat textile sling is, in the

same way, looped and positioned behind the socket, being its free end attached to the fixed hook of the

lever hoist. The second wire rope/flat textile sling or a hook placed in the socket end of the pipe to

insert, is then attached to the moving hook of lever hoist. The assembling is then achieved by operating

on the lever of the lever hoist. In bigger diameter pipes or pipe/fitting jointing operations, more than

one lever hoist should be needed. When using three lever hoists, the two lateral may be kept in their

position using a connecting rope between one another. For the number and capacity of the lever hoists,

the producer’s recommendations should also be respected.

Figure 3 — Assembling bigger diameter pipes by rope winches method

As like pipe jointing, the wire rope or the flat textile sling should be looped and positioned behind the

socket of the pipe and the free end should then be attached to the winch. The second wire rope or the

flat textile sling should be looped and positioned behind the socket of the fitting. The assembling is

achieved by operating the winch (see Figure 4).

Figure 4 — Assembling a fitting to a pipe by the rope winches method

The assembly of push-on fittings may also be done using lever hoists, placing on the pipe barrel two

long flat slings, in loops, by passing plain ends through the eyes diametrically opposite and on the

horizontal centerline. Place then two additional flat slings loops behind the socket of the fitting, with the

eyes diametrically opposite and on the horizontal centerline. Engage the eyes of the flat slings on the

hooks of the lever hoists. Operate the levers of the lever hoists, paying attention to ensure a

simultaneous push-on insertion, on both diametrical opposite sides (Refer to Figure 5).

Figure 5 — Assembling a fitting to a pipe by the lever hoists (rack and lever equipment)

For the assembly pipe/pipe and pipe/fitting types and the recommended number and capacity of rope

winches, lever hoists, wire ropes, flat textile slings, hooks, shackles, etc, the producer’s

recommendations and instructions should be followed.

4.4 Devices with lever/Jointing tackle method

This method of assembling is usually used for pipes and fittings sizes from DN 80 to DN 300. The

operating procedure for one of the possible devices is explained on the following steps (see Figures 6

and 7):

Step 1: place the socket frame behind the socket

of the installed pipe and slide until contact as

shown by the arrow.

Step 2: Place the lever in the lower position and

then move the grip section using the handle to

position correctly the four grips against the pipe

barrel.

Step 3: Stand in front of the socket and firmly pull

the lever towards you, in the direction shown by

the arrow, until the lever reaches again the lower

position (opposite to the initial lower position).

Step 4: If necessary, repeat the procedure from

step 3 until both pipes are totally jointed. Check

the insertion depth and the gasket position (with

a gage metal rule inserted in the socket gap).

Figure 6 — Assembling pipes with a jointing tackle

NOTE For the operation procedure, check the producer written instructions.

Figure 7 — Assembling a fitting to a pipe by a jointing tackle

4.5 Trench excavator method

This method is normally used for the pipes from DN 125 to 2 000. When using a backhoe type excavator

to prepare the trench, this machine may be used to push the spigot into the socket. A timber should be

placed between the pipe to push and the backhoe bucket, to avoid any damages (see Figure 8).

Figure 8 — Trench excavator method

5 Laying in trench

5.1 General

The mechanical performance of a buried pipe can be understood by considering the pipe/soil system:

the interaction of pipes with the surrounding soils depends on their stiffness or flexibility, which

induces stresses under different laying conditions (Figure 9).

Rigid Pipe Semi-rigid pipe Flexible pipe

Figure 9

Ductile iron pipe has a semi-rigid behaviour for it demonstrates an excellent compromise between

mechanical stress in its wall (small DN) and ovality (large DN). It can be laid with high and low depths

of cover and easily in soil of low rigidity (cohesion). The “soil/semi-rigid pipe” system offers optimum

mechanical stability over time, without the risk of buckling in large diameter pipes. Small diameter

pipes are rigid and robust; they do not require excessive compaction rates when they are laid in

trenches, enabling the reuse of native soils as backfills rather than materials imported from distant

quarries. This good practice contributes to the preservation of soil in its natural state while reducing

costs and the site’s ecological footprint.

5.2 Safety rules

For the construction of pipe trenches, national regulations should be followed. Open cut trenches

should be sheeted and braced as required by any national state law or regulation.

After the conclusion of the excavation, the pipes are handled and lowered to the bottom of the trench in

accordance with the safety rules linked to the handling and lifting of heavy loads and in particular using

specific laying hooks and appropriate slings, wire ropes or chains.

Always check primarily the load capacity of the handling and lifting equipment to use and make sure

that it is fitted with a safety device.

Key

Pm

safe working load of a sling (SWL)

Q

maximum load

NOTE Safe working load (SWL) of a sling is the maximum load that may be lifted after considering the SWL of

the sling material, the reeving arrangement and the method of sling termination.

Figure 10 — General Working load limits (load factors) and sling angles

5.3 Laying in the presence of excavation shoring

5.3.1 Obligations

Wherever applicable, national regulations should be followed.

The presence of shoring is compulsory in a narrow trench from 1,30 m deep, when the width is equal or

less than 2/3 of the depth.

The length of the pipes requires in the case of shoring, a particular organization of the working site. For

example, in the case of shoring by trench boxes, to work rationally and safely, four or five boxes are

necessary. The work cycle is then as follows:

1) placement of the panel box;

2) laying of pipes inside the panel boxes;

3) backfilling the trench;

4) recovery of the panel box in a partially backfilled area.

In the case of very congested urban underground soils, the use of couplings allows the use of shorter

pipes.

5.3.2 Deployment

The installation techniques in the presence of shoring may differ depending on the length of the trench

box panels and the position of the holding cylinders or struts.

The most frequently encountered cases are:

Case n° 1 - Descent inside a trench box

The figure below schematically shows us the descent of a ductile iron pipe inside a trench box

(see Figure 11). It is safer to descent the pipe with the socket down (heaviest part of the pipe). Before,

insert a wood timber against the socket of the pipe in place. Then, lower the pipe between the trench

boxes (shoring units) and carry on with the fully aligned jointing (and final angular deviation, if

necessary).

Figure 11 — Descent inside a trench box

Case n° 2 - Descent inside two trench boxes

In the case of a greater depth (see Figure 12), leading to a greater distance between the cylinders or

struts, it is necessary to thread the pipe by playing with two trench boxes (lower main box panels with

the addition of a top box panels).

Figure 12 — Descent inside two trench boxes

Case n° 3 - Descent by the pendulum method

To apply the pendulum method, it is necessary to have a rigid anchorage by sling at the centre of gravity

of the pipe. The pipe gets in below the first cylinder, then swung to pass under the next cylinder/strut.

The balancing is done manually (refer to Figure 13).

Figure 13 — Descent by the pendulum method

Case n° 4 - Descent by an upstream pit

The below figure shows us an example of the construction of an access pit to descend the pipes. The

pipes will be lowered after the access ramps have been completed (see Figure 14).

Figure 14 — Descent by an upstream pit

Case n° 5 - Descent by a fitted hatch

It is necessary to shield the trench over a long length to use this laying method. Two intermediate

cylinders are removed by using reinforcements which leave a free length of approximately 8 m to lower

the 6 m ductile iron pipe horizontally (Refer to Figure 15).

Figure 15 — Descent by a fitted hatch

5.4 Laying on instable soils (low bearing capacity soils)

For this type of soils, commonly associated with water table levels fluctuation, a previous geological

survey should be carried out and the designer should make a structural calculation, check and define

the laying solution, to ensure the correct slope and the required stability of the drain or sewer, enabling

it to accommodate internal and external loads. Depending on the soil’s mechanical characteristics and

on the external coating of the ductile iron pipes, there are several possible laying solutions such as:

a) bedding, lateral infill and direct cover zone backfilled with gravel, being this one surrounded by a

geotextile membrane (Figure 16);

b) bedding (cushion) with gravel surrounded by a geotextile membrane. The lateral infill and the

embedment being done with suitable grained soils (Figure 17);

c) laying of ductile iron/concrete piles, which should support concrete slabs and, eventually, pipe’s

concrete supports. The lateral infill and the embedment should consist of suitable grained soils

over the full width of the pipe trench, in layers not exceeding 150 mm before compaction,

surrounded or not by a geotextile membrane (Figure 18);

d) timber piles inserted and distributed all over the length of the trench, in a first layer of concrete

bedding. The second layer of the bedding being of gravel. Above this layer, the laying of concrete

slabs of the same length (the width as per allowed by the trench shoring) as the ductile iron pipes.

The bedding layer, the lateral infill and the embedment should consist of suitable grained soils over

the full width of the pipe trench, in layers not exceeding 150 mm before compaction, surrounded or

not by a geotextile membrane.

Figure 16 Figure 17 Figure 18

6 Laying above ground

6.1 Permanent installation

Laying a drain or sewer above ground involves the definition of:

— the support system (seating details, straps or clamps details, concrete, metallic – refer

to Figure 19);

— the accommodation of thermal expansion;

— the anchorage of components under hydraulic thrust.

Where the pipeline may be subjected to temperature variation, a suitable gap should be left between

the end of the spigot and the bottom of the socket. Therefore, the final remaining gap, ensured by the

final push-in insertion with unrestrained flexible joints, represents one of the major advantages of

ductile iron pipelines, since it doesn’t require the use and installation of expansion joints. Between each

saddle, the flexible joint acts as a compensator for expansion by absorbing the expansion of a length of

pipe.

Saddles may be previously pre-assembled (pre-fabrication) and easily installed on site. The flexible

joints should adjust to any misalignment of the saddles and act as thermal expansion joints (Figure 20).

Figure 19 Figure 20

It is recommended to place a rubber pad, positioned between pipe and concrete/metallic support.

The fittings of pumping sewers, which are subjected to hydraulic thrust (such as bends, tees, tapers)

should be stabilized with an anchor block. Directional changes such as pipeline curve geometry (large

radius bends) may be achieved by the simple use of the joint deflection capacity (within the specified

limits). For this specific case, care is taken to reinforce the saddles anchorage of the concerned pipes,

after having assessed the hydraulic thrust at the deflected joint positions. Provision of an adequate

safety margin should be undertaken during the design of the saddle dimensions (saddle and clamps), to

compensate the hydraulic forces due to any misalignment of the pipes.

6.2 Interim installation

6.2.1 Gener

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...