EN ISO 22000:2005

(Main)Food safety management systems - Requirements for any organization in the food chain (ISO 22000:2005)

Food safety management systems - Requirements for any organization in the food chain (ISO 22000:2005)

ISO 22000:2005 specifies requirements for a food safety management system where an organization in the food chain needs to demonstrate its ability to control food safety hazards in order to ensure that food is safe at the time of human consumption.

It is applicable to all organizations, regardless of size, which are involved in any aspect of the food chain and want to implement systems that consistently provide safe products. The means of meeting any requirements of ISO 22000:2005 can be accomplished through the use of internal and/or external resources.

ISO 22000:2005 specifies requirements to enable an organization

-- to plan, implement, operate, maintain and update a food safety management system aimed at providing products that, according to their intended use, are safe for the consumer,

-- to demonstrate compliance with applicable statutory and regulatory food safety requirements,

-- to evaluate and assess customer requirements and demonstrate conformity with those mutually agreed customer requirements that relate to food safety, in order to enhance customer satisfaction,

-- to effectively communicate food safety issues to their suppliers, customers and relevant interested parties in the food chain,

-- to ensure that the organization conforms to its stated food safety policy,

-- to demonstrate such conformity to relevant interested parties, and

-- to seek certification or registration of its food safety management system by an external organization, or make a self-assessment or self-declaration of conformity to ISO 22000:2005.

Managementsysteme für die Lebensmittelsicherheit - Anforderungen an Organisationen in der Lebensmittelkette (ISO 22000:2005)

Die vorliegende Internationale Norm definiert Anforderungen an ein Managementsystem für Lebensmittel-sicherheit für Organisationen in der Lebensmittelkette, die nachweisen müssen, dass sie gesundheitliche Gefahren durch Lebensmittel beherrschen können, um sicherzustellen, dass Lebensmittel zum Zeitpunkt des menschlichen Verzehrs sicher sind.

Sie gilt für alle Organisationen, ungeachtet ihrer Größe, die in irgendeiner Form in der Lebensmittelkette mitwirken und Systeme anwenden wollen, die konstant sichere Produkte liefern. Die Übereinstimmung mit den Anforderungen dieser Internationalen Norm kann mittels Verwendung interner und/oder externer Ressourcen erreicht werden.

Die vorliegende Internationale Norm definiert Anforderungen, aufgrund deren eine Organisation in der Lage sein soll,

a) ein Managementsystem für Lebensmittelsicherheit zu planen, zu implementieren, anzuwenden, aufrechtzuerhalten und zu aktualisieren, dessen Zweck darin besteht, Produkte zu liefern, bei deren bestimmungsgemäßem Gebrauch sichergestellt ist, dass diese für den Verbraucher sicher sind,

b) die Einhaltung der zutreffenden rechtlichen Anforderungen zur Lebensmittelsicherheit darzulegen,

c) Kundenanforderungen zu prüfen und zu beurteilen und die Übereinstimmung mit denjenigen gemeinsam vereinbarten Kundenanforderungen darzulegen, die sich auf die Lebensmittelsicherheit beziehen, um die Kundenzufriedenheit zu erhöhen,

d) die Belange der Lebensmittelsicherheit mit ihren Lieferanten, Kunden und relevanten Beteiligten in der Lebensmittelkette effektiv zu kommunizieren,

e) die Übereinstimmung mit ihrer eigenen Lebensmittelsicherheitspolitik sicherzustellen,

f) diese Übereinstimmung gegenüber relevanten Beteiligten darzulegen und

g) die Zertifizierung ihres Managementsystems für Lebensmittelsicherheit hinsichtlich der Übereinstimmung mit dieser Internationalen Norm durch eine externe Stelle anzustreben, eine Selbstbewertung vorzunehmen oder eine Konformitätserklärung abzugeben.

Systèmes de management de la sécurité des denrées alimentaires - Exigences pour tout organisme appartenant à la chaîne alimentaire (ISO 22000:2005)

L'ISO 22000:2005 spécifie les exigences relatives à un système de management de la sécurité des denrées alimentaires dans la chaîne alimentaire, lorsqu'un organisme a besoin de démontrer son aptitude à maîtriser les dangers liés à la sécurité des denrées alimentaires, afin de garantir que la denrée alimentaire est sûre au moment de sa consommation par l'homme.

Elle s'applique à tous les organismes, indépendamment de leur taille, qui sont impliqués dans un aspect de la chaîne alimentaire et veulent mettre en oeuvre des systèmes permettant de fournir en permanence des produits sûrs. Les moyens mis en oeuvre pour satisfaire toutes les exigences de la présente Norme internationale peuvent être réalisés par l'utilisation de ressources internes et/ou externes.

L'ISO 22000:2005 définit des exigences pour permettre à un organisme de:

planifier, mettre en oeuvre, exploiter, maintenir et mettre à jour un système de management de la sécurité des denrées alimentaires destiné à fournir des produits qui, conformément à leur usage prévu, sont sûrs pour le consommateur;

démontrer la conformité avec les exigences légales et réglementaires applicables en matière de sécurité des denrées alimentaires;

évaluer et apprécier les exigences du client, démontrer la conformité avec les exigences établies en accord avec lui et relatives à la sécurité des denrées alimentaires afin d'améliorer la satisfaction du client;

communiquer efficacement sur les questions relatives à la sécurité des denrées alimentaires avec ses fournisseurs, ses clients et les parties intéressées de la chaîne alimentaire;

garantir la conformité avec sa politique déclarée en matière de sécurité des aliments;

démontrer cette conformité aux parties intéressées; et

faire certifier/enregistrer son système de management de la sécurité des denrées alimentaires par un organisme extérieur, ou effectuer une auto-évaluation/ auto-déclaration de conformité à l'ISO 22000:2005.

Sistemi vodenja varnosti živil – Zahteve za vsako organizacijo v prehranski verigi (ISO 22000:2005)

Ta mednarodni standard navaja zahteve za sistem vodenja varnosti živil, ko organizacija v prehranski verigi dokazuje, da je sposobna nadzorovati dejavnike tveganja in s tem zagotoviti varnost živila v času njegovega zaužitja.

Primeren je za vse organizacije ne glede na velikost, ki so kakorkoli vključene v prehransko verigo in želijo izvajati sisteme, ki stalno zagotavljajo varnost izdelkov. Pomen katerekoli zahteve tega mednarodnega standarda je lahko izpopolnjen z uporabo notranjih ali zunanjih virov.

Ta mednarodni standard določa zahteve, ki organizaciji omogočajo:

a)načrtovati, izvajati, voditi, vzdrževati in posodabljati sistem vodenja varnosti živil, s katerim zagotovi izdelke, ki so glede na namen uporabe varni za uživanje;

b)prikazati skladnost z ustreznimi zakonskimi in regulativnimi zahtevami za varnost živil;

c)vrednotiti in oceniti zahteve kupcev in prikazati skladnost z medsebojno usklajenimi zahtevami kupcev glede varnosti živil, da bi se povečalo njihovo zadovoljstvo;

d)uspešno povezati vidike varnosti živil svojih dobaviteljev, odjemalcev in vključenih zainteresiranih strank v prehranski verigi;

e)zagotavljati, da usklajuje določeno politiko zagotavljanja varnih živil;

f)prikazati tako usklajenost pomembnim zainteresiranim strankam in

g)pridobiti certifikacijo ali registracijo svojega sistema vodenja varnosti živil pri zunanji organizaciji ali izvesti samoocenjevanje ali samodeklariranje skladnosti s tem mednarodnim standardom.

Vse zahteve tega mednarodnega standarda so splošne in so namenjene vsem organizacijam v prehranski verigi ne glede na velikost in kompleksnost. To vključuje vse organizacije, ki so neposredno ali posredno vključene v enega ali več členov prehranske verige. Med organizacijami, ki so neposredno vključene, so proizvajalci krme, kmetje, proizvajalci sestavin, proizvajalci živil, trgovci, izvajalci strežbe hrane, oskrbe z živili, izvajalci čiščenja in sanitacije, prevoza, skladiščenja in distribucije. Med drugimi organizacijami, ki so posredno vključene, so dobavitelji opreme, čistilnih in sanitacijskih sredstev, embalaže in drugih materialov, ki vstopajo v stik z živili.

Ta mednarodni standard omogoča majhnim in/ali manj razvitim organizacijam (npr. malim kmetijam, distributerjem, trgovcem ali strežbi), da izvajajo kombinacijo kontrolnih ukrepov, ki je bila razvita z zunanjo pomočjo.

OPOMBA:Napotki za uporabo tega mednarodnega standarda so podani v ISO/TS 22004.

General Information

- Status

- Withdrawn

- Publication Date

- 31-Aug-2005

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/SS C01 - Food products

- Drafting Committee

- CEN/SS C01 - Food products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Jun-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 23-Jul-2014

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 08-Jun-2022

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN ISO 22000:2005 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food safety management systems - Requirements for any organization in the food chain (ISO 22000:2005)". This standard covers: ISO 22000:2005 specifies requirements for a food safety management system where an organization in the food chain needs to demonstrate its ability to control food safety hazards in order to ensure that food is safe at the time of human consumption. It is applicable to all organizations, regardless of size, which are involved in any aspect of the food chain and want to implement systems that consistently provide safe products. The means of meeting any requirements of ISO 22000:2005 can be accomplished through the use of internal and/or external resources. ISO 22000:2005 specifies requirements to enable an organization -- to plan, implement, operate, maintain and update a food safety management system aimed at providing products that, according to their intended use, are safe for the consumer, -- to demonstrate compliance with applicable statutory and regulatory food safety requirements, -- to evaluate and assess customer requirements and demonstrate conformity with those mutually agreed customer requirements that relate to food safety, in order to enhance customer satisfaction, -- to effectively communicate food safety issues to their suppliers, customers and relevant interested parties in the food chain, -- to ensure that the organization conforms to its stated food safety policy, -- to demonstrate such conformity to relevant interested parties, and -- to seek certification or registration of its food safety management system by an external organization, or make a self-assessment or self-declaration of conformity to ISO 22000:2005.

ISO 22000:2005 specifies requirements for a food safety management system where an organization in the food chain needs to demonstrate its ability to control food safety hazards in order to ensure that food is safe at the time of human consumption. It is applicable to all organizations, regardless of size, which are involved in any aspect of the food chain and want to implement systems that consistently provide safe products. The means of meeting any requirements of ISO 22000:2005 can be accomplished through the use of internal and/or external resources. ISO 22000:2005 specifies requirements to enable an organization -- to plan, implement, operate, maintain and update a food safety management system aimed at providing products that, according to their intended use, are safe for the consumer, -- to demonstrate compliance with applicable statutory and regulatory food safety requirements, -- to evaluate and assess customer requirements and demonstrate conformity with those mutually agreed customer requirements that relate to food safety, in order to enhance customer satisfaction, -- to effectively communicate food safety issues to their suppliers, customers and relevant interested parties in the food chain, -- to ensure that the organization conforms to its stated food safety policy, -- to demonstrate such conformity to relevant interested parties, and -- to seek certification or registration of its food safety management system by an external organization, or make a self-assessment or self-declaration of conformity to ISO 22000:2005.

EN ISO 22000:2005 is classified under the following ICS (International Classification for Standards) categories: 03.100.70 - Management systems; 67.020 - Processes in the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN ISO 22000:2005 has the following relationships with other standards: It is inter standard links to EN ISO 22000:2018, EN ISO 3580:2008, EN 15593:2008, EN ISO 22000:2005/AC:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN ISO 22000:2005 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI SIST EN ISO 22000:2005

STANDARD

november 2005

Sistemi vodenja varnosti živil – Zahteve za vsako organizacijo v prehranski

verigi (ISO 22000:2005)

Food safety management systems - Requirements for any organization in the food

chain (ISO 22000:2005)

ICS 67.020 Referenčna številka

© Standard je založil in izdal Slovenski inštitut za standardizacijo. Razmnoževanje ali kopiranje celote ali delov tega dokumenta ni dovoljeno

EUROPEAN STANDARD

EN ISO 22000

NORME EUROPÉENNE

EUROPÄISCHE NORM

September 2005

ICS 67.020

English Version

Food safety management systems - Requirements for any

organization in the food chain (ISO 22000:2005)

Systèmes de management de la sécurité des denrées Managementsysteme für die Lebensmittelsicherheit -

alimentaires - Exigences pour tout organisme appartenant Anforderungen an Organisationen in der gesamten

à la chaîne alimentaire (ISO 22000:2005) Lebensmittelkette (ISO 22000:2005)

This European Standard was approved by CEN on 18 August 2005.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Central Secretariat or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,

Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,

Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

© 2005 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN ISO 22000:2005: E

worldwide for CEN national Members.

Foreword

This document (EN ISO 22000:2005) has been prepared by Technical Committee ISO/TC 34

"Agricultural food products" in collaboration with Technical Committee CEN/SS C01 "Food

Products", the secretariat of which is held by CMC.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by March 2006, and conflicting national

standards shall be withdrawn at the latest by March 2006.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of

the following countries are bound to implement this European Standard: Austria, Belgium,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary,

Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland,

Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

Endorsement notice

The text of ISO 22000:2005 has been approved by CEN as EN ISO 22000:2005 without any

modifications.

INTERNATIONAL ISO

STANDARD 22000

First edition

2005-09-01

Food safety management systems —

Requirements for any organization in the

food chain

Systèmes de management de la sécurité des denrées alimentaires —

Exigences pour tout organisme appartenant à la chaîne alimentaire

Reference number

ISO 22000:2005(E)

©

ISO 2005

ISO 22000:2005(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall

not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In the

unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

©

ii ISO 2005 – All rights reserved

ISO 22000:2005(E)

Contents Page

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Food safety management system . 4

4.1 General requirements . 4

4.2 Documentation requirements . 5

5 Management responsibility . 5

5.1 Management commitment . 5

5.2 Food safety policy . 6

5.3 Food safety management system planning . 6

5.4 Responsibility and authority . 6

5.5 Food safety team leader . 6

5.6 Communication . 7

5.7 Emergency preparedness and response . 8

5.8 Management review . 8

6 Resource management . 8

6.1 Provision of resources . 8

6.2 Human resources . 9

6.3 Infrastructure . 9

6.4 Work environment . 9

7 Planning and realization of safe products . 9

7.1 General . 9

7.2 Prerequisite programmes (PRPs) . 10

7.3 Preliminary steps to enable hazard analysis . 11

7.4 Hazard analysis . 13

7.5 Establishing the operational prerequisite programmes (PRPs) . 14

7.6 Establishing the HACCP plan . 14

7.7 Updating of preliminary information and documents specifying the PRPs

and the HACCP plan . 15

7.8 Verification planning . 16

7.9 Traceability system . 16

7.10 Control of nonconformity . 16

8 Validation, verification and improvement of the food safety management system . 18

8.1 General . 18

8.2 Validation of control measure combinations . 19

8.3 Control of monitoring and measuring . 19

8.4 Food safety management system verification . 19

8.5 Improvement . 20

©

ISO 2005 – All rights reserved iii

ISO 22000:2005(E)

Annex A (informative) Cross references between ISO 22000:2005 and ISO 9001:2000 . 22

Annex B (informative) Cross references between HACCP and ISO 22000:2005 . 27

Annex C (informative) Codex references providing examples of control measures, including

prerequisite programmes and guidance for their selection and use . 28

Bibliography . 32

©

iv ISO 2005 – All rights reserved

ISO 22000:2005(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the International

Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 22000 was prepared by Technical Committee ISO/TC 34, Food products.

©

ISO 2005 – All rights reserved v

ISO 22000:2005(E)

Introduction

Food safety is related to the presence of food-borne hazards in food at the point of consumption (intake by the

consumer). As the introduction of food safety hazards can occur at any stage of the food chain, adequate

control throughout the food chain is essential. Thus, food safety is ensured through the combined efforts of all

the parties participating in the food chain.

Organizations within the food chain range from feed producers and primary producers through food

manufacturers, transport and storage operators and subcontractors to retail and food service outlets (together

with inter-related organizations such as producers of equipment, packaging material, cleaning agents, additives

and ingredients). Service providers are also included.

This International Standard specifies the requirements for a food safety management system that combines the

following generally recognized key elements to ensure food safety along the food chain, up to the point of final

consumption:

— interactive communication;

— system management;

— prerequisite programmes;

— HACCP principles.

Communication along the food chain is essential to ensure that all relevant food safety hazards are identified

and adequately controlled at each step within the food chain. This implies communication between

organizations both upstream and downstream in the food chain. Communication with customers and suppliers

about identified hazards and control measures will assist in clarifying customer and supplier requirements (e.g.

with regard to the feasibility and need for these requirements and their impact on the end product).

Recognition of the organization's role and position within the food chain is essential to ensure effective

interactive communication throughout the chain in order to deliver safe food products to the final consumer. An

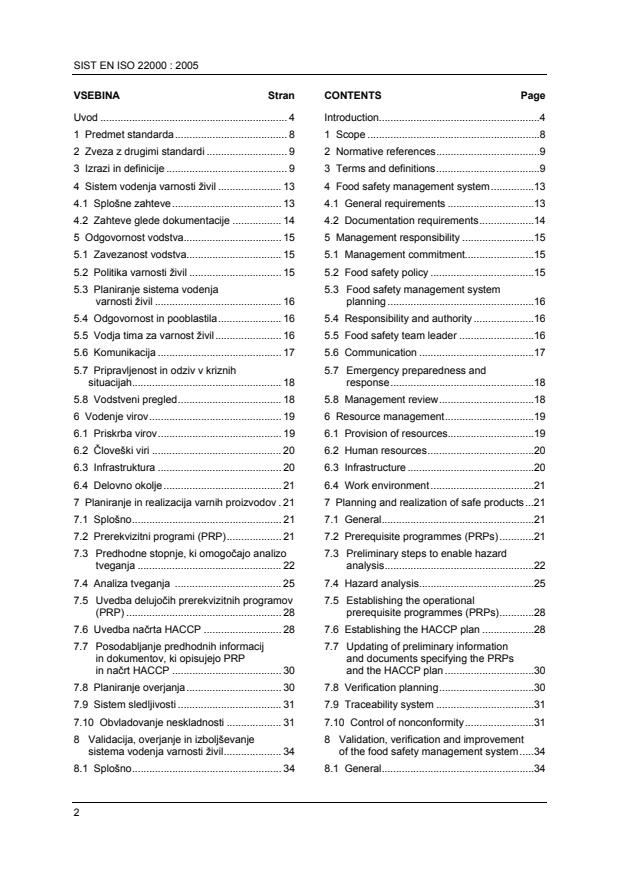

example of the communication channels among interested parties of the food chain is shown in Figure 1.

The most effective food safety systems are established, operated and updated within the framework of a

structured management system and incorporated into the overall management activities of the organization.

This provides maximum benefit for the organization and interested parties. This International Standard has

been aligned with ISO 9001 in order to enhance the compatibility of the two standards. Cross-references

between this International Standard and ISO 9001 are provided in Annex A.

This International Standard can be applied independently of other management system standards. Its

implementation can be aligned or integrated with existing related management system requirements, while

organizations may utilize existing management system(s) to establish a food safety management system that

complies with the requirements of this International Standard.

This International Standard integrates the principles of the Hazard Analysis and Critical Control Point (HACCP)

system and application steps developed by the Codex Alimentarius Commission. By means of auditable

requirements, it combines the HACCP plan with prerequisite programmes (PRPs). Hazard analysis is the key to

an effective food safety management system, since conducting a hazard analysis assists in organizing the

knowledge required to establish an effective combination of control measures. This International Standard

requires that all hazards that may be reasonably expected to occur in the food chain, including hazards that may

be associated with the type of process and facilities used, are identified and assessed. Thus it provides the

means to determine and document why certain identified hazards need to be controlled by a particular

organization and why others need not.

During hazard analysis, the organization determines the strategy to be used to ensure hazard control by

combining the PRP(s), operational PRP(s) and the HACCP plan.

©

vi ISO 2005 – All rights reserved

ISO 22000:2005(E)

NOTE The figure does not show the type of interactive communications along and across the food chain that by-pass

immediate suppliers and customers.

Figure 1 — Example of communication within the food chain

Cross-references between the Codex Alimentarius Commission HACCP principles and application steps (see

Reference [11]) and this International Standard are provided in Annex B.

To facilitate the application of this International Standard, it has been developed as an auditable standard.

However, individual organizations are free to choose the necessary methods and approaches to fulfil the

requirements of this International Standard. To assist individual organizations with the implementation of this

International Standard, guidance on its use is provided in ISO/TS 22004.

This International Standard is intended to address aspects of food safety concerns only. The same approach as

provided by this International Standard can be used to organize and respond to other food specific aspects (e.g.

ethical issues and consumer awareness).

This International Standard allows an organization (such as a small and/or less developed organization) to

implement an externally developed combination of control measures.

The aim of this International Standard is to harmonize on a global level the requirements for food safety

management for businesses within the food chain. It is particularly intended for application by organizations that

seek a more focused, coherent and integrated food safety management system than is normally required by

law. It requires an organization to meet any applicable food safety related statutory and regulatory requirements

through its food safety management system.

©

ISO 2005 – All rights reserved vii

.

viii

INTERNATIONAL STANDARD ISO 22000:2005(E)

Food safety management systems — Requirements for any

organization in the food chain

1Scope

This International Standard specifies requirements for a food safety management system where an

organization in the food chain needs to demonstrate its ability to control food safety hazards in order to ensure

that food is safe at the time of human consumption.

It is applicable to all organizations, regardless of size, which are involved in any aspect of the food chain and

want to implement systems that consistently provide safe products. The means of meeting any requirements of

this International Standard can be accomplished through the use of internal and/or external resources.

This International Standard specifies requirements to enable an organization

a) to plan, implement, operate, maintain and update a food safety management system aimed at providing

products that, according to their intended use, are safe for the consumer,

b) to demonstrate compliance with applicable statutory and regulatory food safety requirements,

c) to evaluate and assess customer requirements and demonstrate conformity with those mutually agreed

customer requirements that relate to food safety, in order to enhance customer satisfaction,

d) to effectively communicate food safety issues to their suppliers, customers and relevant interested parties in

the food chain,

e) to ensure that the organization conforms to its stated food safety policy,

f) to demonstrate such conformity to relevant interested parties, and

g) to seek certification or registration of its food safety management system by an external organization, or

make a self-assessment or self-declaration of conformity to this International Standard.

All requirements of this International Standard are generic and are intended to be applicable to all organizations

in the food chain regardless of size and complexity. This includes organizations directly or indirectly involved in

one or more steps of the food chain. Organizations that are directly involved include, but are not limited to, feed

producers, harvesters, farmers, producers of ingredients, food manufacturers, retailers, food services, catering

services, organizations providing cleaning and sanitation services, transportation, storage and distribution

services. Other organizations that are indirectly involved include, but are not limited to, suppliers of equipment,

cleaning and sanitizing agents, packaging material, and other food contact materials.

This International Standard allows an organization, such as a small and/or less developed organization (e.g. a

small farm, a small packer-distributor, a small retail or food service outlet), to implement an externally developed

combination of control measures.

NOTE Guidance on the application of this International Standard is given in ISO/TS 22004.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced document

(including any amendments) applies.

ISO 9000:2000, Quality management systems — Fundamentals and vocabulary

©

ISO 2005 – All rights reserved 1

ISO 22000:2005(E)

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 9000 and the following apply.

For the convenience of the users of this International Standard, some of the definitions in ISO 9000 are quoted

with added notes that are applicable only to this special application.

NOTE Terms are not defined where they retain their normal dictionary definition. Where bold type is used in a definition,

this indicates a cross-reference to another term defined in this clause, and the number reference for the term is given in

parentheses.

3.1

food safety

concept that food will not cause harm to the consumer when it is prepared and/or eaten according to its

intended use

NOTE 1 Adapted from Reference [11].

NOTE 2 Food safety is related to the occurrence of food safety hazards (3.3) and does not include other human health

aspects related to, for example, malnutrition.

3.2

food chain

sequence of the stages and operations involved in the production, processing, distribution, storage and

handling of a food and its ingredients, from primary production to consumption

NOTE 1 This includes the production of feed for food-producing animals and for animals intended for food production.

NOTE 2 The food chain also includes the production of materials intended to come into contact with food or raw materials.

3.3

food safety hazard

biological, chemical or physical agent in food, or condition of food, with the potential to cause an adverse health

effect

NOTE 1 Adapted from Reference [11].

NOTE 2 The term “hazard” is not to be confused with the term “risk” which, in the context of food safety, means a function

of the probability of an adverse health effect (e.g. becoming diseased) and the severity of that effect (death, hospitalization,

absence from work, etc.) when exposed to a specified hazard. Risk is defined in ISO/IEC Guide 51 as the combination of the

probability of occurrence of harm and the severity of that harm.

NOTE 3 Food safety hazards include allergens.

NOTE 4 In the context of feed and feed ingredients, relevant food safety hazards are those that may be present in and/or

on feed and feed ingredients and that may subsequently be transferred to food through animal consumption of feed and may

thus have the potential to cause an adverse human health effect. In the context of operations other than those directly

handling feed and food (e.g. producers of packaging materials, cleaning agents, etc.), relevant food safety hazards are those

hazards that can be directly or indirectly transferred to food because of the intended use of the provided products and/or

services and thus can have the potential to cause an adverse human health effect.

3.4

food safety policy

overall intentions and direction of an organization related to food safety (3.1) as formally expressed by top

management

3.5

end product

product that will undergo no further processing or transformation by the organization

NOTE A product that undergoes further processing or transformation by another organization is an end product in the

context of the first organization and a raw material or an ingredient in the context of the second organization.

©

2 ISO 2005 – All rights reserved

ISO 22000:2005(E)

3.6

flow diagram

schematic and systematic presentation of the sequence and interactions of steps

3.7

control measure

〈food safety〉 action or activity that can be used to prevent or eliminate a food safety hazard (3.3) or reduce it

to an acceptable level

NOTE Adapted from Reference [11].

3.8

PRP

prerequisite programme

〈food safety〉 basic conditions and activities that are necessary to maintain a hygienic environment throughout

the food chain (3.2) suitable for the production, handling and provision of safe end products (3.5) and safe

food for human consumption

NOTE The PRPs needed depend on the segment of the food chain in which the organization operates and the type of

organization (see Annex C). Examples of equivalent terms are: Good Agricultural Practice (GAP), Good Veterinarian

Practice (GVP), Good Manufacturing Practice (GMP), Good Hygienic Practice (GHP), Good Production Practice (GPP),

Good Distribution Practice (GDP) and Good Trading Practice (GTP).

3.9

operational PRP

operational prerequisite programme

PRP (3.8) identified by the hazard analysis as essential in order to control the likelihood of introducing food

safety hazards (3.3) to and/or the contamination or proliferation of food safety hazards in the product(s) or in

the processing environment

3.10

CCP

critical control point

〈food safety〉 step at which control can be applied and is essential to prevent or eliminate a food safety hazard

(3.3) or reduce it to an acceptable level

NOTE Adapted from Reference [11].

3.11

critical limit

criterion which separates acceptability from unacceptability

NOTE 1 Adapted from Reference [11].

NOTE 2 Critical limits are established to determine whether a CCP (3.10) remains in control. If a critical limit is exceeded

or violated, the products affected are deemed to be potentially unsafe.

3.12

monitoring

conducting a planned sequence of observations or measurements to assess whether control measures (3.7)

are operating as intended

3.13

correction

action to eliminate a detected nonconformity

[ISO 9000:2000, definition 3.6.6]

NOTE 1 For the purposes of this International Standard, a correction relates to the handling of potentially unsafe products,

and can therefore be made in conjunction with a corrective action (3.14).

©

ISO 2005 – All rights reserved 3

ISO 22000:2005(E)

NOTE2 A correction may be, for example, reprocessing, further processing, and/or elimination of the adverse

consequences of the nonconformity (such as disposal for other use or specific labelling).

3.14

corrective action

action to eliminate the cause of a detected nonconformity or other undesirable situation

NOTE 1 There can be more than one cause for a nonconformity.

[ISO 9000:2000, definition 3.6.5]

NOTE 2 Corrective action includes cause analysis and is taken to prevent recurrence.

3.15

validation

〈food safety〉 obtaining evidence that the control measures (3.7) managed by the HACCP plan and by the

operational PRPs (3.9) are capable of being effective

NOTE This definition is based on Reference [11] and is more suitable for the field of food safety (3.1) than the definition

given in ISO 9000.

3.16

verification

confirmation, through the provision of objective evidence, that specified requirements have been fulfilled

[ISO 9000:2000, definition 3.8.4]

3.17

updating

immediate and/or planned activity to ensure application of the most recent information

4 Food safety management system

4.1 General requirements

The organization shall establish, document, implement and maintain an effective food safety management

system and update it when necessary in accordance with the requirements of this International Standard.

The organization shall define the scope of the food safety management system. The scope shall specify the

products or product categories, processes and production sites that are addressed by the food safety

management system.

The organization shall

a) ensure that food safety hazards that may be reasonably expected to occur in relation to products within the

scope of the system are identified, evaluated and controlled in such a manner that the products of the

organization do not, directly or indirectly, harm the consumer,

b) communicate appropriate information throughout the food chain regarding safety issues related to its

products,

c) communicate information concerning development, implementation and updating of the food safety

management system throughout the organization, to the extent necessary to ensure the food safety

required by this International Standard, and

d) evaluate periodically, and update when necessary, the food safety management system to ensure that the

system reflects the organization's activities and incorporates the most recent information on the food safety

hazards subject to control.

©

4 ISO 2005 – All rights reserved

ISO 22000:2005(E)

Where an organization chooses to outsource any process that may affect end product conformity, the

organization shall ensure control over such processes. Control of such outsourced processes shall be identified

and documented within the food safety management system.

4.2 Documentation requirements

4.2.1 General

The food safety management system documentation shall include

a) documented statements of a food safety policy and related objectives (see 5.2),

b) documented procedures and records required by this International Standard, and

c) documents needed by the organization to ensure the effective development, implementation and updating

of the food safety management system.

4.2.2 Control of documents

Documents required by the food safety management system shall be controlled. Records are a special type of

document and shall be controlled according to the requirements given in 4.2.3.

The controls shall ensure that all proposed changes are reviewed prior to implementation to determine their

effects on food safety and their impact on the food safety management system.

A documented procedure shall be established to define the controls needed

a) to approve documents for adequacy prior to issue,

b) to review and update documents as necessary, and re-approve documents,

c) to ensure that changes and the current revision status of documents are identified,

d) to ensure that relevant versions of applicable documents are available at points of use,

e) to ensure that documents remain legible and readily identifiable,

f) to ensure that relevant documents of external origin are identified and their distribution controlled, and

g) to prevent the unintended use of obsolete documents, and to ensure that they are suitably identified as such

if they are retained for any purpose.

4.2.3 Control of records

Records shall be established and maintained to provide evidence of conformity to requirements and evidence of

the effective operation of the food safety management system. Records shall remain legible, readily identifiable

and retrievable. A documented procedure shall be established to define the controls needed for the

identification, storage, protection, retrieval, retention time and disposition of records.

5 Management responsibility

5.1 Management commitment

Top management shall provide evidence of its commitment to the development and implementation of the food

safety management system and to continually improving its effectiveness by

a) showing food safety is supported by the business objectives of the organization,

b) communicating to the organization the importance of meeting the requirements of this International

Standard, any statutory and regulatory requirements, as well as customer requirements relating to food

safety,

©

ISO 2005 – All rights reserved 5

ISO 22000:2005(E)

c) establishing the food safety policy,

d) conducting management reviews, and

e) ensuring the availability of resources.

5.2 Food safety policy

Top management shall define, document and communicate its food safety policy.

Top management shall ensure that the food safety policy

a) is appropriate to the role of the organization in the food chain,

b) conforms with both statutory and regulatory requirements and with mutually agreed food safety

requirements of customers,

c) is communicated, implemented and maintained at all levels of the organization,

d) is reviewed for continued suitability (see 5.8),

e) adequately addresses communication (see 5.6), and

f) is supported by measurable objectives.

5.3 Food safety management system planning

Top management shall ensure that

a) planning of the food safety management system is carried out to meet requirements given in 4.1 as well as

the objectives of the organization that support food safety, and

b) the integrity of the food safety management system is maintained when changes to the food safety

management system are planned and implemented.

5.4 Responsibility and authority

Top management shall ensure that responsibilities and authorities are defined and communicated within the

organization to ensure the effective operation and maintenance of the food safety management system.

All personnel shall have responsibility to report problems with the food safety management system to identified

person(s). Designated personnel shall have defined responsibility and authority to initiate and record actions.

5.5 Food safety team leader

Top management shall appoint a food safety team leader who, irrespective of other responsibilities, shall have

the responsibility and authority

a) to manage a food safety team (see 7.3.2) and organize its work,

b) to ensure relevant training and education of the food safety team members (see 6.2.1),

c) to ensure that the food safety management system is established, implemented, maintained and updated,

and

d) to report to the organization's top management on the effectiveness and suitability of the food safety

management system.

NOTE The responsibility of the food safety team leader may include liaison with external parties on matters relating to the

food safety management system.

©

6 ISO 2005 – All rights reserved

ISO 22000:2005(E)

5.6 Communication

5.6.1 External communication

To ensure that sufficient information on issues concerning food safety is available throughout the food chain, the

organization shall establish, implement and maintain effective arrangements for communicating with

a) suppliers and contractors,

b) customers or consumers, in particular in relation to product information (including instructions regarding

intended use, specific storage requirements and, as appropriate, shelf life), enquiries, contracts or order-

handling including amendments, and customer feedback including customer complaints,

c) statutory and regulatory authorities, and

d) other organizations that have an impact on, or will be affected by, the effectiveness or updating of the food

safety management system.

Such communication shall provide information on food safety aspects of the organization's products that may be

relevant to other organizations in the food chain. This applies especially to known food safety hazards that need

to be controlled by other organizations in the food chain. Records of communications shall be maintained.

Food safety requirements from statutory and regulatory authorities and customers shall be available.

Designated personnel shall have defined responsibility and authority to communicate externally any information

concerning food safety. Information obtained through external communication shall be included as input to

system updating (see 8.5.2) and management review (see 5.8.2).

5.6.2 Internal communication

The organization shall establish, implement and maintain effective arrangements for communicating with

personnel on issues having an impact on food safety.

In order to maintain the effectiveness of the food safety management system, the organization shall ensure that

the food safety team is informed in a timely manner of changes, including but not limited to the following:

a) products or new products;

b) raw materials, ingredients and services;

c) production systems and equipment;

d) production premises, location of equipment, surrounding environment;

e) cleaning and sanitation programmes;

f) packaging, storage and distribution systems;

g) personnel qualification levels and/or allocation of responsibilities and authorizations;

h) statutory and regulatory requirements;

i) knowledge regarding food safety hazards and control measures;

j) customer, sector and other requirements that the organization observes;

k) relevant enquiries from external interested parties;

l) complaints indicating food safety hazards associated with the product;

m) other conditions that have an impact on food safety.

The food safety team shall ensure that this information is included in the updating of the food safety

management system (see 8.5.2). Top management shall ensure that relevant information is included as input to

the management review (see 5.8.2).

©

ISO 2005 – All rights reserved 7

ISO 22000:2005(E)

5.7 Emergency preparedness and response

Top management shall establish, implement and maintain procedures to manage potential emergency

situations and accidents that can impact food safety and which are relevant to the role of the organization in the

food chain.

5.8 Management review

5.8.1 General

Top management shall review the organization's food safety management system at planned intervals to ensure

its continuing suitability, adequacy and effectiveness. This review shall include assessing opportunities for

improvement and the need for change to the food safety management system, including the food safety policy.

Records of management reviews shall be maintained (see 4.2.3).

5.8.2 Review input

The input to management review shall include, but is not limited to, information on

a) follow-up actions from previous management reviews,

b) analysis of results of verification activities (see 8.4.3),

c) changing circumstances that can affect food safety (see 5.6.2),

d) emergency situations, accidents (see 5.7) and withdrawals (see 7.10.4),

e) reviewing results of system-updating activities (see 8.5.2),

f) review of communication activities, including customer feed-back (see 5.6.1), and

g) external audits or inspections.

NOTE The term “withdrawal” includes recall.

The data shall be presented in a manner that enables top management to relate the information to stated

objectives of the food safety management system.

5.8.3 Review output

The output from the management review shall include decisions and actions related to

a) assurance of food safety (see 4.1),

b) improvement of the effectiveness of the food safety management system (see 8.5),

c) resource needs (see 6.1), and

d) revisions of the organization's food safety policy and related objectives (see 5.2).

6 Resource management

6.1 Provision of resources

The organization shall provide adequate resources for the establishment, implementation, maintenance and

updating of the food safety management system.

©

8 ISO 2005 – All rights reserved

ISO 22000:2005(E)

6.2 Human resources

6.2.1 General

The food safety team and the other personnel carrying out activities having an impact on food safety shall be

competent and shall have appropriate education, training, skills and experience.

Where the assistance of external experts is required for the development, implementation, operation or

assessment of the food safety management system, records of agreement or contracts defining the

responsibility and authority of external experts shall be available.

6.2.2 Competence, awareness and training

The organization shall

a) identify the necessary competencies for personnel whose activities have an impact on food safety,

b) provide training or take other action to ensure personnel have the necessary competencies,

c) ensure that personnel responsible for monitoring, corrections and corrective actions of the food safety

management system are trained,

d) evaluate the implementation and the effectiveness of a), b) and c),

e) ensure that the personnel are aware of the relevance and importance of their individual activities in

contributing to food safety,

f) ensure that the requirement for effective communication (see 5.6) is understood by all personnel whose

activities have an impact on food safety, and

g) maintain appropriate records of training and actions described in b) and c).

6.3 Infrastructure

The organization shall provide the resources for the establishment and maintenance of the infrastructure

needed to implement the requirements of this International Standard.

6.4 Work environment

The organization shall provide the resources for the establishment, management and maintenance of the work

environment needed to implement the requirements of this International Standard.

7 Planning and realization of safe products

7.1 General

The organization shall plan and develop the processes needed for the realization of safe products.

The organization shall implement, operate and ensure the effectiveness of the planned activities and any

changes to those activities. This includes PRP(s) as well as operational PRP(s) and/or the HACCP plan.

©

ISO 2005 – All rights reserved 9

ISO 22000:2005(E)

7.2 Prerequisite programmes (PRPs)

7.2.1 The organization shall establish, implement and maintain PRP(s) to assist in controlling

a) the likelihood of introducing food safety hazards to the product through the work environment,

b) biological, chemical and physical contamination of the product(s), including cross contamination between

products, and

c) food safety hazard levels in the product and product processing environment.

7.2.2 The PRP(s) shall

a) be appropriate to the organizational needs with regard to food safety,

b) be appropriate to the size and type of the operation and the nature of the products being manufactured

and/or handled,

c) be implemented across the entire production system, either as programmes applicable in general or as

programmes applicable to a particular product or operational line, and

d) be approved by the food safety team.

The organization shall identify statutory and regulatory requirements related to the above.

7.2.3 When selecting and/or establishing PRP(s), the organization shall consider and utilize appropriate

information [e.g. statutory and regulatory requirements, customer requirements, recognized guidelines, Codex

Alimentarius Commission (Codex) principles and codes of practices, national, international or sector

standards].

NOTE Annex C gives a list of relevant Codex publications.

The organization shall consider the following when establishing these programmes:

a) construction and lay-out of buildings and associated utilities;

b) lay-out of premises, including workspace and employee facilities;

c) supplies of air, water, energy and other utilities;

d) supporting services, including waste and sewage disposal;

e) the suitability of equipment and its accessibility for cleaning, maintenance and preventative maintenance;

f) management of purchased materials (

...

SLOVENSKI SIST EN ISO 22000

STANDARD

november 2005

Sistemi vodenja varnosti živil – Zahteve za vsako organizacijo v prehranski

verigi (ISO 22000:2005)

Food safety management systems – Requirements for any organization in the

food chain (ISO 22000:2005)

Systèmes de management de la sécurité des denrées alimentaires – Exigences

pour tout organisme appartenant à la chaîne alimentaire (ISO 22000:2005)

Managementsysteme für die Lebensmittelsicherheit – Anforderungen an

Organisationen in der gesamten Lebensmittelkette (ISO 22000:2005)

Referenčna oznaka

ICS 67.020 SIST EN ISO 22000:2005 (sl, en)

Nadaljevanje na straneh II in od 1 do 61

2006-09. Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

©

SIST EN ISO 22000 : 2005

NACIONALNI UVOD

Standard SIST EN ISO 22000 (sl,en), Sistemi vodenja varnosti živil – Zahteve za vsako organizacijo v

prehranski verigi (ISO 22000:2005), 2005, ima status slovenskega standarda in je enakovreden

evropskemu standardu EN ISO 22000 (en), Food safety management systems – Requirements for

any organization in the food chain (ISO 22000:2005), 2005-09-01.

NACIONALNI PREDGOVOR

Evropski standard EN ISO 22000:2005 je pripravil tehnični odbor ISO/TC 34 Živilski proizvodi v

sodelovanju s tehničnim odborom Evropskega komiteja za standardizacijo CEN/SS C01 Živilski

proizvodi.

Slovenski standard SIST EN ISO 22000:2005 je prevod evropskega standarda EN ISO 22000:2005.

Ob sporu zaradi besedila slovenskega prevoda v tem standardu je odločilen izvirni evropski standard

v angleškem jeziku. Slovensko izdajo standarda je pripravil tehnični odbor SIST/TC KŽP Kmetijski

pridelki in živilski proizvodi.

ZVEZA S STANDARDOM

S prevzemom tega evropskega standarda veljajo za omejeni namen referenčnih standardov vsi

standardi, navedeni v izvirniku, razen tistega, ki je že sprejet v nacionalno standardizacijo:

SIST EN ISO 9000 (sl,en) Sistemi vodenja kakovosti – Osnove in slovar

OPOMBI

– Povsod, kjer se v besedilu standarda uporablja izraz »evropski standard« oziroma »mednarodni

standard«, v SIST EN ISO 22000:2005 to pomeni »slovenski standard«.

– Nacionalni uvod in nacionalni predgovor nista sestavni del standarda.

– Ta nacionalni dokument je enakovreden EN ISO 22000:2005 in je objavljen z dovoljenjem

CEN

Rue de Stassart 36

1050 Bruselj

Belgija

This national document is equivalent with EN ISO 22000:2005 and is published with the permission

of

CEN

Rue de Stassart, 36

1050 Bruxelles

Belgium

II

EVROPSKI STANDARD EN ISO 22000

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM september 2005

ICS: 67.020

Slovenska izdaja

Sistemi vodenja varnosti živil – Zahteve za vsako organizacijo v prehranski

verigi

Food safety management Systèmes de management de la Managementsysteme für die

systems – Requirements sécurité des denrées alimentaires Lebensmittelsicherheit –

for any organization in the – Exigences pour tout organisme Anforderungen an Organisationen

food chain appartenant à la chaîne in der gesamten Lebensmittelkette

(ISO 22000:2005) alimentaire (ISO 22000:2005) (ISO 22000:2005)

Ta evropski standard je CEN sprejel dne 2005-08-18.

Člani CEN morajo izpolnjevati določila notranjih predpisov CEN/CENELEC, s katerim je predpisano,

da mora biti ta standard brez kakršnihkoli sprememb sprejet kot nacionalni standard. Seznami

najnovejših izdaj teh nacionalnih standardov in njihovi bibliografski podatki so na voljo pri Centralnem

sekretariatu ali članih CEN.

Ta evropski standard obstaja v treh uradnih izdajah (angleški, francoski, nemški). Izdaje v drugih

jezikih, ki jih članice CEN na lastno odgovornost prevedejo in izdajo ter prijavijo pri Centralnem

sekretariatu CEN, veljajo kot uradne izdaje.

Člani CEN so nacionalni organi za standarde Avstrije, Belgije, Cipra, Češke republike, Danske,

Estonije, Finske, Francije, Grčije, Irske, Islandije, Italije, Latvije, Litve, Luksemburga, Madžarske,

Malte, Nemčije, Nizozemske, Norveške, Poljske, Portugalske, Slovaške, Slovenije, Španije, Švedske,

Švice in Združenega kraljestva.

CEN

Evropski komite za standardizacijo

European Committee for Standardization

Europäisches Komitee für Normung

Comité Européen de Normalisation

Centralni sekretariat: Rue de Stassart 36, B-1050 Bruselj

© 2005 CEN Lastnice avtorskih pravic so vse države članice CEN. Ref. št. EN ISO 22000:2005 E

SIST EN ISO 22000 : 2005

VSEBINA Stran CONTENTS Page

Uvod.4 Introduction.4

1 Predmet standarda. 8 1 Scope .8

2 Zveza z drugimi standardi.9 2 Normative references.9

3 Izrazi in definicije . 9 3 Terms and definitions.9

4 Sistem vodenja varnosti živil . 13 4 Food safety management system.13

4.1 Splošne zahteve.13 4.1 General requirements .13

4.2 Zahteve glede dokumentacije.14 4.2 Documentation requirements.14

5 Odgovornost vodstva.15 5 Management responsibility .15

5.1 Zavezanost vodstva. 15 5.1 Management commitment.15

5.2 Politika varnosti živil . 15 5.2 Food safety policy .15

5.3 Planiranje sistema vodenja 5.3 Food safety management system

varnosti živil . 16 planning .16

5.4 Odgovornost in pooblastila.16 5.4 Responsibility and authority .16

5.5 Vodja tima za varnost živil. 16 5.5 Food safety team leader .16

5.6 Komunikacija.17 5.6 Communication .17

5.7 Pripravljenost in odziv v kriznih 5.7 Emergency preparedness and

situacijah. 18 response.18

5.8 Vodstveni pregled. 18 5.8 Management review.18

6 Vodenje virov.19 6 Resource management.19

6.1 Priskrba virov.19 6.1 Provision of resources.19

6.2 Človeški viri . 20 6.2 Human resources.20

6.3 Infrastruktura . 20 6.3 Infrastructure .20

6.4 Delovno okolje. 21 6.4 Work environment.21

7 Planiranje in realizacija varnih proizvodov . 21 7 Planning and realization of safe products.21

7.1 Splošno.21 7.1 General.21

7.2 Prerekvizitni programi (PRP). 21 7.2 Prerequisite programmes (PRPs).21

7.3 Predhodne stopnje, ki omogočajo analizo 7.3 Preliminary steps to enable hazard

tveganja . 22 analysis.22

7.4 Analiza tveganja . 25 7.4 Hazard analysis.25

7.5 Uvedba delujočih prerekvizitnih programov 7.5 Establishing the operational

(PRP) . 28 prerequisite programmes (PRPs).28

7.6 Uvedba načrta HACCP . 28 7.6 Establishing the HACCP plan .28

7.7 Posodabljanje predhodnih informacij 7.7 Updating of preliminary information

in dokumentov, ki opisujejo PRP and documents specifying the PRPs

in načrt HACCP . 30 and the HACCP plan .30

7.8 Planiranje overjanja.30 7.8 Verification planning.30

7.9 Sistem sledljivosti . 31 7.9 Traceability system .31

7.10 Obvladovanje neskladnosti . 31 7.10 Control of nonconformity.31

8 Validacija, overjanje in izboljševanje 8 Validation, verification and improvement

sistema vodenja varnosti živil. 34 of the food safety management system.34

8.1 Splošno.34 8.1 General.34

SIST EN ISO 22000 : 2005

8.2 Validacija kombinacij kontrolnih 8.2 Validation of control measure

ukrepov . 35 combinations .35

8.3 Obvladovanje monitoringa in merjenja. 35 8.3 Control of monitoring and measuring.35

8.4 Overjanje sistema vodenja 8.4 Food safety management system

varnosti živil . 36 verification .36

8.5 Izboljševanje. 38 8.5 Improvement .38

Dodatek A (informativni): Primerjava med ISO Annex A (informative): Cross references

22000:2005 in ISO 9001:2000. 40 between ISO 22000:2005 and

ISO 9001:2000.41

Dodatek B (informativni): Primerjava med Annex B (informative): Cross references

HACCP in ISO 22000:2005 . 52 between HACCP and ISO 22000:2005.53

Dodatek C (informativni): Seznam kodeksov s Annex C (informative): Codex references

primeri kontrolnih ukrepov, prerekvizitnimi providing examples of control measures,

programi in vodili za njihovo izbiro in including prerequisite programmes and

uporabo. 57 guidance for their selection and use.57

Literatura . 61 Bibliography.61

SIST EN ISO 22000 : 2005

Predgovor Foreword

Mednarodna organizacija za standardizacijo ISO (the International Organization for

(ISO) je svetovna zveza nacionalnih organov Standardization) is a worldwide federation of

za standarde (članov ISO). Mednarodne national standards bodies (ISO member bodies).

standarde ponavadi pripravljajo tehnični odbori The work of preparing International Standards is

ISO. Vsak član, ki želi delovati na določenem normally carried out through ISO technical

področju, za katero je bil ustanovljen tehnični committees. Each member body interested in a

odbor, ima pravico biti zastopan v tem odboru. subject for which a technical committee has

Pri delu sodelujejo tudi vladne in nevladne been established has the right to be represented

mednarodne organizacije, povezane z ISO. V on that committee. International organizations,

vseh zadevah, ki so povezane s governmental and non-governmental, in liaison

standardizacijo na področju elektrotehnike, with ISO, also take part in the work. ISO

ISO tesno sodeluje z Mednarodno collaborates closely with the International

elektrotehniško komisijo (IEC). Electrotechnical Commission (IEC) on all matters

of electrotechnical standardization.

Osnutki mednarodnih standardov so International Standards are drafted in

pripravljeni v skladu s pravili, podanimi v accordance with the rules given in the ISO/IEC

drugem delu Direktiv ISO/IEC. Directives, Part 2.

Poglavitna naloga tehničnih odborov je The main task of technical committees is to

priprava mednarodnih standardov. Osnutki prepare International Standards. Draft

mednarodnih standardov, ki jih sprejmejo International Standards adopted by the technical

tehnični odbori, se pošljejo vsem članom v committees are circulated to the member bodies

glasovanje. Za objavo mednarodnega for voting. Publication as an International

standarda je treba pridobiti soglasje najmanj Standard requires approval by at least 75 % of

75 odstotkov članov, ki se udeležijo the member bodies casting a vote.

glasovanja.

Opozoriti je treba na možnost, da so nekateri Attention is drawn to the possibility that some of

elementi tega mednarodnega standarda lahko the elements of this document may be the subject

predmet patentnih pravic. ISO ne prevzema of patent rights. ISO shall not be held responsible

odgovornosti za identifikacijo katerihkoli ali vseh for identifying any or all such patent rights.

takih patentnih pravic.

ISO 22000 je pripravil tehnični odbor ISO/TC ISO 22000 was prepared by Technical

34 Živilski proizvodi. Committee ISO/TC 34, Food products.

Uvod Introduction

Varnost živil je povezana s prisotnostjo Food safety is related to the presence of food-

dejavnikov tveganja v živilih v času, ko borne hazards in food at the point of

uporabnik to živilo zaužije. Ker se dejavniki consumption (intake by the consumer). As the

tveganja lahko pojavijo na vsaki stopnji introduction of food safety hazards can occur at

prehranske verige, je slednjo treba v celoti any stage of the food chain, adequate control

ustrezno nadzirati. Varnost živil je torej throughout the food chain is essential. Thus, food

zagotovljena, če so povezana prizadevanja safety is ensured through the combined efforts of

vseh, ki sodelujejo v prehranski verigi. all the parties participating in the food chain.

V prehransko verigo so vključene Organizations within the food chain range from

najrazličnejše organizacije: proizvajalci krme in feed producers and primary producers through

primarni proizvajalci, predelovalci živil, food manufacturers, transport and storage

prevozniki in izvajalci pri skladiščenju, operators and subcontractors to retail and food

podizvajalci, trgovci, prodajalci (skupaj z service outlets (together with inter-related

drugimi vključenimi organizacijami, kot so organizations such as producers of equipment,

izdelovalci opreme, proizvajalci embalaže in packaging material, cleaning agents, additives and

pakirnih materialov, čistil, aditivov in sestavin). ingredients). Service poviders are also included.

Vključeni so tudi dobavitelji servisnih storitev.

SIST EN ISO 22000 : 2005

Ta mednarodni standard opredeljuje zahteve This International Standard specifies the

za sistem vodenja varnosti živil, ki s requirements for a food safety management

povezovanjem naslednjih splošno znanih system that combines the following generally

ključnih elementov zagotovi varnost živil v vsej recognized key elements to ensure food safety

prehranski verigi, prav do končne točke along the food chain, up to the point of final

potrošnje: consumption:

– vmesne povezave, – interactive communication;

– vodenje sistema, – system management;

– prerekvizitni programi, – prerequisite programmes;

– načela HACCP. – HACCP principles.

Povezovanje v vsej prehranski verigi je nujno za Communication along the food chain is essential to

zagotovitev, da so vsi pomembni dejavniki ensure that all relevant food safety hazards are

tveganja prepoznani in ustrezno nadzorovani identified and adequately controlled at each step

prav na vsaki stopnji prehranske verige, kar within the food chain. This implies communication

vključuje povezave navzgor in navzdol v verigi. between organizations both upstream and

Povezave med odjemalci in dobavitelji zaradi downstream in the food chain. Communication with

prepoznanih dejavnikov tveganja in kontrolnih customers and suppliers about identified hazards

ukrepov pripomorejo k jasni opredelitvi and control measures will assist in clarifying

uporabnikovih in dobaviteljevih zahtev (glede na customer and supplier requirements (e.g. with

možnost in potrebe po teh zahtevah in njihov regard to the feasibility and need for these

vpliv na končni proizvod). requirements and their impact on the end product).

Nujno je tudi prepoznavanje vloge in položaja Recognition of the organization's role and

organizacije v prehranski verigi, saj lahko position within the food chain is essential to

omogoči uspešne medsebojne povezave v ensure effective interactive communication

vsej verigi, da so končnemu uporabniku throughout the chain in order to deliver safe food

dobavljeni varni živilski proizvodi. Na sliki 1 je products to the final consumer. An example of

prikazan primer komunikacijskih povezav med the communication channels among interested

zainteresiranimi v prehranski verigi. parties of the food chain is shown in Figure 1.

Najuspešnejši sistemi varnosti živil so The most effective food safety systems are

vzpostavljeni, delujejo in se posodabljajo v established, operated and updated within the

okviru strukturiranega sistema vodenja ter so framework of a structured management system

vključeni v najširše vodstvene aktivnosti v and incorporated into the overall management

organizaciji. To zagotavlja organizacijam in activities of the organization. This provides

zainteresiranim udeležencem največjo korist. maximum benefit for the organization and

Ta mednarodni standard je usklajen z ISO 9001 interested parties. This International Standard

prav zato, da se poveča vzajemno delovanje has been aligned with ISO 9001 in order to

obeh standardov. Navzkrižni prikaz zahtev enhance the compatibility of the two standards.

tega mednarodnega standarda in ISO 9001 je Cross-references between this International

naveden v dodatku A. Standard and ISO 9001 are provided in Annex A.

Ta mednarodni standard se lahko uporablja This International Standard can be applied inde-

neodvisno od drugih standardov vodenja. pendently of other management system standards.

Njegovo izvajanje lahko poteka vzporedno ali Its implementation can be aligned or integrated

pa tako, da je vključen v že obstoječe zahteve with existing related management system

za vodenje. Organizacije pa lahko uporabijo requirements, while organizations may utilize

obstoječe sisteme vodenja, da vzpostavijo existing management system(s) to establish a food

sistem vodenja varnosti živil, ki je skladen z safety management system that complies with the

zahtevami tega mednarodnega standarda. requirements of this International Standard.

Ta mednarodni standard povezuje načela This International Standard integrates the

sistema analize tveganja in kritičnih kontrolnih principles of the Hazard Analysis and Critical

točk (HACCP) in uporabo stopenj, ki jih je Control Point (HACCP) system and application

razvila komisija Codex Alimentarius steps developed by the Codex Alimentarius

SIST EN ISO 22000 : 2005

Commission. S pomočjo zahtev presoje Commission. By means of auditable requirements,

povezuje načrt HACCP s prerekvizitnimi it combines the HACCP plan with prerequisite

programi. Analiza tveganja je ključ do programmes (PRPs). Hazard analysis is the key to

uspešnega sistema vodenja varnosti živil, saj an effective food safety management system,

prav izvedba analize tveganja pomaga pri since conducting a hazard analysis assists in

organiziranju znanja, potrebnega za organizing the knowledge required to establish an

vzpostavitev uspešne kombinacije kontrolnih effective combination of control measures. This

ukrepov. Ta mednarodni standard zahteva, da International Standard requires that all hazards

so prepoznani in določeni vsi dejavniki tveganja, that may be reasonably expected to occur in the

katerih pojav se v prehranski verigi upravičeno food chain, including hazards that may be

pričakuje, vključno s tistimi, ko so lahko associated with the type of process and facilities

povezani z vrsto procesa ali prostori. Na ta način used, are identified and assessed. Thus it provides

zagotavlja orodje, s katerim se določiin the means to determine and document why certain

dokumentira, zakaj mora organizacija nekatere identified hazards need to be controlled by a

prepoznane dejavnike tveganja nadzorovati, particular organization and why others need not.

drugih pa ne.

Proizvajalci pesticidov, gnojil,

Pridelovalci

veterinarskih zdravil

Crop producers

Producers of pesticides, fertilizers,

and veterinary drugs

Proizvajalci krmil

Proizvajalci aditivov in drugih

Feed producers

dodatkov

Food chain for the production of

ingredients and additives

Primarni proizvajalci

Primary food producers

Izvajalci prevoznih in skladiščnih

storitev

Transport and storage operators

Predelava, proizvodnja

Food manufacturers

Proizvajalci opreme

Producers of equipment

Sekundarna predelava

Secondary food manufacturers

Proizvajalci sredstev za čiščenje

in razkuževanje

Producers of cleaning and

Veletrgovci

sanitizing agents

Wholesalers

Proizvajalci embalaže

Producers of packaging materials

Trgovine, gostinstvo, catering

Retailers, food service operators and

Dobavitelji servisnih storitev

caterers

Service providers

Potrošniki

Consumers

OPOMBA: Slika ne prikazuje medsebojnih komunikacij NOTE The figure does not show the type of interactive

vzdolž in križem prehranske verige, ki obide communications along and across the food chain that

neposredne dobavitelje in potrošnike. by-pass immediate suppliers and customers.

Slika 1: Primer komunikacije znotraj prehranske verige

Figure 1 – Example of communication within the food chain

Zakonski in regulativni organi

Statutory and regulatory authorities

SIST EN ISO 22000 : 2005

Med analizo tveganja organizacija določi During hazard analysis, the organization

strategijo, ki jo mora izvajati, da s kombinacijo determines the strategy to be used to ensure

prerekvizitnih programov, delujočih hazard control by combining the PRP(s),

prerekvizitnih programov in načrtom HACCP operational PRP(s) and the HACCP plan.

zagotovi nadzor nad dejavniki tveganja.

Povezave med načeli HACCP komisije Codex Cross-references between the Codex Alimentarius

Alimentarius in aplikacijskimi koraki (glej Commission HACCP principles and application

referenco 11) ter tem mednarodnim steps (see Reference [11]) and this International

standardom so opredeljene v dodatku B. Standard are provided in Annex B.

Za lažjo uporabo je ta mednarodni standard To facilitate the application of this International

pripravljen kot standard za presojo. Vendar pa Standard, it has been developed as an auditable

se posamezne organizacije svobodno odločajo standard. However, individual organizations are

o potrebnih metodah in pristopih za izpolnitev free to choose the necessary methods and

zahtev tega mednarodnega standarda. Napotki approaches to fulfil the requirements of this

za pomoč posameznim organizacijam pri International Standard. To assist individual

izvajanju tega mednarodnega standarda in za organizations with the implementation of this

njegovo uporabo so opredeljeni v ISO/TS International Standard, guidance on its use is

22004. provided in ISO/TS 22004.

Ta mednarodni standard se nanaša samo na This International Standard is intended to address

tiste vidike, ki zadevajo varnost živil. A enak aspects of food safety concerns only. The same

pristop, kot je določen s tem mednarodnim approach as provided by this International

standardom, se lahko uporabi pri oblikovanju Standard can be used to organize and respond to

in odzivanju na druge specifične vidike glede other food specific aspects (e.g. ethical issues and

živil (npr. etični vidik in zavedanje potrošnika). consumer awareness).