EN 12042:2014

(Main)Food processing machinery - Automatic dough dividers - Safety and hygiene requirements

Food processing machinery - Automatic dough dividers - Safety and hygiene requirements

1.1 This European Standard applies to the design and manufacture of standalone automatic dough dividers, having a feed hopper, an outlet and a dividing system (see 3.2).

These automatic dough dividers are used separately or in a line in the food industry and shops (pastry-making, bakeries, confectionery, etc.) for dividing dough or pastry into adjustable portions to produce the required weight of dough piece during a dividing process. These machines can be fed by hand or mechanically.

This European Standard deals with all significant hazards, hazardous situations and events relevant to the transport, installation, adjustment, operation, cleaning, maintenance, dismantling, disassembling and scrapping of automatic dough dividers, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4).

These machines are not intended to be cleaned with pressurised water.

1.2 This European Standard is not applicable to the following:

- experimental and testing machines, under development by the manufacturer;

- weighing devices;

- pressure dough dividers, without a feed hopper, using knives for the dividing process;

- lines with separate cutting or forming elements outside the housing;

- lifting and tilting machines ) or other separate feeding machines;

- additional hazards generated when the machine is used in a line or mechanically feed.

1.3 A noise test code is included in Annex A to assist manufacturers to measure noise levels for the purpose of the noise emission declaration.

1.4 This European Standard is not applicable to machines which are manufactured before its publication as EN.

Nahrungsmittelmaschinen - Teigteilmaschinen - Sicherheits- und Hygieneanforderungen

1.1 Diese Europäische Norm gilt für die Gestaltung/Konstruktion und Herstellung von autarken Teigteilmaschinen, die einen Einfülltrichter, einen Austrag und ein Teigteilungssystem (siehe 3.2) haben.

Diese Teigteilmaschinen werden, einzeln oder in einer Prozesslinie angeordnet, in der Nahrungsmittel-industrie und in Geschäften (Konditoreien, Bäckereien, Confiserien usw.) für das Teilen von Teig oder Blätterteig in einstellbare Portionen verwendet, um das gewünschte Gewicht der Teigportion beim Teilvorgang zu erzielen. Diese Maschinen werden automatisch oder von Hand beschickt.

Diese Europäische Norm behandelt alle signifikanten Gefährdungen, Gefährdungssituationen und Gefährdungsereignisse, die während Transport, Installation, Einstellarbeiten, Betrieb, Reinigung, Wartung, Zerlegung, Außerbetriebnahme und Demontage von Teigteilmaschinen auftreten können, wenn sie bestimmungsgemäß und unter Bedingungen von durch den Hersteller vernünftigerweise vorhersehbaren Fehlanwendungen verwendet werden (siehe Abschnitt 4).

Diese Maschinen sind nicht für eine Reinigung mit Druckwasser vorgesehen.

1.2 Diese Europäische Norm gilt nicht für Folgendes:

- Versuchs- und Prüfmaschinen, die in der Entwicklung beim Hersteller sind;

- Wägeeinrichtungen;

- Teigpressen ohne Einfülltrichter, die Messer für den Teilvorgang verwenden;

- Prozesslinien mit getrennten Schneid- und Formelementen außerhalb des Gehäuses;

- Hub- und Kippeinrichtungen1

- zusätzliche Gefährdungen, die bei der Anordnung der Maschine in einer Prozesslinie oder bei der mechanischen Beschickung entstehen. ) oder andere separate Zuführeinrichtungen;

1.3 Im Anhang A befindet sich zur Deklaration der Geräuschemission ein Verfahren zur Geräuschmessung als Hilfestellung für den Hersteller zur Geräuschmessung.

1.4 Diese Europäische Norm gilt nicht für Maschinen, die vor deren Veröffentlichung als EN gebaut wurden.

Machines pour les produits alimentaires - Diviseuses automatiques - Prescriptions relatives à la sécurité et à l'hygiène

1.1 La présente Norme européenne s'applique à la conception et à la fabrication de diviseuses automatiques autonomes, possédant une trémie d’alimentation, une sortie et un bâti compacte (voir 3.2).

Ces diviseuses automatiques sont utilisées individuellement ou dans une ligne de production dans l'industrie alimentaire et les commerces de l'alimentation (pâtisseries, boulangeries, confiseries, etc.) pour diviser la pâte ou la pâtisserie en portions ajustables afin de produire des pâtons d’un poids déterminé pendant le procédé de division. Ces machines peuvent être alimentées à la main ou mécaniquement.

La présente Norme européenne spécifie tous les phénomènes dangereux, situations et événements dangereux significatifs relatifs au transport, à l’installation, au réglage, au fonctionnement, au nettoyage, à la maintenance, au démontage, à la mise hors service et à la mise au rebut des diviseuses automatiques lorsqu’elles sont utilisées normalement et dans des conditions de mauvaise utilisation raisonnablement prévisibles par le fabricant (voir Article 4).

Ces machines ne sont pas destinées à être nettoyées avec de l’eau sous pression.

1.2 La présente Norme européenne ne s’applique pas aux machines suivantes :

- les machines expérimentales et d'essais, en cours de mise au point par le fabricant ;

- les dispositifs de pesée ;

- les diviseuses à pression, sans trémie d’alimentation, utilisant des couteaux pour le procédé de division ;

- lignes avec les éléments de découpe ou de mise en forme à l’extérieur du bâti ;

- les élévateurs/basculeurs ) ou autres machines à alimentation séparée ;

- aux phénomènes dangereux supplémentaires engendrés lorsque la machine est utilisée dans une ligne de production ou alimentée mécaniquement.

1.3 Un code d’essai acoustique est inclus dans l’Annexe A pour aider les fabricants à mesurer les niveaux de bruit en vue d’une déclaration d'émission sonore.

1.4 La présente Norme européenne ne s’applique pas aux machines qui ont été fabriquées avant sa date de publication sous forme de norme européenne.

Stroji za predelavo hrane - Avtomatski delilniki testa - Varnostne in higienske zahteve

Standard EN 12042 velja za načrtovanje in proizvodnjo samostojnih avtomatskih delilnikov testa, ki imajo lijak, izpust in sistem za deljenje testa (glej 3.2). Avtomatski delilniki testa se uporabljajo samostojno ali v okviru proizvodne linije v prehrambeni industriji in trgovinah (slaščičarne, pekarne, izdelava sladkornih izdelkov itd.) za deljenje testa ali peciva na kose, primerne za kasnejšo obdelavo, za zagotovitev zahtevane teže kosa testa med delilnim procesom. Stroje se lahko polni ročno ali mehansko. Ta evropski standard opisuje vsa večja tveganja, nevarne situacije in dogodke v zvezi s prevozom, namestitvijo, prilagoditvijo, delovanjem, čiščenjem, razstavljanjem in uničenjem avtomatskih delilnikov testa, kadar se uporabljajo v skladu z njihovim namenom in pod pogoji pričakovane nepravilne uporabe, ki jih določa proizvajalec (glej točko 4). Ti stroji se ne čistijo z vodo pod pritiskom. Ti stroji se ne čistijo z vodo pod pritiskom. Ta evropski standard se ne uporablja za: - eksperimentalne in preskusne stroje, ki jih razvija proizvajalec; - naprave za tehtanje; - delilnike testa, ki delujejo na pritisk, nimajo lijaka in za deljenje testa uporabljajo nože; - proizvodne linije z ločenimi elementi za rezanje in oblikovanje testa zunaj ohišja; - naprave za dvigovanje in nagibanje1) ali druge ločene naprave za polnjenje; - dodatna tveganja, ki nastanejo, ko se stroj uporablja v okviru proizvodne linije ali ko se polni mehansko. Oznaka preskusa hrupa je vključena v dodatku A za pomoč proizvajalcem pri meritvah nivoja hrupa za namene deklaracije o emisijah hrupa. Ta evropski standard se ne uporablja za stroje, ki so bili proizvedeni pred objavo tega dokumenta kot evropskega standarda.

General Information

- Status

- Withdrawn

- Publication Date

- 01-Apr-2014

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 153 - Food processing machinery - Safety and hygiene specifications

- Drafting Committee

- CEN/TC 153/WG 1 - Bakery equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 16-Sep-2020

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 17-Jul-2010

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 1672-2:2005+A1:2009 - Food processing machinery - Basic concepts - Part 2: Hygiene requirements - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 12042:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Food processing machinery - Automatic dough dividers - Safety and hygiene requirements". This standard covers: 1.1 This European Standard applies to the design and manufacture of standalone automatic dough dividers, having a feed hopper, an outlet and a dividing system (see 3.2). These automatic dough dividers are used separately or in a line in the food industry and shops (pastry-making, bakeries, confectionery, etc.) for dividing dough or pastry into adjustable portions to produce the required weight of dough piece during a dividing process. These machines can be fed by hand or mechanically. This European Standard deals with all significant hazards, hazardous situations and events relevant to the transport, installation, adjustment, operation, cleaning, maintenance, dismantling, disassembling and scrapping of automatic dough dividers, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). These machines are not intended to be cleaned with pressurised water. 1.2 This European Standard is not applicable to the following: - experimental and testing machines, under development by the manufacturer; - weighing devices; - pressure dough dividers, without a feed hopper, using knives for the dividing process; - lines with separate cutting or forming elements outside the housing; - lifting and tilting machines ) or other separate feeding machines; - additional hazards generated when the machine is used in a line or mechanically feed. 1.3 A noise test code is included in Annex A to assist manufacturers to measure noise levels for the purpose of the noise emission declaration. 1.4 This European Standard is not applicable to machines which are manufactured before its publication as EN.

1.1 This European Standard applies to the design and manufacture of standalone automatic dough dividers, having a feed hopper, an outlet and a dividing system (see 3.2). These automatic dough dividers are used separately or in a line in the food industry and shops (pastry-making, bakeries, confectionery, etc.) for dividing dough or pastry into adjustable portions to produce the required weight of dough piece during a dividing process. These machines can be fed by hand or mechanically. This European Standard deals with all significant hazards, hazardous situations and events relevant to the transport, installation, adjustment, operation, cleaning, maintenance, dismantling, disassembling and scrapping of automatic dough dividers, when they are used as intended and under conditions of misuse which are reasonably foreseeable by the manufacturer (see Clause 4). These machines are not intended to be cleaned with pressurised water. 1.2 This European Standard is not applicable to the following: - experimental and testing machines, under development by the manufacturer; - weighing devices; - pressure dough dividers, without a feed hopper, using knives for the dividing process; - lines with separate cutting or forming elements outside the housing; - lifting and tilting machines ) or other separate feeding machines; - additional hazards generated when the machine is used in a line or mechanically feed. 1.3 A noise test code is included in Annex A to assist manufacturers to measure noise levels for the purpose of the noise emission declaration. 1.4 This European Standard is not applicable to machines which are manufactured before its publication as EN.

EN 12042:2014 is classified under the following ICS (International Classification for Standards) categories: 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12042:2014 has the following relationships with other standards: It is inter standard links to EN 12042:2005+A1:2010, EN 12042:2014+A1:2020, EN 60529:1991, EN 61310-1:2008, EN 1672-2:2005+A1:2009, EN 1088:1995+A2:2008, EN 619:2002+A1:2010, EN 1037:1995+A1:2008, EN ISO 13856-2:2013, EN ISO 4414:2010, EN ISO 3744:2010, EN 894-4:2010, EN ISO 4413:2010, EN ISO 13855:2010, EN 2286:1989. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12042:2014 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC; Standardization Mandates: M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12042:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stroji za predelavo hrane - Avtomatski delilniki testa - Varnostne in higienske zahteveNahrungsmittelmaschinen - Teigteilmaschinen - Sicherheits- und HygieneanforderungenMachines pour les produits alimentaires - Diviseuses automatiques - Prescriptions relatives à la sécurité et à l'hygièneFood processing machinery - Automatic dough dividers - Safety and hygiene requirements67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industryICS:Ta slovenski standard je istoveten z:EN 12042:2014SIST EN 12042:2014en,de01-junij-2014SIST EN 12042:2014SLOVENSKI

STANDARDSIST EN 12042:2006+A1:20101DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12042

April 2014 ICS 67.260 Supersedes EN 12042:2005+A1:2010English Version

Food processing machinery - Automatic dough dividers - Safety and hygiene requirements

Machines pour les produits alimentaires - Diviseuses automatiques - Prescriptions relatives à la sécurité et à l'hygiène

Nahrungsmittelmaschinen - Teigteilmaschinen - Sicherheits- und Hygieneanforderungen This European Standard was approved by CEN on 27 December 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12042:2014 ESIST EN 12042:2014

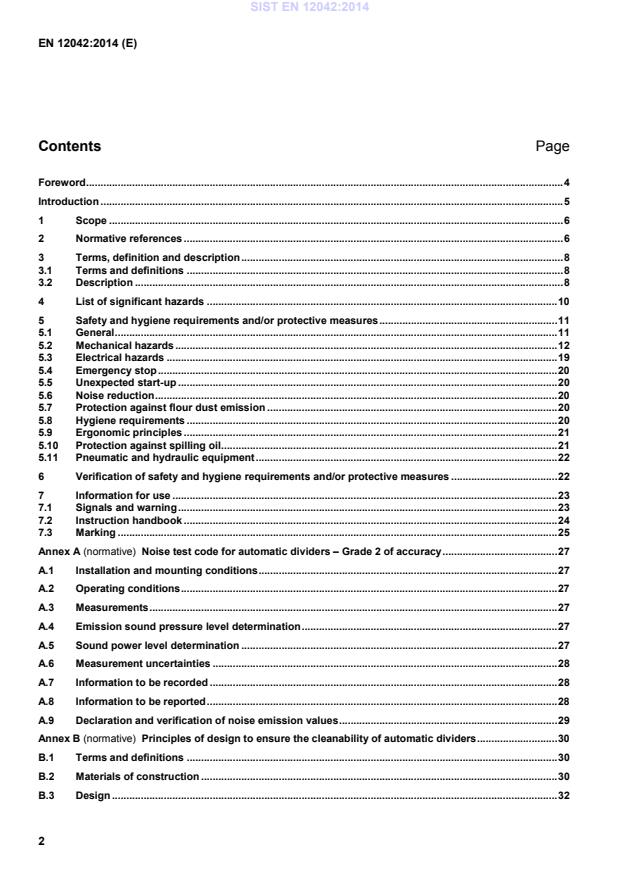

Noise test code for automatic dividers – Grade 2 of accuracy . 27 A.1 Installation and mounting conditions . 27 A.2 Operating conditions . 27 A.3 Measurements . 27 A.4 Emission sound pressure level determination . 27 A.5 Sound power level determination . 27 A.6 Measurement uncertainties . 28 A.7 Information to be recorded . 28 A.8 Information to be reported . 28 A.9 Declaration and verification of noise emission values . 29 Annex B (normative)

Principles of design to ensure the cleanability of automatic dividers . 30 B.1 Terms and definitions . 30 B.2 Materials of construction . 30 B.3 Design . 32 SIST EN 12042:2014

Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC . 47 Bibliography . 48

1) see EN 13288 SIST EN 12042:2014

Figure 1 — Main parts of an automatic dough divider

Key 1 star rollers 2 feeding assistance device (rollers) Figure 2 — Example of a hopper equipped with a feeding assistance device and star rollers SIST EN 12042:2014

Key 1 zone 1 2 zone 2 3 zone 3 4 zone 4 5 zone 5 Figure 3 — Danger zones associated with mechanical hazards 5 Safety and hygiene requirements and/or protective measures 5.1 General Machinery shall comply with the safety requirements and/or protective measures of this clause. In addition, the machine shall be designed according to the principles of EN ISO 12100:2010 for relevant but not significant hazards, which are not dealt with by this document. Fixing systems of fixed guards or of parts of the machine acting as such shall remain attached to the guards or to the machinery when the guards are removed. SIST EN 12042:2014

With D ≥ 550 mm E+F ≥ 850 mm F ≥ 200 mm G ≤ 50 mm Key 1 pressure sensitive edge or AOPD 2 danger zone 3 distance bar D vertical distance between the upper edge of the hopper and the cutting/crushing zone E minimum distance from the edge of the hopper to the danger zone F minimum horizontal distance G maximum height between the edge of the hopper and the distance bar Figure 4 — Example of a hopper equipped with a pressure sensitive edge or AOPD SIST EN 12042:2014

NOTE Dimensions of a, b and c are given in EN ISO 13857:2008, Table 2. Key 1 danger zone a height of danger zone b height of protective structure c horizontal distance to danger zone Figure 5 — Example of a divider equipped with a swan neck hopper 5.2.2.2.5 Interlocked guard If an interlocked guard is used at the top of the hopper the following requirements apply: — if the stopping time is less than or equal to 0,35 s, the distance between the edge of the hopper and the hazard zone shall be more than or equal to 550 mm, or — if the stopping time is more than 0,35 s, the distance between the edge of the hopper and the hazard zone shall be more than or equal to 850 mm, and the guard shall be interlocked with guard locking. The interlocking device shall be activated before the opening gap between the fixed and the movable parts exceeds 25 mm; If the guard is a grid, EN ISO 13857:2008, Table 4, shall apply. 5.2.2.2.6 Cleaning of the hopper If for cleaning reasons (e.g. scraping off the dough), it is necessary to access inside the hopper, one of the following solutions shall apply to stop the machine: SIST EN 12042:2014

Key 1 hopper 2 danger zone Figure 6 — Feeding assistance device — Safety distances 5.2.3 Zone 2: Access to the dividing mechanism and other moving parts via the discharge opening In principle, there is no significant hazard at the discharge side of a drum and piston type dividing mechanism. When a cutting/shearing zone is close to the discharge opening, access to the hazard zone shall be prevented by: — either a fixed guard with opening according to the EN ISO 13857:2008, Table 4; or — movable interlocking guard in accordance with EN ISO 13857:2008, Table 4; or — distance guard in accordance with EN ISO 13857:2008, Table 2. SIST EN 12042:2014

Key 1 discharge belt 2 roller 3 in-running nip Figure 7 — In-running nip on a discharge belt 5.2.5 Zone 4: Drive mechanisms and other moving internal components Access to the drive mechanism and other moving internal components including the dividing mechanisms, and the moulding/rounding device if relevant, from other sides than the discharge opening of the machine shall be prevented. This may be achieved by use of fixed guards complying with EN 953:1997+A1:2009 and where guards have to be removed daily or more regularly for cleaning or maintenance by movable interlocking guards. If the stopping time of the drive mechanism or other moving internal components is more than 1 s, the movable guard shall be interlocked with guard locking. 5.2.6 Zone 5: Flour duster If there are mechanical risks, the flour containers shall be fitted with a fixed or interlocked guard with dimensions according to EN ISO 13857:2008, Table 4, acting on the flour feed system. If the stopping time of the flour duster is more than 1 s, the movable guard shall be interlocked with guard locking. SIST EN 12042:2014

Key

food area

splash area

non-food area Figure 8 — Hygiene areas 5.9 Ergonomic principles For hand-fed machines the manufacturer shall pay particular attention to the ergonomic aspects of the loading of the dough and define procedures for facilitating the loading. Awkward body postures (e.g. hand feeding at a height more than 1,6 m, cleaning a hopper deeper than 850 mm) during maintenance and cleaning as well as filling and emptying the dividers or other operations, shall be avoided (e.g. platform, tilting hopper, etc.). For hand-fed machines where the upper rim of the feeding hopper is at a height of 1,6 m or more a working platform according to 5.2.2.1 shall be provided. Control devices shall be placed within proper reach distance for the operator as stated in EN 894-4:2010, Annex A. 5.10 Protection against spilling oil The divider oil reservoir shall be constructed and positioned so that it can be filled easily, minimizing the risk of spilling oil. The manufacturer shall provide means to collect divider oil, so that it does not spill on the floor e.g. catch trays. SIST EN 12042:2014

Relevant clause Safety and hygiene requirements and/or measures Method of verification 5.2.1 General By visual inspection

By analysis or calculation (see EN ISO 13849-2) 5.2.2 Zone 1 Access to the dividing zone or feeding assistance device via the hopper By functional test

By measurement of the safety distances

By calculation

5.2.2.2.2 Pressure sensitive edge By functional test

By measurement of the safety distances

5.2.2.2.3 AOPD By functional test

By measurement of the safety distances

5.2.2.2.4 Swan neck hopper By measurement of the safety distances

5.2.2.2.5 Interlocked guard By functional test

By measurement of the stopping time

5.2.2.2.6 Cleaning of the hopper By visual inspection

By measurement of the stopping time 5.2.2.2.7 Feeding assistance device inside the hopper By visual inspection and measurement

5.2.3 Zone 2 Access to the dividing mechanisms and other moving parts via the discharge opening By visual inspection and measurement

5.2.4 Zone 3 discharge belt By visual inspection and measurement

5.2.5 Zone 4 drive mechanisms and other moving internal components By functional test

By measurement of the safety distances 5.2.7 Loss of stability For free standing machines, when the machine is tilted 10°, it shall remain stable

5.3 Electrical hazards Verification shall be in accordance with Clause 18 of

EN 60204–1:2006

5.4 Emergency stop By inspection

5.5 Unexpected start-up By visual inspection

5.6 Noise reduction and noise declaration By measurement according to Annex A

5.7 Protection against flour dust emission By inspection and measurement

5.8 Hygiene requirements In accordance with Clause 6 of EN 1672–2:2005+A1:2009 and Annex B

5.9 Ergonomic principles By measurement (forces, height of the hopper, height for the hand loading), by inspection of the visibility of the indications, operational control devices, etc.

5.10 Protection against spilling oil By inspection

5.11 Pneumatic and hydraulic equipment By inspection and testing.

7 Information for use 7.1 Signals and warning The following warning signs shall be placed on the automatic dividers attached to the hopper, warning the shearing hazard at the dividing device at the base of the hopper, with appropriate dimensions according to EN 61310-1. Warning signs (see an example at Figure 9) shall be attached close to the bottom of the hopper and close to the guard on the hopper to warn of the danger points inside the machine.

Figure 9 — Example of warning sign SIST EN 12042:2014

— the A-weighted sound power level emitted by the machinery, where the A-weighted emission sound pressure level at workstations exceeds 80 dB(A). Whenever sound emission values are indicated the uncertainties “K” surrounding these values shall be specified. The operating conditions of the machinery during measurement and the measuring methods used shall be described. — the instructions shall advise the user of the hazard of oil spilt to the floor and the importance of cleaning up oil spills immediately they occur. The instructions shall indicate the most appropriate way of filling the oil reservoir and collecting oil to minimize the risk of spilled oil. SIST EN 12042:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...