CEN/TS 15427-2-2:2021

(Main)Railway applications - Wheel/Rail friction management - Part 2-2: Properties and Characteristics - Top of Rail materials

Railway applications - Wheel/Rail friction management - Part 2-2: Properties and Characteristics - Top of Rail materials

This document specifies the requirements of materials intended to be applied to the interface between the wheel tread and the rail crown (active interface). It can be applied either directly or indirectly to the wheel tread or rail.

It outlines the information required for most approval procedures, the method of testing and routine control/monitoring of the material.

This document does not deal with adhesion materials, for example:

- sand;

- adhesion enhancers.

Bahnanwendungen - Reibungsmanagement zwischen Rad und Schiene - Teil 2-2: Eigenschaften und Merkmale - Kraftschlussmodifikatoren

Dieses Dokument legt die Anforderungen an Materialien für die Anwendung auf der Kontaktfläche zwischen der Radlauffläche und der Fahrfläche der Schiene (aktive Kontaktfläche) fest. Sie kann direkt oder indirekt auf die Radlauffläche oder die Schiene angewendet werden.

Es beschreibt die erforderlichen Informationen für die meisten Genehmigungsverfahren, das Prüfverfahren und die regelmäßige Kontrolle/Überwachung des Materials.

Dieses Dokument behandelt keine kraftschlusserhöhenden Materialien wie etwa:

- Sand;

- Haftverstärker.

Applications ferroviaires - Gestion des frottements roue/rail - Partie 2-2 : Propriétés et caractéristiques - Lubrifiants de tête de rail

Le présent document spécifie les exigences applicables aux lubrifiants destinés à être appliqués sur l'interface entre la bande de roulement de la roue et la tête de rail (interface active). Ils peuvent être appliqués directement ou indirectement, sur la bande de roulement ou sur le rail.

Il précise également les informations nécessaires à la plupart des procédures de validation, la méthode d'essai et les tâches de contrôle/surveillance de routine du lubrifiant.

Le présent document n'aborde pas les matériaux assurant l'adhérence, notamment :

- le sable ;

- les amplificateurs d'adhérence.

Železniške naprave - Trenje na stiku kolo-tirnica - 2-2. del: Lastnosti in karakteristike - Materiali za zgornjo površino tirnic

General Information

- Status

- Withdrawn

- Publication Date

- 19-Jan-2021

- Withdrawal Date

- 13-Apr-2025

- Technical Committee

- CEN/TC 256 - Railway applications

- Drafting Committee

- CEN/TC 256/SC 2/WG 38 - Flange lubrication

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Oct-2023

- Completion Date

- 14-Apr-2025

Relations

- Effective Date

- 19-Jan-2023

Frequently Asked Questions

CEN/TS 15427-2-2:2021 is a technical specification published by the European Committee for Standardization (CEN). Its full title is "Railway applications - Wheel/Rail friction management - Part 2-2: Properties and Characteristics - Top of Rail materials". This standard covers: This document specifies the requirements of materials intended to be applied to the interface between the wheel tread and the rail crown (active interface). It can be applied either directly or indirectly to the wheel tread or rail. It outlines the information required for most approval procedures, the method of testing and routine control/monitoring of the material. This document does not deal with adhesion materials, for example: - sand; - adhesion enhancers.

This document specifies the requirements of materials intended to be applied to the interface between the wheel tread and the rail crown (active interface). It can be applied either directly or indirectly to the wheel tread or rail. It outlines the information required for most approval procedures, the method of testing and routine control/monitoring of the material. This document does not deal with adhesion materials, for example: - sand; - adhesion enhancers.

CEN/TS 15427-2-2:2021 is classified under the following ICS (International Classification for Standards) categories: 45.080 - Rails and railway components; 45.120 - Equipment for railway/cableway construction and maintenance. The ICS classification helps identify the subject area and facilitates finding related standards.

CEN/TS 15427-2-2:2021 has the following relationships with other standards: It is inter standard links to CEN/TS 15427-2-2:2023. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

CEN/TS 15427-2-2:2021 is associated with the following European legislation: EU Directives/Regulations: 2008/57/EC; Standardization Mandates: M/483. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase CEN/TS 15427-2-2:2021 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2021

Železniške naprave - Trenje na stiku kolo-tirnica - 2-2. del: Lastnosti in

karakteristike - Materiali za zgornjo površino tirnic

Railway applications - Wheel/Rail friction management - Part 2-2: Properties and

Characteristics - Top of Rail materials

Bahnanwendungen - Reibungsmanagement zwischen Rad und Schiene - Teil 2-2:

Eigenschaften und Merkmale - Behandlung der Schienenoberfläche

Applications ferroviaires - Gestion de la friction rail/roue - Partie 2-2 : Propriétés et

caractéristiques - Matériaux de la surface du rail

Ta slovenski standard je istoveten z: CEN/TS 15427-2-2:2021

ICS:

45.040 Materiali in deli za železniško Materials and components

tehniko for railway engineering

45.080 Tračnice in železniški deli Rails and railway

components

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

CEN/TS 15427-2-2

TECHNICAL SPECIFICATION

SPÉCIFICATION TECHNIQUE

January 2021

TECHNISCHE SPEZIFIKATION

ICS 45.080; 45.120

English Version

Railway applications - Wheel/Rail friction management -

Part 2-2: Properties and Characteristics - Top of Rail

materials

Applications ferroviaires - Gestion des frottements Bahnanwendungen - Reibungsmanagement zwischen

roue/rail - Partie 2-2 : Propriétés et caractéristiques - Rad und Schiene - Teil 2-2: Eigenschaften und

Lubrifiants de tête de rail Merkmale - Behandlung der Schienenoberfläche

This Technical Specification (CEN/TS) was approved by CEN on 23 November 2020 for provisional application.

The period of validity of this CEN/TS is limited initially to three years. After two years the members of CEN will be requested to

submit their comments, particularly on the question whether the CEN/TS can be converted into a European Standard.

CEN members are required to announce the existence of this CEN/TS in the same way as for an EN and to make the CEN/TS

available promptly at national level in an appropriate form. It is permissible to keep conflicting national standards in force (in

parallel to the CEN/TS) until the final decision about the possible conversion of the CEN/TS into an EN is reached.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2021 CEN All rights of exploitation in any form and by any means reserved Ref. No. CEN/TS 15427-2-2:2021 E

worldwide for CEN national Members.

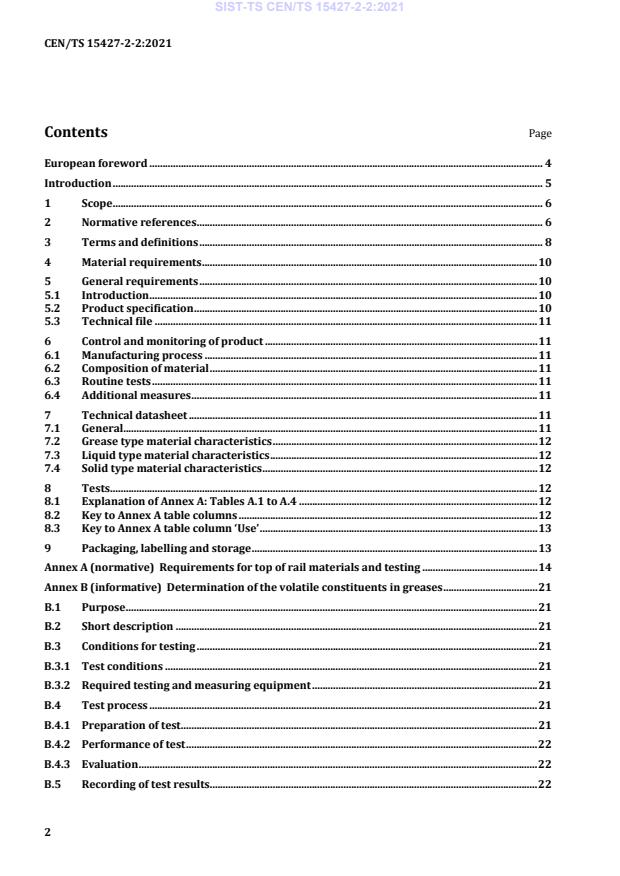

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 8

4 Material requirements . 10

5 General requirements . 10

5.1 Introduction . 10

5.2 Product specification . 10

5.3 Technical file . 11

6 Control and monitoring of product . 11

6.1 Manufacturing process . 11

6.2 Composition of material . 11

6.3 Routine tests . 11

6.4 Additional measures . 11

7 Technical datasheet . 11

7.1 General. 11

7.2 Grease type material characteristics . 12

7.3 Liquid type material characteristics . 12

7.4 Solid type material characteristics . 12

8 Tests . 12

8.1 Explanation of Annex A: Tables A.1 to A.4 . 12

8.2 Key to Annex A table columns . 12

8.3 Key to Annex A table column ‘Use’ . 13

9 Packaging, labelling and storage . 13

Annex A (normative) Requirements for top of rail materials and testing . 14

Annex B (informative) Determination of the volatile constituents in greases . 21

B.1 Purpose . 21

B.2 Short description . 21

B.3 Conditions for testing . 21

B.3.1 Test conditions . 21

B.3.2 Required testing and measuring equipment . 21

B.4 Test process . 21

B.4.1 Preparation of test . 21

B.4.2 Performance of test . 22

B.4.3 Evaluation . 22

B.5 Recording of test results. 22

Annex C (informative) Functional test on specific equipment . 23

C.1 General . 23

C.2 Sprayability of liquid TOR materials . 23

C.2.1 Purpose . 23

C.2.2 Short description . 23

C.2.3 Conditions for testing . 23

C.2.4 Test process . 24

Annex D (informative) Twin-disc machine Retentivity and Coefficient of Traction test . 25

D.1 Purpose . 25

D.2 Description . 25

D.3 Conditions for test . 25

D.3.1 Test conditions . 25

D.3.2 Twin discs . 25

D.3.3 Performance of the Test . 26

D.3.4 Evaluation of the Test. 26

Annex E (informative) Twin-disc machine test for determining Creep force vs Creep rate curve

(for solid sticks comparable to MTM machine test). 28

E.1 Purpose . 28

E.2 Description . 28

E.3 Conditions for test . 29

E.3.1 Test conditions . 29

E.3.2 Twin discs . 29

E.3.3 Test Process Example . 29

E.3.4 Evaluation of the Test. 30

Annex F (informative) MTM machine creep curve test . 32

F.1 General . 32

F.1.1 Purpose . 32

F.1.2 Description . 32

F.2 Test equipment. 32

F.3 Application of TOR material to metal disk . 33

F.4 Performance of the Test . 35

F.5 Evaluation of the Test. 36

Bibliography . 37

European foreword

This document (CEN/TS 15427-2-2:2021) has been prepared by Technical Committee CEN/TC 256

“Railway applications”, the secretariat of which is held by DIN.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document is part of the EN 15427 series, Railway applications - Wheel/Rail friction management,

which consists of the following parts:

— Part 1-1: Equipment and Application - Flange Lubrication;

— Part 1-2: Equipment and Application - Top of Rail materials;

— Part 1-3: Equipment and Application - Adhesion materials;

— Part 2-1: Properties and Characteristics - Flange lubricants;

— Part 2-2: Properties and Characteristics - Top of Rail materials;

— Part 2-3: Properties and Characteristics - Adhesion materials;

— Part 3: Rationale for requirements and further background information.

According to the CEN/CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to announce this Technical Specification: Austria, Belgium, Bulgaria,

Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland,

Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of

North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United

Kingdom.

Introduction

Friction management using solid or fluid (oil, grease, etc.) substances at the wheel-rail interface is a

complex subject and includes the following aspects:

— lubrication of the wheel flange / rail gauge corner interface, commonly referred to as “flange or rail

lubrication”;

— lubrication of the back of flange/ check rail interface; commonly referred to as “check rail

lubrication”;

— altering the level of friction at the interface between the top of rail and the wheel tread, commonly

referred to as “top of rail friction management”;

— altering the level of adhesion at the interface between the top of rail and the wheel tread.

This document sets out requirements for the material to be used on the top of rail. It specifies

requirements for the material, how to test it and how to approve it.

The material for top of rail should be tested to confirm there is:

— compatibility with top of rail material applicator equipment;

— no intolerable increased risk of fire;

— no harmful environmental effects;

— no incompatibility between the different materials/lubricants in use, particularly between solid and

fluid systems;

— satisfactory and consistent product quality and performance;

— no degradation to the safety of the railway (braking, signalling).

The main purpose of a top of rail material is to influence the third layer to reduce friction to a level where

a reduction in noise or wear can be realized.

1 Scope

This document specifies the requirements of materials intended to be applied to the interface between

the wheel tread and the rail crown (active interface). It can be applied either directly or indirectly to the

wheel tread or rail.

It outlines the information required for most approval procedures, the method of testing and routine

control/monitoring of the material.

This document does not deal with adhesion materials, for example:

— sand;

— adhesion enhancers.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN ISO 868, Plastics and ebonite - Determination of indentation hardness by means of a durometer (Shore

hardness) (ISO 868)

EN ISO 2160, Petroleum products - Corrosiveness to copper - Copper strip test (ISO 2160)

EN ISO 2592, Petroleum and related products - Determination of flash and fire points - Cleveland open cup

method (ISO 2592)

EN ISO 3104, Petroleum products - Transparent and opaque liquids - Determination of kinematic viscosity

and calculation of dynamic viscosity (ISO 3104)

EN ISO 3146, Plastics - Determination of melting behaviour (melting temperature or melting range) of semi-

crystalline polymers by capillary tube and polarizing-microscope methods (ISO 3146)

EN ISO 3675, Crude petroleum and liquid petroleum products - Laboratory determination of density -

Hydrometer method (ISO 3675)

EN ISO 4589-1, Plastics - Determination of burning behaviour by oxygen index - Part 1: General

requirements (ISO 4589-1)

EN ISO 4589-2, Plastics - Determination of burning behaviour by oxygen index - Part 2: Ambient-

temperature test (ISO 4589-2)

EN ISO 5659-1, Plastics — Smoke generation — Part 1: Guidance on optical-density testing (ISO 5659-1)

EN ISO 5659-2, Plastics - Smoke generation - Part 2: Determination of optical density by a single-chamber

test (ISO 5659-2)

ISO/TR 5659-3, Plastics — Smoke generation — Part 3: Determination of optical density by a dynamic-flow

method

EN ISO 7827, Water quality - Evaluation of the "ready", "ultimate" aerobic biodegradability of organic

compounds in an aqueous medium - Method by analysis of dissolved organic carbon (DOC) (ISO 7827)

EN ISO 9408, Water quality - Evaluation of ultimate aerobic biodegradability of organic compounds in

aqueous medium by determination of oxygen demand in a closed respirometer (ISO 9408)

EN ISO 9439, Water quality - Evaluation of ultimate aerobic biodegradability of organic compounds in

aqueous medium - Carbon dioxide evolution test (ISO 9439)

EN ISO 10707, Water quality - Evaluation in an aqueous medium of the "ultimate" aerobic biodegradability

of organic compounds - Method by analysis of biochemical oxygen demand (closed bottle test) (ISO 10707)

EN ISO 12185, Crude petroleum and petroleum products - Determination of density - Oscillating U-tube

method (ISO 12185)

ISO 2049, Petroleum products — Determination of colour (ASTM scale)

ISO 3016, Petroleum and related products from natural or synthetic sources — Determination of pour point

ISO 6072, Rubber — Compatibility between hydraulic fluids and standard elastomeric materials

ISO 6743-99, Lubricants, industrial oils and related products (class L) — Classification — Part 99: General

ISO 7120, Petroleum products and lubricants — Petroleum oils and other fluids — Determination of rust-

preventing characteristics in the presence of water

ISO 9772, Cellular plastics — Determination of horizontal burning characteristics of small specimens

subjected to a small flame

ISO 11007, Petroleum products and lubricants — Determination of rust-prevention characteristics of

lubricating greases

DIN 51418-1, X-ray spectrometry — X-ray emissions and X-ray fluorescence analysis (XRF) — Part 1:

Definitions and principles

DIN 51418-2, X-ray spectrometry — X-ray emissions and X-ray fluorescence analysis (XRF) — Part 2:

Definitions and basic principles for measurements, calibration and evaluation of results

DIN 51451, Testing of petroleum products and related products — Analysis by infrared spectrometry —

General working principles

DIN 51817, Testing of lubricants — Determination of oil separation from greases under static conditions

DIN 51820-1, Testing of lubricants — Analysis of greases by infrared spectrometry — Taking and

evaluating an infrared spectrum

3 Terms and definitions

For the purposes of this document, the terms and definitions given in EN 15085-1, EN 17018 and in

EN 13306 as well as the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https://www.iso.org/obp

— IEC Electropedia: available at http://www.electropedia.org/

3.1

top of rail (TOR) material

substance that influences the rheology of the third layer body

3.2

liquid lubricant

oil, water or emulsion-based products

Note 1 to entry: Oil can be mineral, natural or synthetic in origin and can have additives included.

3.3

grease

semi-solid lubricant

Note 1 to entry: Grease consists of a thickener and additives integrated in a lubricating oil.

3.4

stick

encapsulated solid lubricant

Note 1 to entry: Typically, the stick comprises a solid lubricant which is encapsulated in a polymeric binder/carrier.

The product is designed for direct contact with a rotating wheel flange; the polymeric binder has a sufficiently high

melting point such that it does not melt but rather wears when in contact with the wheel flange to ensure

dimensional stability.

3.5

batch

entire content of a single identified production of material from the same manufacturing process

3.6

active interface

contact area between the wheel tread and the crown of the rail

Note 1 to entry: For more information on this definition, see CEN/TS 15427-1-2.

3.7

rail lubrication

lubrication of the active interface by applying a lubricant to the rail gauge side face

3.8

lubricant application unit

LAU

component of the lubrication system (trainborne or trackside) that delivers lubricant to the active

interface

Note 1 to entry: This includes spray nozzles, trackside grease distribution units/blades, stick applicators, etc.

3.9

lubrication system

components required to apply lubricant to the active interface

Note 1 to entry: A lubrication system can include one or more Lubricant Application Units, a reservoir unit, pump

and/or a control device.

3.10

trainborne equipment

type of equipment that delivers product to the active interface installed on a train

3.11

trackside

type of lubrication system installed on or adjacent to the track

3.12

customer

railway undertaking, infrastructure owner, manufacturer or buyer of railway products or subassemblies,

or their representative

3.13

supplier

supplier of lubricants

Note 1 to entry: A supplier might also be the manufacturer of the product.

3.14

product specification

document prepared by the customer that describes the conditions and requirements for the lubricant

3.15

coefficient of friction

COF

and the multi- vector reaction between the wheel and rail

relationship between the force of friction

Note 1 to entry: Used between the flange and gauge corner of the rail.

3.16

coefficient of adhesion

COA

ratio of the tangential force at the wheel-rail interface and the force at this interface acting perpendicular

to the surface of the rail

3.17

coefficient of traction

COT

ratio of the tangential force at the wheel-rail interface and the force at this interface acting perpendicular

to the surface of the rail

4 Material requirements

The material shall be designed to meet at least one of the following:

— reduction in noise and vibration;

— reduction in the rate of wear;

— reduction of the rate of corrugation growth;

— reduction in the number of wheel and rail defects.

When applied within the specified limits to the active interface the material shall not compromise the

safety of the railway (i.e. braking distances, signalling systems).

NOTE Specified limits are normally understood and agreed before use of material.

5 General requirements

5.1 Introduction

This section outlines the information required to gain approval on most railway networks. It does not

cover its performance on the railway.

5.2 Product specification

The product specification shall be fully documented and shall include the following information:

a) purpose of material;

b) conformity to the applicable type tests as set out in Tables A.1 to A.3;

c) conformance with other relevant local requirements (such as environmental, fire, toxicity, etc.);

d) application data:

1) including equipment, it can be used with;

2) operating temperatures;

NOTE 1 The typical operating temperature range to take into account is from −25 °C to +80 °C.

e) additional validation tests (see Table A.4);

f) any previous relevant experience;

g) conditions for packaging, storage and labelling (see Clause 9);

h) environmental tests are defined in Tables A.1 to A.3.

NOTE 2 Where legislation and regulations (European, national or local) concerning ecological and

environmental compatibility of lubricants (biodegradability, toxicity, etc.) are applicable, consideration will need to

be given to the relevant requirements.

5.3 Technical file

A file of technical data showing compliance with the requirements in the product specification and the

results of type tests and trials shall be provided. A technical datasheet shall also be provided (see

Clause 7).

A material safety data sheet (MSDS) for the product in the language of the interested customer or country

shall be included.

6 Control and monitoring of product

6.1 Manufacturing process

If the manufacturing process is changed in a way that may affect the chemical composition, it shall be

documented and the customer shall be notified.

NOTE In some cases, this leads to a new approval being required.

6.2 Composition of material

If the composition of the material is changed in any way, it shall be documented and the customer shall

be notified.

NOTE In some cases, this leads to a new approval being required.

6.3 Routine tests

Routine tests ensure product consistency from batch to batch.

The routine tests are listed in Tables A1 to A3. If additional tests are required (such as those not included

in the tables or a type test) this and the frequency can be agreed between the client and supplier.

The sample of material assessed for quality testing shall have been manufactured in a regular production

batch. The entire sample of material used for the approval tests shall be taken from the same production

batch and delivered in a single consignment.

The results of the routine tests shall be recorded.

6.4 Additional measures

Retention of test records and samples, witnessing of tests, calibration of test equipment shall be

considered.

7 Technical datasheet

7.1 General

The technical datasheet shall include the individual identifying code or name of the material, a description

of the product’s field of use and typical means of application. For each material type, the information in

the following subclauses shall also be included.

7.2 Grease type material characteristics

The product shall be described by its consistency, its temperature range, the type of thickener and type

of base oil used. Where solid particulates are used, the type and content shall be reported. Further

technical data shall be provided as listed under the ‘datasheet’ column in Table A.1.

7.3 Liquid type material characteristics

The material, which includes, water based, oil based and hybrid based, shall be described by its viscosity,

its temperature range and by the type of oil used. Where solid particulates are used, the type and content

shall be reported. Further technical data shall be provided as listed under the ‘datasheet’ column in

Table A.2.

7.4 Solid type material characteristics

The product shall be described by its melting point, hardness, dimensions and its temperature range.

Further technical data shall be provided as listed under the ‘datasheet’ column in Table A.3.

The product shall be designed to minimize stick debris on the ballast.

It is suggested that the mass of any piece of debris should be no greater than 5 g.

8 Tests

8.1 Explanation of Annex A: Tables A.1 to A.4

The tables have 2 purposes:

1. Tests to show the product can be used in the railway environment;

NOTE Values may vary depending on where the material is used.

2. Product consistency.

For each required property of the material, Tables A.1, A.2 and A.3 list the mandatory and optional tests

for grease, oil, water based and sticks respectively, and parameters for trainborne and trackside

applications.

Table A.4 lists additional tests to check the performance characteristics of the material and that the

material will operate correctly with the equipment it is to be used with.

8.2 Key to Annex A table columns

The key to the columns ‘Type’, ‘Routine’ and ‘Technical Datasheet’ in Tables A.1 to A.4 is as follows:

— ‘Type’ = This indicates the type tests required for the purpose of approval testing (see 6.1 and 6.2).

— ‘Routine’ = This indicates the routine tests required for testing from approved mass-produced

batches (see 6.3).

— ‘Technical Datasheet’ = This indicates the characteristics to be listed in the product documentation.

In each column, a symbol is used to indicate the required test or information:

— ‘X’ indicates the test or piece of information is mandatory;

— ‘O’ indicates the test or piece of information is optional;

8.3 Key to Annex A table column ‘Use’

Tables A.1 to A.4 include a column headed ‘Use’ and the letters used mean the following:

— A = Trainborne using liquid or grease type materials;

— B = Trackside using liquid or grease type materials;

— C = Trainborne using a solid material.

This column identifies the most common systems in current use. Most trainborne equipment sprays the

material and most trackside equipment pumps the material. However, where alternatives exist, careful

consideration to the tests required is needed.

9 Packaging, labelling and storage

The packaging shall protect the contents from contamination and damage.

The labelling shall include at least the following:

— supplier’s name;

— brand name and/or code of the material;

— batch number and date of manufacture, uncoded or coded;

— net mass/quantity/volume;

NOTE Local regulatory requirements will apply.

The following additional information shall be included if specified in the product specification:

— customer stock number;

— an indication that the batch has been accepted by the customer.

The storage conditions and, if necessary, the date limit of use of the material shall be provided.

Annex A

(normative)

Requirements for top of rail materials and testing

Table A.1 — Requirements for greases

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.1.1 Appearance A - Visual Homogenous X X X This is useful to see if the product looks as it

and should.

B

A.1.2 Colour A - ISO 2049 Homogenous X O X

and

B

A.1.3 Consistency A - ISO 6743-99 To be provided for X X X

information

B - ISO 6743-99 To be provided for X X X

information

A.1.7 Flash point A °C EN ISO 2592 ≥ 200 X X This test is required for safety purposes and

and should be retained.

B

Need a standard for finished grease product.

Current ISO quoted is for oils.

A.1.12 Oil separation / Required for TOR, left in as it indicates the

“bleeding” stability of the product.

A.1.12.1 (18 h at 40 °C) A % mass DIN 51817 ≤ 5 X O Without 100 g weight

A.1.12.2 (168 h [7 days] at B % mass DIN 51817 5 % maximum by X O With 100 g weight

40 °C) weight for NLGI No.2

grease &

7 % maximum by

weight for a NLGI No.1

grease

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.1.13 Corrosion test Required for TOR, only need to check against

steel and only ISO test is required.

a) Steel A Level Annex C 1 O O O Deleted as not needed for TOR

A Rating ISO 11007 using 0; 0 X O X

and water

B

b) Copper A Grade DIN 51811 1 O O O

and

24 h at 50 °C

B

A.1.14 Compatibility with A Where applicable

elastomers (60 °C for and

168 h) B

a) Change in volume for % ISO 6072 +15/-0 O Other elastomer types may be tested as

NBR1 necessary

b) Change in hardness for IRHD ISO 6072 ±8 O Other elastomer types may be tested as

NBR1 necessary

A.1.15 Identity testing: A Standard laboratory For routine tests X O Applicable standards:

and method. compare with approved

Using Infrared, or DIN 51418-1

B batch using same

(See comments for

Xray fluorescence, or DIN 51418-2

process

applicable standards)

Inductively coupled DIN 51451

plasma

DIN 51820-1

Required for TOR, not required as it is a quality

test.

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.1.16 Apparent viscosity A

(1° cone, s = 300 s,

−1

D = 1 000 s ) at:

a) 25 °C mPa·s DIN 51810-1 ≥ 150 O O O

b) 0 °C ≥ 400 O O O

c) −25 °C ≤ 4 000 O O O

A.1.19 Low temperature flow B mbar DIN 51805 compatibility with O O Required for TOR – values yet to be defined.

pressure equipment

(pumpability)

A.1.20 Density at 15 °C A kg/m3 EN ISO 12185 Informative – no criteria O O O Required for TOR

EN ISO 3675

A.1.21 Biodegradability A % One of the following Local conditions may X O As defined in Product Specification.

and test methods: apply

See normative references in Clause 2.

B

EN ISO 7827

Required for TOR – need to check values

EN ISO 9408

EN ISO 9439

EN ISO 10707

A.1.22 Fire behaviour A As defined in client/ Local conditions may O O Required for TOR

and supplier discussion. apply

a) Smoke

B

b) Spread of flame

c) Toxicity

A.1.24 Water pollution A As As defined in the Local conditions may O For example, in Germany: Verwaltungsvorschrift

and required Product Specification, apply wassergefährdender Stoffe [German

B see comment. Administrative Regulation on Substances

Hazardous to Water]

Required in the TOR

A.1.27 Electrical resistance A As defined in the O Required for TOR, no standard test needs to be

and Product Specification defined.

B

Table A.2 — Requirements for liquid materials

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.2.1 Appearance A - Visual Homogenous X X O Appearance is a holistic assessment of the

product.

A.2.2 Colour A - ISO 2049 Homogenous X O O

A.2.3 Flash point A °C EN ISO 2592 ≥ 200 X X Deferred to understand minimum temperatures

required for flashpoint.

A.2.4 Corrosion test

a) Steel A level ISO 7120 1 O O O

b) Copper A grade EN ISO 2160 1b O O O

3 h at 50 °C

A.2.5 Compatibility with A Where applicable

elastomers (60 °C for

– required to check compatibility with rubber

168 h)

valves and seals.

a) Change in volume for % ISO 6072 +15/-0 O Other elastomer types may be tested as necessary

NBR1 (change in volume of elastomer)

b) Change in hardness for IRHD ISO 6072 ±8 O Other elastomer types may be tested as necessary

NBR1 (change in hardness of elastomer)

A.2.6 Identity testing: A Standard laboratory For routine tests O O Applicable standards:

method. compare with approved

Using Infrared, or DIN 51418-1

batch using same

(See comments for

Xray fluorescence, or DIN 51418-2

process

applicable standards)

ICP DIN 51451

DIN 51820-1

A.2.7 Density at 15 °C A EN ISO 12185 Informative – no criteria O O O

kg/m

EN ISO 3675

A.2.8 Biodegradability A % EN ISO 9439 Local conditions may X O As defined in Product Specification.

apply

See normative references in Clause 2.

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.2.9 Fire behaviour A As defined in the O O Read EN 45545–1 and understand whether or not

Product Specification it is relevant to this standard. Only relevant for

a) Smoke

trainborne? IEC 60721

b) Spread of flame

c) Toxicity

A.2.10 Pour point A °C ISO 3016 Lower than operating O O

range lower limit

A.2.11 Dynamic viscosity at A mPa⋅s EN ISO 3104 Informative – no criteria O O O

40 °C

A.2.12 Brookfield viscosity at A mPa⋅s DIN 51398 Informative – no criteria O O O Deletion deferred until further discussion

40 °C (required to give the kinematic viscosity which is

required for ISO class)

A.2.13 Dynamic viscosity at A mPa⋅s EN ISO 3104 Informative – no criteria O O O

40 °C

A.2.14 Brookfield viscosity at A mPa⋅s DIN 51398 Informative – no criteria O O O Deletion deferred until further discussion

40 °C (required to give the kinematic viscosity which is

required for ISO class)

A.2.15 Water pollution A As As defined in the Local conditions may O For example, in Germany: Verwaltungsvorschrift

required Product Specification, apply wassergefährdender Stoffe [German

see comment Administrative Regulation on Substances

Hazardous to Water].

Table A.3 — Requirements for sticks

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.3.1 Appearance C - Visual Homogeneous X X O Batch to batch comparison.

A.3.2 Colour C - ISO 2049 Homogeneous X X X Batch to batch comparison.

A.3.3 Melting point C °C EN ISO 3146 Higher than operating X Add definition of operating range.

range

a) Smoke - See comments O O EN ISO 5659-1

EN ISO 5659-2

ISO/TR 5659-3

b) Spread of - See comments O O EN ISO 4589-1

flame

EN ISO 4589-2

ISO 9772

c) Toxicity - See comments O O

A.3.8 Identity C Standard laboratory For routine tests compare O

testing method with approved batch using

same process

Using ICP /

LECO or

X-ray

fluorescence

A.3.10 Hardness C Shore EN ISO 868 For routine tests compare X X See Note 3.

with approved batch

A.3.11 Water C As As defined in the Local conditions might also O For example, in Germany: Verwaltungsvorschrift

pollution required Product Specification, apply wassergefährdender Stoffe [German Administrative

see comment Regulation on Substances Hazardous to Water]

NOTE 1 Consistent stick dimensions are critical to ensure that the solid sticks fit and do not jam in the applicator.

NOTE 2 Significant differences in density could indicate a change in composition or level of solid lubricants, or presence of voids in product.

NOTE 3 Different hardness value could lead to differing stick consumption values under similar operating conditions.

Table A.4 — Functional tests for all material types

Item Property Use Unit Test method Values Type Routine Datasheet Comments

A.4.2 Functional tests using A and Annex D O – Annex K to be revised

application B accordingly.

equipment (at low,

normal and high

temperature)

A.4.3 Field testing A, B Refer to O Refer to CEN/TS 15427-1-2,

and C CEN/TS 15427-1-2, Annex B for more guidance

Annex B for more

guidance

A.4.4 Film retention A, B Twin disc test in film retention O

and C Annex L

A.4.5 Creep test A, B Mini Traction O

Machine (MTM) test

Annex M

A.4.6 Rolling contact A, B Twin disc test in O

fatigue and C Annex N

A.4.7 Friction value C Twin disk test

Annex P

Annex B

(informative)

Determination of the volatile constituents in greases

B.1 Purpose

The volatile constituent in a lubricant is the low-boiling point component of the grease used to improve

low-temperature behaviour. The volatile constituents determined with the method below are

predominantly solvents. It is of considerable interest in real-life practice to know the solvent content of

a wheel-flange lubricant; and since no suitable standard exists to date, the method described below has

been developed as a guide.

This method can help identify where solvents are used to lower the lubricant viscosity at low

temperature. The use of these modified lubricants can lead to problems when the solvent content

evaporates with time.

B.2 Short description

A defined amount of grease is weighed out onto an evaporating dish and placed in a heating cabinet for a

period of time. It is then weighed to determine the volatile constituent content.

B.3 Conditions for testing

B.3.1 Test conditions

The test is carried out at a temperature of (60 ± 0,5) °C for a duration of 24 h. The conditions for the tests

are set by a heating cabinet.

B.3.2 Required testing and measuring equipment

— thermometer, with a measuring range of 0 °C to 70 °C and accuracy of 0,5 °C.

— analytical balance, with a range of 0 g to 200 g and accuracy of 0,001 g.

— heating cabinet.

— flat porcelain evaporating dish, 95 mm in diameter. For the test described, here, the dish above is

used. Where other sizes or types are used, the result might be different.

— desiccator.

B.4 Test process

B.4.1 Preparation of test

None.

B.4.2 Performance of test

1) Weigh the empty porcelain evaporating dish with the analytical balance. Add (10 ± 0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...