EN 14116:2012+A1:2014

(Main + Amendment)Tanks for transport of dangerous goods - Digital interface for product recognition devices for liquid fuels

Tanks for transport of dangerous goods - Digital interface for product recognition devices for liquid fuels

This European Standard covers the digital interface at the product loading and/or discharge coupling which is used for the transfer of product related information and specifies the performance requirements, critical safety aspects and tests to provide compatibility of devices.

Tanks für die Beförderung gefährlicher Güter - Digitale Schnittstelle für das Produkterkennungssystem für flüssige Kraft- und Brennstoffe

Diese Europäische Norm behandelt die digitale Schnittstelle an den Kupplungen zum Befüllen und/oder Entladen des Produkts, die für die Übertragung von produktbezogenen Informationen verwendet wird, und legt die Anforderungen an die Leistungseigenschaften, kritische Sicherheitsaspekte und Prüfungen fest, um die Kompatibilität der Einrichtungen sicherzustellen.

Citernes destinées au transport de matières dangereuses - Interface numérique du dispositif de reconnaissance de produits pétroliers

La présente Norme européenne traite de l’interface numérique au point de connexion de chargement et/ou de

déchargement du produit, qui est utilisée pour le transfert des informations associées au produit, et spécifie

les exigences en matière de performances, les aspects critiques concernant la sécurité et les essais destinés

à garantir la compatibilité des dispositifs.

Cisterne za prevoz nevarnega blaga - Digitalni vmesnik za napravo za prepoznavanje proizvoda za tekoča goriva

Ta evropski standard pokriva digitalni vmesnik na spojki za polnjenje in/ali praznjenje proizvoda, ki se uporablja za prenos informacij v povezavi s proizvodom in določa zmogljivostne zahteve, kritične varstvene vidike in preskuse za zagotavljanje združljivosti naprave.

General Information

- Status

- Withdrawn

- Publication Date

- 23-Sep-2014

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 296 - Tanks for transport of dangerous goods

- Drafting Committee

- CEN/TC 296/WG 8 - Electronic equipment and products

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 27-Jun-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 23-Jul-2014

- Effective Date

- 23-Jul-2014

- Refers

EN IEC 60079-11:2024 - Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i" - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 18-Jan-2017

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

NSF International

Global independent organization facilitating standards development and certification.

CIS Institut d.o.o.

Personal Protective Equipment (PPE) certification body. Notified Body NB-2890 for EU Regulation 2016/425 PPE.

Sponsored listings

Frequently Asked Questions

EN 14116:2012+A1:2014 is a standard published by the European Committee for Standardization (CEN). Its full title is "Tanks for transport of dangerous goods - Digital interface for product recognition devices for liquid fuels". This standard covers: This European Standard covers the digital interface at the product loading and/or discharge coupling which is used for the transfer of product related information and specifies the performance requirements, critical safety aspects and tests to provide compatibility of devices.

This European Standard covers the digital interface at the product loading and/or discharge coupling which is used for the transfer of product related information and specifies the performance requirements, critical safety aspects and tests to provide compatibility of devices.

EN 14116:2012+A1:2014 is classified under the following ICS (International Classification for Standards) categories: 13.300 - Protection against dangerous goods; 23.020.20 - Vessels and containers mounted on vehicles; 35.240.60 - IT applications in transport. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14116:2012+A1:2014 has the following relationships with other standards: It is inter standard links to EN 14116:2012+A2:2018, EN 14116:2012/FprA1, EN 14116:2012, EN IEC 60079-11:2024, EN IEC 60079-0:2018, EN 13616:2004, EN 1090-5:2017, EN 196-1:1994, EN 15208:2014, EN 15969-1:2015, EN 15969-1:2017, EN 14116:2012+A1:2014/prA2. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14116:2012+A1:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Tanks für die Beförderung gefährlicher Güter - Digitale Schnittstelle für das Produkterkennungssystem für flüssige Kraft- und BrennstoffeCiternes destinées au transport de matières dangereuses - Interface numérique du dispositif de reconnaissance de produits pétroliersTanks for transport of dangerous goods - Digital interface for product recognition devices for liquid fuels35.240.60Uporabniške rešitve IT v transportu in trgoviniIT applications in transport and trade23.020.20Posode in vsebniki, montirani na vozilaVessels and containers mounted on vehicles13.300Varstvo pred nevarnimi izdelkiProtection against dangerous goodsICS:Ta slovenski standard je istoveten z:EN 14116:2012+A1:2014SIST EN 14116:2012+A1:2014en,fr,de01-december-2014SIST EN 14116:2012+A1:2014SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14116:2012+A1

September 2014 ICS 13.300; 23.020.20; 35.240.60 Supersedes EN 14116:2012English Version

Tanks for transport of dangerous goods - Digital interface for product recognition devices for liquid fuels

Citernes destinées au transport de matières dangereuses -Interface numérique du dispositif de reconnaissance de produits pétroliers

Tanks für die Beförderung gefährlicher Güter - Digitale Schnittstelle für das Produkterkennungssystem für flüssige Kraft- und Brennstoffe This European Standard was approved by CEN on 1 September 2012 and includes Amendment 1 approved by CEN on 7 August 2014.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2014 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 14116:2012+A1:2014 ESIST EN 14116:2012+A1:2014

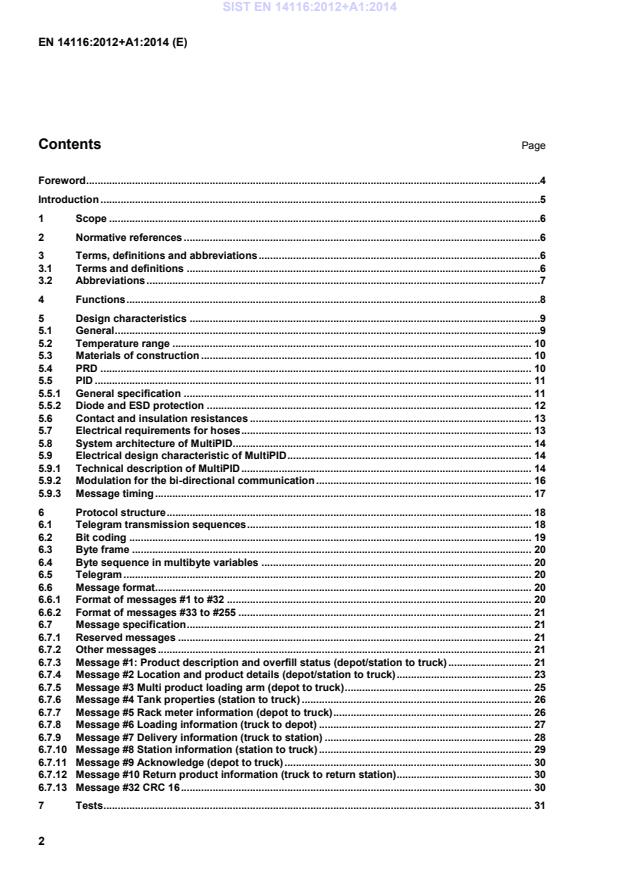

Manufacturer ID . 38 Annex B (normative)

Calculation algorithm for CRC 16 . 39 Annex C (informative)

A-deviations . 40 Annex D (normative)

Company code . 41 D.1 Reason for the company code . 41 D.2 Host of the list . 41 D.3 Website . 41 D.4 Rules . 41 D.4.1 General . 41 D.4.2 Preliminary registration . 41 D.4.3 Access to “Oil Company code” table . 41 D.4.4 Registration of a new company code . 41 D.4.5 Automatic notification of changes . 42 Bibliography . 43

Least Significant Bit — MSB Most Significant Bit — PID

Product Identification Device — PRD Product Recognition Device — RON Research Octane Number SIST EN 14116:2012+A1:2014

Key 1 pipework of loading arm with insulated coupling 2 pipework of transport tank with insulated coupling 3 vapour line 4 product line 5 PID, vapour 6 PID, product 7 PRD a required, if only one connection is established Figure 1 — Loading SIST EN 14116:2012+A1:2014

Key 1 pipework of transport tank with insulated coupling 2 conductive hoses b and pipework of stationary tank with insulated couplings 3 vapour line 4 product line 5 PRD 6 PID, product 7 PID, vapour a required, if only one connection is established b if the discharge hoses are not conductive then the conductivity of these hoses shall be achieved by other means Figure 2 — Unloading PRD supplies an intrinsically safe circuit. 5 Design characteristics 5.1 General The PRD shall be located on the transport tank. The PID shall be connected in series to a current loop with the PRD. The PRD reads the PID by powering the PID through the hose or loading arm. The PID then sends its data by modulating the supply current, which is sensed by the PRD; see Figure 3. The PID sends its data, using messages, which are numbered from 1 to 255. The PID always transmits "message #1". By implementing more messages, it is possible to program the PID with other types of information; see 6.6. Since the PID modulates the supply current, PIDs shall not be connected in parallel. SIST EN 14116:2012+A1:2014

Key Components: 1 electronic circuit ST modulating switch IL supply current without modulation ITD supply current amplitude Figure 3 — Basic circuit diagram of PID 5.2 Temperature range Unless otherwise specified, the operating temperature range shall be - 20 °C to + 50 °C. Where the product recognition device is subjected to temperatures outside the specified temperature range, all applicable temperature values shall be extended. All other requirements shall remain unchanged. 5.3 Materials of construction The manufacturer shall provide with the equipment a full material specification for those parts, which may come into contact with the substances according to Clause 1. 5.4 PRD The PRD shall provide an intrinsically safe power supply with the values according to Table 1 to the PID. Table 1 — DC electrical characteristics of PRD Parameter Unit Min Nom Max Ex-values a Open-circuit voltage V 11 12 15 U0 = 15 Short-circuit current mA - - 300 I0 = 300 Output power W - - 1,1 P0 = 1,1 a Maximum value to ensure compliance with EN 60079-11. Explosive protection shall be at least Ex ia IIA according to EN 60079-0 and EN 60079-11. SIST EN 14116:2012+A1:2014

Key fTC = 2 × baud rate (fbit) t2, t3 = t at i = IL + 90 % ITD IH supply current with modulation ITD supply current amplitude IL supply current without modulation tTdS transmission delay after power on t0 t at power ON tTf fall time of output signal t1, t4, t5 = t at i = IL + 10 % ITD tTr rise time of output signal Figure 4 — Timing diagram of PID 5.5.2 Diode and ESD protection To maintain ESD protection, a resistor has to be implemented into the PID; see Figure 5 and Table 4.

Key Components: 1 electronic circuit D diode R ESD resistor Figure 5 — PID schematic wiring diagram SIST EN 14116:2012+A1:2014

100 300 Diode D forward current ID mA 300 - Diode D forward voltage at ID < 50 mA UD V - 1 5.6 Contact and insulation resistances The contact and insulation resistances shall be according to Table 5. Table 5 — Contact and insulations resistances Parameter Symbol Unit Min Max Closed loop resistance a RL

- 10 Closed loop resistance for PRD design b RLD

- 100 Insulation resistance c RIns

15 - PRD ESD protection resistance RESD kΩ 100 500 a All electrical contacts and wires. If hoses are used it includes also the hoses and couplings. b This equals the closed loop resistance RL within a safety factor of 10. c Between different PID scan channels and between any PID scan channel and ground. ! 5.7 Electrical requirements for hoses The electrical requirements for hoses used for loading and unloading shall be according to Table 6. Hose design should minimise the built up of electrical charge during product flow. Table 6 — Electrical requirements for hoses Parameter Unit Minimum Maximum Resistance between the couplings (end to end)a Ω 0 5 Resistance between signal path and the external surface of the hosec Ω 1 500 — Inductance between the couplings (end to end)a mH 0 0,4 Capacitancea, b nF 0 200 a These parameters are for single hoses and combinations of hoses, when the combination is used to make a single hose. These parameters shall also include the signal return line. b Hose coupling to ground or signal return path. c Measurement surrounding/measurement condition: clamp DN 78, 20 mm wide, tighten, preferable full-faced bearing. For other nominal diameters (DN) the clamp shall be coextensive, so appropriate smaller or expanded. " SIST EN 14116:2012+A1:2014

Key I

depot II

truck III

station IV station computer V depot computer

a isolated vapour recovery b isolated API-coupling c

isolated coupling discharge

and vapour recovery d

Diesel (standard) e

RON 94 f

RON 96 g

Bio diesel h

RON 98 i vapour recovery Figure 6 — Systematic of MultiPID 5.9 Electrical design characteristic of MultiPID 5.9.1 Technical description of MultiPID The principle block diagram of MultiPID is given in Figure 7. The electrical characteristics of MultiPID are according to Table 7. The operational data of MultiPID is according to Figure 8. Details of the operation of a MultiPID is described in EN 15208. SIST EN 14116:2012+A1:2014

Key 1 modulator 2 reader 3 microprocessor 4 recommended host interface ia Cn isolated coupling (product/vapour recovery) Pn port a required, if only one connection is established Figure 7 — Multi-PID principle block diagram Table 7 — Electrical characteristics Relevant for Functional block Parameter Symbol Unit min max PID Current modulation Supply current without modulation IL mA - 10

Supply current amplitude ITD mA 10 20

Clock rate fTC Hz 4 800 4 960 PRD Voltage modulation Voltage difference for modulation ûUM V ± 0,5 ± 1,5 PRD Supply via PRD Supply voltage U V 6 15 Common Ambient temperature Temperature T °C - 25 + 60 SIST EN 14116:2012+A1:2014

Key 1 bit stream sent by Multi-PID 2 current modulated by Multi-PID (Manchester code) 3 voltage modulated by PRD (level code) 4 sampling interval of Multi-PID retrieving bit stream from PRD U voltage in volt I current in ampere t time in seconds tTds see Figure 4 Il current for signal low ITD see Figure 4 ûUM voltage modulation tTr see Figure 4 tTf see Figure 4 fTC see Figure 4 cdT duty cycle Figure 8 — Operational data of Multi-PID 5.9.2 Modulation for the bi-directional communication The communication between PRD and Multi-PID shall be of the type "full duplex" i.e. while MultiPID is talking, PRD sends its message to MultiPID. Both shall be able to read the messages. The current modulation by MultiPID shall result in a voltage modulation in PRD, due to its internal serial resistor. MultiPID shall be able to differentiate this from the modulation of the supply voltage performed by PRD. Therefore MultiPID shall measure the voltage changes caused by its own current modulation. PRD shall start its transmission not before the end of the start bit of the MultiPID and synchronously to the current SIST EN 14116:2012+A1:2014

Key AC

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...