EN 14932:2006

(Main)Plastics - Stretch thermoplastic films for wrapping bales - Requirements and test methods

Plastics - Stretch thermoplastic films for wrapping bales - Requirements and test methods

This European Standard specifies the requirements for dimensional, mechanical and optical characteristics of stretch thermoplastic films for wrapping round bales used for outdoor ensiling of forage.

This European Standard specifies classifications for durability and solar reflectance of stretch films for wrapping round bales.

This European Standard specifies also test methods to check these requirements.

This European Standard is applicable to white, black or coloured films based on polyethylene and/or ethylene copolymers. The range of film widths considered is from 250 mm up to 1 000 mm.

NOTE 6 layers of stretch films, pre stretched up to 80 %, should be used for wrapping round bales.

Kunststoffe - Thermoplastische Stretchfolien zum Umwickeln von Ballen - Anforderungen und Prüfverfahren

Diese Europäische Norm legt die Maßanforderungen und die Anforderungen an die mechanischen und optischen Eigenschaften von thermoplastischen Stretchfolien (Streck-, Dehnfolien) fest, die zum Umwickeln runder Ballen für das Silieren (Einsäuern) von Futter im Freien verwendet werden.

Diese Norm legt Klassifizierungen für die Dauerhaftigkeit und das Solarreflexionsvermögen von Stretchfolien zum Umwickeln runder Ballen fest.

Diese Norm legt zudem Prüfverfahren zum Überprüfen dieser Anforderungen fest

Diese Europäische Norm gilt für weiße, schwarze und farbige Folien auf Basis von Polyethylen und/oder Ethylencopolymerisaten. Berücksichtigt werden Folienbreiten im Bereich von 250 mm bis 1 000 mm.

ANMERKUNG Die runden Ballen sollten mit 6 Lagen der Stretchfolie, die auf bis zu 80 % vorgedehnt ist, umwickelt werden.

Plastiques - Films thermoplastiques étirables pour l' enrubannage de balles - Exigences et méthodes d'essai

Polimerni materiali - Raztegljive plastomerne folije za zavijanje v bale - Zahteve in preskusne metode

General Information

- Status

- Withdrawn

- Publication Date

- 12-Dec-2006

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 249 - Plastics

- Drafting Committee

- CEN/TC 249/WG 7 - Thermoplastic films for use in agriculture

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 10-Jan-2018

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 14-Nov-2012

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

BRCGS (Brand Reputation Compliance Global Standards)

Global food safety and quality standards owner.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 14932:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics - Stretch thermoplastic films for wrapping bales - Requirements and test methods". This standard covers: This European Standard specifies the requirements for dimensional, mechanical and optical characteristics of stretch thermoplastic films for wrapping round bales used for outdoor ensiling of forage. This European Standard specifies classifications for durability and solar reflectance of stretch films for wrapping round bales. This European Standard specifies also test methods to check these requirements. This European Standard is applicable to white, black or coloured films based on polyethylene and/or ethylene copolymers. The range of film widths considered is from 250 mm up to 1 000 mm. NOTE 6 layers of stretch films, pre stretched up to 80 %, should be used for wrapping round bales.

This European Standard specifies the requirements for dimensional, mechanical and optical characteristics of stretch thermoplastic films for wrapping round bales used for outdoor ensiling of forage. This European Standard specifies classifications for durability and solar reflectance of stretch films for wrapping round bales. This European Standard specifies also test methods to check these requirements. This European Standard is applicable to white, black or coloured films based on polyethylene and/or ethylene copolymers. The range of film widths considered is from 250 mm up to 1 000 mm. NOTE 6 layers of stretch films, pre stretched up to 80 %, should be used for wrapping round bales.

EN 14932:2006 is classified under the following ICS (International Classification for Standards) categories: 55.040 - Packaging materials and accessories; 83.140.10 - Films and sheets. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14932:2006 has the following relationships with other standards: It is inter standard links to EN 14932:2018, EN 4138:2009, EN ISO 7765-1:2004, EN 4343:2002, EN ISO 6383-2:2004, EN 2155-5:1989, EN ISO 4892-2:2006, EN ISO 527-1:2019, EN ISO 527-3:2018. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14932:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Plastics - Stretch thermoplastic films for wrapping bales - Requirements and test methodsPolimerni materiali - Raztegljive plastomerne folije za zavijanje v bale - Zahteve in preskusne metodePlastiques - Films thermoplastiques étirables pour l' enrubannage de balles - Exigences et méthodes d'essaiKunststoffe - Thermoplastische Stretchfolien zum Umwickeln von Ballen - Anforderungen und PrüfverfahrenTa slovenski standard je istoveten z:EN 14932:2006SIST EN 14932:2007en;fr;de83.140.10Filmi in folijeFilms and sheets55.040SDNLUDQMHPackaging materials and accessoriesICS:SLOVENSKI

STANDARDSIST EN 14932:200701-april-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 14932December 2006ICS 55.040; 83.140.10 English VersionPlastics - Stretch thermoplastic films for wrapping bales -Requirements and test methodsPlastiques - Films thermoplastiques étirables pour l'enrubannage de balles - Exigences et méthodes d'essaiKunststoffe - Thermoplastische Stretchfolien zumUmwickeln von Ballen - Anforderungen und PrüfverfahrenThis European Standard was approved by CEN on 9 November 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 14932:2006: E

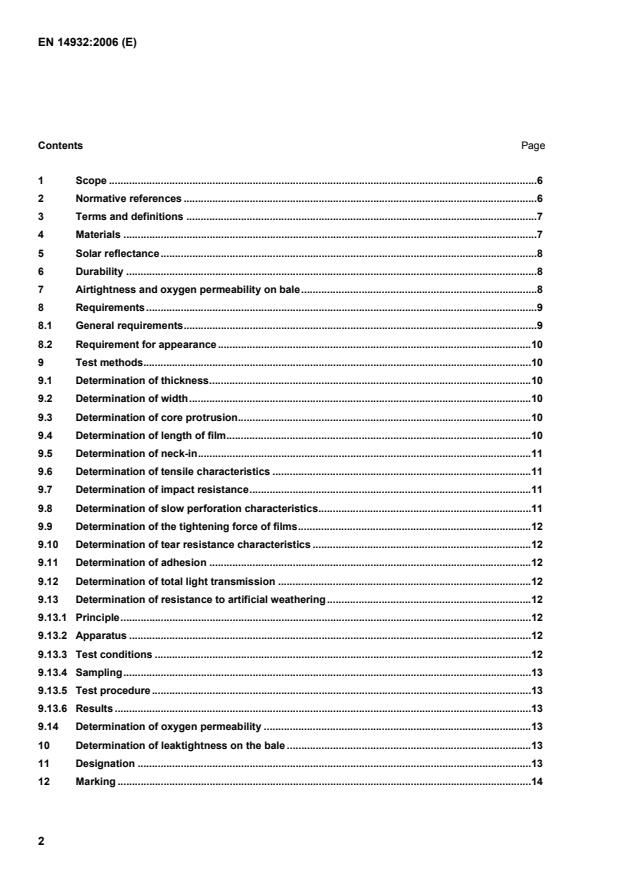

Determination of solar reflectance.15 A.1 Introduction.15 A.2 Principle.16 A.3 Terms and definitions.16 A.4 Determination of solar reflectance, Rs.17 A.4.1 Reflectance spectra acquisition.17 A.4.2 Calculation of Rs.17 Annex B (normative)

Determination of neck-in characteristic.19 B.1 Introduction.19 B.2 Apparatus.19 B.3 Procedure.20 Annex C (normative)

Determination of perforation resistance.21 C.1 Principle.21 C.2 Description.21 C.3 Apparatus.21 C.4 Procedure.21 C.4.1 Definitions.21 C.4.2 Conditioning.21 C.4.3 Specimen preparation.21 C.4.4 Test conditions.22 C.4.5 Test procedure.22 C.4.6 Number of tests.22 C.5 Results.22 Annex D (normative)

Determination of tightening force.25 D.1 Principle.25 D.2 Apparatus.25 D.3 Procedure.25 D.4 Preparation of the specimens.25 D.5 Results.26 D.6 Repeatability.26 Annex E (normative)

Determination of adhesion characteristic.27 E.1 Principle.27 E.2 Apparatus.27 E.3 Preparation of apparatus.27 E.4 Procedure.32 Annex F (informative)

Determination of leaktightness on the bale.33 F.1 Airtightness on an artificial bale.33 F.2 Oxygen permeability on an artificial bale.33

Table 1 — Classification according to solar reflectance Class of film Solar reflectance Rs % High reflectance ≥ 28 Low reflectance < 28

6 Durability The durability of stretch films is defined by the classes A and B. This classification, given in Table 2, is depending of the duration of exposure of the film to an artificial weathering, conforming to 9.13, which induces a decrease of the value of tensile strain at break equal or less than 50 % of the initial value. The class of durability shall be declared by the manufacturer. Table 2 — Classification according to artificial weathering Class of film Duration of exposure h A 1 400 B 2 500

NOTE Usually an empirical correlation between the durations of stretch films exposed to artificial weathering (according to 9.13) and the durations of natural weathering is the following: Class A corresponds to an exposure of 1 year in the North of Europe; Class B corresponds to an exposure of 1 year in the South of Europe. 7 Airtightness and oxygen permeability on bale The final result of silageing is very much depending on the total airtightness of the bale. There are a lot of parameters involved that can influence measurable properties as film permeability, cling force, holding force, but also properties that is difficult to measure with laboratory equipment such as wrinkles, tiger stripes, film appearance when stretched and others. Annex F gives guidance for assessing the airtightness and the oxygen permeability on an artificial bale.

Regular See 8.2 Nominal thickness µm ≥ 25

Tolerance of average thickness/ nominal thickness % - 8, + 12 ISO 4593 Tolerance of single point thickness/ nominal thickness % - 20, + 28 ISO 4593 Nominal width W0 mm 250 ≤ W0 ≤ 1 000

Width tolerance mm W0 - 5 ≤ W0 ≤ W0 + 5 ISO 4592 Core protrusion mm Min 3, Max 10 See 9.3 Length of film m ≥ 99,0 % L0 See 9.4 Neck-in % < 25 See 9.5 Tensile stress at break in (MD) in (TD)

MPa MPa

≥ 25 ≥ 23

EN ISO 527-3 Tensile stress at yield in (MD,TD)

MPa

≥ 9

EN ISO 527-3 Tensile strain at break in (MD) in (TD)

% %

≥ 400 ≥ 600 EN ISO 527-3 Impact resistance g ≥ 120 Method A of

EN ISO 7765-1 Perforation resistance properties Maximum force

Total energy

N

J

≥ 4

≥ 0,04 Annex C Tightening force N ≥ 1,75 Annex D Tear resistance cN ≥ 120 in MD ≥ 400 in TD EN ISO 6383-2 Adhesion cN > 300 Annex E Total light transmission % < 75

EN 2155-5 Coefficient of oxygen permeability a cm³ /(m²

24 h) < 1 400 Annex A of ISO 15105-2:2003 a

Checked on 6 layers of un-stretched film.

8.2 Requirement for appearance The edges of the reels shall be straight. The winding shall be without bubbles and wrinkles affecting film quality on the face of the roll. The film shall be homogeneous and free from visible defects which may affect the fitness for purpose of the stretch film: check by unrolling at least 2 m of the film and examining it against the light holding it tight at arms length. 9 Test methods 9.1 Determination of thickness The thickness of the single points and average thickness of the film shall be determined in accordance with ISO 4593. The test is performed using one strip of film cut in transverse direction of the roll (TD). 9.2 Determination of width The width of the film shall be determined in accordance with ISO 4592. 9.3 Determination of core protrusion The core protrusion shall be measured on each side of the roll. The value shall be expressed in mm. 9.4 Determination of length of film The length of the film shall be determined by unwinding the roll with a calibrated reel in contact continuously with its outside surface (see Figure 1). The calibrated reel is connected to a revolution counter. The diameter of the calibrated reel is measured with an accuracy of ± 0,2 %. The roll is totally unwound at a speed of

100 m/min ± 10 m/min. The value of the length of the film is calculated with the following equation: l = n

x

π d where l is the value of the length of the film, expressed in m; n is the number of revolutions of the calibrated reel during the total unwinding of the roll; d is the value of the diameter of the calibrated reel, expressed in m.

Key 1 roll to be tested 2 calibrated reel with a revolution counter 3 collection reel Figure 1 — Apparatus for the determination of the length of the film

9.5 Determination of neck-in The neck-in shall be determined in accordance with Annex B. The result is expressed as the shrinkage in transverse direction in percentage of the original width. Ni = [(W1 – W2) / W1] x 100 where Ni is the value of neck in expressed in %, W1 is the measure of width of the un-stretche

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...