EN 14932:2018

(Main)Plastics - Thermoplastic stretch films for wrapping silage bales

Plastics - Thermoplastic stretch films for wrapping silage bales

This European Standard specifies the requirements for dimensional, mechanical, oxygen transmission rate and optical characteristics of stretch thermoplastic films for wrapping bales used for ensilaging of forage. It specifies a classification for solar reflectance of the films.

This European Standard specifies also test methods to check these requirements.

It specifies also test methods for the determination of the airtightness and oxygen permeability determined on a wrapped artificial bale.

This European Standard is applicable to white, black or coloured films based on polyolefin materials. It covers the width range from 250 mm up to 1 000 mm.

The performances of the stretch films in conformance with this European Standard are based on the use of at least six layers of films, pre-stretched at a ratio between 60 % and 70 % for round bales and a ratio of 55 % and 65 % for wrapping square bales.

This European Standard also gives guidance for storage of rolls and instructions for wrapping, storage of wrapped bales and for disposal of films.

Kunststoffe - Thermoplastische Stretchfolien zum Umwickeln von Silage-Ballen

Diese Europäische Norm legt die Anforderungen an Maße, mechanische Eigenschaften, Sauerstoffdurchlässig¬keitsrate und optische Charakteristiken von thermoplastischen Stretchfolien zur Umwicklung von Ballen, die zum Silieren von Futtermittel genutzt werden, fest. Sie spezifiziert eine Klassifizierung für den Solar¬reflexionsgrad der Folien.

Diese Europäische Norm legt außerdem Prüfverfahren zur Überprüfung dieser Anforderungen fest.

Außerdem legt sie Prüfverfahren für die Bestimmung der Luftdichtheit sowie der Sauerstoffdurchlässigkeit fest, die auf umwickelten künstlichen Ballen bestimmt wurden.

Diese Europäische Norm ist für weiße, schwarze und farbige Folien, die aus polyolefinen Werkstoffen bestehen, gültig. Sie umfasst den Breitenbereich von 250 mm bis zu 1 000 mm.

Die Funktionen von Stretchfolien in Übereinstimmung mit dieser Europäischen Norm basieren auf der Nutzung von mindestens sechs Folienlagen, vorgedehnt auf ein Verhältnis zwischen 60 % und 70 % für Rund¬ballen sowie 55 % und 65 % zur Umwicklung von Quaderballen.

Diese Europäische Norm gibt zudem eine Anleitung zur Lagerung von Rollen zur Umwicklung, Lagerung von umwickelten Ballen und zur Entsorgung der Folien.

Plastiques — Films thermoplastiques étirables pour l'enrubannage de balles d'ensilage

La présente Norme européenne spécifie les exigences relatives aux caractéristiques dimensionnelles, mécaniques, au coefficient de transmission de l’oxygène et aux caractéristiques optiques des films thermoplastiques étirables utilisés pour enrubanner les balles pour l’ensilage du fourrage. Elle spécifie une classification du facteur de réflectance solaire des films.

La présente Norme européenne spécifie également des méthodes d’essai permettant de vérifier ces exigences.

Elle spécifie également des méthodes d’essai pour la détermination de l’étanchéité à l’air et la perméabilité à l’oxygène sur une balle artificielle enrubannée.

La présente Norme européenne est applicable aux films blancs, noirs et de couleur, à base de polyoléfines. Elle couvre une plage de largeur allant de 250 mm à 1 000 mm.

Les performances des films étirables en conformité avec la présente Norme européenne reposent sur l’utilisation d’au moins six couches de film, pré-étiré à un taux d’étirage compris entre 60 % et 70 % pour les balles rondes et entre 55 % et 65 % pour les balles carrées.

La présente Norme européenne fournit également des préconisations pour le stockage des bobines et des instructions d’enrubannage, de stockage des balles enrubannées et d’élimination des films.

Polimerni materiali - Raztegljive plastomerne folije za zavijanje v bale

Ta evropski standard določa zahteve za dimenzijske, mehanske in optične lastnosti raztegljivih plastomernih folij za zavijanje v bale, ki se uporabljajo za silažo ali krmo. Določa razvrščanje folij na podlagi njihove odsevnosti sončne svetlobe.

Ta evropski standard določa tudi preskusne metode za preverjanje teh zahtev.

Ta evropski standard se uporablja za bele, črne ali barvne folije na osnovi poliolefinskih materialov. Zajema širine v razponu od 250 mm do 1000 mm.

Učinkovitosti raztegljivih folij, skladne s tem evropskim standardom, temeljijo na uporabi najmanj šestih plasti folij, ki so predhodno raztegnjene med 60 % in 70 % za okrogle bale ter med 55 % in 65 % za ovijanje kvadratnih bal.

Ta evropski standard podaja tudi smernice za shranjevanje zvitkov ter navodila za ovijanje, shranjevanje ovitih bal in odstranjevanje folij.

General Information

- Status

- Withdrawn

- Publication Date

- 09-Jan-2018

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 249 - Plastics

- Drafting Committee

- CEN/TC 249/WG 7 - Thermoplastic films for use in agriculture

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 23-Jul-2025

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 14-Nov-2012

- Effective Date

- 24-Jan-2023

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Smithers Quality Assessments

US management systems and product certification.

BRCGS (Brand Reputation Compliance Global Standards)

Global food safety and quality standards owner.

DIN CERTCO

DIN Group product certification.

Sponsored listings

Frequently Asked Questions

EN 14932:2018 is a standard published by the European Committee for Standardization (CEN). Its full title is "Plastics - Thermoplastic stretch films for wrapping silage bales". This standard covers: This European Standard specifies the requirements for dimensional, mechanical, oxygen transmission rate and optical characteristics of stretch thermoplastic films for wrapping bales used for ensilaging of forage. It specifies a classification for solar reflectance of the films. This European Standard specifies also test methods to check these requirements. It specifies also test methods for the determination of the airtightness and oxygen permeability determined on a wrapped artificial bale. This European Standard is applicable to white, black or coloured films based on polyolefin materials. It covers the width range from 250 mm up to 1 000 mm. The performances of the stretch films in conformance with this European Standard are based on the use of at least six layers of films, pre-stretched at a ratio between 60 % and 70 % for round bales and a ratio of 55 % and 65 % for wrapping square bales. This European Standard also gives guidance for storage of rolls and instructions for wrapping, storage of wrapped bales and for disposal of films.

This European Standard specifies the requirements for dimensional, mechanical, oxygen transmission rate and optical characteristics of stretch thermoplastic films for wrapping bales used for ensilaging of forage. It specifies a classification for solar reflectance of the films. This European Standard specifies also test methods to check these requirements. It specifies also test methods for the determination of the airtightness and oxygen permeability determined on a wrapped artificial bale. This European Standard is applicable to white, black or coloured films based on polyolefin materials. It covers the width range from 250 mm up to 1 000 mm. The performances of the stretch films in conformance with this European Standard are based on the use of at least six layers of films, pre-stretched at a ratio between 60 % and 70 % for round bales and a ratio of 55 % and 65 % for wrapping square bales. This European Standard also gives guidance for storage of rolls and instructions for wrapping, storage of wrapped bales and for disposal of films.

EN 14932:2018 is classified under the following ICS (International Classification for Standards) categories: 55.040 - Packaging materials and accessories; 83.140.10 - Films and sheets. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 14932:2018 has the following relationships with other standards: It is inter standard links to EN 14932:2006, EN 14932:2025, EN ISO 7765-1:2004, EN 4343:2002, EN ISO 13468-2:2021, EN ISO 6383-2:2004, EN ISO 4892-2:2013, EN ISO 527-1:2019, EN ISO 527-3:2018, EN 4138:2009. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 14932:2018 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Polimerni materiali - Raztegljive plastomerne folije za zavijanje v baleKunststoffe - Thermoplastische Stretchofolien zum Umwickeln von BallenPlastiques - Films thermoplastiques étirables pour l'enrubannage de balles d'ensilagePlastics - Thermoplastic stretch films for wrapping silage bales83.140.10Filmi in folijeFilms and sheets55.040SDNLUDQMHPackaging materials and accessoriesICS:Ta slovenski standard je istoveten z:EN 14932:2018SIST EN 14932:2018en,fr,de01-marec-2018SIST EN 14932:2018SLOVENSKI

STANDARDSIST EN 14932:20071DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 14932

January

t r s z ICS

w wä r v râ

z uä s v rä s r Supersedes EN

s v { u tã t r r xEnglish Version

Plastics æ Thermoplastic stretch films for wrapping silage bales Plastiques æ Films thermoplastiques étirables pour l 5enrubannage de balles d 5ensilage

Kunststoffe æ Thermoplastische Stretchfolien zum Umwickeln von SilageæBallen This European Standard was approved by CEN on

t r November

t r s yä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Serbiaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey and United Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Rue de la Science 23,

B-1040 Brussels

t r s z CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s v { u tã t r s z ESIST EN 14932:2018

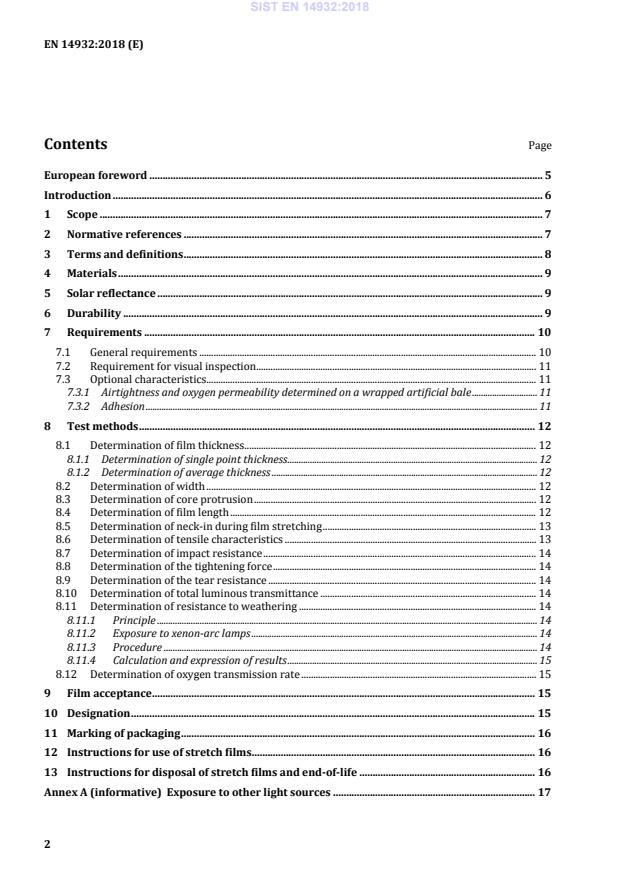

Contents Page European foreword . 5 Introduction . 6 1 Scope . 7 2 Normative references . 7 3 Terms and definitions . 8 4 Materials . 9 5 Solar reflectance . 9 6 Durability . 9 7 Requirements . 10 7.1 General requirements . 10 7.2 Requirement for visual inspection . 11 7.3 Optional characteristics . 11 7.3.1 Airtightness and oxygen permeability determined on a wrapped artificial bale . 11 7.3.2 Adhesion . 11 8 Test methods . 12 8.1 Determination of film thickness . 12 8.1.1 Determination of single point thickness . 12 8.1.2 Determination of average thickness . 12 8.2 Determination of width . 12 8.3 Determination of core protrusion . 12 8.4 Determination of film length . 12 8.5 Determination of neck-in during film stretching . 13 8.6 Determination of tensile characteristics . 13 8.7 Determination of impact resistance . 14 8.8 Determination of the tightening force . 14 8.9 Determination of the tear resistance . 14 8.10 Determination of total luminous transmittance . 14 8.11 Determination of resistance to weathering . 14 8.11.1 Principle . 14 8.11.2 Exposure to xenon-arc lamps . 14 8.11.3 Procedure . 14 8.11.4 Calculation and expression of results . 15 8.12 Determination of oxygen transmission rate . 15 9 Film acceptance . 15 10 Designation . 15 11 Marking of packaging . 16 12 Instructions for use of stretch films . 16 13 Instructions for disposal of stretch films and end-of-life . 16 Annex A (informative)

Exposure to other light sources . 17 SIST EN 14932:2018

Numerical correlation between durations of stretch forage films exposed to artificial weathering and a natural exposure . 20 B.1 Exposure to xenon-arc lamps . 20 B.2 Exposure to medium pressure mercury vapour lamps . 20 B.3 Exposure to fluorescent UV lamps . 21 Annex C (normative)

Determination of solar reflectance . 22 C.1 General. 22 C.2 Principle . 23 C.3 Terms and definitions . 23 C.4 Apparatus . 23 C.5 Test specimens . 24 C.6 Procedure . 24 C.7 Calculation of the solar reflectance Rs . 24 Annex D (normative)

Determination of neck-in during stretching . 25 D.1 Introduction . 25 D.2 Principle . 25 D.3 Apparatus . 25 D.4 Atmosphere for conditioning and testing . 26 D.5 Procedure . 26 Annex E (normative)

Determination of tightening force . 27 E.1 Principle . 27 E.2 Apparatus . 27 E.3 Procedure . 27 E.4 Preparation of the specimens . 27 E.5 Results . 27 Annex F (informative)

Determination of oxygen permeability and airtightness on an artificial bale . 29 F.1 General. 29 F.2 Principle . 29 F.3 Apparatus . 29 F.4 Films . 31 F.5 Conditioning of the film . 31 F.6 Procedure . 32 Annex G (informative)

Determination of adhesion characteristic . 35 G.1 Principle . 35 G.2 Apparatus . 35 SIST EN 14932:2018

Guidance for use and disposal of stretch films . 40 H.1 Instructions for storage of rolls . 40 H.2 Instructions for baling . 40 H.3 Instruction for wrapping . 40 H.4 Instruction for storage of wrapped bales . 41 H.5 Instruction for disposal of films . 41 Bibliography. 43

makes reference to the exposure of films by artificial weathering; — optional characteristics are introduced by revised annexes; — paragraphs on instructions for use, for disposal and end-of-life of stretch films have been added. According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 14932:2018

3.4 film length largest dimension of a film corresponding to the length of the unwinded roll (or reel) Note 1 to entry: It is expressed in metres (m). 3.5 nominal length L0 length of the film, as declared by the manufacturer Note 1 to entry: It is expressed in metres (m). 3.6 longitudinal direction MD direction parallel to the film length corresponding to the extrusion direction 3.7 transverse direction TD direction parallel to the film width (at right angles to the length) 3.8 core protrusion Cp distance from the edge of a roll to the edge of its core Note 1 to entry: It is expressed in millimetres (mm). SIST EN 14932:2018

It is expressed as a %. 3.10 radiant exposure H time integral of irradiance

«2) [SOURCE: ISO 9370:2017, 3.27 [2]] 4 Materials Stretch films for wrapping silage bales according this European Standard are usually manufactured from polyolefin materials. 5 Solar reflectance The stretch silage films shall be classified in two classes “High reflectance” or “Low reflectance” according to the solar reflectance, as defined in Table 1. The solar reflectance shall be determined according to Annex C by using one layer of unstretched film [2]. The class of solar reflectance shall be declared by the manufacturer. Table 1 — Classification according to the solar reflectance Class of film Solar reflectance Rs % High reflectance

· 24 Low reflectance < 24 6 Durability The durability of stretch forage films shall be declared by the manufacturer in kLy1. The duration of exposure of the film shall be determined by an artificial weathering using xenon-arc lamps, conforming to 8.11, which induces a decrease of the value of tensile strain at break equal or less than 50 % of the initial value. Other light sources may be used provided that a correlation between the test results obtained with these light sources and these obtained after a natural exposure can be demonstrated. Details of these methods are given in Annex A (informative). In case of dispute, the exposure to xenon-arc lamps according to 8.11 shall be used.

1 1kLy = 0,04184 GJ/m2 SIST EN 14932:2018

Shall conform to 7.2 7.2 Tolerance of average thickness/nominal thickness % from

« z to

s t 8.1 Tolerance of single point thickness/nominal thickness % from

« t r to

t z 8.1 Width tolerance mm W0 - 5

¶ W

¶ W0 + 5 8.2 Core protrusion mm 3

¶ Cp

¶ 10 8.3 Film length m

· 99,0 % of nominal roll length 8.4 Neck in during film stretching % < 25 8.5 Tensile stress at break

8.6

MD MPa

· 25

TD MPa

· 23

Tensile stress at yield

8.6

MD MPa

· 9

Tensile strain at break

8.6

MD %

· 400

TD %

· 600

Impact resistance g

· 150 8.7 Tightening force N

· 8,75 8.8 Tear resistance

8.9

MD cN

· 120

TD cN

· 600

Total luminous transmittance % < 50 8.10 Oxygen transmission rate a (expressed as for one layer of unstretched film)

8.12 For film with solar reflectance b

· 24 % cm3 /(m2 < 10 000

· 10 % and

< 24 % cm3 /(m2b t vhbbar e) < 9 500

For film with solar reflectance d < 10 % cm3 /(m2b t vhbbar e) < 8 500

a A commonly used unit for the oxygen gas transmission rate is the cm3 (STP)/(m2 pressure differential, where: 1cm3 at Standard Temperature and Pressure (STP = 273,15K; 1,013 × 105 Pa) is 44,62

× 103 s . The oxygen transmission rate in mol/(m2 multiplying the value in cm3 (STP)/(m2

×

s r Í10. b Example white and light green films c

Example dark green films d

Example black films e 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2 7.2 Requirement for visual inspection The edges of the reels shall be straight. Bubbles and wrinkles on the reel and visible defects on the film which affect the proper use of the film shall be limited. 7.3 Optional characteristics 7.3.1 Airtightness and oxygen permeability determined on a wrapped artificial bale NOTE 1 The quality of silage is strongly depending on the global airtightness of wrapped bales. Several parameters can influence the global airtightness results: measurable properties such as the permeability cling force or tightening force of the film and also properties difficult to quantify by means of laboratory equipments, such as wrinkles, tiger stripes or film appearance when stretched. NOTE 2 At the date of publication of this standard, there is no European or international standardized method to determine the airtightness and the oxygen permeability by wrapping an artificial bale. Guidance for assessing the airtightness and the oxygen permeability of a stretch silage film by wrapping an artificial bale is given in Annex F. The oxygen permeability is defined in Annex F as the amount of permeated oxygen (from the atmosphere) through the artificial bale per 100 h. The airtightness is defined in Annex F as the time for the internal pressure to increase from

« w r r Pa to

« s r r Pa. 7.3.2 Adhesion NOTE Adhesion is a major property of stretch films for wrapping silage bales but no specific method has been developed for this application. SIST EN 14932:2018

is the density of the film as stated by the manufacturer, expressed in kilograms per cubic metres (kg/m3). 8.2 Determination of width The width of the film shall be determined in accordance with ISO 4592. 8.3 Determination of core protrusion The core protrusion of a roll shall be measured on each side of the roll. The two values shall be expressed in millimetres (mm) recorded and compared with the value in Table 2. 8.4 Determination of film length The length of the film shall be determined by unwinding the roll by means of a calibrated reel in contact continuously with its outside surface

(see Figure 1). The calibrated reel is connected to a revolution counter. The diameter of the calibrated reel shall be measured with a accuracy of ± 0,2 %. The roll shall be totally unwound at a speed of 100 m/min ± 10 m/min. The value of the length of the film is calculated by using Formula (2): π=⋅⋅lnd (2) where l is the value of the length of the film, expressed in metres (m); SIST EN 14932:2018

Key 1 film roll 2 calibrated reel with a revolution counter 3 collection reel Figure 1 — Apparatus for the determination of the film length 8.5 Determination of neck-in during film stretching The neck-in during film stretching shall be determined in accordance with Annex D. The test result, corresponding to the film shrinkage in TD, shall be expressed as a percentage of the original width by using Formula (3): −=121100iWWNW

(3) where Ni is the value of neck-in, expressed as a percentage (%); W1 is the measured width of the unstretched film according to 8.2, expressed in millimetres (mm); W2 is the measured width of the stretched film on the bale (D.5.4), expressed in millimetres (mm). 8.6 Determination of tensile characteristics The tensile characteristics shall be determined according to EN ISO 527-1 and EN ISO 527-3 using five test pieces type 2, see EN ISO 527-3:1995, Figure 1, 15 mm wide, cut in MD and TD of the film, at a test speed of 500 mm/min, with an initial grip-to-grip separation of 50 mm. Calculate the arithmetic average value of the five measurements. The arithmetic average values shall fulfil the requirements of Table 2, as applicable. NOTE A possible way to prepare the test specimens is to cut

from a stack of 2 or more (max. 10) layers of the film under investigation and then separate them individually by delaminating in order to limit the risk of creating micro-fractures in the specimens because stretch films are thin and sticky SIST EN 14932:2018

made of

preferably not pigmented rigid plastic (e.g. fluorinated polymer) and the tacky side of the film facing the backing. After the exposure, determine the tensile strain at break according to EN ISO 527-1 and EN ISO 527-3, using five type 2 test pieces, see Figure 1 of EN ISO 527-3:1995, 15 mm wide, taken in MD of the film, at a test speed of 500 mm/min, with an initial grip-to-grip separation of 50 mm. SIST EN 14932:2018

Exposure to other light sources A.1 Medium pressure mercury vapour lamps A.1.1 Exposure method Carry out the exposure according to EN 16472 using the test conditions given in A.1.2 and A.1.3. The exposure may be carried out in the presence of moisture in the form of water spray, condensation or by immersion cycles with or without light. In this case, test parameters shall be agreed between parties and recorded in the test report. NOTE Information on the influence of water and additive migration can be found in ISO 10640 [10]. A.1.2 Irradiance The irradiance at the surface of the test specimens shall be (95 ± 15) W/m2 in the spectral passband 290 nm to 420 nm. A.1.3 Temperature NOTE An accurate control of the actual temperature of exposed specimens is critical since the thermal activation energy of photochemical processes leads to exponential variation of the degradation rate according to a type-Arrhenius law. For apparatus including a platinum sensor in contact with a specimen attached to the specimen holder, the film temperature shall be controlled at (60 ± 4) °C. For apparatus including a platinum sensor inserted in a white thermally-controlled component, the initial set point of the temperature shall be (58 ± 0,5) °C. As a given temperature set point can lead to different results depending on the apparatus, it is necessary to calibrate them. See A.1.4. A.1.4 Apparatus calibration The calibration of the apparatus shall be carried out relatively to the photochemistry be means of an actinometer made from a polyethylene reference specimens (PERS), as defined in ISO/TR 19032:2006 [11]. The calibration by means of a PERS allows controlling accurately the photochemical attack from both irradiance and temperature. PERS shall be exposed during 72 h using test conditions specified in A.1.2 and A.1.3. The oxidation level shall be measured by using an infrared spectrometer in the transmission mode. The absorbance ratio (carbonyl index); Ar, shall satisfy the following condition: ≤=≤171520201,82,4rAAA (A.1) SIST EN 14932:2018

for the duration specified by the film manufacturer. The test method consists of an irradiance step (dry, with irradiance) and a condensation step (high humidity, without irradiation), with the following test conditions: a) irradiance shall be (0,76 ± 0,06) W/m2, measured at 340 nm at the surface of the test specimen. b) the temperature of the test specimen shall be (60 ± 3) °C during irradiance and (50 ± 3) °C during condensation step. The temperature shall be measured with an uninsulated black-panel thermometer (BPT). An accurate control of the effective temperature of the test specimen is of main importance. The thermal activation energy of photochemical processes leads to an exponential variation of the rate of degradation according to an Arrhenius type law. A.2.2 Procedure The sample shall be exposed according to A.2.1 for the duration specified by the film manufacturer. After the exposure, the tensile strain at break shall be determined according to EN ISO 527-1 and EN ISO 527-3, using five type 2 test pieces, 15 mm wide, taken longitudinally in the film (MD), at a test speed of 500 mm/min, with an initial grip-to-grip separation of 50 mm. SIST EN 14932:2018

Numerical correlation between durations of stretch forage films exposed to artificial weathering and a natural exposure B.1 Exposure to xenon-arc lamps The method specified in EN ISO 4892-2:2013, Method A, consists to expose stretch forage films to radiations in the ultraviolet (UV) and visible regions of the spectrum that are very similar to the solar spectrum. For this reason it is reasonable to presume that a correlation exists between the artificial exposure and the natural exposure of a film to daylight. A numerical correlation between durations of exposure to artificial weathering according to 8.11.2 and durations of natural exposure, measured in terms of average yearly global solar radiant exposure, of stretch forage films is given in Table B.1. Table B.1 — Correlation between the exposure to artificial weathering using xenon-arc lamps and natural weathering Global solar radiant exposure GJ/m2/year (kLy/year) Duration of exposure for an expected lifetime of 1 year h Up to 4,2 (up to 100) 1 370 Up

to 5,4 (up to 130) 1 780 Up to 6,7 (up to 160) 2 200 1kLy = 0,0418 4 GJ/m2 In practice many factors reduce the correlation between the duration of a stretch film used for forage bale wrapping in outdoor real conditions and the duration of the same film exposed to artificial weathering. Among these it is appropriate to mention the use of agrochemicals that may

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...