EN 13616-2:2016

(Main)Overfill prevention devices for static tanks for liquid fuels - Part 2: Overfill prevention devices without a closure device

Overfill prevention devices for static tanks for liquid fuels - Part 2: Overfill prevention devices without a closure device

This European Standard specifies requirements and the corresponding test/assessment methods applicable to overfill prevention devices without closure device.

The overfill prevention device is usually composed of

- sensor,

- electric-mechanical interface.

These overfill prevention devices intended to be used in/with underground or above ground, non-pressurised, metallic or non-metallic, static tanks designed for liquid fuels.

NOTE In further text, for liquid fuels the term liquid is used.

Überfüllsicherungen für ortsfeste Tanks für flüssige Brenn- und Kraftstoffe - Teil 2: Überfüllsicherungen ohne Schließeinrichtung

Diese Europäische Norm enthält Anforderungen, Prüf und Bewertungsverfahren, Kennzeichnung, Etikettie¬rung und Verpackung, die für Überfüllsicherungen ohne Schließeinrichtung gelten.

Die Überfüllsicherung ohne Schließeinrichtung besteht gewöhnlich aus:

— Überfüllsicherungssensor, bestehend aus

— Sensor;

— elektrischer Schnittstelle;

— mechanischer Schnittstelle;

— Steuereinrichtung der Überfüllsicherung nach EN 16657.

Diese Überfüllsicherungen sind für die Verwendung in/mit unter oder oberirdischen, drucklosen, ortsfesten Tanks für flüssige Brenn und Kraftstoffe vorgesehen.

ANMERKUNG 1 Flüssige Brenn und Kraftstoffe bedeutet Flüssigkeiten für interne Verbrennungsmotoren, Heiz /Kühlkessel und Generatoren.

ANMERKUNG 2 Im Folgenden wird für den Begriff „flüssige Brenn und Kraftstoffe“ der Begriff „Flüssigkeit“ verwendet.

Dispositifs limiteurs de remplissage pour réservoirs statiques pour carburants liquides - Partie 2: Dispositifs limiteurs de remplissage sans dispositif de fermeture

La présente Norme européenne spécifie les exigences et les méthodes d’essai/d’évaluation correspondantes applicables aux dispositifs limiteurs de remplissage sans dispositif de fermeture.

Le dispositif limiteur de remplissage est généralement constitué

- d’un capteur ;

- d’une interface électromécanique.

Ces dispositifs limiteurs de remplissage sont prévus pour être utilisés dans/avec des réservoirs statiques enterrés ou aériens, hors pression, métalliques ou non, conçus pour les carburants liquides.

NOTE Dans le reste du texte, le terme liquide est utilisé pour carburants liquides.

Naprave za preprečitev prepolnitve za nepremične rezervoarje za tekoča goriva - Zahteve in metode za preskušanje in ocenjevanje - 2. del: Naprave za preprečitev prepolnitve brez zaporne naprave

Ta evropski standard določa zahteve ter ustrezne metode za preskušanje in ocenjevanje, ki se uporabljajo za naprave za preprečitev prepolnitve brez zaporne naprave.

Naprava za preprečitev prepolnitve je običajno sestavljena iz

– senzorja,

– električno-mehanskega vmesnika.

Te naprave za preprečitev prepolnitve so namenjene za uporabo v kovinskih ali nekovinskih stabilnih rezervoarjih za tekoča goriva, ki so pod ali nad zemljo in niso pod tlakom, ali z njimi.

OPOMBA: V nadaljevanju se za tekoča goriva uporablja izraz tekočina.

General Information

- Status

- Withdrawn

- Publication Date

- 07-Jun-2016

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 393 - Equipment for storage tanks and for service stations

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 03-Sep-2025

- Completion Date

- 11-Feb-2026

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 08-Jun-2022

- Replaces

EN 13616:2004/AC:2006 - Overfill prevention devices for static tanks for liquid petroleum fuels - Effective Date

- 15-Jun-2016

- Effective Date

- 09-Jul-2025

- Refers

EN IEC 60079-11:2024 - Explosive atmospheres - Part 11: Equipment protection by intrinsic safety "i" - Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ABS Quality Evaluations Inc.

American Bureau of Shipping quality certification.

Element Materials Technology

Materials testing and product certification.

ABS Group Brazil

ABS Group certification services in Brazil.

Sponsored listings

Frequently Asked Questions

EN 13616-2:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Overfill prevention devices for static tanks for liquid fuels - Part 2: Overfill prevention devices without a closure device". This standard covers: This European Standard specifies requirements and the corresponding test/assessment methods applicable to overfill prevention devices without closure device. The overfill prevention device is usually composed of - sensor, - electric-mechanical interface. These overfill prevention devices intended to be used in/with underground or above ground, non-pressurised, metallic or non-metallic, static tanks designed for liquid fuels. NOTE In further text, for liquid fuels the term liquid is used.

This European Standard specifies requirements and the corresponding test/assessment methods applicable to overfill prevention devices without closure device. The overfill prevention device is usually composed of - sensor, - electric-mechanical interface. These overfill prevention devices intended to be used in/with underground or above ground, non-pressurised, metallic or non-metallic, static tanks designed for liquid fuels. NOTE In further text, for liquid fuels the term liquid is used.

EN 13616-2:2016 is classified under the following ICS (International Classification for Standards) categories: 23.020.10 - Stationary containers and tanks; 75.200 - Petroleum products and natural gas handling equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13616-2:2016 has the following relationships with other standards: It is inter standard links to EN 13616:2004, EN 13616:2004/AC:2006, EN 13616-2:2016+A1:2025, EN IEC 60079-11:2024, EN 61000-6-3:2007, EN IEC 60079-0:2018, EN 61000-6-2:2005, EN 590:2025, EN 14879-4:2007, EN ISO 13849-1:2023, EN 16657:2016, EN 16657:2016+A1:2018, EN 12514:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13616-2:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/131. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13616-2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Überfüllsicherungen für ortsfeste Tanks für flüssige Brenn- und Kraftstoffe - Anforderungen und Prüf-/Bewertungsverfahren - Teil 2: Überfüllsicherungen ohne SchließeinrichtungDispositifs limiteurs de remplissage pour réservoirs statiques pour carburants pétroliers liquides - Exigences et méthodes d'essai/d'évaluation - Partie 2: Dispositifs limiteurs de remplissage sans dispositfs de fermetureOverfill prevention devices for static tanks for liquid fuels - Requirements and test/assessment methods - Part 2: Overfill prevention devices without closure device75.200Petroleum products and natural gas handling equipment23.020.10UH]HUYRDUMLStationary containers and tanksICS:Ta slovenski standard je istoveten z:EN 13616-2:2016SIST EN 13616-2:2016en,fr,de01-oktober-2016SIST EN 13616-2:2016SLOVENSKI

STANDARDSIST EN 13616:2004/AC:2006SIST EN 13616:20041DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13616-2

June

t r s x ICS

t uä r t rä s r Supersedes EN

s u x s xã t r r vEnglish Version

Overfill prevention devices for static tanks for liquid fuels æPart

tã Overfill prevention devices without a closure device Dispositifs limiteurs de remplissage pour rßservoirs statiques pour carburants liquides æ Partie

tã Dispositifs limiteurs de remplissage sans dispositif de fermeture

Überfüllsicherung für ortsfeste Tanks für flüssige Brennæ und Kraftstoffe æ Teil

tã Überfüllsicherungen ohne Schließeinrichtung This European Standard was approved by CEN on

z April

t r s xä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s u x s xæ tã t r s x ESIST EN 13616-2:2016

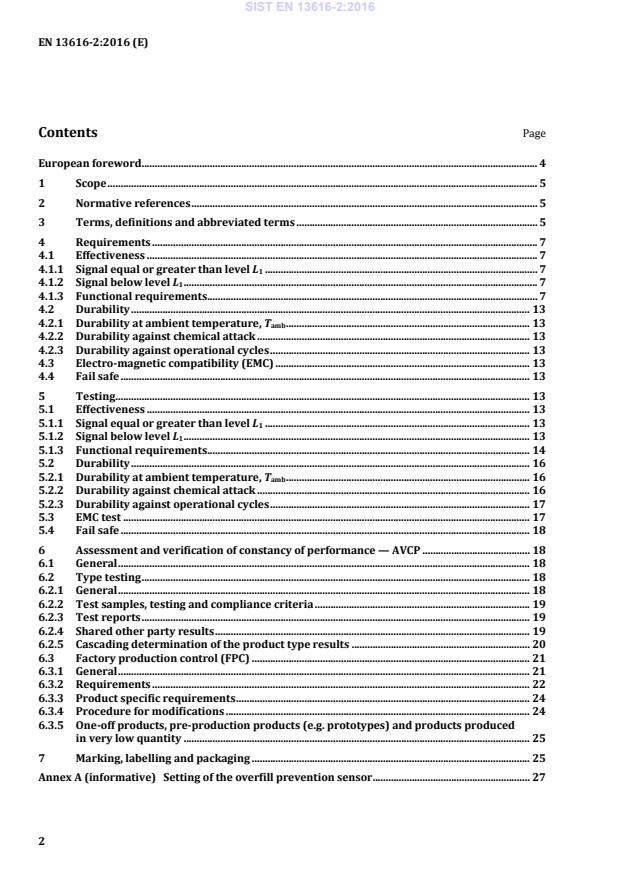

Setting of the overfill prevention sensor . 27 SIST EN 13616-2:2016

Clauses of this European Standard addressing the provisions of the EU Construction Products Regulation . 30 ZA.1 Scope and relevant characteristics . 30 ZA.2 Procedure for AVCP of overfill prevention devices without closure device . 31 ZA.2.1 System(s) of AVCP . 31 ZA.2.2 Declaration of performance (DoP) . 32 ZA.2.2.1 General . 32 ZA.2.2.2 Content . 32 ZA.2.2.3 Example of DoP . 33 ZA.3 CE marking and labelling . 35 Bibliography . 37

« t w °C to +50 °C. If the fuel temperature Tliq range deviates from the standard, it shall be declared by the manufacturer. The operational characteristics for the overfill prevention sensor shall be according to Figure 1 and Table 1. Any additional use of the electrical interface shall not influence the operating characteristics and the functioning of the overfill prevention sensor. To obtain the characteristics in Figure 1 the voltage of the supply circuit has to be stabilized over the whole temperature range to a value of (19 ± 0,3) V. The voltage value of (19 ± 0,3) V shall also be up to a current of 80 mA. The internal resistance of the supply circuit shall be (160 ± 3,2)

Key

range for signal “filling permitted”

range for signal “filling not permitted” t1 time of recognition of start of sensor warm up (I > I1) t2 time of recognition of reaching sensor operating condition 0,5 s < (t2 – t1) < 180 s NOTE If (t2 – t1) > 180 s no product flow is possible. t3 time of wetting sensor t4 time of recognition of a wet sensor i.e. stop of product flow shall be initiated tR R = t4 – t3 Reaction time of the overfill prevention sensor (R) from status permissive to status non-permissive shall be

¶ 1,5 s. Figure 1 — Cycle of electrical interface Table 1 — Current values at electrical interface Current Max. value mA Min. value mA Remark I1 49,5 41 I1 > I2 I2 44 38 I3 10 2 — 4.1.3.2 Installation of the overfill prevention sensor in the tank The principle installation of the sensor and its main parts shall be according to Figure 2. See also Annex A. SIST EN 13616-2:2016

Key X adjusted dimension 1 plug according to Figure 3 Y control dimension 2 sensor pipe Z probe length between markings 3 connection thread of the tank for the overfill prevention sensor L1 level at which the sensor for overfill prevention sensor is wetted 4 protection against spraying liquid Lmax maximum filling level 5 installation body of the overfill prevention sensor, optional with adjustability for the overfill prevention sensor

6 place for value Z in mm

7 sensor Figure 2 — Structure of the overfill prevention sensor with installation in the static tank 4.1.3.3 Mechanical interface The plug part of the connection between the overfill prevention sensor and the mating part of the transport tank equipment is shown in Figure 4 and Figure 5. The mating part (socket) is described in EN 16657. The wiring at the storage tank between the PID and the listener contact shall be according to Figure 3. SIST EN 13616-2:2016

Key 1 overfill prevention system socket BK black colour of the wire 2 fill coupling BL blue colour of the wire 3 optional vapour recovery BN brown colour of the wire 4 listener line RD red colour of the wire Figure 3 — Wiring between the PID and the listener contact SIST EN 13616-2:2016

a) Plug type 907 and AS 907 b) Plug insert for type AS 907 c) Plug insert for type 907 Key 1 contact pin, material: brass nickel plated 2 terminal 3 insulating sleeve Figure 4 — Mechanical construction of the overfill prevention sensor plug for type 907 and type AS 907 SIST EN 13616-2:2016

a) Plug type 904 b) Plug for type 905

c) Plug insert for type 905 and 904 Key 1 contact pin, material: brass nickel plated 2 drill for terminal cross section 1,5 mm2 with wire protect 3 fastening lug Figure 5 — Mechanical construction of the overfill prevention sensor plug for type 904 and type 905 SIST EN 13616-2:2016

« t w °C to +60 °C. Deviations shall be declared by the manufacturer. 4.2.2 Durability against chemical attack The overfill prevention sensor, or parts normally exposed to liquids or their vapours, shall be durable in contact with the declared liquids. 4.2.3 Durability against operational cycles The overfill prevention sensor shall withstand

· 3.000 operational cycles. 4.3 Electro-magnetic compatibility (EMC) Overfill prevention devices contain active electronic components, so they shall fulfil the requirements according to: — EN 61000-6-3 for emission; — EN 61000-6-2 for immunity. The classification shall be provided by the manufacturer, only if active electronic components are incorporated. Concerning immunity the overfill prevention sensor shall work as intended under all conditions or shall provide a signal as above level L1 for the non-permissive state. 4.4 Fail safe Resistors with a positive temperature coefficient (PTC-resistor) shall fulfil fail safe requirements. NOTE The fail safe property of a PTC-resistor is contained in the requirements according to 4.1.3.1.2 and verified according to 5.1.3.1.2 and a test according to 5.4 is not required. Failure of any active electronic component, one at a time, in short circuit or open circuit state or a permanent automatic self-test shall result in a non-permissive output or correct operation. All components shall not be loaded more than 2/3 of their nominal load with respect to the ambient temperature. If a binary digital system is used the electronic circuitry of the sensors and the electronics to the interface shall be designed according to the performance level PL b of EN ISO 13849-1. 5 Testing 5.1 Effectiveness 5.1.1 Signal equal or greater than level L1 The test according to 5.1.3 shall demonstrate the effectiveness of the overfill prevention device by providing the signal above level L1 for the status non-permissive. 5.1.2 Signal below level L1 The test according to 5.1.3 shall demonstrate the effectiveness of the overfill prevention device by providing the signal below level L1 for the status permissive. SIST EN 13616-2:2016

« t w °C to +50 °C with an accuracy of 2 K; — test liquid: diesel according to EN 590. b) Test method The overfill prevention sensor under test shall be connected with a power supply according to 4.1.3.1.1. Prior to each test to be conducted, and with the overfill prevention sensor fully operational, the environmental chamber shall be at the required test temperature. All equipment (including the test liquid) shall have reached the test temperature ± 2 K, before the test is performed. The test temperature of the environmental chamber and the test liquid shall be equal: —

«25 °C — +20 °C — +50 °C respectively +20 °C and the limits of the temperatures defined by the manufacturer. The following series of tests shall be performed three times for each liquid for each temperature. Results shall be recorded: 1) Heating up range — sensor not activated Measurements commence when the overfill prevention sensor is connected to the power supply. Measure initial current I1 and the time according to Figure 1. Measure current I2 according to Figure 1 after heating up. 2) Reaction time of the overfill prevention sensor – sensor activated Electrical current I is measured during the time the sensor is taken in the test liquid. The reaction time of the overfill prevention sensor R shall be determined according to 4.1.3.1.2. SIST EN 13616-2:2016

® 15 min-1 The change of temperature shall not exceed 5 K

® min-1 during heating up and cooling down the environmental chamber. 5.2.1.3 Test result A visual inspection and functional test according to 5.1.3.1.2 shall be carried out at (20 ± 10) °C. The results shall be recorded. There shall be no evident visible damage to the overfill prevention sensor and the overfill prevention sensor shall operate in compliance with the criteria listed in 4.1.3.1.2, Figure 1 and Table 1. 5.2.2 Durability against chemical attack 5.2.2.1 General Third party test results, data sheet of suppliers, as well as empirical values shall be accepted. If such documents are not available, the durability of all materials of the overfill prevention sensor or parts, normally exposed to liquids or their vapours, against chemical attack for the declared liquid shall be checked with the test liquid of each relevant group according to Annex C of EN 14879-4:2007. SIST EN 13616-2:2016

1) The formulation of such an agreement can be done by licence, contract, or any other type of written consent. 2) This can be, for instance, a contract, license or whatever kind of written agreement, which should also contain clear provisions with regard to responsibility and liability of the component producer (system house, on the one hand, and the assembler of the finished product, on the other hand. 3) These companies may produce components but they are not required to do so. SIST EN 13616-2:2016

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...