EN 1873:2014+A1:2016

(Main)Prefabricated accessories for roofing - Individual rooflights of plastics - Product specification and test methods

Prefabricated accessories for roofing - Individual rooflights of plastics - Product specification and test methods

This European Standard specifies requirements for rooflights made of plastic materials (e.g. GF-UP, PC, PMMA, PVC) and rooflights with upstands made of e.g. GF-UP, PVC, steel, aluminium or wood for installation in roofs. These rooflights serve the purpose of introducing daylight.

This European Standard applies to rooflights with a rectangular or circular ground plan (see Figures 1 and 2), with an opening span (width) or diameter not larger than 2,5 m and an opening length not larger than 3,0 m in roof pitches up to 25°. This document does not cover rooflights which contribute to the load-bearing or stiffness of the roof itself.

This European Standard applies to rooflights and rooflights with upstand, where a single manufacturer provides all components of the rooflight with upstand, which are bought in a single purchase.

This European Standard applies to rooflights with one or several translucent parts.

Rooflights may be opened by means of opening devices in one or more parts for ventilation.

The possible additional functions of day to day ventilation, smoke and heat ventilation e.g. in case of fire in accordance with EN 12101 2, roof access, and/ or slinging point e.g. in accordance with EN 795 are outside the scope of this document.

This European Standard does not include calculations with regard to construction, design requirements and installation techniques.

NOTE Guidelines for safety, application, use and maintenance of individual rooflights are presented in Annex A.

Vorgefertigte Zubehörteile für Dachdeckungen - Lichtkuppeln aus Kunststoff - Produktspezifikation und Prüfverfahren

This European Standard applies to rooflights with a rectangular or circular ground plan (see Figures 1 and 2), with an opening span (width) or diameter not larger than 2,5 m and an opening length not larger than 3,0 m in roof pitches up to 25°. This document does not cover rooflights which contribute to the load-bearing or stiffness of the roof itself.

This European Standard applies to rooflights and rooflights with upstand, where a single manufacturer provides all components of the rooflight with upstand, which are bought in a single purchase.

This European Standard applies to rooflights with one or several translucent parts.

Rooflights may be opened by means of opening devices in one or more parts for ventilation.

The possible additional functions of day to day ventilation, smoke and heat ventilation e.g. in case of fire in accordance with EN 12101 2, roof access, and/ or slinging point e.g. in accordance with EN 795 are outside the scope of this document.

This European Standard does not include calculations with regard to construction, design requirements and installation techniques.

NOTE Guidelines for safety, application, use and maintenance of individual rooflights are presented in Annex A.

Accessoires préfabriqués pour couverture - Lanterneaux ponctuels en matière plastique - Spécifications des produits et méthodes d'essais

La présente Norme européenne spécifie les exigences pour les lanterneaux en matière plastique (par exemple polyester renforcé par des fibres de verre (PRV), polycarbonate (PC), polyméthacrylate de méthyle (PMMA), polychlorure de vinyle (PVC) avec costières, fabriqués par exemple en PRV, PVC, acier, aluminium ou bois, et destinés à être installés sur des toitures. Ces lanterneaux permettent de laisser passer la lumière du jour.

La présente Norme européenne s’applique aux lanterneaux ayant une embase rectangulaire ou circulaire (voir Figures 1 et 2), dont la portée (largeur) ou le diamètre d’ouverture ne dépasse pas 2,5 m et dont la longueur d’ouverture n’est pas supérieure à 3,0 m sur des toitures en pente jusqu’à 25°. Le présent document ne couvre pas les lanterneaux qui contribuent à la portance ou à la raideur de la toiture proprement dite.

La présente Norme européenne s'applique aux lanterneaux simples et aux lanterneaux avec costière dont tous les éléments constitutifs, partie intégrante d'un achat unique, sont fournis par un seul fabricant.

La présente Norme européenne s'applique aux lanterneaux avec une ou plusieurs parois translucides.

Les lanterneaux peuvent s'ouvrir au moyen de dispositifs d’ouverture en une ou plusieurs parties pour la ventilation.

Les éventuelles fonctions supplémentaires de ventilation quotidienne, d’évacuation des fumées et de la chaleur, comme par exemple en cas d'incendie, conformément à l'EN 12101-2, d'accès à la toiture, et/ou de points d'ancrage conformes par exemple à l'EN 795, ne relèvent pas du domaine d'application du présent document.

La présente Norme européenne ne comprend pas les calculs concernant les constructions, les exigences de conception et les méthodes d'installation.

NOTE Les directives relatives à la sécurité, à l'application, à l'utilisation et à l'entretien des lanterneaux ponctuels sont présentées en Annexe A.

Predizdelani dodatki za ostrešja - Plastični svetlobniki - Specifikacija izdelka in preskusne metode

Ta evropski standard velja za svetlobnike s pravokotnim ali okroglim tlorisom (glej sliki 1 in 2), z razponom odprtine (širine) ali premerom, ki ni večji od 2,5 m, in dolžino odprtine, ki ni večja od 3,0 m, na poševnih strehah z nagibom do 25°. Ta dokument ne zajema svetlobnikov, ki prispevajo k nosilnosti ali togosti strehe.

Ta evropski standard velja za svetlobnike in svetlobnike s podstavki, pri katerih en sam proizvajalec zagotavlja vse komponente svetlobnikov s podstavki, ki so kupljeni hkrati.

Ta evropski standard velja za svetlobnike z enim ali več prosojnimi deli.

Svetlobniki se lahko odprejo s pomočjo naprave za odpiranje, in sicer se lahko odpre en ali več delov za prezračevanje.

Morebitne dodatne funkcije za vsakodnevno prezračevanje, prezračevanje dima in toplote, npr. v primeru požara v skladu s standardom EN 12101 2, dostopa na streho in/ali oporne točke, npr. v skladu z EN 795, so izven obsega tega dokumenta.

Ta evropski standard ne vključuje izračunov v zvezi z gradnjo, projektiranjem in montažnimi tehnikami.

OPOMBA: Smernice glede varnosti, aplikacije, uporabe in vzdrževanja posameznih svetlobnikov so podane v Dodatku A.

General Information

- Status

- Published

- Publication Date

- 16-Feb-2016

- Withdrawal Date

- 30-Aug-2016

- Technical Committee

- CEN/TC 128 - Roof covering products for discontinuous laying and products for wall cladding

- Drafting Committee

- CEN/TC 128/SC 9 - Prefabricated accessories for roofing

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 17-Feb-2016

- Completion Date

- 17-Feb-2016

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 18-Nov-2015

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN ISO/CIE 11664-2:2022 - Colorimetry - Part 2: CIE standard illuminants (ISO/CIE 11664-2:2022) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 410:2011 - Glass in building - Determination of luminous and solar characteristics of glazing - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1873:2014+A1:2016 (EN 1873) specifies product requirements and test methods for prefabricated plastic rooflights used to introduce daylight into roofs. It covers individual rooflights made from plastics (e.g. GF‑UP, PC, PMMA, PVC) and rooflights with upstands (e.g. GF‑UP, PVC, steel, aluminium, wood). The standard applies to rectangular or circular rooflights with an opening span (width/diameter) ≤ 2.5 m and opening length ≤ 3.0 m in roof pitches up to 25°. It does not apply to rooflights that form part of the roof’s load‑bearing structure or to design/installation calculations.

Key topics and technical requirements

The standard organizes requirements, tests and classification around measurable product characteristics:

- Radiation properties

- Total luminous transmittance (light transmission)

- Solar direct transmittance (τe) and total solar energy transmittance (g)

- Durability

- Accelerated ageing tests; variation of light transmission and yellowness index

- Watertightness

- Test procedures for sealing performance under simulated rainfall/pressure

- Mechanical performance

- Resistance to upward and downward loads, impact resistance

- Fire behaviour

- Reaction to fire, resistance to fire and external fire performance (classification and testing)

- Air permeability, thermal transmittance and acoustic performance

- U‑value determination methods, air leakage tests, airborne sound insulation

- Other

- Release of dangerous substances; test specimen and reporting rules

- Conformity & factory requirements

- Type testing, assessment and verification of constancy of performance (AVCP), and factory production control (FPC)

- Annexes

- Annex A: informative guidelines for safety, application, use and maintenance

Practical applications and users

Who uses EN 1873:

- Manufacturers of plastic rooflights and integrated upstands - for product specification, type testing and FPC compliance

- Test laboratories - to perform standardized tests (light transmission, impact, watertightness, thermal transmittance, etc.)

- Architects, specifiers and consultants - to select compliant rooflights for daylighting, energy and acoustic targets

- Building product assessors and procurement teams - to verify conformity, classification and performance data for tendering and CE marking Practical uses include daylighting design, specifying thermal performance (U‑values), ensuring watertightness and durability of rooflight installations, and documenting fire and acoustic characteristics.

Related standards

- EN 12101‑2 (smoke and heat ventilation) - related functions (outside EN 1873 scope)

- EN 795 - anchorage/slinging point requirements (outside EN 1873 scope)

Keywords: EN 1873, SIST EN 1873, plastic rooflights, prefabricated accessories for roofing, rooflight test methods, light transmission, thermal transmittance, watertightness, mechanical performance, durability.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 1873:2014+A1:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Prefabricated accessories for roofing - Individual rooflights of plastics - Product specification and test methods". This standard covers: This European Standard specifies requirements for rooflights made of plastic materials (e.g. GF-UP, PC, PMMA, PVC) and rooflights with upstands made of e.g. GF-UP, PVC, steel, aluminium or wood for installation in roofs. These rooflights serve the purpose of introducing daylight. This European Standard applies to rooflights with a rectangular or circular ground plan (see Figures 1 and 2), with an opening span (width) or diameter not larger than 2,5 m and an opening length not larger than 3,0 m in roof pitches up to 25°. This document does not cover rooflights which contribute to the load-bearing or stiffness of the roof itself. This European Standard applies to rooflights and rooflights with upstand, where a single manufacturer provides all components of the rooflight with upstand, which are bought in a single purchase. This European Standard applies to rooflights with one or several translucent parts. Rooflights may be opened by means of opening devices in one or more parts for ventilation. The possible additional functions of day to day ventilation, smoke and heat ventilation e.g. in case of fire in accordance with EN 12101 2, roof access, and/ or slinging point e.g. in accordance with EN 795 are outside the scope of this document. This European Standard does not include calculations with regard to construction, design requirements and installation techniques. NOTE Guidelines for safety, application, use and maintenance of individual rooflights are presented in Annex A.

This European Standard specifies requirements for rooflights made of plastic materials (e.g. GF-UP, PC, PMMA, PVC) and rooflights with upstands made of e.g. GF-UP, PVC, steel, aluminium or wood for installation in roofs. These rooflights serve the purpose of introducing daylight. This European Standard applies to rooflights with a rectangular or circular ground plan (see Figures 1 and 2), with an opening span (width) or diameter not larger than 2,5 m and an opening length not larger than 3,0 m in roof pitches up to 25°. This document does not cover rooflights which contribute to the load-bearing or stiffness of the roof itself. This European Standard applies to rooflights and rooflights with upstand, where a single manufacturer provides all components of the rooflight with upstand, which are bought in a single purchase. This European Standard applies to rooflights with one or several translucent parts. Rooflights may be opened by means of opening devices in one or more parts for ventilation. The possible additional functions of day to day ventilation, smoke and heat ventilation e.g. in case of fire in accordance with EN 12101 2, roof access, and/ or slinging point e.g. in accordance with EN 795 are outside the scope of this document. This European Standard does not include calculations with regard to construction, design requirements and installation techniques. NOTE Guidelines for safety, application, use and maintenance of individual rooflights are presented in Annex A.

EN 1873:2014+A1:2016 is classified under the following ICS (International Classification for Standards) categories: 91.060.20 - Roofs. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1873:2014+A1:2016 has the following relationships with other standards: It is inter standard links to EN 1873:2014, EN 1873:2014/FprA1:2015, EN ISO 178:2019, EN ISO 6946:2017, EN ISO 4892-1:2024, EN ISO 12567-2:2005, EN 13501-5:2016, EN ISO 11925-2:2010, EN ISO/CIE 11664-1:2019, EN 1013:2012+A1:2014, EN ISO/CIE 11664-2:2022, EN ISO 10140-5:2021, EN 410:2011, EN ISO 10211:2017, EN ISO 527-1:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1873:2014+A1:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/122. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1873:2014+A1:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Vorgefertigte Zubehörteile für Dacheindeckungen - Lichtkuppeln aus Kunststoff - Produktfestlegungen und PrüfverfahrenAccessoires préfabriqués pour couverture - Lanterneaux ponctuels en matière plastique - Spécifications des produits et méthodes d'essaisPrefabricated accessories for roofing - Individual rooflights of plastics - Product specification and test methods91.060.20StreheRoofsICS:Ta slovenski standard je istoveten z:EN 1873:2014+A1:2016SIST EN 1873:2014+A1:2016en,fr,de01-april-2016SIST EN 1873:2014+A1:2016SLOVENSKI

STANDARDSIST EN 1873:20141DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1873:2014+A1

February

t r s x ICS

{ sä r x rä t r Supersedes EN

s z y uã t r s vEnglish Version

Prefabricated accessories for roofing æ Individual rooflights of plastics æ Product specification and test methods Accessoires préfabriqués pour couverture æ Lanterneaux ponctuels en matière plastique æ Spécifications des produits et méthodes d 5essais

Vorgefertigte Zubehörteile für Dacheindeckungen æ Lichtkuppeln aus Kunststoff æ Produktfestlegungen und Prüfverfahren This European Standard was approved by CEN on

t u February

t r s v and includes Amendment

s approved by CEN on

y December

t r s wä

egulations which stipulate the conditions for giving this European Standard the status of a national standard without any alterationä Upætoædate lists and bibliographical references concerning such national standards may be obtained on application to the CENæCENELEC Management Centre or to any CEN memberä

translation under the responsibility of a CEN member into its own language and notified to the CENæCENELEC Management Centre has the same status as the official versionsä

CEN members are the national standards bodies of Austriaá Belgiumá Bulgariaá Croatiaá Cyprusá Czech Republicá Denmarká Estoniaá Finlandá Former Yugoslav Republic of Macedoniaá Franceá Germanyá Greeceá Hungaryá Icelandá Irelandá Italyá Latviaá Lithuaniaá Luxembourgá Maltaá Netherlandsá Norwayá Polandá Portugalá Romaniaá Slovakiaá Sloveniaá Spainá Swedená Switzerlandá Turkey andUnited Kingdomä

EUROPEAN COMMITTEE FOR STANDARDIZATION COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels

t r s x CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Membersä Refä Noä EN

s z y uã t r s v ªA sã t r s x ESIST EN 1873:2014+A1:2016

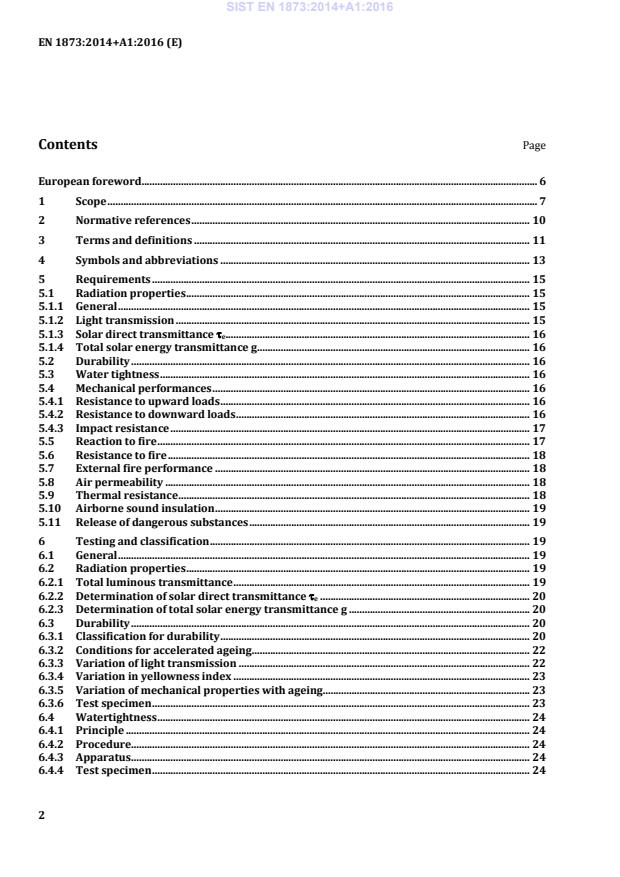

Contents Page European foreword . 6 1 Scope . 7 2 Normative references . 10 3 Terms and definitions . 11 4 Symbols and abbreviations . 13 5 Requirements . 15 5.1 Radiation properties . 15 5.1.1 General . 15 5.1.2 Light transmission . 15 5.1.3 Solar direct transmittance τe . 16 5.1.4 Total solar energy transmittance g . 16 5.2 Durability . 16 5.3 Water tightness . 16 5.4 Mechanical performances . 16 5.4.1 Resistance to upward loads . 16 5.4.2 Resistance to downward loads . 16 5.4.3 Impact resistance . 17 5.5 Reaction to fire . 17 5.6 Resistance to fire . 18 5.7 External fire performance . 18 5.8 Air permeability . 18 5.9 Thermal resistance . 18 5.10 Airborne sound insulation . 19 5.11 Release of dangerous substances . 19 6 Testing and classification . 19 6.1 General . 19 6.2 Radiation properties . 19 6.2.1 Total luminous transmittance . 19 6.2.2 Determination of solar direct transmittance τe . 20 6.2.3 Determination of total solar energy transmittance g . 20 6.3 Durability . 20 6.3.1 Classification for durability . 20 6.3.2 Conditions for accelerated ageing . 22 6.3.3 Variation of light transmission . 22 6.3.4 Variation in yellowness index . 23 6.3.5 Variation of mechanical properties with ageing. 23 6.3.6 Test specimen . 23 6.4 Watertightness . 24 6.4.1 Principle . 24 6.4.2 Procedure. 24 6.4.3 Apparatus . 24 6.4.4 Test specimen . 24 SIST EN 1873:2014+A1:2016

Dimensions in millimetres . 25 6.5 Mechanical performances . 26 6.5.1 Resistance to upward and downward loads . 26 6.5.2 Impact resistance . 27 6.6 Fire behaviour . 29 6.7 Air permeability . 29 6.8 Thermal transmittance. 30 6.9 Relationship between characteristics, families and test specimens . 30 6.10 Test report . 32 7 Assessment and verification of constancy of performance - AVCP . 32 7.1 General . 32 7.2 Type testing . 33 7.2.1 General . 33 7.2.2 Test reports . 33 7.3 Factory production control (FPC) . 33 7.3.1 General . 33 7.3.2 General requirements . 34 7.3.3 Product specific requirements . 36 7.3.4 Initial inspection of factory and of FPC . 37 7.3.5 Continuous surveillance of FPC . 38 7.3.6 Procedure for modifications . 38 8 Designation and marking . 38 Annex A (informative)

Guidelines for safety, application, use and maintenance . 40 A.1 General . 40 A.2 Guidelines for safety . 40 A.3 Guidelines for application and use . 40 A.4 Maintenance . 41 Annex B (normative)

Alternative test method for the determination of light transmission . 42 B.1 General . 42 B.2 Apparatus . 42 B.3 Test pieces . 43 B.4 Procedure . 43 B.5 Expression of results . 43 Annex C (normative)

Test method for air permeability . 44 C.1 General . 44 C.2 Test apparatus . 44 C.3 Test specimen . 44 C.4 Test procedure . 45 C.5 Evaluation of the results . 45 C.6 Rounding off to be used for the air permeability . 45 C.7 Test report . 46 Annex D (normative)

Determination of thermal transmittance of rooflight . 47 SIST EN 1873:2014+A1:2016

D.1 General . 47 D.2 Determination of thermal transmittance of rooflight components . 47 D.2.1 Determination by measurement . 47 D.2.2 Determination by calculation . 47 D.2.2.1 General . 47 D.2.2.2 Thermal transmittance of the upstand Uup and Uup,e . 47 D.2.2.3 Thermal transmittance of the edge profile Ue . 47 D.2.2.4 Thermal transmittance of the junction part Uj . 47 D.2.2.5 Thermal transmittance of the translucent parts Ut . 47 D.2.2.6 Linear thermal transmittances Ψe,Ψj, Ψt . 48 D.2.2.7 Definition of starting point for calculation of thermal transmittance . 48 D.3 Determination of areas of a rooflight . 49 D.3.1 Components . 49 D.3.2 Area of the rooflight upstand . 50 D.3.3 Area of the edge profile . 51 D.3.4 Area of the junction part . 53 D.3.5 Area of the translucent part At. 54 D.3.6 Surface of the rooflight . 54 D.4 Total thermal transmittance of individual rooflights . 55 D.4.1 General . 55 D.4.2 Total thermal transmittance Ur of individual rooflights including the edge profile . 56 D.4.3 Total thermal transmittance Urc of individual rooflights including the edge profile and upstand . 57 D.4.4 Total thermal transmittance Urc of individual rooflights including the edge profile and upstand (alternative method). 59 D.4.5 Total thermal transmittance Urc of individual rooflights including the upstand without edge profile . 60 D.4.6 Total thermal transmittance Urc of individual rooflights including the edge profile and upstand with more than one translucent part . 62 D.4.7 Rounding off to be used for thermal transmittance in calculation and classification . 63 D.5 Test specimen for evaluation of thermal transmittance: Ur,ref, Urc,ref300 . 63 D.5.1 General . 63 D.5.2 Reference models . 64 D.5.2.1 Individual rooflight without upstand . 64 D.5.2.2 Individual rooflight with upstand . 64 D.6 Characteristics for supplied rooflight . 65 Annex E (normative)

Reaction to fire test . 66 SIST EN 1873:2014+A1:2016

E.1 Class E . 66 E.1.1 General . 66 E.1.2 Mounting and fixing for the small flame test in accordance to EN ISO 11925-2 . 66 E.2 Class A2 to class D . 67 E.2.1 General . 67 E.2.2 Mounting and fixing for the SBI test . 67 E.3 Class A1 . 67 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of the EU Construction Products Regulation . 68 ZA.1 Scope and relevant characteristics . 68 ZA.2 Procedure for AVCP of prefabricated accessories for roofing – individual rooflights of plastics. . 70 ZA.2.1 Systems of AVCP . 70 ZA.2.2 Declaration of performance (DoP) . 72 ZA.2.2.1 General . 72 ZA.2.2.2 Content . 73 ZA.2.2.3 Example of DoP . 74 ZA.3 CE marking and labelling . 77 Bibliography . 79

European foreword This document (EN 1873:2014+A1:2016) has been prepared by Technical Committee CEN/TC 128 “Roof covering products for discontinuous laying and products for wall cladding”, the secretariat of which is held by NBN. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by August 2016, and conflicting national standards shall be withdrawn at the latest by August 2016. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. This document includes Amendment 1 approved by CEN on 2015-12-07. This document supersedes !EN 1873:2014". The start and finish of text introduced or altered by amendment is indicated in the text by tags !". This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association, and supports essential requirements of EU Directive(s). For relationship with the EU Regulation concerning the CPR, see informative Annex ZA, which is an integral part of this document. !deleted text" According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 1873:2014+A1:2016

1 Scope This European Standard specifies requirements for rooflights made of plastic materials (e.g. GF-UP, PC, PMMA, PVC) and rooflights with upstands made of e.g. GF-UP, PVC, steel, aluminium or wood for installation in roofs. These rooflights serve the purpose of introducing daylight. This European Standard applies to rooflights with a rectangular or circular ground plan (see Figures 1 and 2), with an opening span (width) or diameter not larger than 2,5 m and an opening length not larger than 3,0 m in roof pitches up to 25°. This document does not cover rooflights which contribute to the load-bearing or stiffness of the roof itself. This European Standard applies to rooflights and rooflights with upstand, where a single manufacturer provides all components of the rooflight with upstand, which are bought in a single purchase. This European Standard applies to rooflights with one or several translucent parts. Rooflights may be opened by means of opening devices in one or more parts for ventilation. The possible additional functions of day to day ventilation, smoke and heat ventilation e.g. in case of fire in accordance with EN 12101-2, roof access, and/ or slinging point e.g. in accordance with EN 795 are outside the scope of this document. This European Standard does not include calculations with regard to construction, design requirements and installation techniques. NOTE Guidelines for safety, application, use and maintenance of individual rooflights are presented in Annex A. SIST EN 1873:2014+A1:2016

Section X –X without and with additional horizontal skin

Key a daylight diameter f roof opening length b roof opening diameter g daylight size c daylight width h roof opening size d roof opening width i upstand height e daylight length j rooflight height Figure 1 — Typical individual rooflights SIST EN 1873:2014+A1:2016

2a) Individual rooflight

2b) Individual rooflight with upstand

2c) Individual rooflight with upstand and edge profile

with edge profile without edge profile 2d) Vertical upstands Key 1 multi skin 4 insulated upstand

7 roof finish 2 single skin 5 non insulated upstand 3 edge profile 6 splayed upstand Figure 2 — Cross sections of typical individual rooflights and upstands SIST EN 1873:2014+A1:2016

2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 410:2011, Glass in building — Determination of luminous and solar characteristics of glazing EN 596, Timber structures — Test methods — Soft body impact test of timber framed walls EN 673, Glass in building — Determination of thermal transmittance (U value) — Calculation method EN 674, Glass in building — Determination of thermal transmittance (U value) — Guarded hot plate method EN 675, Glass in building — Determination of thermal transmittance (U value) — Heat flow meter method EN 1013, Light transmitting single skin profiled plastics sheets for internal and external roofs, walls and ceilings — Requirements and test methods CEN/TS 1187, Test methods for external fire exposure to roofs EN 12412-2, Thermal performance of windows, doors and shutters — Determination of thermal transmittance by hot box method — Part 2: Frames EN 13501-1, Fire classification of construction products and building elements — Part 1: Classification using data from reaction to fire tests EN 13501-5, Fire classification of construction products and building elements — Part 5: Classification using data from external fire exposure to roof tests EN 14351-1, Windows and doors — Product standard, performance characteristics — Part 1: Windows and external pedestrian doorsets without resistance to fire and/or smoke leakage characteristics EN 13823, Reaction to fire tests for building products — Building products excluding floorings exposed to the thermal attack by a single burning item EN 16153, Light transmitting flat multiwall polycarbonate (PC) sheets for internal and external use in roofs, walls and ceilings — Requirements and test methods EN ISO 178, Plastics — Determination of flexural properties (ISO 178) EN ISO 527-1, Plastics — Determination of tensile properties — Part 1: General principles (ISO 527-1) EN ISO 527-2, Plastics — Determination of tensile properties — Part 2: Test conditions for moulding and extrusion plastics (ISO 527-2) EN ISO 4892-1, Plastics — Methods of exposure to laboratory light sources — Part 1: General guidance (ISO 4892-1) EN ISO 4892-2, Plastics — Methods of exposure to laboratory light sources — Part 2: Xenon-arc lamps (ISO 4892-2) SIST EN 1873:2014+A1:2016

EN ISO 6946, Building components and building elements — Thermal resistance and thermal transmittance — Calculation method (ISO 6946) EN ISO 10077-2, Thermal performance of windows, doors and shutters — Calculation of thermal transmittance — Part 2: Numerical method for frames (ISO 10077-2) EN ISO 10140-1, Acoustics — Laboratory measurement of sound insulation of building elements — Part 1: Application rules for specific products (ISO 10140-1) EN ISO 10140-2, Acoustics — Laboratory measurement of sound insulation of building elements — Part 2: Measurement of airborne sound insulation (ISO 10140-2) EN ISO 10140-4, Acoustics — Laboratory measurement of sound insulation of building elements — Part 4: Measurement procedures and requirements (ISO 10140-4) EN ISO 10140-5, Acoustics — Laboratory measurement of sound insulation of building elements — Part 5: Requirements for test facilities and equipment (ISO 10140-5) EN ISO 10211, Thermal bridges in building construction — Heat flows and surface temperatures —Detailed calculations (ISO 10211) EN ISO 11664-1, Colorimetry — Part 1: CIE standard colorimetric observers (ISO 11664-1) EN ISO 11664-2, Colorimetry — Part 2: CIE standard illuminants (ISO 11664-2) EN ISO 12017:1996, Plastics — Poly(methyl methacrylate) double- and triple-skin sheets — Test methods (ISO 12017:1995) EN ISO 12567-2, Thermal performance of windows and doors — Determination of thermal transmittance by hot box method — Part 2: Roof windows and other projecting windows (ISO 12567-2) EN ISO 13468-1, Plastics — Determination of total luminous transmittance of transparent materials — Part 1: Single-beam instrument (ISO 13468-1) EN ISO 13468-2, Plastics — Determination of the total luminous transmittance of transparent materials — Part 2: Double-beam instrument (ISO 13468-2) EN ISO 14125, Fibre-reinforced plastic composites — Determination of flexural properties (ISO 14125) EN ISO 11925-2:2010, Reaction to fire tests — Ignitability of products subjected to direct impingement of flame — Part 2: Single-flame source test (ISO 11925-2:2010) 3 Terms and definitions For the purposes of this document, the following terms and definitions apply. 3.1 rooflight building component used to introduce daylight which consists of a translucent part and associated edge profiles, if applicable SIST EN 1873:2014+A1:2016

3.2 translucent part consists of at least an outside plastic skin and several additional translucent skins below optionally Note 1 to entry: The additional skins can follow or be integrated with the outer skin or be an additional flat skin. Note 2 to entry: Additional flat skin may not be in plastic. 3.3 upstand element which is single- or multi-walled or composite with vertical and/or pitched walls; with or without thermal insulation and having the two-fold purpose of providing an area for the fixture of plastic rooflights and for connection to the substructure, the roof covering or the roof sealing Note 1 to entry: The upstand transmits the loads acting upon the plastic rooflight into the substructure. Note 2 to entry: Upstands may include ventilation devices. 3.4 accessories connections, opening and locking devices and seals for the assembly of the elements (rooflight, translucent part, upstand and edge profiile) 3.5 rooflight with upstand building element which consists of at least the separate elements in accordance with rooflight, translucent part, upstand and accessories 3.6 batch quantity of material made in a single operation, or in the case of continuous production for a defined quantity which shall be demonstrated by the producer to have a uniform composition 3.7 edge profile any frame and/or profile necessary to fix and/or open the translucent part of the rooflight Note 1 to entry: edge profiles can be made out of plastic materials. 3.8 junction part any additional element (e.g. frame and/or profile) used with the edge profile to assemble the rooflight, when made with more than one translucent part Note 1 to entry: Junction part can be made out of plastic materials. 3.9 starting point of calculation horizontal surface or point where adiabatic conditions are to be taken into account for calculation SIST EN 1873:2014+A1:2016

Key a single skin, solid sheet b double skin, solid sheet c triple skin, solid sheet d multiwalled sheet Note 1 to entry: In case of more than one skin, thicknesses of the sheets can be different. Figure 3 — Cross sections of typical plastic sheets 4 Symbols and abbreviations YI Change in the yellowness index Hc Energy applied during ageing procedure Ls Light transmission of a test piece Lsn Light transmission of the nth test piece D65 Total luminous transmittance for the CIE-standard illuminant D65 in % Ms Average (see B.5.1) of R1 and R3 Mv Light transmission of the sample R Thermal resistance in m2·K/W R1 and R3 Reading of galvanometer without any test piece R2 Reading of galvanometer with the test piece Rw Airborne sound index in dB U Heat transmittance in W/(m2·K) YI Value of the yellowness index of aged test piece SIST EN 1873:2014+A1:2016

YI0 Value of the yellowness index of unaged test piece

Variation of E-modulus in %

Variation of strength in % XCIE, YCIE, ZCIE Colourimetric coordinates Ae Area of the outer exposed surface of the edge profile, in m2 Aj The outer exposed surface of the junction part, in m2 Ar The surface of the rooflight without upstand, in m2 Arc The surface of the rooflight with upstand, in m2 Arc,ref The surface of the rooflight without upstand of the reference model, in m2 Arc,ref300 The surface of the rooflight with upstand of the reference model, in m2 At Area of the outer exposed surface of the translucent part bordered with the perimeter of the translucent part, in m2 At,flat area of the horizontal projection of the clear opening of the translucent part of individual rooflight, in m2 Aup Area of the outer exposed surface of the rooflight upstand, in m2 ee The width of the edge profile, in m ee,h Horizontal distance between the upper outside border of the insulation and the clear opening of the translucent part, in m ee,v Vertical distance between the upper level of the translucent part and the upper level of the upstand, in m ej.h The width of the junction part, in m eup The height of the upstand, in m h Horizontal envelope boundary k Factor to take into account the shape of the translucent part le Length of the sealing of the edge profile, in m lj Length of the transition zone between translucent part and junction part, in m lt Length of the transition zone between translucent part and edge profile, in m Pe Perimeter of the edge profile, in m Pt Perimeter of the translucent part, equal to the perimeter of the clear opening of the translucent part, in m Pup The reference perimeter of the upstand Pup,u Upper outer perimeter of the upstand, in m Pup,l Lower outer perimeter of the upstand, in m Ue Thermal transmittance of the edge profile, in W/(m2„K) Uj Thermal transmittance of the junction part, in W/(m2„K) Ur Total thermal transmittance of rooflights including the edge profile, if applicable, in W/(m2„K) Ur,ref Total thermal transmittance of a rooflight without upstand (reference model), in W/(m2„K) Urc Total thermal transmittance of rooflights including the edge profile, if applicable and upstand, in W/(m2„K) Urc,ref300 Total thermal transmittance of a rooflight with upstand (300 mm height, reference model), in SIST EN 1873:2014+A1:2016

W/(m2„K) Ut Thermal transmittance of the translucent part, in W/(m2„K) Uup Thermal transmittance of the upstand, in W/(m2„K) Uup,e Thermal transmittance of the upstand and the edge profile, if applicable, in W/(m2„K) v Vertical envelope boundary e Linear thermal transmittance in the transition zone of edge profile and upstand, in W/(m„K) j Linear thermal transmittance in the transition zone of the translucent part and junction part, in W/(m„K) t Linear thermal transmittance in the transition zone of the translucent part and edge profile, in W/(m „ K) 5 Requirements 5.1 Radiation properties 5.1.1 General The radiation properties of individual rooflights shall be assessed when subject to regulatory requirement and may be assessed voluntarily. D65, the direct solar e and the total solar energy transmittance g. The spectral characteristics of the transparent part of an individual rooflight include the luminous and solar characteristics, and the reflection and transmission characteristics. The characteristics are as follows: -

nm to 2450 nm; - the lD65 D65 for standard illuminant D65; - e e ; - the total solar energy transmittance (solar factor) g. The characteristics are determined for quasi-parallel, near normal radiation incidence using the radiation distribution of standard illuminant D65 (see EN 410:2011, Table 1), solar radiation in accordance with

EN 410:2011, Table 2 and ultraviolet (UV) radiation in accordance with EN 410:2011, Table 3. The solar factor depends, as all other optical material characteristics, on the angle of incidence. The angle of incidence should be taken into account for different sun positions. 5.1.2 Light transmission The light transmission of the rooflight material is determined as total luminous transmittance of each skin and possible combinations of skins in new plastic rooflights and is stated by the manufacturer according to 6.2.1. D65 value of the total luminous transmittance shall be within ± 5 % of the stated value. SIST EN 1873:2014+A1:2016

5.1.3 e The solar direct transmittance of the rooflight material is determined as the solar transmittance of each skin and possible combinations of skins in new plastic rooflights and is stated by the manufacturer according to 6.2.2. e value of the solar transmittance shall be within ± 5 % of the stated value. 5.1.4 Total solar energy transmittance g The total solar energy transmittance, g, as defined in EN 410 shall be determined by calculation according to 6.2.3 or by measurement according to 6.2.3. The calculation method is applicable only to transparent parts with symmetrical on-plan cross-section. Where the calculation method is not applicable, then the total solar energy transmittance shall be measured. 5.2 Durability This characteristic shall be assessed when subject to regulatory requirements and may be assessed voluntarily. Durability of the product is evaluated by measuring the variation of total luminous transmittance, yellowness index and mechanical properties after ageing procedure of the material of the translucent part with the same energy level for the three following characteristics either on flat sheets and/or finished product. The ageing procedure shall be conducted in accordance with 6.3. 5.3 Water tightness This characteristic shall be assessed when subject to regulatory requirements and may be assessed voluntarily. The plastic rooflight in the closed condition shall be tested in accordance with 6.4. No water shall drop from the internal surface. The design of the rooflight shall ensure that water drains away externally. 5.4 Mechanical performances 5.4.1 Resistance to upward loads This characteristic shall be assessed. For the determination of the resistance to upward load the plastic rooflight shall be tested and classified in accordance with 6.5.1.2. A successful test is achieved if neither damage nor significant permanent deformation occurs. 5.4.2 Resistance to downward loads This characteristic shall be assessed. For the determination of the resistance to downward load the plastic rooflight shall be tested and classified in accordance with 6.5.1.3. A successful test is achieved if neither damage nor significant permanent deformation occurs. SIST EN 1873:2014+A1:2016

5.4.3 Impact resistance 5.4.3.1 Small, hard body impact This characteristic shall be assessed when subject to regulatory requirements and may be assessed voluntarily. A successful test is achieved when plastic rooflights are resistant to the impact of a small hard body when tested in accordance with 6.5.2.1. The products shall always be tested with the manufacturer's corresponding or specified upstand. The identification of the tested assembly (the rooflight and the upstand) is part of the information accompanying the declared performance. 5.4.3.2 Large soft body impact This characteristic shall be assessed when subject to regulatory requirements and may be assessed voluntarily. For .the determination of the resistance to the impact of a large soft body the plastic rooflight shall be tested and classified in accordance with 6.5.2.3. The products shall always be tested with the manufacturer's corresponding or specified upstand. The identification of the tested assembly (the rooflight and the upstand) is part of the information accompanying the declared performance. A successful test is achieved if neither the bag nor the gauge can pass through the specimen. 5.5 Reaction to fire This characteristic shall be assessed when subject to regulatory requirements and may be assessed otherwise. The reaction to fire of the materials of the rooflight shall be classified in accordance with EN 13501-1. NOTE 1 In accordance with the Construction Product Regulation (CPR) products will need to be evaluated under “end use conditions” in the pre-flashover period of a fire. This generally implies that it is not possible to judge the performance of a product made up of many components (like rubber seals, aluminium frame, PE ventilator) by assessing the materials individually. The rooflight shall be classified with the least favourable classification of any of the materials it is made of, if it can be clearly shown that the reaction to fire properties of the complete rooflight is likely not to perform worse than the worst material in terms of its reaction to fire performance. In this case tests for the purpose of classification where mounting and fixing of a material can influence the performance of a material (SBI test EN 13823 and the test wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...