EN 12952-8:2002

(Main)Water-tube boilers and auxiliary installations - Part 8: Requirements for firing systems for liquid and gaseous fuels for the boiler

Water-tube boilers and auxiliary installations - Part 8: Requirements for firing systems for liquid and gaseous fuels for the boiler

1. Firing systems: These requirements apply to oil and gas firing systems of steam and hot water generators. For multifuel firing systems using separate or combined burners these requirements shall apply to the oil and/or gas firing part involved. Where several fuels are burnt simultaneously, improved safety measures may be necessary, especially in respect to limitation of heat input into the firing system and proper air supply to the individual fuels. 2. Fuels (...) 3. Operation (...)

Wasserrohrkessel und Anlagenkomponenten - Teil 8: Anforderungen an Feuerungsanlagen für flüssige und gasförmige für den Kessel

1. Feuerungsanlagen: Diese Anforderungen gelten für Öl nd Gasfeurungsanlagen an Dampf- und Heißwasserzeugen. Für kombinierte Feuerungsanlagen mit getrennten oder kombinierten Brennern gelten diese Anforderungen für den Öl- und/oder Gasfeuerungsteil. Wenn verschiedene Brennstoffe gleichzeitig verbrannt werden, können erhöhte Sicherheitsmaßnahmen nötig werden, vorzugsweise im Hinblick auf die Begrenzung der Wärmeleistung der Feuerungsanlage und richtige Lufzuführung zu den einzelnen Brennstoffen. 2. Brensstoffe (...) 3. Betrieb (...)

Chaudières à tubes d'eau et installations auxiliaires - Partie 8: Exigences pour les équipements de chauffe pour combustibles gazeux et liquides de la chaudière

1.1 Équipements de chauffe

La présente Norme européenne spécifie les exigences qui s'appliquent aux équipements de chauffe pour fioul et gaz des générateurs de vapeur et d'eau surchauffée.

Ces exigences s'appliquent aux équipements de chauffe des chaudières de récupération chimique (chaudières à liqueur noire) avec les compléments et les amendements spécifiés dans l'annexe A de la présente norme.

NOTE 1 Indépendamment du fait que les chaudières à serpentins (chaudières à vaporisation instantanée/chaudières à faible volume) sont des chaudières à tube d'eau, les exigences pour les équipements de chauffe pour fioul et gaz conformément au prEN 12953-7 s'appliquent aux installations à un seul brûleur.

NOTE 2 Des règles applicables au stockage de combustibles liquides et aux postes de livraison équipés de tuyauteries de transport de très grande longueur existent dans les législations nationales. Elles ne sont pas couvertes par la présente norme.

1.2 Combustibles

La présente partie spécifie les exigences qui concernent l'utilisation de combustibles liquides et gazeux tels que définis dans la présente partie. Les combustibles s'écartant des types normalisés disponibles dans le commerce peuvent nécessiter des mesures de sécurité supplémentaires ou alternatives. Pour la liqueur noire, ces mesures de sécurité sont données en annexe A.

1.3 Exploitation

La présente norme spécifie dans les articles 4 à 8 les exigences relatives aux équipements d'exploitation s'appliquant aux générateurs de vapeur et d'eau surchauffée, sous surveillance permanente par des personnels correctement formés et familiarisés aux particularités de l'équipement de chauffe et du type de combustible utilisé.

Vodocevni kotli in pomožne napeljave - 8. del: Zahteve za gorilnike kotlov na tekoča in plinasta goriva

General Information

- Status

- Withdrawn

- Publication Date

- 21-May-2002

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 3 - Equipment

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 19-Oct-2022

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 26-Oct-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

DNV

DNV is an independent assurance and risk management provider.

Lloyd's Register

Lloyd's Register is a global professional services organisation specialising in engineering and technology.

DNV Energy Systems

Energy and renewable energy certification.

Sponsored listings

Frequently Asked Questions

EN 12952-8:2002 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water-tube boilers and auxiliary installations - Part 8: Requirements for firing systems for liquid and gaseous fuels for the boiler". This standard covers: 1. Firing systems: These requirements apply to oil and gas firing systems of steam and hot water generators. For multifuel firing systems using separate or combined burners these requirements shall apply to the oil and/or gas firing part involved. Where several fuels are burnt simultaneously, improved safety measures may be necessary, especially in respect to limitation of heat input into the firing system and proper air supply to the individual fuels. 2. Fuels (...) 3. Operation (...)

1. Firing systems: These requirements apply to oil and gas firing systems of steam and hot water generators. For multifuel firing systems using separate or combined burners these requirements shall apply to the oil and/or gas firing part involved. Where several fuels are burnt simultaneously, improved safety measures may be necessary, especially in respect to limitation of heat input into the firing system and proper air supply to the individual fuels. 2. Fuels (...) 3. Operation (...)

EN 12952-8:2002 is classified under the following ICS (International Classification for Standards) categories: 27.040 - Gas and steam turbines. Steam engines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12952-8:2002 has the following relationships with other standards: It is inter standard links to EN 12952-8:2022, EN 50156-1:2024, EN 12952-5:2021, EN ISO 3677:2024, EN ISO 9606-1:2017, EN 521:2019, EN 161:2022+A1:2025, prEN 15116, EN 13480-2:2024, EN ISO 23553-1:2022, EN 751-1:1996, EN 751-2:1996, EN ISO 17672:2024, EN 751-3:2022+A1:2023, EN 12952-7:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12952-8:2002 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12952-8:2002 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Wasserrohrkessel und Anlagenkomponenten - Teil 8: Anforderungen an Feuerungsanlagen für flüssige und gasförmige für den KesselChaudieres a tubes d'eau et installations auxiliaires - Partie 8: Exigences pour les équipements de chauffe pour combustibles gazeux et liquides de la chaudiereWater-tube boilers and auxiliary installations - Part 8: Requirements for firing systems for liquid and gaseous fuels for the boiler27.060.30Grelniki vode in prenosniki toploteBoilers and heat exchangersICS:Ta slovenski standard je istoveten z:EN 12952-8:2002SIST EN 12952-8:2002en01-november-2002SIST EN 12952-8:2002SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 12952-8May 2002ICS 27.040English versionWater-tube boilers and auxiliary installations - Part 8:Requirements for firing systems for liquid and gaseous fuels forthe boilerChaudières à tubes d'eau et installations auxiliaires - Partie8: Exigences pour les équipements de chauffe pourcombustibles gazeux et liquides de la chaudièreWasserrohrkessel und Anlagenkomponenten - Teil 8:Anforderungen an Feuerungsanlagen für flüssige undgasförmige für den KesselThis European Standard was approved by CEN on 15 May 2002.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Management Centre or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,Iceland, Ireland, Italy, Luxembourg, Malta, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2002 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 12952-8:2002 ESIST EN 12952-8:2002

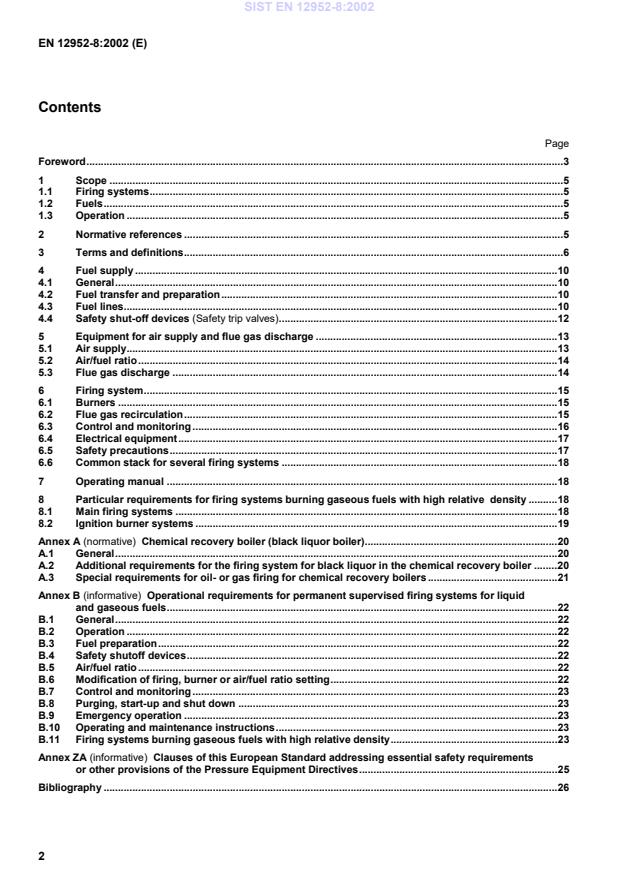

density.188.1Main firing systems.188.2Ignition burner systems.19Annex A (normative)

Chemical recovery boiler (black liquor boiler).20A.1General.20A.2Additional requirements for the firing system for black liquor in the chemical recovery boiler.20A.3Special requirements for oil- or gas firing for chemical recovery boilers.21Annex B (informative)

Operational requirements for permanent supervised firing systems for liquidand gaseous fuels.22B.1General.22B.2Operation.22B.3Fuel preparation.22B.4Safety shutoff devices.22B.5Air/fuel ratio.22B.6Modification of firing, burner or air/fuel ratio setting.22B.7Control and monitoring.23B.8Purging, start-up and shut down.23B.9Emergency operation.23B.10Operating and maintenance instructions.23B.11Firing systems burning gaseous fuels with high relative density.23Annex ZA (informative)

Clauses of this European Standard addressing essential safety requirementsor other provisions of the Pressure Equipment Directives.25Bibliography.26SIST EN 12952-8:2002

Automatic shut-off valves for gas burners and gas appliances.EN 264,

Safety shut-off devices for combustion plants using liquid fuels — Safety requirements and testing.EN 287-1,

Approval testing of welders — Fusion welding — Part 1: Steels.EN 751-1,

Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hotwater — Part 1: Anaerobic jointing compounds.EN 751-2,

Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hotwater — Part 2: Non-hardening jointing compounds.EN 751-3,

Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases and hotwater — Part 3: Unsintered PTFE tapes.EN 1044,

Brazing — Filler metals.EN 12952-1,

1: General.EN 12952-5:2001,

Part 5: Workmanship and construction ofpressure parts of the boiler.EN 13480-2,

Metallic industrial piping — Part 2: Materials.SIST EN 12952-8:2002

Electrical equipment for furnaces and ancillary equipment — Part 1: Requirements for applicationdesign and installation.EN ISO 3677,

Filler metal for soft soldering, brazing and braze welding — Designation (ISO 3677:1992).ISO 7-1,

Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances anddesignation. (ISO 7-1:1994)ISO 228-1,

Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions, tolerancesand designation (ISO 228-1:2000).3 Terms and definitionsFor the purposes of this Part of this European Standard and the following terms and definitions apply.3.1black liquorspent liquor from the pulp cook3.2black liquor gundevice for the introduction of the black liquor as a spray of droplets into the furnace. The black liquor gun is not aburner3.3high volume low concentration odorous gasmixtures of air and a low concentration of odorous gases collected from the pulp mill processes, where theconcentration of the combustible odorous gas is always kept below the lower explosion limit3.4burnersdevices (including main or igniter burners) for the introduction of fuel and air into a combustion chamber at requiredvelocities, turbulence and local fuel concentration to establish and maintain proper ignition and stable combustionof the fuel. Burners are differentiated by their mode of operation3.4.1automatic burnersburners equipped with automatic ignition, flame monitoring and safety control devices that control the firing ratewithout the intervention by operating personnel3.4.2semi-automatic burnersburners equipped with automatic ignition, flame monitoring and safety control devices which are started andstopped by the intervention of operating personnel3.4.3chemical recovery boiler start up burneroil- or gasfired burner mainly intended for the initiation of the black liquor combustion process. The chemicalrecovery boiler start up burners are located in and integrated with a combustion air register, like the primary or thesecondary air register of the furnace. Thus they have no individual air supply and no individual combustion aircontrol3.4.4multi-fuel burnersburners in which more than one fuel is burned either simultaneously or alternately3.4.5pilot burnerburner which maintains a proper permanent ignition source for one or a group of other non-monitored burnersSIST EN 12952-8:2002

firing systemheat input including the reserve required for load control at which the boiler can be safely operated3.16maximum firing rate of the burnersfiring rate at which the burner may be operatedSIST EN 12952-8:2002

EN 13480-2.4.3.4Flexible lines shall be used for connecting the burner to the fixed piping. For fuel oil in the preheated stateonly jacketed metallic hoses shall be permitted.Furthermore, flexible lines may be used instead of expansion joints at protected locations. For oil, these linesshould be jacketed metallic hoses, otherwise they shall be provided with a protective device consisting of e.g. adouble line with an oil monitor which switches off the oil supply pump in case of an oil leakage. For gas, these linesshall be corrugated steel pipes.All flexible lines shall be as short as possible, be readily visible, and shall be installed with adequate bending radii.The flexible lines and the connections shall carry the manufacturer's symbols and indication of the nominalpressure. The design pressure shall be at least 1,5 times the maximum allowable pressure. The lines shall beprotected against unacceptable external heating.4.3.5To protect fuel lines against unacceptable high pressure, automatic control and safety devices shall beprovided. For oil lines, pressure relief valves shall be installed. Protection of oil pumps and the effect of pressurerise in lines between closed shut-off devices due to heating shall also be taken into consideration. For gas lines thenecessary protection against overpressure shall be performed by a safety shut-off valve plus a pressure reliefvalve.4.3.6On completion of installation, all fuel piping including valves and other equipment within the fuel lines up tothe burner nozzles shall be cleaned to remove any weld spatter, corrosion products and foreign matter. The typeand performance of the cleaning process shall also be recorded. In addition leakage testing and strength testing inaccordance with a good engineering practice shall be performed.For oil and gas, each safety shut-off device shall be subject to internal leakage testing, to confirm that fuels doesnot leak through the device.After any welding work or replacement of components on fuel lines, the aforementioned tests shall be repeated.The performance of the tests shall be authenticated by certificates recording the test procedure, the medium used,the test pressure and the test results obtained.The certificates shall be issued by the person responsible for the testing.4.3.7Gas escape lines for intermediate venting and for purging or charging shall be arranged such, that theescaping gas is either reliably ignited and burnt off with a flame trap installed in the pipe where the gases aretransferred to the burning device or is safely discharged to the atmosphere if unburnt. The joining together of theselines shall only permitted if no dangerous operating conditions are expected. When necessary, gas escape linesshall be equipped with the necessary draining facilities. Connections for test devices shall be provided so that theadequacy of venting can be checked.For oil, intermediate drains shall be provided to ensure the safe discharge of escaping oil.SIST EN 12952-8:2002

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...