EN 12952-16:2022

(Main)Water-tube boilers and auxiliary installations - Part 16: Requirements for grate and fluidized-bed firing systems for solid fuels for the boiler

Water-tube boilers and auxiliary installations - Part 16: Requirements for grate and fluidized-bed firing systems for solid fuels for the boiler

1.1 Firing systems

This document applies to atmospheric fluidized-bed and grate firing systems of steam boilers and hot water generators. These systems commence at the fuel bunkers and end at the ash extraction plant. For combination of various firing systems, the individual requirements of each system apply, especially those included in EN 12952-8:2022 and EN 12952-9:2022.

If several fuels are burnt simultaneously or if a fuel quality varies considerably (e.g. moisture content), additional safety measures can be necessary, especially with respect to limitation of the fuel flow into the firing system and ensuring proper air supply to the individual fuels.

Pressurized firing systems can require enhanced safety measures, which are not given in this European Standard.

1.2 Fuels

This document covers the use of solid fuels. Pulverized fuel fired in an entrained air flow (burner) system is covered by EN 12952-9:2022.

Solid fuels covered are:

• all coal qualities, e.g. lignite or brown coal, sub-bituminous or hard brown coal, bituminous coal or hard coal, pitch coal, anthracite, coke, coal culm, coal sludge;

• other fossil solid fuels (e.g. peat, oil shale);

• biomass solid fuels (e.g. wood, wood wastes [bark], pellets, energy plants [miscanthus], harvest wastes [straw] and briquettes);

• municipal waste solid fuels (e.g. garbage, sewage sludge, refuse derived fuels [RDF]);

• industrial waste solid fuels (e.g. petrol coke, soot, tyres, paper wastes, coated wood chips, spent wood, animal product wastes).

Fuel blends from two or more groups, or fuels of unconventional or unknown quality can require special safety measures which can be proved either by practical experience gained from comparable fuels, or by suitable tests, e.g. in accordance with EN 14034-2:2006+A1:2011. Such measures specified and documented by the manufacturer.

Fuels on which the design is documented in the operating instructions (see 11.2). This includes the fuel data for 100 % input of the basic fuel and the data for any supplementary fuels together with their maximum thermal input percentage.

1.3 Operation

The requirements for operational equipment in Clause 4, Clause 5, Clause 6, Clause 7, Clause 8, Clause 9, Clause 10 and Clause 11 apply to steam boilers and hot water generators with permanent supervision by properly trained personnel familiar with the special conditions of the firing systems and the type of fuel.

Wasserrohrkessel und Anlagenkomponenten - Teil 16: Anforderungen an Rost- und Wirbelschichtfeuerungsanlagen für feste Brennstoffe für den Kessel

1.1 Feuerungsanlagen

Dieses Dokument gilt für atmosphärische Wirbelschicht- und Rostfeuerungsanlagen von Dampfkesseln und Heißwassererzeugern. Diese beginnen bei den Brennstoffbunkern und enden bei der Entaschungsanlage. Bei Kombination verschiedener Feuerungsanlagen gelten auch deren spezielle Anforderungen, insbesondere die, die in EN 12952 8:2022 und EN 12952 9:2022 enthalten sind.

Werden mehrere Brennstoffe gleichzeitig verbrannt oder variiert eine Brennstoffqualität stark (z. B. Feuchtegehalt), können zusätzliche Sicherheitsmaßnahmen erforderlich sein, insbesondere hinsichtlich der Begrenzung des Brennstoffstroms in die Feuerungsanlage und der Sicherstellung einer ordnungsgemäßen Luftzufuhr zu den einzelnen Brennstoffen.

Druckfeuerungsanlagen können erhöhte Sicherheitsmaßnahmen erfordern, die in dieser Europäischen Norm nicht festgelegt sind.

1.2 Brennstoffe

Dieses Dokument behandelt den Einsatz von festen Brennstoffen. Kohlenstaub, der in einem Flug-strom (Brenner-)system verfeuert wird, ist in EN 12952 9:2022 behandelt.

Erfasste feste Brennstoffe sind:

— alle Kohlenarten, z. B. Lignit oder Braunkohle, hoch- oder niederflüchtige Steinkohle, Pechkohle, Anthrazit, Koks, Koksgrus, Kohlenschlamm;

— andere fossile feste Brennstoffe (z. B. Torf, Ölschiefer);

— feste Biomasse-Brennstoffe (z. B. Holz, Holzabfälle (Rinde), Pellets, Zuchtpflanzen (Miscanth), Ernteabfälle (Stroh) und Briketts);

— feste städtische Abfallbrennstoffe (z. B. Müll, Klärschlamm, aus Müll gewonnene Brennstoffe (BRAM));

— feste Industrie-Abfallbrennstoffe (z. B. Petrolkoks, Ruß, Reifen, Papierabfälle, Späne von beschichtetem Holz, genutztes Holz, Schlachthofabfälle).

Brennstoffmischungen von einer oder mehreren Gruppen oder Brennstoffe ungewöhnlicher oder unbekannter Art können besondere Sicherheitsmaßnahmen erfordern, deren Eignung entweder durch praktische Erfahrungen, gewonnen mit vergleichbaren Brennstoffen, oder durch geeignete Versuche, z. B. entsprechend EN 14034 2:2006+A1:2011, bestätigt werden kann. Derartige Maßnahmen sind durch den Hersteller festzulegen und zu dokumentieren.

Brennstoffe, auf denen die Auslegung basiert, sind in den Betriebsanleitungen (siehe 11.2) festzulegen. Dies umfasst die Brennstoffdaten für 100 % Zufuhr des Grundbrennstoffes und alle Daten für Zusatzbrennstoffe zusammen mit ihrem maximalen thermischen Zufuhranteil.

1.3 Betrieb

Die Anforderungen an die betriebliche Ausrüstung in Abschnitt 4, Abschnitt 5, Abschnitt 6, Abschnitt 7, Abschnitt 8, Abschnitt 9, Abschnitt 10 und Abschnitt 11 gelten für Dampf- und Heißwassererzeuger mit ständiger Beaufsichtigung durch entsprechend ausgebildete Personen, die mit den besonderen Bedingungen der Feuerungsanlage und der Brennstoffart vertraut sind.

Chaudières à tubes d’eau et installations auxiliaires - Partie 16: Exigences pour les équipements de chauffe à lit fluidisé pour combustibles solides

1.1 Équipements de chauffe

Le présent document s'applique aux équipements de chauffe à lit fluidisé et à grille des chaudières à vapeur et des générateurs d’eau surchauffée. Ces équipements commencent aux trémies à combustible et se terminent à l'installation d'extraction des cendres. Pour ce qui concerne la combinaison de différents équipements de chauffe, les exigences spécifiques de chaque équipement s’appliquent, notamment celles spécifiées dans l’EN 12952 8:2022 et l’EN 12952 9:2022.

Lorsque plusieurs combustibles sont brûlés simultanément ou lorsqu'une qualité de combustible varie de manière significative (par exemple la teneur en humidité), des mesures de sécurité supplémentaires peuvent se révéler nécessaires, notamment pour ce qui concerne la réduction du débit de combustible approvisionnant l'équipement de chauffe et la bonne alimentation en air pour les différents combustibles.

Des équipements de chauffe sous pression peuvent nécessiter des mesures de sécurité accrues qui ne sont pas spécifiées dans la présente Norme européenne.

1.2 Combustibles

Le présent document couvre l'utilisation de combustibles solides. L’EN 12952 9:2022 couvre le combustible pulvérisé brûlé dans un système d’écoulement d’air entraîné (brûleur).

Les combustibles solides couverts sont :

• toutes les qualités de charbon, par exemple le lignite ou le charbon brun, le charbon brun subbitumineux ou dur, le charbon bitumineux ou la houille, le charbon de brai, l'anthracite, le coke, la poussière de charbon, les résidus de charbon ;

• d'autres combustibles solides (par exemple la tourbe, le schiste bitumineux) ;

• les combustibles solides biomasses (par exemple le bois, les déchets de bois [l'écorce], les boulettes, les plantes énergétiques [miscanthus], les résidus de moisson [paille] et briquettes) ;

• les combustibles solides de déchets urbains (par exemple des ordures, des boues d'eaux d'égouts, des combustibles dérivés des déchets [RDF]) ;

• des combustibles solides de déchets industriels (par exemple du coke de pétrole, de la suie, des pneus, des déchets de papier, des copeaux de bois revêtus, du bois usagé, des déchets de produits animaux).

Des mélanges de combustibles provenant de deux groupes ou plus, ou des combustibles d'une qualité inhabituelle ou inconnue peuvent nécessiter des mesures de sécurité particulières. Ce besoin peut être révélé par l'expérience pratique acquise avec des combustibles comparables, ou par des essais appropriés, par exemple conformément à l’EN 14034 2:2006+A1:2011. De telles mesures doivent être spécifiées et consignées par le fabricant.

Les combustibles autorisés à la conception sont consignés dans les instructions d'exploitation (voir 11.2). Ceci concerne les données de combustible pour un approvisionnement de 100 % de combustible de base, et les données de tous combustibles supplémentaires selon leur pourcentage d'apport thermique maximal.

1.3 Mode opératoire

Les exigences relatives aux équipements d'exploitation des Article 4, Article 5, Article 6, Article 7, Article 8, Article 9, Article 10 et Article 11 s'appliquent aux chaudières à vapeur et aux générateurs d'eau surchauffée, sous surveillance permanente assurée par un personnel correctement formé et familiarisé aux particularités des équipements de chauffe et du type de combustible.

Vodocevni kotli in pomožne napeljave - 16. del: Zahteve za kurilne sisteme na trdna goriva z zgorevalno rešetko ali z lebdečo plastjo

General Information

- Status

- Published

- Publication Date

- 18-Oct-2022

- Technical Committee

- CEN/TC 269 - Shell and water tube boilers

- Drafting Committee

- CEN/TC 269/WG 1 - Water-tube boilers

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 19-Oct-2022

- Due Date

- 26-Aug-2021

- Completion Date

- 19-Oct-2022

Relations

- Effective Date

- 26-Oct-2022

Overview

EN 12952-16:2022 is the CEN standard for grate and atmospheric fluidized-bed firing systems for solid fuels used with water-tube boilers and hot water generators. It covers the firing system from fuel bunkers through preparation, combustion (grate or fluidized-bed), combustion air and flue gas handling, to the ash extraction plant. The standard applies to a wide range of solid fuels (coal types, peat, biomass, municipal and industrial waste) and defines safety, design and operational requirements for permanently supervised installations.

Key topics and requirements

- Scope and fuels: Defines covered fuel types and notes that pulverized fuel in entrained-air burners is covered by EN 12952-9. It highlights the need for special measures when burning mixed or variable-quality fuels.

- Fuel storage and conveying (Clause 4): Requirements for bunkers, bins and conveying plant that form the start of the firing system.

- Fuel treatment (Clause 5): Provisions for size reduction and drying where applicable.

- Fuel feeding (Clause 6): Safe fuel transport into the furnace (feeders, chutes, lances, through-grate feeding).

- Explosion prevention (Clause 7): Measures and an overview table for prevention in different operational areas.

- Combustion air & flue gas (Clause 8): Air supply design, combustion air/fuel ratio considerations and flue gas discharge requirements.

- Firing system design, monitoring & safety (Clause 9): Requirements for combustion process monitoring devices, control systems, electrical equipment and operational safety (purging, lighting-up, start-up, shutdown).

- Ash handling (Clause 10): Requirements for extraction and safe removal of ash.

- Operating manual & operation (Clause 11 & Annex A): Documentation and training requirements; systems are intended for use under permanent supervision by trained personnel.

- Special cases: Pressurized firing systems may need enhanced measures not covered by this standard. For unconventional fuels, testing (e.g., EN 14034-2) or manufacturer-documented measures are recommended.

Practical applications and users

EN 12952-16 is intended for:

- Boiler manufacturers and system integrators designing grate firing and fluidized-bed combustion (FBC) systems.

- Plant engineers, boiler operators and safety managers responsible for fuel handling, combustion control and ash extraction.

- Project engineers specifying firing systems for biomass, coal, waste-to-energy and co-firing plants.

- Inspection bodies and compliance teams verifying conformity with CEN standards and EU requirements (see Annex ZA).

Practical uses include ensuring safe fuel supply, preventing explosions, optimizing combustion air systems, and documenting operating instructions and safety procedures.

Related standards

- EN 12952-8:2022 (liquid & gaseous firing systems)

- EN 12952-9:2022 (pulverized solid fuels)

- EN 12952-18:2012 (operating instructions)

- EN 14034-2:2006+A1:2011 (tests for unconventional fuel behavior)

Keywords: EN 12952-16, grate firing systems, fluidized-bed firing systems, solid fuels, water-tube boilers, firing systems safety, fuel handling, combustion air, ash handling.

Frequently Asked Questions

EN 12952-16:2022 is a standard published by the European Committee for Standardization (CEN). Its full title is "Water-tube boilers and auxiliary installations - Part 16: Requirements for grate and fluidized-bed firing systems for solid fuels for the boiler". This standard covers: 1.1 Firing systems This document applies to atmospheric fluidized-bed and grate firing systems of steam boilers and hot water generators. These systems commence at the fuel bunkers and end at the ash extraction plant. For combination of various firing systems, the individual requirements of each system apply, especially those included in EN 12952-8:2022 and EN 12952-9:2022. If several fuels are burnt simultaneously or if a fuel quality varies considerably (e.g. moisture content), additional safety measures can be necessary, especially with respect to limitation of the fuel flow into the firing system and ensuring proper air supply to the individual fuels. Pressurized firing systems can require enhanced safety measures, which are not given in this European Standard. 1.2 Fuels This document covers the use of solid fuels. Pulverized fuel fired in an entrained air flow (burner) system is covered by EN 12952-9:2022. Solid fuels covered are: • all coal qualities, e.g. lignite or brown coal, sub-bituminous or hard brown coal, bituminous coal or hard coal, pitch coal, anthracite, coke, coal culm, coal sludge; • other fossil solid fuels (e.g. peat, oil shale); • biomass solid fuels (e.g. wood, wood wastes [bark], pellets, energy plants [miscanthus], harvest wastes [straw] and briquettes); • municipal waste solid fuels (e.g. garbage, sewage sludge, refuse derived fuels [RDF]); • industrial waste solid fuels (e.g. petrol coke, soot, tyres, paper wastes, coated wood chips, spent wood, animal product wastes). Fuel blends from two or more groups, or fuels of unconventional or unknown quality can require special safety measures which can be proved either by practical experience gained from comparable fuels, or by suitable tests, e.g. in accordance with EN 14034-2:2006+A1:2011. Such measures specified and documented by the manufacturer. Fuels on which the design is documented in the operating instructions (see 11.2). This includes the fuel data for 100 % input of the basic fuel and the data for any supplementary fuels together with their maximum thermal input percentage. 1.3 Operation The requirements for operational equipment in Clause 4, Clause 5, Clause 6, Clause 7, Clause 8, Clause 9, Clause 10 and Clause 11 apply to steam boilers and hot water generators with permanent supervision by properly trained personnel familiar with the special conditions of the firing systems and the type of fuel.

1.1 Firing systems This document applies to atmospheric fluidized-bed and grate firing systems of steam boilers and hot water generators. These systems commence at the fuel bunkers and end at the ash extraction plant. For combination of various firing systems, the individual requirements of each system apply, especially those included in EN 12952-8:2022 and EN 12952-9:2022. If several fuels are burnt simultaneously or if a fuel quality varies considerably (e.g. moisture content), additional safety measures can be necessary, especially with respect to limitation of the fuel flow into the firing system and ensuring proper air supply to the individual fuels. Pressurized firing systems can require enhanced safety measures, which are not given in this European Standard. 1.2 Fuels This document covers the use of solid fuels. Pulverized fuel fired in an entrained air flow (burner) system is covered by EN 12952-9:2022. Solid fuels covered are: • all coal qualities, e.g. lignite or brown coal, sub-bituminous or hard brown coal, bituminous coal or hard coal, pitch coal, anthracite, coke, coal culm, coal sludge; • other fossil solid fuels (e.g. peat, oil shale); • biomass solid fuels (e.g. wood, wood wastes [bark], pellets, energy plants [miscanthus], harvest wastes [straw] and briquettes); • municipal waste solid fuels (e.g. garbage, sewage sludge, refuse derived fuels [RDF]); • industrial waste solid fuels (e.g. petrol coke, soot, tyres, paper wastes, coated wood chips, spent wood, animal product wastes). Fuel blends from two or more groups, or fuels of unconventional or unknown quality can require special safety measures which can be proved either by practical experience gained from comparable fuels, or by suitable tests, e.g. in accordance with EN 14034-2:2006+A1:2011. Such measures specified and documented by the manufacturer. Fuels on which the design is documented in the operating instructions (see 11.2). This includes the fuel data for 100 % input of the basic fuel and the data for any supplementary fuels together with their maximum thermal input percentage. 1.3 Operation The requirements for operational equipment in Clause 4, Clause 5, Clause 6, Clause 7, Clause 8, Clause 9, Clause 10 and Clause 11 apply to steam boilers and hot water generators with permanent supervision by properly trained personnel familiar with the special conditions of the firing systems and the type of fuel.

EN 12952-16:2022 is classified under the following ICS (International Classification for Standards) categories: 27.040 - Gas and steam turbines. Steam engines. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12952-16:2022 has the following relationships with other standards: It is inter standard links to EN 12952-16:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12952-16:2022 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

You can purchase EN 12952-16:2022 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of CEN standards.

Standards Content (Sample)

SLOVENSKI STANDARD

01-december-2022

Nadomešča:

SIST EN 12952-16:2003

Vodocevni kotli in pomožne napeljave - 16. del: Zahteve za kurilne sisteme na

trdna goriva z zgorevalno rešetko ali z lebdečo plastjo

Water-tube boilers and auxiliary installations - Part 16: Requirements for grate and

fluidized-bed firing systems for solid fuels for the boiler

Wasserrohrkessel und Anlagenkomponenten - Teil 16: Anforderungen an Rost- und

Wirbelschichtfeuerungsanlagen für feste Brennstoffe für den Kessel

Chaudières à tubes d’eau et installations auxiliaires - Partie 16: Exigences pour les

équipements de chauffe à lit fluidisé pour combustibles solides

Ta slovenski standard je istoveten z: EN 12952-16:2022

ICS:

27.060.30 Grelniki vode in prenosniki Boilers and heat exchangers

toplote

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 12952-16

EUROPEAN STANDARD

NORME EUROPÉENNE

October 2022

EUROPÄISCHE NORM

ICS 27.040 Supersedes EN 12952-16:2002

English Version

Water-tube boilers and auxiliary installations - Part 16:

Requirements for grate and fluidized-bed firing systems

for solid fuels for the boiler

Chaudières à tubes d'eau et installations auxiliaires - Wasserrohrkessel und Anlagenkomponenten - Teil 16:

Partie 16: Exigences pour les équipements de chauffe à Anforderungen an Rost- und

lit fluidisé pour combustibles solides Wirbelschichtfeuerungsanlagen für feste Brennstoffe

für den Kessel

This European Standard was approved by CEN on 15 August 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2022 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 12952-16:2022 E

worldwide for CEN national Members.

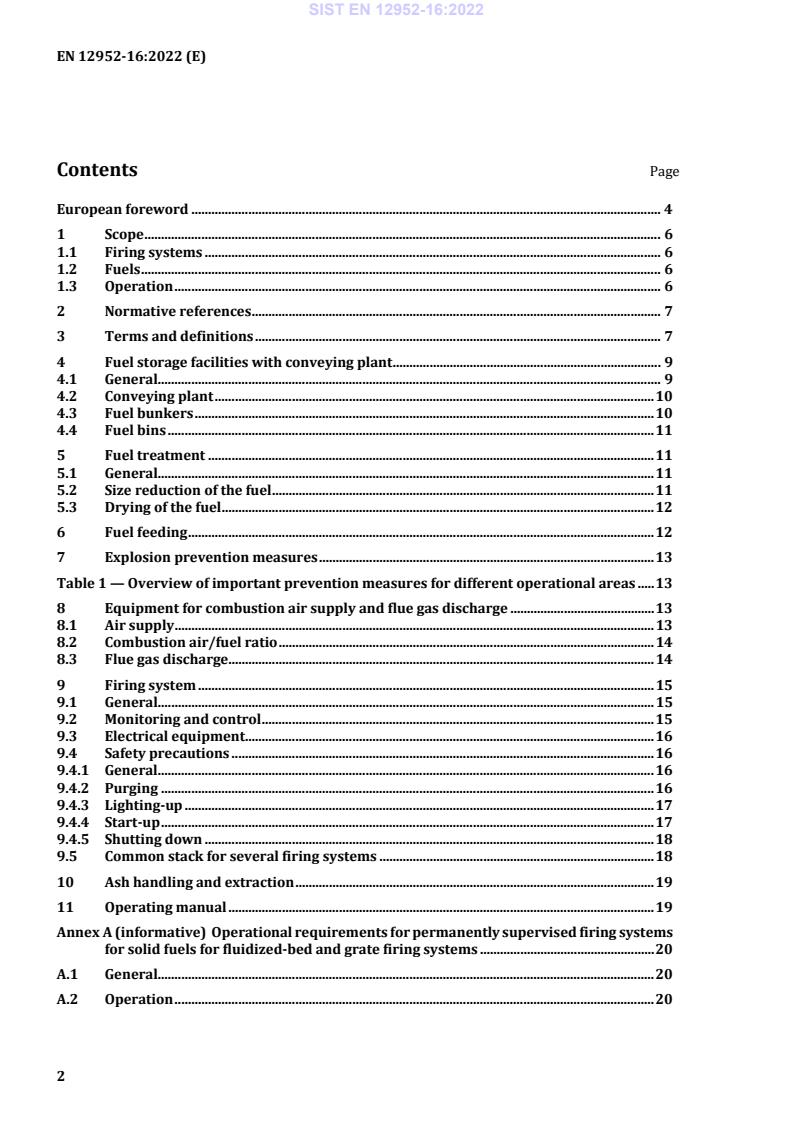

Contents Page

European foreword . 4

1 Scope . 6

1.1 Firing systems . 6

1.2 Fuels . 6

1.3 Operation . 6

2 Normative references . 7

3 Terms and definitions . 7

4 Fuel storage facilities with conveying plant . 9

4.1 General. 9

4.2 Conveying plant . 10

4.3 Fuel bunkers . 10

4.4 Fuel bins . 11

5 Fuel treatment . 11

5.1 General. 11

5.2 Size reduction of the fuel . 11

5.3 Drying of the fuel . 12

6 Fuel feeding . 12

7 Explosion prevention measures . 13

Table 1 — Overview of important prevention measures for different operational areas . 13

8 Equipment for combustion air supply and flue gas discharge . 13

8.1 Air supply . 13

8.2 Combustion air/fuel ratio . 14

8.3 Flue gas discharge . 14

9 Firing system . 15

9.1 General. 15

9.2 Monitoring and control . 15

9.3 Electrical equipment. 16

9.4 Safety precautions . 16

9.4.1 General. 16

9.4.2 Purging . 16

9.4.3 Lighting-up . 17

9.4.4 Start-up . 17

9.4.5 Shutting down . 18

9.5 Common stack for several firing systems . 18

10 Ash handling and extraction . 19

11 Operating manual . 19

Annex A (informative) Operational requirements for permanently supervised firing systems

for solid fuels for fluidized-bed and grate firing systems . 20

A.1 General. 20

A.2 Operation . 20

A.3 Operation and maintenance . 20

A.3.1 General . 20

A.3.2 Operating instructions . 20

Annex B (informative) Significant technical changes between this European Standard and

the previous edition . 21

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2014/68/EU aimed to be covered . 22

Table ZA.1 — Correspondence between this European Standard and Directive 2014/68/EU

................................................................................................................................................................... 22

Bibliography . 23

European foreword

This document (EN 12952-16:2022) has been prepared by Technical Committee CEN/TC 269 “Shell and

water-tube boilers”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of

an identical text or by endorsement, at the latest by April 2023, and conflicting national standards shall

be withdrawn at the latest by April 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 12952-16:2002.

The technical modifications in comparison with the previous edition are listed in Annex B.

The EN 12952 series concerning water-tube boilers and auxiliary installations consists of the following

parts:

• Part 1: General;

• Part 2: Materials for pressure parts of boilers and accessories;

• Part 3: Design and calculation for pressure parts;

• Part 4: In service boiler life expectancy calculations;

• Part 5: Workmanship and construction of pressure parts of the boiler;

• Part 6: Inspection during construction, documentation and marking of pressure parts of the boiler;

• Part 7: Requirements for equipment for the boiler;

• Part 8: Requirements for firing systems for liquid and gaseous fuels for the boiler;

• Part 9: Requirements for firing systems for pulverized solid fuels for the boiler;

• Part 10: Requirements for safeguards against excessive pressure;

• Part 11: Requirements for limiting devices of the boiler and accessories;

• Part 12: Requirements for boiler feedwater and boiler water quality;

• Part 13: Requirements for flue gas cleaning systems;

• Part 14: Requirements for flue gas DENOX systems using liquefied pressurized ammonia and ammonia

water solution;

• Part 15: Acceptance tests;

• Part 16: Requirements for grate and fluidized-bed firing systems for solid fuels for the boiler;

• CR 12952 Part 17: Guideline for the involvement of an inspection body independent of the

manufacturer;

• Part 18: Operating instructions.

Although these parts can be obtained separately, it should be recognized that the parts are inter-

dependent. As such, the design and manufacture of water-tube boilers requires the application of more

than one part in order for the requirements of the document to be satisfactorily fulfilled.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

1.1 Firing systems

This document applies to atmospheric fluidized-bed and grate firing systems of steam boilers and hot

water generators. These systems commence at the fuel bunkers and end at the ash extraction plant. For

combination of various firing systems, the individual requirements of each system apply, especially those

included in EN 12952-8:2022 and EN 12952-9:2022.

If several fuels are burnt simultaneously or if a fuel quality varies considerably (e.g. moisture content),

additional safety measures can be necessary, especially with respect to limitation of the fuel flow into the

firing system and ensuring proper air supply to the individual fuels.

Pressurized firing systems can require enhanced safety measures, which are not given in this European

Standard.

1.2 Fuels

This document covers the use of solid fuels. Pulverized fuel fired in an entrained air flow (burner) system

is covered by EN 12952-9:2022.

Solid fuels covered are:

• all coal qualities, e.g. lignite or brown coal, sub-bituminous or hard brown coal, bituminous coal or

hard coal, pitch coal, anthracite, coke, coal culm, coal sludge;

• other fossil solid fuels (e.g. peat, oil shale);

• biomass solid fuels (e.g. wood, wood wastes [bark], pellets, energy plants [miscanthus], harvest

wastes [straw] and briquettes);

• municipal waste solid fuels (e.g. garbage, sewage sludge, refuse derived fuels [RDF]);

• industrial waste solid fuels (e.g. petrol coke, soot, tyres, paper wastes, coated wood chips, spent

wood, animal product wastes).

Fuel blends from two or more groups, or fuels of unconventional or unknown quality can require special

safety measures which can be proved either by practical experience gained from comparable fuels, or by

suitable tests, e.g. in accordance with EN 14034-2:2006+A1:2011. Such measures specified and

documented by the manufacturer.

Fuels on which the design is documented in the operating instructions (see 11.2). This includes the fuel

data for 100 % input of the basic fuel and the data for any supplementary fuels together with their

maximum thermal input percentage.

1.3 Operation

The requirements for operational equipment in Clause 4, Clause 5, Clause 6, Clause 7, Clause 8, Clause 9,

Clause 10 and Clause 11 apply to steam boilers and hot water generators with permanent supervision by

properly trained personnel familiar with the special conditions of the firing systems and the type of fuel.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 12952-8:2022, Water-tube boilers and auxiliary installations — Part 8: Requirements for firing systems

for liquid and gaseous fuels for the boiler

EN 12952-9:2022, Water-tube boilers and auxiliary installations — Part 9: Requirements for firing systems

for pulverized solid fuel for the boiler

EN 12952-18:2012, Water-tube boilers and auxiliary installations - Part 18: Operating instructionsyy

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

• IEC Electropedia: available at https://www.electropedia.org/

• ISO Online browsing platform: available at https://www.iso.org/obp

3.1

annunciator

device to sense a non-standard or abnormal condition and initiate a visual and/or audible signal

3.2

back-up firing system

separate firing system to maintain safe ignition and stable combustion

3.3

basic fire

in the case of grate firing systems the layer of glowing fuel, fire bed, or flame of the fed fuel

Note 1 to entry: The basic fire ensures safe ignition.

3.4

carrier gas

transport medium for pneumatic conveying

3.5

combustion air

total air supplied to the firing system for combustion

3.6

combustion process monitoring device

device which detects the presence of the fire, or the conditions required for a stable combustion process

3.7

firing system heat input

heat input into the combustion chamber

Note 1 to entry: This normally is calculated as the mass flow of the fuel multiplied by its net calorific value.

3.8

firing system

total equipment required for the combustion of fuels

Note 1 to entry: Included are the installation for the storage in the boiler house, preparation and supply of fuels, the

combustion air supply, the grate or fluidized bed, the flue gas discharge, and all related control and monitoring

devices

3.9

fluidized-bed combustion firing system (FBC)

fuel is burnt in its fluidized state together with an inert component

3.10

fuel bin

silo

dust-tight and air-tight container for storage of fuels

3.11

fuel bunker

container for the storage of solid fuel

3.12

fuel feeding system

device to transport fuel into the combustion chamber

Note 1 to entry: This can be effected e.g. by feeders through ports in the furnace walls, by means of chutes or lances,

through the bottom grate or fluidizing gas distributor, or indirectly into the ash recirculation or combustion air

supply.

3.13

fuel handling plant

installation for conveying, mixing and distributing solid fuels to the individual fuel bunkers or fuel bins

3.14

grate firing system

fuel is burnt in a layer supported by a system e.g. firebars, which can have a cooling system

3.15

indicator

measuring instrument which indicates a variable value (e.g. pressure, temperature, flow, level)

Note 1 to entry: It can be equipped with an annunciator.

3.16

lighting-up equipment

facility to achieve safe ignition of the feed fuel

3.17

limiter

transducer, which, on reaching a fixed limit value (e.g. pressure, temperature, flow, level) is used to

interrupt and lock-out the energy supply. It requires manual unlocking before restart

3.18

lockout

interruption of the energy supply

Note 1 to entry: Manual unlocking is required before restart.

3.19

minimum fluidized-bed temperature

lowest temperature of the fluidized material at which it can be safely burnt

3.20

minimum heat input of the firing system

minimum heat input at which the firing system can be safely operated

3.21

monitor

transducer which on reaching of a fixed limit value and initiates an alarm and/or a cut-out. The output

signal only reverses if the causing value has changed at a defined range

3.22

purging of the flue gas passes

flow including air through the combustion chamber, flue gas passes, treatment systems and associated

ducts which effectively removes any gaseous combustibles

3.23

cold start-up condition

plant started when the temperature of ceramic lining and bed material is at ambient value

3.24

safety time

time period during which the effectiveness of the safety device may be inhibited without a hazardous

condition occurring

4 Fuel storage facilities with conveying plant

4.1 General

4.1.1 All facilities shall be designed so as to withstand mechanical and thermal stresses. Fuel shall not

be heated to an unacceptable level. Sites where fuel can accumulate shall be avoided.

4.1.2 Conveyance, temporary storage, and extraction of fuel shall be arranged such that blockage is

avoided.

4.1.3 Fuels liable to volatise or pyrolysis in the absence of external heating require measures to prevent

fire, explosion and injuries to personnel.

WARNING — Wet sludges can have an inherent explosion risk due to the release of volatiles (e.g.

methane) when stored. Dried sludges have a fire and dust explosion risk comparable to that of pulverized

fuels. Sludge storage in bins is preferable to bunker storage (see 4.4.1).

4.1.4 The storage of fuels supplied in small grain sized particles or fibres which can be stirred up and

become airborne shall only be permitted in bins (silos).

4.1.5 If different types of fuels are used, dangerous operating conditions due to blending shall be

excluded, e.g. by the use of separate bunkers or bins and separate feeding systems.

4.1.6 If there is a risk of blockage of conveying systems or firing systems by coarse fuel lumps, foreign

matter, and tramp metal, it shall be removed, preferably before entering the bunker.

4.2 Conveying plant

4.2.1 Several continuous conveyors arranged in series to form one conveying line shall be interlocked

such that the normal operation of any conveyor is possible only if the downstream conveyors are in

operation and the storage facility is ready to accept the fuel.

4.2.2 Automatic facilities for open mechanical conveyance and distribution of fuel shall only start after

visual and/or audible warning signals have been given.

Precautions shall be taken for the protection of personnel against injury from moving components.

Sufficient time shall be provided between a warning signal and starting of the plant.

4.2.3 If the type and format of the fuel requires bins (silos) for temporary storage in accordance with

4.1.3 or 4.1.4, subsequent conveyance shall be performed in a closed system, which shall be air-tight if

operated under internal pressure

4.2.4 For pneumatic conveyance of fuel in closed pipes, deposition shall be prevented by sufficient

velocity of the carrier gas depending on the type and format of the fuel.

4.2.5 All piping system components of a pneumatic conveying system shall be capable of being purged

of fuel.

4.2.6 Feeding of fuel into the pneumatic conveying line shall be interlocked in such a way that feeding

is possible only if sufficient carrier gas is supplied. Suitable monitoring devices, e.g. monitors for flow or

pressure of the carrier gas shall be provided.

4.2.7 If the carrier gas is exhausted to the atmosphere via a dust separator, the outlet shall be protected

against contact with ignition sources, or sparks.

4.2.8 If multiple lines are installed, devices shall be provided to isolate idle conveying lines from the

downstream storage facility or the furnace.

4.2.9 If fuels are conveyed hydraulically by pumps, 4.2.3 to 4.2.5 shall apply.

4.3 Fuel bunkers

4.3.1 With exception of bunkers emptied by cranes, fuel bunkers shall be built to achieve uniform

discharge by the selection of proper shape and design, in order to ensure a continuous uniform fuel flow

and to avoid segregation.

4.3.2 To avoid ingress of hot air/gas into the bunker, a minimum fuel level shall be maintained and

monitored in the bunker, or other suitable measures shall be taken.

4.3.3 The inner surface of the fuel bunker roof shall be designed to prevent the accumulation of dust

and gas in dead pockets.

4.3.4 Bunker charging openings shall be guarded to prevent personnel from falling in.

4.3.5 Fuel bunkers shall be equipped with fire fighting or fire prevention equipment. Coal bunkers may

be emptied by use of emergency chutes.

4.4 Fuel bins

4.4.1 Some fuels according to their type and format shall be stored in dust-tight bins (silos). The

requirements for pulverized fuel bins defined in EN 12952-9:2022, 5.4 and 6.2.2 shall apply.

4.4.2 The permissible maximum storage temperature shall be specified for each single fuel and fuel

blends and shall be monitored during the storage, if there is a risk of self ignition.

4.4.3 If emanation of combustible gas from the fuel cannot be prevented, bins shall be equipped with

suitable gas monitoring and safe venting devices, or an explosion-proof bin or inert gas protection shall

be provided.

4.4.4 Fuels described in 4.1.4 shall be stored in bins equipped with a stationary non-freezing fire

extinguishing system to enable fire to be fought without opening access doors. The extinguishing

compound shall be evenly sprayed across the entire cross sectional area of the bin. Spray nozzles shall be

protected against blockage by the ingress of dust. Where stationary spray-type extinguishing systems are

operated automatically, manual initiation shal

...

記事のタイトル:EN 12952-16:2022 - 水管ボイラーと補助設備 - 第16部:ボイラの固体燃料用グレートおよび流動化床燃焼システムの要件 記事の内容:この文書は、蒸気ボイラや給湯発生器の大気圧流動化床およびグレート燃焼システムに適用されます。これらのシステムは燃料バンカーから始まり、灰抽出プラントで終了します。複数の燃焼システムの組み合わせの場合、各システムの個別の要件が適用されます。特にEN 12952-8:2022およびEN 12952-9:2022で含まれる要件が適用されます。 複数の燃料を同時に燃焼する場合や、燃料の品質が著しく異なる場合(例:水分含有量)には、燃焼システムへの燃料流入の制約や各燃料への適切な空気供給を確保するために、追加の安全対策が必要になる場合があります。 加圧燃焼システムには、本欧州規格では指定されていない追加の安全対策が必要となる場合があります。 この文書は固体燃料の使用をカバーしています。送風式の粉状燃料燃焼システムに関しては、EN 12952-9:2022を参照してください。 カバーされる固体燃料は以下の通りです: - 石炭(褐炭や褐色石炭、硬炭、ピッチ炭、無煙炭、コークス、石炭コルム、石炭スラッジなど) - その他の化石燃料(トーク、オイルシェールなど) - バイオマス固形燃料(木材、木くず[樹皮]、ペレット、エネルギー作物[ミスカンサス]、収穫くず[わら]およびブリケット) - 廃棄物固形燃料(ゴミ、下水汚泥、廃棄物由来燃料[RDF]など) - 産業廃棄物固形燃料(コークス、煙、タイヤ、紙廃棄物、コーティング木チップ、廃材、動物性廃棄物など) 2つ以上のグループからの燃料ブレンドや非伝統的または品質のわからない燃料の場合、製造業者によって特別な安全対策が必要とされる場合があり、これは類似の燃料による実務経験に基づくこともあり、またはEN 14034-2:2006+A1:2011に準拠した適切なテストによって証明されることもあります。 蒸気ボイラや給湯発生器の操作には、燃焼システムと燃料の種類に精通した適切に訓練されたスタッフによる常時監視が必要とされます。ただし、本記事は加圧燃焼システムについて触れず、粉塵燃料燃焼システムに関しては別の欧州規格を参照するよう指示されています。

The article discusses the requirements for grate and fluidized-bed firing systems for solid fuels in water-tube boilers and auxiliary installations. It covers atmospheric fluidized-bed and grate firing systems, from the fuel bunkers to the ash extraction plant. It notes that for combinations of various firing systems, the individual requirements of each system apply. Additional safety measures may be necessary if multiple fuels are burnt simultaneously or if the fuel quality varies significantly. The use of solid fuels is covered, including coal, other fossil solid fuels, biomass solid fuels, municipal waste solid fuels, and industrial waste solid fuels. Fuel blends or unconventional fuels may require special safety measures as determined by the manufacturer. Operational requirements are outlined for steam boilers and hot water generators, which must be supervised by trained personnel familiar with the firing systems and fuel type. However, the article does not cover pressurized firing systems and refers to other European Standards for pulverized fuel fired systems.

기사 제목: EN 12952-16:2022 - 수관 보일러와 보조 설비 - 파트 16: 보일러를 위한 격자 및 유동층 연소 시스템에 대한 요구 사항 기사 내용: 이 문서는 기화식 유동층 및 격자 연소 시스템에 적용되며, 증기 보일러와 온수 발생기에 해당합니다. 이러한 시스템은 연료 저장고에서 시작하여 회진 추출 공정에서 끝납니다. 다양한 연소 시스템의 조합의 경우, 각 시스템의 개별 요구 사항이 적용되며, 특히 EN 12952-8:2022 및 EN 12952-9:2022에 포함된 요구 사항이 해당됩니다. 여러 연료가 동시에 연소되는 경우 또는 연료 품질이 상당히 다른 경우(예: 수분 함량)에는 연소 시스템으로의 연료 유입 제한 및 각 연료에 대한 적절한 공기 공급을 보장하기 위해 추가적인 안전 조치가 필요할 수 있습니다. 압력 연소 시스템은이 유럽 표준에서 제공되지 않는 강화된 안전 조치가 필요할 수 있습니다. 이 문서는 고체 연료의 사용을 다룹니다. 공기 유동층 연소(버너) 시스템에서 분진 연료 연소는 EN 12952-9:2022에 따릅니다. 다음은 다루는 고체 연료입니다: - 석탄 (잔텀 석탄, 갈색 석탄, 흑연, 고안석, 코크, 석탄 쿨름, 석탄 슬러지 등) - 기타 화석 연료 (토사, 유류 석탄 등) - 생물 질 고체 연료 (나무, 목재 폐기물 [수피], 펠렛, 에너지 식물 [미스칸투스], 수확 폐기물 [짚] 및 브리켓) - 시티쓰 폐기물 고체 연료 (쓰레기, 하수 슬러지, 연료 유도 폐기물 [RDF]) - 산업 폐기물 고체 연료 (휘발유 코크, 벽돌 가루, 타이어, 종이 폐기물, 코팅된 목칩, 폐목재, 동물 부산물 폐기물 등) 두 개 이상의 그룹으로부터의 연료 혼합물이나 정평하지 않은 품질의 연료의 경우, 이에 대한 특수 안전 조치가 필요할 수 있으며, 이는 비슷한 연료로부터 얻은 실제 경험에 기초한 것이거나 EN 14034-2:2006+A1:2011에 따른 적절한 테스트로 입증될 수 있습니다. 이러한 조치는 제조업자에 의해 지정되고 문서화됩니다. 운영에 대한 요구 사항에는 증기 보일러와 온수 발생기의 영구적인 감독이 포함되며, 이는 연소 시스템과 연료 유형의 특수한 조건에 익숙한 적절하게 훈련 된 인력에 의해 이루어져야 합니다. 그러나, 기사는 압력 연소 시스템을 다루지 않으며, 분진 연료 연소 시스템에 대해서는 다른 유럽 표준을 참조하라고 언급합니다.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...