EN 15001-1:2023

(Main)Gas Infrastructure - Gas installation pipework with an operating pressure greater than 0,5 bar for industrial installations and greater than 5 bar for industrial and non-industrial installations - Part 1: Detailed functional requirements for design, materials, construction, inspection and testing

Gas Infrastructure - Gas installation pipework with an operating pressure greater than 0,5 bar for industrial installations and greater than 5 bar for industrial and non-industrial installations - Part 1: Detailed functional requirements for design, materials, construction, inspection and testing

This European Standard specifies detailed functional requirements for the design, selection of materials, construction, inspection and testing of:

- industrial gas installation pipework and assemblies with an operating pressure greater than 0,5 bar; and

- non-industrial gas installation pipework (residential and commercial) with an operating pressure greater than 5 bar in buildings;

starting from the outlet of the network operator’s point of delivery up to the inlet connection to the gas appliance; normally the inlet isolation valve. This standard also covers the pipework to the inlet connection of a gas appliance that is not included within the scope of the appliance standard.

NOTE 1 The use of the term installation and pipework is interchangeable.

Apart from the exceptions stated below, this standard applies to gas installations operating at ambient temperatures between −20 °C and 40 °C and operating pressures up to and including 60 bar. For operating conditions outside these limitations, reference should additionally be made to EN 13480 (all parts) for metallic pipework.

For industrial gas installations up to and including 0,5 bar and for non-industrial (residential and commercial) gas installations up to and including 5 bar in buildings, EN 1775 applies.

For gas installations that do not fall within the scope of EN 1775 or other European Standards, this standard applies.

In this European Standard, the term “gas“ refers to combustible gases, which are gaseous at 15 °C and 1 013 mbar absolute atmospheric pressure (normal conditions). These gases are commonly referred to as manufactured gas, natural gas or Liquefied Petroleum Gas (LPG). They are also referred to as first, second or third family gases as classified in EN 437:2003+A1:2009, Table 1. The given values are considered as normal conditions for all volumes given in this standard.

This European Standard is applicable to installation pipework for the carriage of:

- processed, non-toxic and non-corrosive natural gas according to EN 437:2003+A1:2009 and EN 16726 "Gas infrastructure - Quality of gas - Group H";

- vaporized LPG;

- biomethane, complying with EN 16723 1;

- vaporized LNG.

NOTE 2 The specification of vaporized LNG is equal to that of natural gas as classified in EN 437:2003+A1:2009.

This European Standard does not cover pipework for hydrogen rich gases that fall outside the definitions within EN 437:2003+A1:2009.

LPG storage vessels (including all ancillaries fitted directly to storage vessels) are excluded. Also excluded are LPG installations and sections of LPG installations operating at vapour pressure in the liquid state (e.g. between the storage vessel and any pressure regulator).

In this standard, all pressures are gauge pressures unless otherwise stated.

This standard has been harmonized to address the essential safety requirements of the Pressure Equipment Directive (PED, 2014/68/EU [formerly 97/23/EC]) relevant for the joining of gas installation pipework (assemblies) falling within the scope of the PED. These are listed in Annex ZA. However, "this Directive does not cover the assembly of pressure equipment on the site and under the responsibility of the user, as in the case of industrial installations" (PED, Preamble, 7th recital, last paragraph).

Although in this respect, the standard takes into account the essential safety requirements of the PED, no inference can be drawn from this as to whether or not the installation or parts of the installation falls within the scope of the PED. Reference should therefore be made to the PED and relevant national legislation.

This European Standard specifies common basic principles for gas supply systems. Users of this European Standard should be aware (...)

Gasinfrastruktur - Gasleitungsanlagen mit einem Betriebsdruck größer 0,5 bar für industrielle Installationen und größer 5 bar für industrielle und nicht-industrielle Installationen - Teil 1: Detaillierte funktionale Anforderungen an Planung, Material, Bau, Inspektion und Prüfung

Diese Europäische Norm legt detailliert die funktionalen Anforderungen hinsichtlich der Planung und Werkstoffauswahl sowie des Baus, der Inspektion und der Prüfung von:

- industriellen Gasleitungsanlagen und Baugruppen mit einem Betriebsdruck größer 0,5 bar; und

- nicht-industriellen Gasleitungsanlagen in Gebäuden (Haushalte und Gewerbebetriebe) mit einem Betriebsdruck größer 5 bar,

beginnend am Ausgangsanschluss der Übergabestelle des Netzbetreibers bis zum Eingangsanschluss der Gasgeräte, d. h. in der Regel der Absperrarmatur vor dem Gerät, fest. Diese Norm gilt auch für die Rohrleitungen zum Eingangsanschluss der Gasgeräte, die nicht in den Anwendungsbereich der Gasgerätenorm fallen.

ANMERKUNG 1 Der Gebrauch der Begriffe "Anlage" (en: installation) und "Rohrleitungen" (en: pipework) ist austauschbar.

Abgesehen von den nachstehend angegebenen Ausnahmen gilt diese Norm für den Betrieb von Gasleitungsanlagen bei Umgebungstemperaturen zwischen −20 °C und 40 °C mit Betriebsdrücken bis einschließlich 60 bar. Bei Betriebszuständen außerhalb dieser Grenzen sollte zusätzlich auf EN 13480 (alle Teile) für metallische Rohrleitungen Bezug genommen werden.

Für industrielle Gasleitungsanlagen mit Betriebsdrücken bis einschließlich 0,5 bar und für nicht-industrielle Gasleitungsanlagen in Gebäuden (Haushalten und Gewerbebetrieben) mit Betriebsdrücken bis einschließlich 5 bar gilt EN 1775.

Diese Norm gilt für Gasleitungsanlagen, die nicht in den Anwendungsbereich der EN 1775 oder anderer Europäischer Normen fallen.

In dieser Europäischen Norm bezeichnet der Begriff „Gas“ brennbare Gase, die bei einer Temperatur von 15 °C und einem absoluten atmosphärischen Druck von 1 013 mbar (Normalzustand) in gasförmigem Zustand vorliegen. Diese Gase werden im Allgemeinen als erzeugtes Gas, Erdgas oder Flüssiggas (LPG) bezeichnet. Sie werden auch als Gase der ersten, zweiten oder dritten Gasfamilie entsprechend der Klassifizierung nach EN 437:2003+A1:2009, Tabelle 1, bezeichnet. Die angegebenen Werte beziehen sich auf den "Normalzustand" für alle in dieser Norm angegebenen Volumina.

Diese Europäische Norm gilt für Rohrleitungsanlagen für den Transport von:

- aufbereitetem, ungiftigem und nicht korrosivem Erdgas nach EN 437:2003+A1:2009 und EN 16726 "Gasinfrastruktur - Beschaffenheit von Gas - Gruppe H";

- verdampftem LPG;

- Biomethan nach EN 16723 1;

- verdampftem LNG.

ANMERKUNG 2 Die Spezifikation von verdampftem LNG gleicht der von Erdgas entsprechend der Klassifizierung nach EN 437:2003+A1:2009.

Diese Europäische Norm gilt nicht für Rohrleitungen für Gase mit hohem Wasserstoffanteil, die nicht den Definitionen nach EN 437:2003+A1:2009 entsprechen.

Hiervon ausgenommen sind Flüssiggasbehälter (einschließlich aller unmittelbar an den Behältern angebrachten Geräte). Ebenfalls ausgenommen sind Flüssiggasanlagen und Abschnitte von Flüssig-gasanlagen, die in flüssigem Zustand unter Dampfdruck betrieben werden (z. B. zwischen dem Behälter und einem Druckregelgerät).

Sofern nicht anders angegeben, handelt es sich bei allen in diesem Dokument verwendeten Drücken um Überdrücke.

Diese Norm wurde im Hinblick auf die grundlegenden Sicherheitsanforderungen an das Verbinden von Gasleitungsanlagen (Baugruppen), die in den Anwendungsbereich der PED fallen, an die Druckgeräte-richtlinie (PED, 2014/68/EU [zuvor PED, 97/23/EG]) angepasst. Diese Anforderungen sind in Anhang ZA aufgeführt. Allerdings gilt diese Richtlinie "nicht für den Zusammenbau von Druckgeräten..., der " beispielsweise in Industrieanlagen " auf dem Gelände und unter der Verantwortung eines Anwenders erfolgt." (PED, Präambel, 7. Aufzählung, letzter Absatz).

Diese Norm berücksichtigt in diesem Zusammenhang zwar die grundlegenden Sicherheitsanforderungen der PED, allerdings kann sich daraus nicht ableiten lassen, ob eine Anlage ganz oder teilweise in den Anwendungsbereich der PED fällt. (...)

Infrastructures gazières - Canalisations d’installations de gaz avec une pression de service supérieure à 0,5 bar pour les installations industrielles et supérieure à 5 bar pour les installations industrielles et non industrielles (domestiques et commerciales) - Partie 1 : Exigences fonctionnelles détaillées relatives à la conception, aux matériaux, à la construction, à l'inspection et aux essais

Cette Norme européenne spécifie les exigences fonctionnelles détaillées relatives à la conception, au choix des matériaux, à la construction, à l’inspection et aux essais :

- d’installations et d'ensembles industriels de gaz avec une pression de service supérieure à 0,5 bar ; et

- d’installations de gaz non industrielles (résidentielles et commerciales) avec une pression de service supérieure à 5 bar dans les bâtiments ;

allant du point de livraison de l'exploitant du réseau de distribution de gaz jusqu'au raccordement d'entrée de l'appareil à gaz, ce dernier étant habituellement le robinet d'isolement d'entrée. La présente norme est aussi applicable à la tuyauterie du raccordement d’un appareil à gaz qui ne fait pas partie du domaine d'application de la norme de l'appareil.

NOTE 1 Les termes installation et tuyauterie sont interchangeables.

Outre les exceptions énoncées ci-après, la présente norme est applicable aux installations de gaz exploitées à des températures ambiantes comprises entre −20 °C et 40 °C et des pressions de service inférieures ou égales à 60 bar. Pour des conditions de service en dehors de ces limites, il convient de se référer à l’EN 13480 (toutes les parties) dans le cas d’une canalisation métallique.

Pour les installations de gaz industrielles dont la pression de service est inférieure ou égale à 0,5 bar et pour les installations de gaz non industrielles (domestiques et commerciales) dont la pression de service est inférieure ou égale à 5 bar dans des bâtiments, c'est l’EN 1775 qui s’applique.

Pour les installations industrielles de gaz non visées par l’EN 1775 ni par d'autres Normes européennes, cette norme s’applique.

Dans la présente Norme européenne, le terme « gaz » est applicable à des gaz combustibles, qui sont gazeux à 15 °C et à 1 013 mbar de pression atmosphérique absolue (conditions normales). Ces gaz sont couramment appelés gaz manufacturé, gaz naturel ou gaz de pétrole liquéfiés (GPL). Ils sont aussi dénommés respectivement gaz de la 1ère, 2e et 3e famille selon le classement de l’EN 437:2003+A1:2009, Tableau 1. Les valeurs données sont considérées aux conditions normales pour tous les volumes donnés dans cette norme.

La présente Norme européenne s’applique aux canalisations d'installations pour le transport du :

- gaz traité, non toxique et non corrosif, naturel, conformément à l’EN 437:2003+A1:2009 et à l’EN 16726, « Infrastructures gazières - Qualité du gaz - Groupe H » ;

- GPL vaporisé ;

- biométhane, conforme à l’EN 16723-1 ;

- GNL vaporisé.

NOTE 2 La spécification du GNL vaporisé équivaut à celle du gaz naturel classé dans l’EN 437:2003+A1:2009.

La présente Norme européenne ne couvre pas la tuyauterie pour les gaz riches en hydrogène ne relevant pas de la définition figurant dans l’EN 437:2003+A1:2009.

Les réservoirs de stockage de GPL (y compris tous les accessoires fixés directement sur les réservoirs de stockage) sont exclus. Il en est de même pour les installations de GPL et les parties d'installations de GPL exploitées à la pression de vapeur à l’état liquide (par exemple entre le réservoir de stockage et chaque régulateur de pression).

Dans cette norme, toutes les pressions sont, sauf indication contraire, des pressions relatives.

Cette norme a été harmonisée pour satisfaire aux exigences essentielles de la Directive relative aux équipements sous pression (DESP, 2014/68/UE [anciennement 97/23/CE]) en matière de raccordement de canalisations d'installations de gaz (ensembles) qui entrent dans le domaine d'application de la DESP. Ces exigences sont listées en Annexe ZA. Cependant, « cette Directive ne couvre pas l’assemblage d’équipements sous pression effectué sur le site de l’usager, sous la responsabilité de celui-ci, telles que des installations industrielles » (...)

Infrastruktura za plin - Plinske napeljave z delovnim tlakom nad 0,5 bar za industrijsko uporabo in delovnim tlakom nad 5 bar za industrijsko in neindustrijsko uporabo - 1. del: Podrobne funkcionalne zahteve za načrtovanje, materiale, gradnjo, nadzor in preskušanje

Ta standard določa podrobne funkcionalne zahteve za načrtovanje, izbiro materialov, konstrukcijo, pregled in preskušanje industrijskih plinskih napeljav in sklopov z obratovalnim tlakom nad 0,5 bara ter neindustrijskih plinskih napeljav (stanovanjskih in poslovnih) z obratovalnim tlakom nad 5 barov v stavbah, od izhoda iz dobavnega mesta upravljavca omrežja do dovodnega priključka plinske naprave: običajno do dovodnega izolirnega ventila. Ta standard zajema tudi dovodni priključek plinske naprave, ki obsega cevovode, ki ne spadajo na področje uporabe standarda za naprave.

OPOMBA: Izraza napeljava in cevovod sta zamenljiva.

Ta standard se uporablja za plinske naprave: ki delujejo pri temperaturah okolice med −20 °C in 40 °C ter pri obratovalnih tlakih do vključno 60 barov. Za obratovalne pogoje zunaj teh omejitev se je treba dodatno sklicevati na standard EN 13480 za kovinske cevovode.

Za industrijske plinske napeljave do vključno 0,5 bara in za neindustrijske (stanovanjske in poslovne) plinske napeljave do vključno 5 barov v stavbah se uporablja standard EN 1775.

Za plinske napeljave, ki ne spadajo na področje uporabe standarda EN 1775 ali drugih evropskih standardov, se uporablja ta standard.

V tem standardu se izraz »plin« nanaša na gorljive pline, ki so plinasti pri 15 °C in absolutnem atmosferskem tlaku 1013 mbar (normalni pogoji). Ti plini se običajno imenujejo industrijski plin, zemeljski plin ali utekočinjeni naftni plin (LPG). Imenujemo jih tudi plini prve, druge ali tretje plinske družine (glej preglednico 1 standarda EN 437:2003). Navedene vrednosti veljajo za normalne pogoje za vse količine, navedene v tem standardu.

General Information

- Status

- Published

- Publication Date

- 21-Feb-2023

- Technical Committee

- CEN/TC 234 - Gas infrastructure

- Drafting Committee

- CEN/TC 234/WG 8 - Industrial piping

- Current Stage

- 6060 - Definitive text made available (DAV) - Publishing

- Start Date

- 22-Feb-2023

- Due Date

- 04-Aug-2019

- Completion Date

- 22-Feb-2023

Not Harmonized97/23/EC - Pressure equipment

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 15001-1:2023 (CEN) defines detailed functional requirements for gas installation pipework with operating pressures greater than 0,5 bar for industrial installations and greater than 5 bar for industrial and non‑industrial (residential and commercial) installations. The standard covers the pipework from the network operator’s point of delivery to the gas appliance inlet (normally the inlet isolation valve). It applies to common combustible gases (natural gas, vaporized LPG, biomethane, vaporized LNG) at ambient temperatures between −20 °C and 40 °C and pressures up to 60 bar (all pressures are gauge unless stated).

Key topics and technical requirements

- Scope of application: industrial installations >0,5 bar; non‑industrial installations >5 bar; exclusions include hydrogen‑rich gases outside EN 437 definitions and LPG storage vessels operating in liquid state.

- Design principles: layout, dimensioning, pressure loss, gas velocity, wall thickness, and provisions for expansion and flexibility.

- Materials and components: requirements and specifications for carbon steel, stainless steel, copper, polyethylene, valves, flanges and ancillaries; certification and traceability.

- Construction and jointing: detailed jointing methods, assembly processes for metallic materials, hot tapping of carbon steel pipe and acceptable techniques.

- Pressure control and metering: design of regulating systems, instrumentation, bypasses, filters, sensing lines, venting and compressor considerations.

- Inspection and testing: pressure tests, inspection regimes, documentation, measuring and test instruments and technical files.

- Safety and protection: resistance to fire and corrosion, protection against gas hazards, electrical installation requirements, support structures, isolation and depressurising/purging.

- Regulatory alignment: harmonized to address essential safety requirements of the Pressure Equipment Directive (PED 2014/68/EU) for joined assemblies (see Annex ZA), while advising users to confirm PED and national legislation applicability.

Applications

- Design and construction of high‑pressure gas distribution and industrial process gas systems.

- Specification and procurement of pipes, fittings, valves and pressure control equipment.

- Commissioning, inspection and periodic testing of gas installations in factories, commercial buildings and multi‑unit residential systems where pressure limits apply.

- Risk assessment, safety engineering and maintenance planning for gas infrastructure.

Who should use EN 15001-1:2023

- Gas system designers and consulting engineers

- EPC contractors and installers of gas pipework

- Plant operators, facility managers and gas network operators

- Component manufacturers, testing and certification bodies

- Inspectors, safety assessors and compliance officers

Related standards and references

- EN 1775 - installations up to 5 bar (non‑industrial) / 0,5 bar (industrial)

- EN 13480 - metallic industrial piping (for conditions outside EN 15001‑1 limits)

- EN 437, EN 16726, EN 16723 - gas classification and quality

- PED 2014/68/EU - Pressure Equipment Directive (see Annex ZA)

Keywords: EN 15001-1:2023, gas installation pipework, high‑pressure gas systems, design materials construction inspection testing, CEN, Pressure Equipment Directive.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15001-1:2023 is a standard published by the European Committee for Standardization (CEN). Its full title is "Gas Infrastructure - Gas installation pipework with an operating pressure greater than 0,5 bar for industrial installations and greater than 5 bar for industrial and non-industrial installations - Part 1: Detailed functional requirements for design, materials, construction, inspection and testing". This standard covers: This European Standard specifies detailed functional requirements for the design, selection of materials, construction, inspection and testing of: - industrial gas installation pipework and assemblies with an operating pressure greater than 0,5 bar; and - non-industrial gas installation pipework (residential and commercial) with an operating pressure greater than 5 bar in buildings; starting from the outlet of the network operator’s point of delivery up to the inlet connection to the gas appliance; normally the inlet isolation valve. This standard also covers the pipework to the inlet connection of a gas appliance that is not included within the scope of the appliance standard. NOTE 1 The use of the term installation and pipework is interchangeable. Apart from the exceptions stated below, this standard applies to gas installations operating at ambient temperatures between −20 °C and 40 °C and operating pressures up to and including 60 bar. For operating conditions outside these limitations, reference should additionally be made to EN 13480 (all parts) for metallic pipework. For industrial gas installations up to and including 0,5 bar and for non-industrial (residential and commercial) gas installations up to and including 5 bar in buildings, EN 1775 applies. For gas installations that do not fall within the scope of EN 1775 or other European Standards, this standard applies. In this European Standard, the term “gas“ refers to combustible gases, which are gaseous at 15 °C and 1 013 mbar absolute atmospheric pressure (normal conditions). These gases are commonly referred to as manufactured gas, natural gas or Liquefied Petroleum Gas (LPG). They are also referred to as first, second or third family gases as classified in EN 437:2003+A1:2009, Table 1. The given values are considered as normal conditions for all volumes given in this standard. This European Standard is applicable to installation pipework for the carriage of: - processed, non-toxic and non-corrosive natural gas according to EN 437:2003+A1:2009 and EN 16726 "Gas infrastructure - Quality of gas - Group H"; - vaporized LPG; - biomethane, complying with EN 16723 1; - vaporized LNG. NOTE 2 The specification of vaporized LNG is equal to that of natural gas as classified in EN 437:2003+A1:2009. This European Standard does not cover pipework for hydrogen rich gases that fall outside the definitions within EN 437:2003+A1:2009. LPG storage vessels (including all ancillaries fitted directly to storage vessels) are excluded. Also excluded are LPG installations and sections of LPG installations operating at vapour pressure in the liquid state (e.g. between the storage vessel and any pressure regulator). In this standard, all pressures are gauge pressures unless otherwise stated. This standard has been harmonized to address the essential safety requirements of the Pressure Equipment Directive (PED, 2014/68/EU [formerly 97/23/EC]) relevant for the joining of gas installation pipework (assemblies) falling within the scope of the PED. These are listed in Annex ZA. However, "this Directive does not cover the assembly of pressure equipment on the site and under the responsibility of the user, as in the case of industrial installations" (PED, Preamble, 7th recital, last paragraph). Although in this respect, the standard takes into account the essential safety requirements of the PED, no inference can be drawn from this as to whether or not the installation or parts of the installation falls within the scope of the PED. Reference should therefore be made to the PED and relevant national legislation. This European Standard specifies common basic principles for gas supply systems. Users of this European Standard should be aware (...)

This European Standard specifies detailed functional requirements for the design, selection of materials, construction, inspection and testing of: - industrial gas installation pipework and assemblies with an operating pressure greater than 0,5 bar; and - non-industrial gas installation pipework (residential and commercial) with an operating pressure greater than 5 bar in buildings; starting from the outlet of the network operator’s point of delivery up to the inlet connection to the gas appliance; normally the inlet isolation valve. This standard also covers the pipework to the inlet connection of a gas appliance that is not included within the scope of the appliance standard. NOTE 1 The use of the term installation and pipework is interchangeable. Apart from the exceptions stated below, this standard applies to gas installations operating at ambient temperatures between −20 °C and 40 °C and operating pressures up to and including 60 bar. For operating conditions outside these limitations, reference should additionally be made to EN 13480 (all parts) for metallic pipework. For industrial gas installations up to and including 0,5 bar and for non-industrial (residential and commercial) gas installations up to and including 5 bar in buildings, EN 1775 applies. For gas installations that do not fall within the scope of EN 1775 or other European Standards, this standard applies. In this European Standard, the term “gas“ refers to combustible gases, which are gaseous at 15 °C and 1 013 mbar absolute atmospheric pressure (normal conditions). These gases are commonly referred to as manufactured gas, natural gas or Liquefied Petroleum Gas (LPG). They are also referred to as first, second or third family gases as classified in EN 437:2003+A1:2009, Table 1. The given values are considered as normal conditions for all volumes given in this standard. This European Standard is applicable to installation pipework for the carriage of: - processed, non-toxic and non-corrosive natural gas according to EN 437:2003+A1:2009 and EN 16726 "Gas infrastructure - Quality of gas - Group H"; - vaporized LPG; - biomethane, complying with EN 16723 1; - vaporized LNG. NOTE 2 The specification of vaporized LNG is equal to that of natural gas as classified in EN 437:2003+A1:2009. This European Standard does not cover pipework for hydrogen rich gases that fall outside the definitions within EN 437:2003+A1:2009. LPG storage vessels (including all ancillaries fitted directly to storage vessels) are excluded. Also excluded are LPG installations and sections of LPG installations operating at vapour pressure in the liquid state (e.g. between the storage vessel and any pressure regulator). In this standard, all pressures are gauge pressures unless otherwise stated. This standard has been harmonized to address the essential safety requirements of the Pressure Equipment Directive (PED, 2014/68/EU [formerly 97/23/EC]) relevant for the joining of gas installation pipework (assemblies) falling within the scope of the PED. These are listed in Annex ZA. However, "this Directive does not cover the assembly of pressure equipment on the site and under the responsibility of the user, as in the case of industrial installations" (PED, Preamble, 7th recital, last paragraph). Although in this respect, the standard takes into account the essential safety requirements of the PED, no inference can be drawn from this as to whether or not the installation or parts of the installation falls within the scope of the PED. Reference should therefore be made to the PED and relevant national legislation. This European Standard specifies common basic principles for gas supply systems. Users of this European Standard should be aware (...)

EN 15001-1:2023 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general; 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15001-1:2023 has the following relationships with other standards: It is inter standard links to EN 15001-1:2009, EN 60529:1991/A2:2013, EN 60529:1991/A1:2000, EN 60529:1991, HD 60364-1:2008, EN 60079-14:2014, EN 12266-1:2012, EN 12279:2000, EN 14382:2005, EN 1515-4:2021, EN 1254-4:2021, EN 13480-3:2017/A3:2020, EN ISO 683-4:2018, EN 13100-1:2017, EN 13480-2:2017/A7:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15001-1:2023 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071, M/601. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 15001-1:2023 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-april-2023

Nadomešča:

SIST EN 15001-1:2009

Infrastruktura za plin - Plinske napeljave z delovnim tlakom nad 0,5 bar za

industrijsko uporabo in delovnim tlakom nad 5 bar za industrijsko in

neindustrijsko uporabo - 1. del: Podrobne funkcionalne zahteve za načrtovanje,

materiale, gradnjo, nadzor in preskušanje

Gas Infrastructure - Gas installation pipework with an operating pressure greater than

0,5 bar for industrial installations and greater than 5 bar for industrial and non-industrial

installations - Part 1: Detailed functional requirements for design, materials, construction,

inspection and testing

Gasinfrastruktur - Gasleitungsanlagen mit einem Betriebsdruck größer 0,5 bar für

industrielle Installationen und größer 5 bar für industrielle und nicht-industrielle

Installationen - Teil 1: Detaillierte funktionale Anforderungen an Planung, Material, Bau,

Inspektion und Prüfung

Infrastructures gazières - Canalisations d’installations de gaz avec une pression de

service supérieure à 0,5 bar pour les installations industrielles et supérieure à 5 bar pour

les installations industrielles et non industrielles (domestiques et commerciales) - Partie

1 : Exigences fonctionnelles détaillées relatives à la conception, aux matériaux, à la

construction, à l'inspection et aux essais

Ta slovenski standard je istoveten z: EN 15001-1:2023

ICS:

91.140.40 Sistemi za oskrbo s plinom Gas supply systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15001-1

EUROPEAN STANDARD

NORME EUROPÉENNE

February 2023

EUROPÄISCHE NORM

ICS 23.040.01 Supersedes EN 15001-1:2009

English Version

Gas Infrastructure - Gas installation pipework with an

operating pressure greater than 0,5 bar for industrial

installations and greater than 5 bar for industrial and non-

industrial installations - Part 1: Detailed functional

requirements for design, materials, construction,

inspection and testing

Infrastructures gazières - Canalisations d'installations Gasinfrastruktur - Gasleitungsanlagen mit einem

de gaz avec une pression de service supérieure à 0,5 Betriebsdruck größer 0,5 bar für industrielle

bar pour les installations industrielles et supérieure à 5 Installationen und größer 5 bar für industrielle und

bar pour les installations industrielles et non nicht-industrielle Installationen - Teil 1: Detaillierte

industrielles (domestiques et commerciales) - Partie 1 : funktionale Anforderungen an Planung, Material, Bau,

Exigences fonctionnelles détaillées relatives à la Inspektion und Prüfung

conception, aux matériaux, à la construction, à

l'inspection et aux essais

This European Standard was approved by CEN on 9 October 2022.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2023 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15001-1:2023 E

worldwide for CEN national Members.

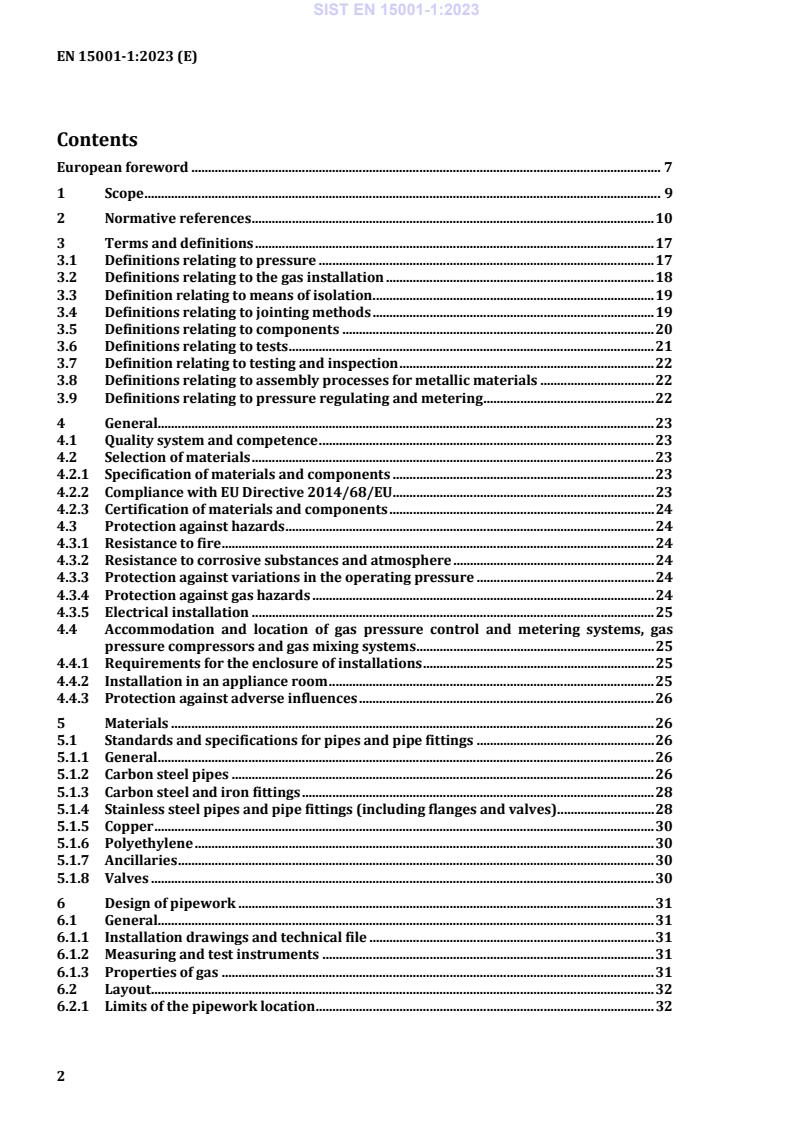

Contents

European foreword . 7

1 Scope . 9

2 Normative references . 10

3 Terms and definitions . 17

3.1 Definitions relating to pressure . 17

3.2 Definitions relating to the gas installation . 18

3.3 Definition relating to means of isolation . 19

3.4 Definitions relating to jointing methods . 19

3.5 Definitions relating to components . 20

3.6 Definitions relating to tests . 21

3.7 Definition relating to testing and inspection . 22

3.8 Definitions relating to assembly processes for metallic materials . 22

3.9 Definitions relating to pressure regulating and metering . 22

4 General. 23

4.1 Quality system and competence . 23

4.2 Selection of materials . 23

4.2.1 Specification of materials and components . 23

4.2.2 Compliance with EU Directive 2014/68/EU . 23

4.2.3 Certification of materials and components . 24

4.3 Protection against hazards . 24

4.3.1 Resistance to fire . 24

4.3.2 Resistance to corrosive substances and atmosphere . 24

4.3.3 Protection against variations in the operating pressure . 24

4.3.4 Protection against gas hazards . 24

4.3.5 Electrical installation . 25

4.4 Accommodation and location of gas pressure control and metering systems, gas

pressure compressors and gas mixing systems . 25

4.4.1 Requirements for the enclosure of installations . 25

4.4.2 Installation in an appliance room . 25

4.4.3 Protection against adverse influences . 26

5 Materials . 26

5.1 Standards and specifications for pipes and pipe fittings . 26

5.1.1 General. 26

5.1.2 Carbon steel pipes . 26

5.1.3 Carbon steel and iron fittings . 28

5.1.4 Stainless steel pipes and pipe fittings (including flanges and valves) . 28

5.1.5 Copper . 30

5.1.6 Polyethylene . 30

5.1.7 Ancillaries . 30

5.1.8 Valves . 30

6 Design of pipework . 31

6.1 General. 31

6.1.1 Installation drawings and technical file . 31

6.1.2 Measuring and test instruments . 31

6.1.3 Properties of gas . 31

6.2 Layout . 32

6.2.1 Limits of the pipework location . 32

6.2.2 Above-ground pipework . 32

6.2.3 Buried pipework . 32

6.2.4 Distance between buried pipework and buildings . 32

6.2.5 Unacceptable locations for gas pipework in buildings . 32

6.3 Dimensioning . 33

6.3.1 Pressure loss . 33

6.3.2 Gas velocity . 33

6.4 Pressure and wall thickness . 33

6.4.1 PS and test pressure . 33

6.4.2 Pipe wall thickness. 34

6.5 Safety engineering . 39

6.5.1 Principles of pipework . 39

6.5.2 Isolation of the gas supply . 40

6.5.3 Location of pipework . 43

6.5.4 Supporting structures . 43

6.5.5 Depressurising and purging . 43

6.6 Detail engineering . 43

6.6.1 Pipe transits . 43

6.6.2 Branches . 44

6.6.3 Joints. 47

6.6.4 Ancillaries . 49

6.6.5 Above ground pipework inside and outside buildings . 50

6.6.6 Buried pipework . 53

6.6.7 Wall thickness related to bending of steel pipes . 55

6.6.8 Provision for expansion and flexibility . 56

6.7 Hot tapping carbon steel pipe . 56

6.7.1 General . 56

6.7.2 Principles . 56

6.7.3 Conditions . 56

6.7.4 Design evaluation . 57

7 Design of pressure control systems . 57

7.1 General . 57

7.2 Pressure regulating system . 58

7.3 Instrumentation . 58

7.4 Permanent bypasses . 59

7.4.1 Bypasses for equalization or testing. 59

7.4.2 Bypasses of the safety system . 59

7.5 Construction requirements . 59

7.5.1 Pressure resistance. 59

7.5.2 Operation . 59

7.5.3 Insulating joint/flange . 59

7.5.4 Gas velocity . 59

7.5.5 External sensing lines . 59

7.5.6 Breather and vent pipes . 60

7.5.7 Isolating valves . 61

7.5.8 Filter, separators . 61

7.5.9 Pressure gauges . 61

7.5.10 Pressure tappings and purge connections . 61

7.6 Low gas temperature . 61

7.6.1 Functional requirements . 61

7.6.2 Design temperature effects . 61

7.6.3 Condensation . 62

7.7 Gas compressors . 62

7.7.1 Construction . 62

7.7.2 Temperature rise . 62

7.7.3 Pressure variation . 62

7.8 Safety systems . 62

7.8.1 Pressure safety system . 62

7.8.2 Gas pressure compressors . 65

7.8.3 Gas mixing systems . 66

8 Construction . 66

8.1 Identification of the installation . 66

8.1.1 Installation drawings . 66

8.1.2 Identification of the components . 66

8.1.3 Weld identification . 66

8.2 External hazards . 67

8.2.1 Mechanical loads . 67

8.2.2 Electric currents . 67

8.2.3 Environmental influences . 67

8.3 Gas pipework passing through exterior walls . 67

8.3.1 Buried pipe transits . 67

8.3.2 Aboveground pipe transits . 69

8.4 Identification of pipework . 70

8.4.1 Identification of above-ground pipework . 70

8.4.2 Identification of buried pipework . 70

8.5 Specifications and requirements for joints . 70

8.5.1 Welded joints and pipe fittings in carbon steel and stainless steel pipes . 70

8.5.2 Joints in copper pipework . 75

8.5.3 Fusion joints in plastic pipes . 75

8.5.4 Flange joints . 75

8.5.5 Compression joints . 75

8.5.6 Threaded joints . 75

8.6 Joint suitability . 75

8.7 Connections . 76

8.7.1 Connection points/pipe ends . 76

8.7.2 Appliance isolating valves . 76

8.8 Corrosion protection . 77

8.8.1 Metal-to-metal contact . 77

8.8.2 Above-ground protection of pipework . 77

8.8.3 Protection of buried pipework . 79

8.8.4 Corrosion at pipe supports . 82

8.9 Handling and installation of pipework . 82

8.9.1 PE pipework . 82

8.9.2 Steel pipework . 82

8.9.3 Copper pipework . 83

8.9.4 Pipe trench filling . 83

8.10 Bending of pipes . 84

8.10.1 Bending of steel pipes . 84

8.10.2 PE pipe bending . 84

8.10.3 Copper pipe bending . 85

8.11 Welding of supports and anchor points to carbon steel pipework . 85

8.12 Installation of pressure regulating systems . 86

8.12.1 Protection of the installation space . 86

8.12.2 Construction requirements . 87

9 Documentation, inspection and testing . 87

9.1 General . 87

9.2 Documentation . 88

9.2.1 General . 88

9.2.2 Technical file . 88

9.3 Inspection . 89

9.3.1 Joint inspection . 89

9.3.2 Corrosion protection . 93

9.3.3 Recording of test results . 93

9.4 Testing . 94

9.4.1 General . 94

9.4.2 Instrumentation . 94

9.4.3 Test Media . 95

9.4.4 Strength testing . 95

9.4.5 Tightness testing . 96

9.4.6 Procedure for strength and tightness testing. 96

9.4.7 Safety during tests . 96

9.4.8 Hot tapping . 97

9.4.9 Pressure regulating systems and ancillaries . 97

9.4.10 Recording of test results . 97

Annex A (informative) Examples of methods for testing . 98

A.1 General . 98

A.2 Strength test on metallic pipework . 98

A.2.1 Duration . 98

A.2.2 Conditions . 98

A.2.3 Pneumatic testing . 99

A.2.4 Hydrostatic testing . 99

A.2.5 Pressure assessment . 99

A.3 Tightness test on metallic pipework . 100

A.3.1 General . 100

A.3.2 Pipework which can be inspected visually . 100

A.3.3 Pipework which cannot be inspected fully by visual means. 101

A.4 Strength and tightness test on PE pipework . 102

Annex B (informative) Flammable gases mixing systems . 104

B.1 Reverse Flow . 104

B.2 Control of mixture composition . 104

B.3 Matching pressures of components for mixing . 106

Annex C (informative) Examples of supports . 107

Annex D (normative) Materials . 115

D.1 General . 115

D.2 Materials with a demonstrated safe history of application in this type of equipment

................................................................................................................................................................ 118

Annex E (informative) Significant technical changes between this European standard and

the previous version EN 15001-1:2009 . 120

Annex ZA (informative) Relationship between this European Standard and the essential

requirements of EU Directive 2014/68/EU aimed to be covered . 125

Bibliography . 127

European foreword

This document (EN 15001-1:2023) has been prepared by Technical Committee CEN/TC 234 “Gas

Infrastructure”, the secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by August 2023, and conflicting national standards shall be

withdrawn at the latest by August 2023.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15001-1:2009.

A list of the significant changes compared to EN 15001-1:2009 can be found in informative Annex E,

Table E.1.

This document includes requirements concerning current design practice and reflects the state of the art

at the time of publication. It provides clear solutions for users of the document. Other design solutions

and construction materials, as well as new developments, may be used if equal or greater safety than that

required by this document can be demonstrated or established.

The scope of this revised document is extended with biomethane and vaporized LNG gases. This

document is not designed for various mixtures of natural gas and hydrogen which may be allowed in the

different member states.

With respect to hydrogen there are proposals to inject hydrogen (H2) from renewable sources into the

natural gas network. Investigations have been conducted to evaluate the impact. According to

EN 16726:2015+A1:2018 at present it is not possible to specify a limiting hydrogen value which would

generally be valid for all parts of the European gas infrastructure.

There is a complete suite of functional standards prepared by CEN/TC 234 “Gas infrastructure” to cover

all parts of the gas supply system from the input of gas to the transmission system up to the inlet

connection of the gas appliances, whether for residential, commercial or industrial purposes.

In preparing this document, a basic understanding of gas supply by the user has been assumed.

Gas supply systems are complex and the importance on safety of their construction and use has led to the

development of very detailed codes of practice and operating manuals in the member countries. These

detailed statements embrace recognized standards of gas engineering and the specific requirements

imposed by the legal structures of the member countries.

This document has been prepared under a Standardization Request given to CEN by the European

Commission and the European Free Trade Association, and supports essential requirements of EU

Directive(s) / Regulation(s).

For relationship with EU Directive(s) / Regulation(s), see informative Annex ZA, which is an integral part

of this document.

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

1 Scope

This document specifies detailed functional requirements for the design, selection of materials,

construction, inspection and testing of:

— industrial gas installation pipework and assemblies with an operating pressure greater than 0,5 bar;

and

— non-industrial gas installation pipework (residential and commercial) with an operating pressure

greater than 5 bar in buildings;

starting from the outlet of the network operator’s point of delivery up to the inlet connection to the gas

appliance; normally the inlet isolation valve. This document also covers the pipework to the inlet

connection of a gas appliance that is not included within the scope of the appliance standard.

Apart from the exceptions stated below, this document applies to gas installation pipework operating at

ambient temperatures between −20 °C and 40 °C and operating pressures up to and including 60 bar. For

operating conditions outside these limitations, reference is additionally made to EN 13480 (all parts) for

metallic pipework.

For industrial gas installation pipework up to and including 0,5 bar and for non-industrial (residential

and commercial) gas installation pipework up to and including 5 bar in buildings, EN 1775 applies.

For gas installation pipework that do not fall within the scope of EN 1775 or other European Standards,

this document applies.

In this document, the term “gas“ refers to combustible gases, which are gaseous at 15 °C and 1 013 mbar

absolute atmospheric pressure (normal conditions). These gases are commonly referred to as

manufactured gas, natural gas or Liquefied Petroleum Gas (LPG). They are also referred to as first, second

or third family gases as classified in EN 437:2021, Table 1. The given values are considered as normal

conditions for all volumes given in this document.

This document is applicable to gas installation pipework for the carriage of:

— processed, non-toxic and non-corrosive natural gas according to EN 437:2021 and

EN 16726:2015+A1:2018 “Gas infrastructure — Quality of gas — Group H”;

— biomethane, complying with EN 16723-1:2016;

— vaporized LNG.

NOTE The specification of vaporized LNG is equal to that of natural gas as classified in EN 437:2021.

This document does not cover pipework for hydrogen rich gases that fall outside the definitions within

EN 437:2021.

LPG storage vessels (including all ancillaries fitted directly to storage vessels) are excluded. Also excluded

are LPG installations and sections of LPG installations operating at vapour pressure or in the liquid state.

In this document, all pressures are gauge pressures unless otherwise stated.

This document has been harmonized to address the essential safety requirements of the Pressure

Equipment Directive (PED, 2014/68/EU [formerly 97/23/EC]) relevant for the joining of gas installation

pipework (assemblies) falling within the scope of the PED. These are listed in Annex ZA. “However, this

Directive should not apply to the assembly of pressure equipment on the site and under the responsibility

of a user who is not the manufacturer, as in the case of industrial installations.” (PED, Preamble, 7th

recital, last paragraph).

Although in this respect, the document takes into account the essential safety requirements of the PED,

no inference can be drawn from this as to whether or not the installation pipework or parts of the

installation pipework falls within the scope of the PED. Reference should therefore be made to the PED

and relevant national legislation.

This document specifies common basic principles for gas supply systems. Users of this document are

expected to be aware that more detailed national standards and/or code of practice may exist in the CEN

member countries.

This document is intended to be applied in association with these national standards and/or codes of

practice setting out the above-mentioned basic principles.

In the event of conflicts in terms of more restrictive requirements in national legislation/regulation with

the requirements of this document, the national legislation/regulation takes precedence as illustrated in

CEN/TR 13737-1 and CEN/TR 13737-2.

This provision does not apply to requirements that are harmonized to directive 2014/68/EU (see

Annex ZA).

CEN/TR 13737-1 and CEN/TR 13737-2 give:

— clarification of all legislations/regulations applicable in a country;

— if appropriate, more restrictive national requirements thereof;

— a national contact point for the latest information.

Functional requirements for commissioning, operation and maintenance of industrial gas installation

pipework with an operating pressure greater than 0,5 bar and of gas installation pipework greater than

5 bar in buildings and areas intended for non-industrial installation pipework are described in EN 15001-

2:2023.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 331:2015, Manually operated ball valves and closed bottom taper plug valves for gas installations for

buildings

EN 334:2005+A1:2009, Gas pressure regulators for inlet pressure up to 10 MPa (100 bar)

EN 751-1:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases

and hot water - Part 1: Anaerobic jointing compounds

EN 751-2:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases

and hot water - Part 2: Non-hardening jointing compounds

EN 751-3:1996, Sealing materials for metallic threaded joints in contact with 1st, 2nd and 3rd family gases

and hot water — Part 3: Unsintered PTFE tapes

EN 764-5:2014, Pressure equipment - Part 5: Inspection documentation of metallic materials and

compliance with the material specification

As impacted by EN 751-3:1996/AC:1997.

EN 1057:2006+A1:2010, Copper and copper alloys - Seamless, round copper tubes for water and gas in

sanitary and heating applications

EN 1092-1:2018, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 1: Steel flanges

EN 1092-2:1997, Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN

designated - Part 2: Cast iron flanges

EN 1092-3:2003, Flanges and their joints — Circular flanges for pipes, valves, fittings and accessories, PN

designated — Part 3: Copper alloy flanges

EN 1254-1:2021, Copper and copper alloys - Plumbing fittings - Part 1: Capillary fittings for soldering or

brazing to copper tubes

EN 1254-2:2021, Copper and copper alloys - Plumbing fittings - Part 2: Compression fittings for use with

copper tubes

EN 1254-3:2021, Copper a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...