EN 13951:2003+A1:2008

(Main)Liquid pumps - Safety requirements - Agrifoodstuffs equipment - Design rules to ensure hygiene in use

Liquid pumps - Safety requirements - Agrifoodstuffs equipment - Design rules to ensure hygiene in use

This European Standard is concerned with the special technical safety requirements for liquid pumps and pump units operating with agrifoodstuffs. It augments EN 809 and contains a list of the additional significant hazards which can arise from the pump and pump units used with substances intended for human and domestic animal consumption.

In drafting this standard it was assumed that the pumps falling within its scope will conform to all relevant requirement of EN 809.

It also establishes requirements and/or measures which lead to a reduction of the risks.

This standard is not intended to be used for pumps and pump units at any stage in the public water supply, nor for pumps handling pharmaceutical products, nor for any other application for which more appropriate standards can exist.

Conformity to this standard aims to ensure that the pump, if used in accordance with the instruction handbook, will remain safe and, provided it is adequately cleaned, will not cause contamination of the pumped product. Although it is the responsibility of the manufacturer to ensure that the pump can be cleaned, due to the influence of the product, the process and the cleaning regime adopted, the hygiene of the pump should ultimately be the responsibility of the end-user.

The pumps and pump units which fall within the scope of this standard are described as:

- rotodynamic pumps;

- rotary positive displacement pumps;

- reciprocating positive displacement pumps.

Pumps handling agrifoodstuffs which do not fall within this scope should comply with EN 1672-2.

Flüssigkeitspumpen - Sicherheitsanforderungen - Nahrungsmittelausrüstungen - Konstruktionsregeln zur Sicherstellung der Hygiene bei der Verwendung

Pompes pour liquides - Prescriptions de sécurité - Matériel agroalimentaire - Règles de conception pour assurer l'hygiène à l'utilisation

La présente Norme européenne traite des prescriptions techniques spéciales de sécurité applicables aux pompes et

groupes motopompes pour liquides utilisés pour des produits agroalimentaires. Elle complète l’EN 809 et comprend

une liste des phénomènes dangereux significatifs supplémentaires qui peuvent être générés par une pompe ou un

groupe motopompe utilisés avec des substances destinées à la consommation humaine ou des animaux

domestiques.

En rédigeant la présente norme il a été supposé que les pompes relevant de son domaine d’application sont

conformes à toutes les prescriptions appropriées de l’EN 809.

La présente norme établit aussi des prescriptions et/ou des mesures qui conduisent à une réduction des risques.

La présente norme n’est pas destinée à être utilisée pour des pompes et groupes motopompes pour

l’approvisionnement public en eau, à quelque stade que ce soit, ni pour les pompes véhiculant des produits

pharmaceutiques, ni pour toute autre application pour laquelle des normes plus appropriées peuvent exister.

La conformité à cette norme a pour objectif d’assurer que la pompe, si elle est utilisée en accord avec la notice

d’instructions reste sans danger et à condition qu’elle soit nettoyée de façon adéquate, ne provoque pas de

contamination du produit pompé. Bien qu’il soit de la responsabilité du fabricant de s’assurer que la pompe puisse

être nettoyée, en raison de l’influence du produit, du procédé et du type de nettoyage adopté, il convient que l’hygiène

de la pompe reste, en fin de compte de la responsabilité de l’utilisateur final.

Les pompes et groupes motopompes qui relèvent du domaine d’application de la présente norme sont :

- les pompes rotodynamiques ;

- les pompes volumétriques rotatives ;

- les pompes volumétriques alternatives.

Il convient que les pompes véhiculant des produits agroalimentaires qui ne relèvent pas de ce domaine d’application

soient conformes à l’EN 1672-2.

Črpalke za tekočine - Varnostne zahteve - Kmetijsko-živilska oprema - Pravila načrtovanja za zagotovljanje higiene pri uporabi

General Information

- Status

- Withdrawn

- Publication Date

- 30-Sep-2008

- Withdrawal Date

- 10-Apr-2012

- Technical Committee

- CEN/TC 197 - Pumps

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Apr-2012

- Completion Date

- 11-Apr-2012

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - MachineryOJ Ref: C 74, C 74, C 74, C 74, C 74, C 74, C 74, C 74, C, OJ Date: 28-Mar-2009

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 05-Feb-2011

Get Certified

Connect with accredited certification bodies for this standard

BSI Group

BSI (British Standards Institution) is the business standards company that helps organizations make excellence a habit.

Bureau Veritas

Bureau Veritas is a world leader in laboratory testing, inspection and certification services.

DNV

DNV is an independent assurance and risk management provider.

Sponsored listings

Frequently Asked Questions

EN 13951:2003+A1:2008 is a standard published by the European Committee for Standardization (CEN). Its full title is "Liquid pumps - Safety requirements - Agrifoodstuffs equipment - Design rules to ensure hygiene in use". This standard covers: This European Standard is concerned with the special technical safety requirements for liquid pumps and pump units operating with agrifoodstuffs. It augments EN 809 and contains a list of the additional significant hazards which can arise from the pump and pump units used with substances intended for human and domestic animal consumption. In drafting this standard it was assumed that the pumps falling within its scope will conform to all relevant requirement of EN 809. It also establishes requirements and/or measures which lead to a reduction of the risks. This standard is not intended to be used for pumps and pump units at any stage in the public water supply, nor for pumps handling pharmaceutical products, nor for any other application for which more appropriate standards can exist. Conformity to this standard aims to ensure that the pump, if used in accordance with the instruction handbook, will remain safe and, provided it is adequately cleaned, will not cause contamination of the pumped product. Although it is the responsibility of the manufacturer to ensure that the pump can be cleaned, due to the influence of the product, the process and the cleaning regime adopted, the hygiene of the pump should ultimately be the responsibility of the end-user. The pumps and pump units which fall within the scope of this standard are described as: - rotodynamic pumps; - rotary positive displacement pumps; - reciprocating positive displacement pumps. Pumps handling agrifoodstuffs which do not fall within this scope should comply with EN 1672-2.

This European Standard is concerned with the special technical safety requirements for liquid pumps and pump units operating with agrifoodstuffs. It augments EN 809 and contains a list of the additional significant hazards which can arise from the pump and pump units used with substances intended for human and domestic animal consumption. In drafting this standard it was assumed that the pumps falling within its scope will conform to all relevant requirement of EN 809. It also establishes requirements and/or measures which lead to a reduction of the risks. This standard is not intended to be used for pumps and pump units at any stage in the public water supply, nor for pumps handling pharmaceutical products, nor for any other application for which more appropriate standards can exist. Conformity to this standard aims to ensure that the pump, if used in accordance with the instruction handbook, will remain safe and, provided it is adequately cleaned, will not cause contamination of the pumped product. Although it is the responsibility of the manufacturer to ensure that the pump can be cleaned, due to the influence of the product, the process and the cleaning regime adopted, the hygiene of the pump should ultimately be the responsibility of the end-user. The pumps and pump units which fall within the scope of this standard are described as: - rotodynamic pumps; - rotary positive displacement pumps; - reciprocating positive displacement pumps. Pumps handling agrifoodstuffs which do not fall within this scope should comply with EN 1672-2.

EN 13951:2003+A1:2008 is classified under the following ICS (International Classification for Standards) categories: 23.080 - Pumps; 67.260 - Plants and equipment for the food industry. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13951:2003+A1:2008 has the following relationships with other standards: It is inter standard links to EN 13951:2003, EN 13951:2012. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13951:2003+A1:2008 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13951:2003+A1:2008 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Flüssigkeitspumpen - Sicherheitsanforderungen - Nahrungsmittelausrüstungen - Konstruktionsregeln zur Sicherstellung der Hygiene bei der VerwendungPompes pour liquides - Prescriptions de sécurité - Matériel agroalimentaire - Règles de conception pour assurer l'hygiène à l'utilisationLiquid pumps - Safety requirements - Agrifoodstuffs equipment - Design rules to ensure hygiene in use67.260Tovarne in oprema za živilsko industrijoPlants and equipment for the food industry23.080ýUSDONHPumpsICS:Ta slovenski standard je istoveten z:EN 13951:2003+A1:2008SIST EN 13951:2004+A1:2008en01-december-2008SIST EN 13951:2004+A1:2008SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13951:2003+A1

October 2008 ICS 23.080; 67.260 Supersedes EN 13951:2003 English Version

Liquid pumps - Safety requirements - Agrifoodstuffs equipment -Design rules to ensure hygiene in use

Pompes pour liquides - Prescriptions de sécurité -Matériel agroalimentaire - Règles de conception pour assurer l'hygiène à l'utilisation

Flüssigkeitspumpen - Sicherheitsanforderungen - Nahrungsmittelausrüstungen - Konstruktionsregeln zur Sicherstellung der Hygiene bei der Verwendung This European Standard was approved by CEN on 28 November 2002 and includes Amendment 1 approved by CEN on 14 August 2008.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels © 2008 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13951:2003+A1:2008: ESIST EN 13951:2004+A1:2008

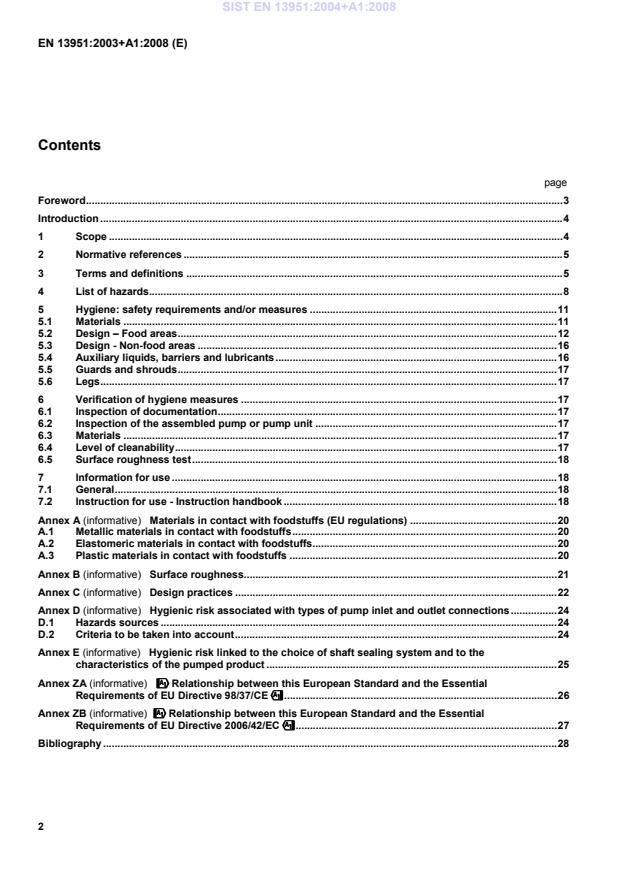

Materials in contact with foodstuffs (EU regulations).20 A.1 Metallic materials in contact with foodstuffs.20 A.2 Elastomeric materials in contact with foodstuffs.20 A.3 Plastic materials in contact with foodstuffs.20 Annex B (informative)

Surface roughness.21 Annex C (informative)

Design practices.22 Annex D (informative)

Hygienic risk associated with types of pump inlet and outlet connections.24 D.1 Hazards sources.24 D.2 Criteria to be taken into account.24 Annex E (informative)

Hygienic risk linked to the choice of shaft sealing system and to the characteristics of the pumped product.25 Annex ZA (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/CE"""".26 Annex ZB (informative)

!!!!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC"""".27 Bibliography.28

NOTE These areas are not to be confused with any others amongst those defined in other standards (e.g. electro-technical standards). (Note in accordance with EN 1672-2:1997) 3.4.1 food area area composed of surfaces in contact with food. The food area also includes the surfaces with which the product may come into contact under intended conditions of use, after which it returns into the product (Definition in accordance with EN 1672-2:1997) 3.4.2 non-food area any area other than those specified above (Definition in accordance with EN 1672-2:1997) SIST EN 13951:2004+A1:2008

Figure 1 — The iterative process to achieve safety

Table 1 — List of Hazards related to Hygiene which are addressed in this standard

EN 13951

Reference to sub-clause Significant hazards to Hygiene Measures to reduce the hazard Means of verification Hazards arising from the ingress of foreign matter

Clause Clause

- wear debris.……. 5.1.1, 5.1.2.1 6.3

- sealing of openings and joints.……. 5.2.6, 5.2.11, 5.2.12, 5.3.1 6.2

- sealing around shafts.……. 5.2.9 6.2

- spillage of product.……. 5.3.1 6.2

- vermin.…. 5.3.1, 5.6 6.2 Hazards arising from microbiological causes

- retention of product.

- general. 5.2.1, 5.2.2, 5.3.1 6.4

- cleaning. 5.2.2, 5.2.3 6.4

- draining.…. 5.2.2, 5.2.3.1, 5.2.11 6.2

- surface finish/texture.…. 5.2.5 6.5

- obstructions/protrusions.…. 5.2.2, 5.2.7 6.2

- bearings.……. 5.2.8, 5.3.2 6.1, 6.2

- shaft seals.……. 5.2.9 6.2

- fasteners.………. 5.2.10, 5.3.3 6.2

- sensors.……. 5.2.12 6.1, 6.2

- lubricants.……. 5.4 6.1, 6.2 Hazards arising from chemical causes

- material compatibility 5.1 6.3

- general. 5.1.1, 5.1.2.1,5.2.9 6.3

- metals. 5.1.2.2 6.1, 6.3

- non-metals. 5.1.2.3 6.1, 6.3

- non-food areas. 5.1.3 6.3

- soldering. 5.2.6 6.2

- cleaning fluids. 5.2.3.1 6.2, 6.4

- sensors. 5.2.12 6.2

- auxiliary liquids. 5.2.8, 5.4 6.1,6.3

- barrier liquids. 5.4 6.1, 6.2 Hazards arising from mechanical causes

- material finishes. 5.1 6.2,6.5

- joints.…. 5.2.6 6.1,6.2

- fasteners.……. 5.2.10 6.1,6.2

- mis-assembly. 5.3.3 6.1,6.2

5 Hygiene: safety requirements and/or measures The operating conditions and features required of every pump unit falling within the scope of this standard will be either defined by the user in a specification or by the manufacturer description which includes limits of operation. The manufacturer shall assess any foreseeable hazards of hygiene arising from operating conditions where specified of the pump or pump unit. The pump or pump unit shall be designed in such a way as to reduce hazards of this standard to an acceptable level. Specifications shall classify the pumps and units, including auxiliary equipment, according to the levels of cleanability required. It is the purchaser's responsibility to select the levels of cleanability appropriate to the application, taking into account the risks arising from the pumped product, the placement of the pump in the process and the cleaning regime anticipated. Where the means of reducing the risk is by a safe system of working the machinery, the manufacturer shall include in the information for use details of the systems of the element of training required by the operating personnel. 5.1 Materials 5.1.1 Common requirements Materials shall be suitable for intended use. Surfaces of materials and coatings shall be durable, cleanable, without being damaged, and be without breaks, resistant to chipping, flaking, erosion, corrosion and abrasion, and prevent penetration of unwanted matter during intended use. The pump components intended to be dismantled for cleaning shall not be painted. 5.1.2 Food areas 5.1.2.1 Additional requirements In addition to the common requirements set out in 5.1.1, materials used in the food contact area shall be compatible with the pumped product under all foreseeable conditions of use. The compatibility shall not be compromised by the cleaning solutions nor by any disinfection and sterilization treatments specified by the customer. The materials shall be non-absorbant, except where this is technically or functionally unavoidable in which circumstance it shall not reduce the level of safety intended. Operation at intended pressures and product velocities shall not be detrimental to the performance of the materials nor shall temperature give rise to risks from thermal expansion or contraction nor any other thermal degradation. The materials shall be non-toxic and not deleterious to health, and incapable of being dissolved or broken down into elements or compounds which are. Where coatings (metallic or non-metallic) and/or adhesives are used to meet these requirements, the bond shall be and remain continuous. The pumped product shall remain non toxic. Where parts within the pump are subject to wear (for example, mechanical seal rings or close-fitting, rotating rubber components), any wear debris shall be of a size and quantity which is not deleterious to health or to the quality of the pumped product. If abrasive (for example, crystalline or fibrous) foodstuffs will be pumped, the possibility of abrasive wear of the surfaces should be considered and the choice of material subject to agreement between customer and supplier. The manufacturer shall define the safe working value of NPSHR/NPIPR to avoid damage to the material surfaces from cavitation erosion. SIST EN 13951:2004+A1:2008

≤

0,08 % Cr ≥ 13 % Ni ≥ 8% Other stainless steels such as duplex stainless steels are often used in pumps. A typical specification for duplex stainless steel is: Cr 22 % Ni 5 %. NOTE 2 Consideration should be given to designating stainless steels in accordance with EN10088 –1. 5.1.2.3 Plastics and elastomers All plastic materials used shall be produced only from monomers according to EU regulation (see annex A) and shall conform to the general requirements of this standard. All elastomeric materials used shall conform to the general requirements of this standard and take into account the informat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...