EN 15091:2006

(Main)Sanitary tapware - Electronic opening and closing sanitary tapware

Sanitary tapware - Electronic opening and closing sanitary tapware

The purpose of the document is to define requirements for marking, identification, leaktightness, electrical and operational safety and mechanical resistance for sanitary tapware with opening and closing controlled electronically.

Sanitärarmaturen - Sanitäramaturen mit elektronischer Öffnungs- und Schließfunktion

Das Dokument legt die Anforderungen an die Kennzeichnung, Identifizierung, Dichtheit, elektrische Sicherheit, Betriebssicherheit und mechanische Festigkeit von Sanitärarmaturen mit elektronisch geregelter Öffnungs- und Schließfunktion fest.

Die Einsatzbedingungen für die Wasserversorgungssysteme sind in Tabelle 2 festgelegt.

Tabelle 2 — Einsatzbedingungen

Wasser¬versorgungssystem Anwendungsgrenzen Empfohlene

Grenzwerte

für den Betrieb

Monostabile

Magnetventile Bistabile

Magnetventile

Typ 1

siehe Bild 1 Fließdruck min. 0,05 MPa

(0,5 bar) 0,05 MPa

(0,5 bar) 0,1 MPa bis 0,5 MPa

(1 bar bis 5 bar)

Ruhedruck max. 1 MPa

(10 bar) 0,8 MPa

(8 bar)

Typ 2a

siehe Bild 2 Fließdruck min. 0,01 MPa

(0,1 bar) 0,01 MPa

(0,1 bar) 0,01 MPa bis 0,2 MPa

(0,1 bar bis 2 bar)

Ruhedruck max. 0,8 MPa

(8 bar) 0,6 MPa

(6 bar)

Temperatur 75 °C 75 °C 65 °C

a Für Typ 2 muss der Hersteller den Mindest-Betriebsdruck angeben, bei dem die Öffnungs- und Schließfunktion und der fest¬gelegte Durchfluss erreicht werden kann.

Bei Auslaufarmaturen für Wasserversorgungssysteme vom Typ 2 gibt es üblicherweise keine Geräuschklassifizierung und keine Spezifikation, die den Geräuschpegel dieser Systeme regelt. Wenn durch Eingangsdrücke übermäßige Geräusche erzeugt werden, wird empfohlen, Strahlregler im System zu installieren. Falls möglich, werden auch Auslaufarmaturen eingesetzt, die einer Geräuschklassifizierung entsprechen.

Robinetterie sanitaire - Robinet sanitaire à ouverture et fermeture électroniques

L’objectif du présent document est de définir les exigences de marquage, d’identification, d’étanchéité, de sécurité électrique et de fonctionnement et de résistance mécanique pour la robinetterie sanitaire à ouverture et fermeture électroniques.

Les conditions d’utilisation relatives au type de système d’alimentation sont spécifiées dans le Tableau 2 :

Tableau 2 Conditions d’utilisation

Système d’alimentation en eau Limites d’utilisation Limites recommandées de fonctionnement

Robinetterie à électrovannes monostables Robinetterie à électrovannes bistables

Type 1 (voir Figure 1) Pression dynamique minimale 0,05 MPa (0,5 bar) 0,05 MPa (0,5 bar) (0,1 à 0,5) MPa [(1 à 5) bar]

Pression statique maximale 1 MPa (10 bar) 0,8 MPa (8 bar)

Type 2a (voir Figure 2) Pression dynamique minimale 0,01 MPa (0,1 bar) 0,01 MPa (0,1 bar) (0,01 à 0,2) MPa [(0,1 à 2) bar]

Pression statique maximale 0,8 MPa (8 bar) 0,6 MPa (6 bar)

Température de l’eau 75 °C 75 °C 65 °C

a Pour le type 2, il faut que le fabricant déclare la pression minimale de fonctionnement à laquelle l’ouverture, la fermeture et le débit spécifié peuvent être obtenus.

Il n’y a généralement pas de classification acoustique relative à la robinetterie utilisée dans les systèmes d’alimentation de type 2 ni de spécifications déterminant le niveau de bruit émis par ces installations d’alimentation en eau. Si les pressions d’alimentation sont telles qu’un bruit excessif est produit, il est recommandé d’équiper le système de régulateurs de pression ou de débit ou d’utiliser, dans la mesure du possible, une robinetterie conforme à la classification acoustique appropriée.

Tableau 3 Caractéristiques de performance à préciser en cas d’utilisation en dehors du domaine de fonctionnement recommandé

Objet Système d’alimentation de type 1 Système d’alimentation de type 2

Sanitarne armature - Elektronsko odpiranje in zapiranje sanitarnih armatur

General Information

- Status

- Withdrawn

- Publication Date

- 12-Dec-2006

- Withdrawal Date

- 10-Dec-2013

- Technical Committee

- CEN/TC 164 - Water supply

- Drafting Committee

- CEN/TC 164/WG 8 - Sanitary tapware

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 11-Dec-2013

- Completion Date

- 11-Dec-2013

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13959:2004 - Anti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15091:2006 is a standard published by the European Committee for Standardization (CEN). Its full title is "Sanitary tapware - Electronic opening and closing sanitary tapware". This standard covers: The purpose of the document is to define requirements for marking, identification, leaktightness, electrical and operational safety and mechanical resistance for sanitary tapware with opening and closing controlled electronically.

The purpose of the document is to define requirements for marking, identification, leaktightness, electrical and operational safety and mechanical resistance for sanitary tapware with opening and closing controlled electronically.

EN 15091:2006 is classified under the following ICS (International Classification for Standards) categories: 91.140.70 - Sanitary installations. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15091:2006 has the following relationships with other standards: It is inter standard links to EN 15091:2013, EN IEC 61000-6-1:2019, EN 60529:1991, EN IEC 61000-6-3:2021, EN IEC 60730-2-8:2025, EN IEC 60335-1:2023, EN ISO 3822-1:1999, EN 35:2014, EN 1717:2025, EN ISO 5167-1:2022, EN 13959:2004, EN ISO 228-1:2003, EN 246:2021, EN 13407:2006, EN 248:2002. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15091:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Sanitary tapware - Electronic opening and closing sanitary tapwareSanitarne armature - Elektronsko odpiranje in zapiranje sanitarnih armaturRobinetterie sanitaire - Robinet sanitaire a ouverture et fermeture électroniquesSanitärarmaturen - Sanitäramaturen mit elektronischer Öffnungs- und SchließfunktionTa slovenski standard je istoveten z:EN 15091:2006SIST EN 15091:2007en,fr,de91.140.70Sanitarne napraveSanitary installationsICS:SLOVENSKI

STANDARDSIST EN 15091:200701-oktober-2007

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 15091December 2006ICS 91.140.70 English VersionSanitary tapware - Electronic opening and closing sanitarytapwareRobinetterie sanitaire - Robinet sanitaire à ouverture etfermeture électroniqueSanitärarmaturen - Sanitäramaturen mit elektronischerÖffnungs- und SchließfunktionThis European Standard was approved by CEN on 4 November 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 15091:2006: E

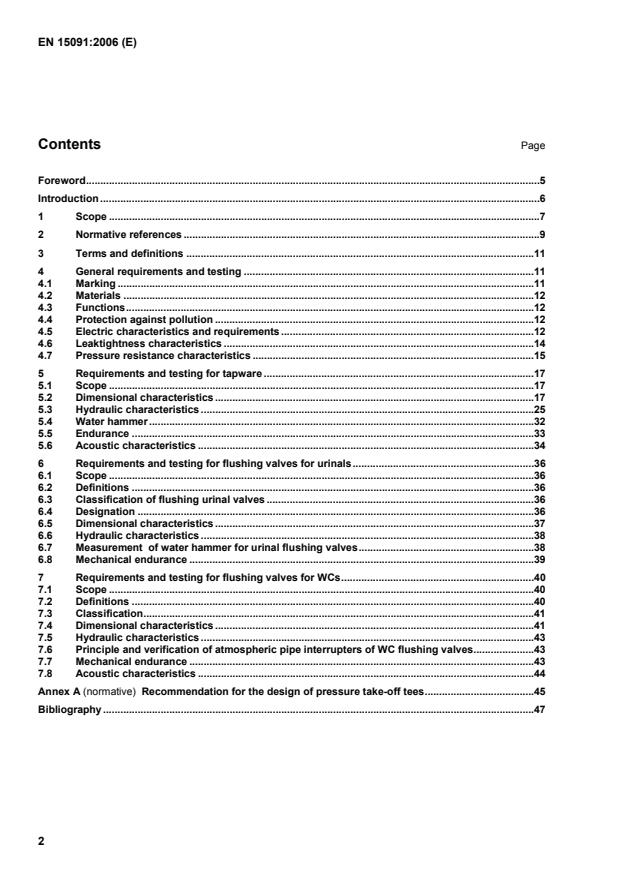

of water hammer for urinal flushing valves.38 6.8 Mechanical endurance.39 7 Requirements and testing for flushing valves for WCs.40 7.1 Scope.40 7.2 Definitions.40 7.3 Classification.41 7.4 Dimensional characteristics.41 7.5 Hydraulic characteristics.43 7.6 Principle and verification of atmospheric pipe interrupters of WC flushing valves.43 7.7 Mechanical endurance.43 7.8 Acoustic characteristics.44 Annex A (normative)

Recommendation for the design of pressure take-off tees.45 Bibliography.47

with captive nuts.24 Figure 12 — Mixer with opposed inlets.25 Figure 13 — Supply circuits.26 Figure 14 — Test circuits for tapware intended for Type 1 water supply systems.28 Figure 15 — Mounting of mixing valves.29 Figure 16 — Flow rate test apparatus for taps intended for type 2 supply systems.30 Figure 17 — Test rig for water hammer test.32 Figure 18 — Top-entry urinal flushing valve.37 Figure 19 — Side-entry urinal flushing valve.37 Figure 20 — Side-entry WC flushing valves.43 Figure 21 — Top-entry WC flushing valves.43 Figure A.1 — Examples of pressure take-off tees.45

MARKING-IDENTIFICATION ELECTRICAL SAFETY OPERATIONAL SAFETY LEAKTIGHTNESS MECHANICAL RESISTANCE HYDRAULIC CHARACTERISTICS WATER HAMMER WATER HAMMER FOLLOWING PRODUCT STANDARD Clause 4.General requirements and testing X x x x x

Clause 5.Requirements and testing for tapware

x x

Clause 6.Requirements and testing for flushing valves for urinals

x x

Clause 7. Requirements and testing for flushing valves for WCs

x

x

Tapware with monostable solenoid valves Tapware with bistable solenoid valves Recommended limits of operation Minimum dynamic pressure 0,05 MPa (0,5 bar)0,05 MPa (0,5 bar) (0,1 to 0,5) MPa [(1 to 5) bar] Type 1 (see Figure 1) Maximum static pressure 1 MPa (10 bar) 0,8 MPa (8 bar)

Minimum dynamic pressure 0,01 MPa (0,1 bar)0,01 MPa (0,1 bar) (0,01 to 0,2) MPa [(0,1 to 2) bar] Type 2a (see Figure 2) Maximum static pressure 0,8 MPa (8 bar) 0,6 MPa (6 bar)

Temperature of the water ≤ 75 °C ≤ 75 °C ≤ 65 °C

a For Type 2, The manufacturer is to declare the minimum operating pressure at which opening, closing and the specified flow rate can be obtained. There is usually no acoustic classification for tapware used in supply systems of Type 2 and no specifications governing the level of noise emissions from these water installations. If supply pressures are such that excessive noise is generated it is recommended that pressure or flow regulators are fitted in the system. Or where practicable, tapware conforming to the appropriate acoustic classification are used. Table 3 — Performance characteristics to be noted if used outside the recommended operating range Issue Supply system type 1 Supply system type 2 Flow performance Taps for Type 2 systems may result in excessive flow velocity Taps for Type 1 system may not provide an acceptable flow rate Noise National regulations shall be observed, the criteria for classification in acoustic groups according to these national (special) regulations being different and more detailed than those given in this standard Taps for type 1 and type 2 systems may result in excessive noise when used above the recommended pressure.

Key 1 Cold water 3 Mains supply pipe (Supply pressures from (0,05 to 1,0) MPa [(0,5 - 10) bar) 2 Hot water 4 Water heater Figure 1 — Type 1 - Supply system with a pressure range of (0,05 to 1,0) MPa [(0,5 to 10) bar]

Key 1 Cold water storage cistern (cover omitted for clarity) 2 Warning pipe 3 Vent pipe 4 Hot water cylinder 5 Alternative cistern fed cold supply to sanitary appliances 6 To boiler 7 Mains supply pipe (Supply pressures up to 10 bar) Figure 2 — Type 2 - Supply system with a pressure range of (0,01 to 1,0) MPa [(0,1 to 10) bar]. A vented domestic hot water and cold water supply system incorporating gravity hot water, mains cold water and alternative gravity cold water supply to sanitary appliances. 2 Normative references The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 31, Pedestal wash basins - Connecting dimensions EN 32, Wall-hung wash basins - Connecting dimensions

Acoustics - Laboratory tests on noise emission from appliances and equipment used in water supply installations - Part 3: Mounting and operating conditions for in-line valves and appliances (ISO 3822-3: 1997)

EN ISO 3822-4:1997, Acoustics - Laboratory tests on noise emission from appliances and equipment used in water supply installations - Part 4: Mounting and operating conditions for special appliances (ISO 3822-4:1985)

device for initiating the process of opening and/or closing NOTE Such sensors can be touch or touchless (handsfree) operation. 3.4 valve electrically operated obturator for controlling the flow of water 3.5 monostable valve obturation system continuously fed electrically while operated 3.6 bistable valve obturation system electrically fed only for operating opening and closing 3.7 electronic circuitry whole of electronic components that operate both the system of detection and the valve 3.8 integrated tap tapware with all or part of the electronic components inside the body

4 General requirements and testing 4.1 Marking Tapware conforming to the requirements of this standard shall be permanently and legibly marked with: name or logo of the manufacturer; EC marking rules; acoustic and flow-rate classes (if relevant); volume class for urinals (e.g. class 6 or class 9).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...