EN 13959:2004

(Main)Anti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D

Anti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D

The purpose of this European Standard is to specify:

- field of application of Anti-pollution Check Valves;

- backflow prevention properties, dimensional and physio-chemical properties, and properties of general hydraulic, mechanical and acoustic design to which Anti-pollution Check Valves of nominal sizes DN 6 to DN 250 inclusive shall conform;

- Family E, type A, controllable Anti-pollution Check Valve (with test port);

- Family E, type B, non-controllable Anti-pollution Check Valve, including Cartridge Check Valve;

- Family E, type C, controllable Anti-pollution Double Check Valve (with test ports);

- Family E, type D, non-controllable Anti-pollution Double Check Valve, including Cartridge Double Check Valve;

- test procedures and requirements for verifying the backflow protection properties of stop valves, draw-off taps etc. which incorporate a check valve function. Stop valves, draw off taps etc, need also to comply with a recognised standard;

- marking;

- presentation at delivery.

This standard specifies the characteristics of Anti-pollution Check Valves of DN 6 up to and including DN 250 that are suitable for use in drinking water systems. For application feasibility see Table 1.

Table 1 - Nominal size vs Conditions of use

Nominalsize(DN) Max. Operatingtemperature Max. Operating pressure Installation

DN <= 50 65 °C + 90 °C, 1 hour 1 000 kPa (10 bar) Any position

DN > 50 65 °C 1 000 kPa (10 bar) Horizontal only

Anti-pollution Check Valves covered by this standard are of Pressure Class PN 10.

The field of application of EN 1717 is limited to 10 bar, flanges could be drilled in PN 16 pattern.

Anti-pollution Check Valves of PN 16 shall satisfy the requirements of standard EN 13959 and comply with tests which characterise the PN of the device.

Rückflussverhinderer - DN 6 bis DN 250 - Familie E, Typ A, B, C und D

Clapets de non-retour antipollution - DN 6 à DN 250 inclus - Famille E, Type A, B, C et D

Protipovratni ventili za preprečevanje onesnaževanja – DN 6 do DN 250, vključno z družino E, vrste A, B, C in D

General Information

- Status

- Published

- Publication Date

- 19-Oct-2004

- Withdrawal Date

- 29-Apr-2005

- Technical Committee

- CEN/TC 164 - Water supply

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 08-Jul-2020

- Completion Date

- 11-Feb-2026

Not Harmonized89/106/EEC - Construction products

Relations

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 3094:2017 - Aerospace series - Sealants - Test method - Determination of the application time - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13959:2004 is a CEN European standard that specifies requirements for anti-pollution check valves (family E) used in drinking water systems. It covers single and double check valves in nominal sizes DN 6 to DN 250 and defines four types: Type A (controllable single), Type B (non-controllable single, including cartridge), Type C (controllable double) and Type D (non-controllable double, including cartridge). Devices covered are primarily Pressure Class PN 10; where PN 16 devices are used, they must satisfy the tests that characterise the higher pressure class. EN 13959 sets out functional, dimensional, physio‑chemical, hydraulic, mechanical and acoustic requirements, plus test methods, marking and presentation at delivery.

Key topics and requirements

- Field of application: Devices suitable for potable water backflow prevention across DN 6–250; see Table 1 for operating conditions.

- Operating limits:

- DN ≤ 50: max operating temperature 65 °C (with a 1‑hour allowance at 90 °C), max pressure 1 000 kPa (10 bar), install in any position.

- DN > 50: max operating temperature 65 °C, max pressure 1 000 kPa (10 bar), horizontal installation only.

- Types & formats:

- Controllable devices (A, C) include test ports for verification.

- Non‑controllable devices (B, D) may be provided as housings or as cartridge units.

- Flanged valves can be Class a (with inspection hatch) or Class b (without).

- Testing & verification: Staged test procedures for hydraulic performance, pressure tightness (low and high reverse pressures), mechanical strength, endurance, acoustic performance and chemical compatibility (e.g., disinfection agents).

- Materials & physio‑chemical: Requirements for suitable materials and resistance (e.g., dezincification) are defined to ensure drinking water compatibility.

- Marking & documentation: Devices must be permanently marked (manufacturer, flow direction arrow, etc.) and supplied with technical documents and delivery presentation per the standard.

Applications and users

- Applications: Backflow prevention in potable water distribution, service connections, meters, valves, taps and combined products incorporating check valve functions.

- Who uses it: Valve manufacturers, water utilities, plumbing engineers, installers, testing laboratories and compliance officers specifying or verifying anti‑pollution check valves for drinking water systems.

Related standards

- EN 1717 - Protection against pollution of potable water (general backflow protection principles).

- EN 558‑1, EN 1092 series, EN 1267 and relevant EN ISO standards referenced for dimensions, flanges, flow testing and acoustics.

EN 13959:2004 is essential when selecting, testing or approving anti‑pollution check valves for potable water installations across Europe, ensuring consistent backflow protection, mechanical integrity and installation compatibility.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13959:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Anti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D". This standard covers: The purpose of this European Standard is to specify: - field of application of Anti-pollution Check Valves; - backflow prevention properties, dimensional and physio-chemical properties, and properties of general hydraulic, mechanical and acoustic design to which Anti-pollution Check Valves of nominal sizes DN 6 to DN 250 inclusive shall conform; - Family E, type A, controllable Anti-pollution Check Valve (with test port); - Family E, type B, non-controllable Anti-pollution Check Valve, including Cartridge Check Valve; - Family E, type C, controllable Anti-pollution Double Check Valve (with test ports); - Family E, type D, non-controllable Anti-pollution Double Check Valve, including Cartridge Double Check Valve; - test procedures and requirements for verifying the backflow protection properties of stop valves, draw-off taps etc. which incorporate a check valve function. Stop valves, draw off taps etc, need also to comply with a recognised standard; - marking; - presentation at delivery. This standard specifies the characteristics of Anti-pollution Check Valves of DN 6 up to and including DN 250 that are suitable for use in drinking water systems. For application feasibility see Table 1. Table 1 - Nominal size vs Conditions of use Nominalsize(DN) Max. Operatingtemperature Max. Operating pressure Installation DN <= 50 65 °C + 90 °C, 1 hour 1 000 kPa (10 bar) Any position DN > 50 65 °C 1 000 kPa (10 bar) Horizontal only Anti-pollution Check Valves covered by this standard are of Pressure Class PN 10. The field of application of EN 1717 is limited to 10 bar, flanges could be drilled in PN 16 pattern. Anti-pollution Check Valves of PN 16 shall satisfy the requirements of standard EN 13959 and comply with tests which characterise the PN of the device.

The purpose of this European Standard is to specify: - field of application of Anti-pollution Check Valves; - backflow prevention properties, dimensional and physio-chemical properties, and properties of general hydraulic, mechanical and acoustic design to which Anti-pollution Check Valves of nominal sizes DN 6 to DN 250 inclusive shall conform; - Family E, type A, controllable Anti-pollution Check Valve (with test port); - Family E, type B, non-controllable Anti-pollution Check Valve, including Cartridge Check Valve; - Family E, type C, controllable Anti-pollution Double Check Valve (with test ports); - Family E, type D, non-controllable Anti-pollution Double Check Valve, including Cartridge Double Check Valve; - test procedures and requirements for verifying the backflow protection properties of stop valves, draw-off taps etc. which incorporate a check valve function. Stop valves, draw off taps etc, need also to comply with a recognised standard; - marking; - presentation at delivery. This standard specifies the characteristics of Anti-pollution Check Valves of DN 6 up to and including DN 250 that are suitable for use in drinking water systems. For application feasibility see Table 1. Table 1 - Nominal size vs Conditions of use Nominalsize(DN) Max. Operatingtemperature Max. Operating pressure Installation DN <= 50 65 °C + 90 °C, 1 hour 1 000 kPa (10 bar) Any position DN > 50 65 °C 1 000 kPa (10 bar) Horizontal only Anti-pollution Check Valves covered by this standard are of Pressure Class PN 10. The field of application of EN 1717 is limited to 10 bar, flanges could be drilled in PN 16 pattern. Anti-pollution Check Valves of PN 16 shall satisfy the requirements of standard EN 13959 and comply with tests which characterise the PN of the device.

EN 13959:2004 is classified under the following ICS (International Classification for Standards) categories: 23.060.50 - Check valves. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13959:2004 has the following relationships with other standards: It is inter standard links to EN 1254-1:2021, EN 1092-2:2023, EN 1267:2012, EN 1092-1:2018, EN 1717:2025, EN ISO 3822-3:2018, EN 1254-3:2021+A1:2025, EN 3094:2017, EN 558:2022, EN 1092-3:2003, EN 1254-4:2021, EN ISO 6509-1:2014, EN ISO 5167-3:2022, EN ISO 3822-1:1999, EN 1254-2:2021. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13959:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/EXP. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13959:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Rückflussverhinderer - DN 6 bis DN 250 - Familie E, Typ A, B, C und DClapets de non-retour antipollution - DN 6 a DN 250 inclus - Famille E, Type A, B, C et DAnti-pollution check valves - DN 6 to DN 250 inclusive family E, type A, B, C and D23.060.50Blokirni ventiliCheck valvesICS:Ta slovenski standard je istoveten z:EN 13959:2004SIST EN 13959:2005en01-marec-2005SIST EN 13959:2005SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13959October 2004ICS 23.060.50 English versionAnti-pollution check valves - DN 6 to DN 250 inclusive family E,type A, B, C and DClapets de non retour antipollution DN 6 à DN 250 - FamilleE, Type A, B, C et DRückflussverhinderer - DN 6 bis DN 250 - Familie E, Typ A,B, C und DThis European Standard was approved by CEN on 22 July 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13959:2004: ESIST EN 13959:2005

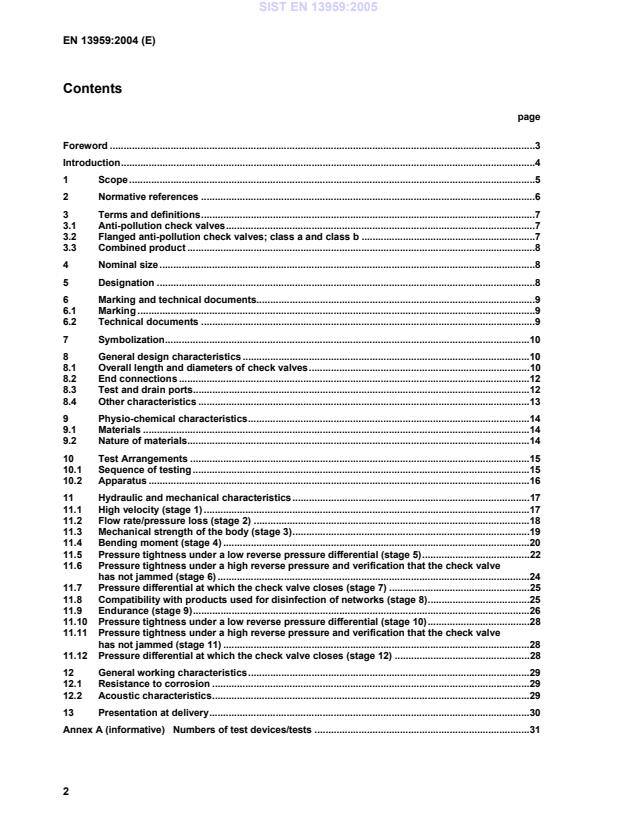

has not jammed (stage 6).24 11.7 Pressure differential at which the check valve closes (stage 7).25 11.8 Compatibility with products used for disinfection of networks (stage 8).25 11.9 Endurance (stage 9).26 11.10 Pressure tightness under a low reverse pressure differential (stage 10).28 11.11 Pressure tightness under a high reverse pressure and verification that the check valve

has not jammed (stage 11).28 11.12 Pressure differential at which the check valve closes (stage 12).28 12 General working characteristics.29 12.1 Resistance to corrosion.29 12.2 Acoustic characteristics.29 13 Presentation at delivery.30 Annex A (informative)

Numbers of test devices/tests.31

Anti-pollution check valves covered by this document are of pressure class PN 10. In case of devises with pres-sure class PN 16, the anti–pollution check valves has to comply with the tests which characterise the PN of the devise. The field of application of EN 1717 is limited to 10 bar, flanges could be drilled in PN 16 pattern. SIST EN 13959:2005

EN ISO 5167-3, Measurement of fluid flow by means of pressure differential devices inserted in circular cross-section conduits running full — Part 3: Nozzles and Venturi nozzles (ISO 5167-3:2003). EN ISO 6509, Corrosion of metals and alloys — Determination of dezincification resistance of brass (ISO 6509:1981). ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests. SIST EN 13959:2005

family E, type A, controllable anti-pollution check valve (with test port) controllable single check valve, consisting one closing element, is mechanical protection device to permit flow in one direction only. It will open automatically when the pressure in the direction of flow upstream of the valve is greater than the pressure downstream. In case when the pressure is higher downstream or no flow condi-tion exists the valve is closed by anticipation acting under a force, for example of a mechanical assembly or a spring. For verification needs this type of check valve has a test cock upstream of the closing element 3.1.2

family E, type B, non-controllable anti-pollution check valve non-controllable single check valve, consisting one closing element, is a mechanical protection device to per-mit flow in one direction only. It will open automatically when the pressure in the direction of flow upstream of the valve is greater than the pressure downstream. In case when the pressure is higher downstream or no flow condition exists the valve is closed by anticipation acting under a force, for example of a mechanical as-sembly or a spring. A family E, type B, non-controllable anti-pollution check valve is constructed in two formats: With housing (final product); Without housing (called cartridge check valve) 3.1.3

family E, type C, controllable double anti-pollution check valve (with test ports) controllable double check valve, consisting of two independent acting closing elements, is a mechanical protection device to permit flow in one direction only. It will open automatically when the pressure in the direction of flow upstream of the valve is greater than the pressure downstream. In case when the pressure is higher downstream or no flow condition exists the valve is closed by anticipation acting under a force, for example of a mechanical assembly or a spring. For verification needs this type of check valve has a test cock upstream of each closing element 3.1.4

family E, type D, non-controllable anti-pollution double check valve non-controllable double check valve, consisting two independent acting closing elements, is a mechanical pro-tection device to permit flow in one direction only. It will open automatically when the pressure in the direction of flow upstream of the valve is greater than the pressure downstream. In case when the pressure is higher downstream or no flow condition exists the valve is closed by anticipation acting under a force, for example of a mechanical assembly or a spring. A family E, type D, non-controllable anti-pollution double check valve is constructed in two formats: With housing (final product); Without housing (called cartridge double check valve) For the purpose of this document, "anti-pollution check valves" are hereafter referred to as "devices" 3.2

flanged anti-pollution check valves; class a and class b controllable check valves need to be accessible for inspection, test and replacement. To assist their repair, flanged check valves may be provided with an inspection hatch and for designation pur-poses two classes are specified: Class a : with an inspection hatch; SIST EN 13959:2005

combined product a combined product is an end product which incorporates beside the check valve function other function(s)

EXAMPLES stop valves, draw-off taps etc. which incorporate a check valve function 4 Nominal size For the purpose of this document the nominal size DN as given in Table 6 relates to flow characteristics. The dimensions of the end connections shall be either equal to or one DN smaller, or one DN greater than the nominal size of the device, except for the flanged devices of which the connecting size shall correspond to DN. The DN-range covered by this document for single check valves (type A and B) and double check valves (type C and D) is DN 6 to DN 250 inclusive. Limitations are given in the applicable tables. 5 Designation Devices are designated by: its name; its family (E); its type (A, B, C and D); its class (a or b for flanged devices only, see 3.2 and 8.4.2.1); its nominal size (DN) (see Table 6); its pressure class (PN); its connections: type and size (not applicable to cartridge check valves); its housing material (not applicable to cartridge check valves); its surface finish (possible coating); the acoustic group (up to DN 32 inclusive only); reference to this document. Examples of designation Non-controllable anti-pollution check valve, family E, type B, DN 20, G ¾ × G ¾, bronze, I, EN 13959. Controllable anti-pollution check valve, family E, type A, class a, DN 100, Flanged, Pressure class 10, Epoxy coated ductile iron, EN 13959. SIST EN 13959:2005

EA with test port

EB without test port NOTE Applies also for cartridge check valves. Figure 1 — Check valve symbols

EC with test port

ED without test port NOTE Applies also for Cartridge Double Check Valves. Figure 2 — Double check valve symbols 8 General design characteristics 8.1 Overall length and diameters of check valves 8.1.1 General Where necessary, the overall lengths and diameters of check valves are specified for each type in 8.1.2 to 8.1.5. 8.1.2 Check valves with threaded ends or compression ends The overall lengths of check valve housings with threaded ends or compression ends or with ends suitable for connection with capillary unions shall be determined by the manufacturer. SIST EN 13959:2005

Alternative face-to-face dimensions within the scope of EN 558-1 are permissible by agreement with the customers. 8.1.4 Cartridge check valves The cartridge check valves mounting dimensions for retention and leak tightness shall be determined and provided by the cartridge supplier, with the exception of one kind of water meter cartridge check valves (see Figure 3), having dimensions given in Table 3.

Figure 3 — Water meter cartridge check valve Table 3 — Dimensions of water meter cartridge check valves Dimensions in millimetres DN 15 20 25 40 D1 (max) 18,3 22,1 28,5 40,3 L (max) 19,5 25,5 38,5 50,0

D2

0 20,0 -0,15

0 25,0 –0,15

0 32,0 –0,2

0 46,0 –0,3 h 3,0 ± 0,1 7,0 ± 0,1 8,0 ± 0,1 10,0 ± 0,1

8.1.5 Double Check Valves The overall length of this type of check valve is left to the discretion of the manufacturer. SIST EN 13959:2005

Figure 4 — Test and drain ports Table 4 — Dimensions of test and drain ports Nominal size DN Thread size a a (mm) ≤15 G é or G ¼ > 6,5 15 < DN ≤ 50 G ¼ > 6,5 > 50 G ê or G ½ > 13 a Thread shall be in accordance with EN 1254-4.

The test and drain ports shall be produced so that the plug can be adequately sealed. 8.4 Other characteristics 8.4.1 Double check valves The components of the two check valves shall not interfere with each other in all operating conditions. 8.4.2 Flanged check valves 8.4.2.1 Accessibility When installed, controllable check valves shall be accessible for inspection, test and replacement. To assist their repair, flanged check valves may be provided with an inspection hatch and for designation pur-poses, 2 classes are specified: Class a : with an inspection hatch; Class b : without an inspection hatch. Inspection hatches shall be adequately sized to permit maintenance. The installation of either a class a device or a class b device depends on national installation requirements. 8.4.2.2 Flanged check valves with inspection hatch Class a devices which retain water with the inspection hatch removed shall be fitted with a drain port at the bottom of the chamber. SIST EN 13959:2005

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...