EN 1267:2012

(Main)Industrial valves - Test of flow resistance using water as test fluid

Industrial valves - Test of flow resistance using water as test fluid

This European Standard specifies a method for determining valve pressure loss coefficient and fluid flow coefficient using water as test fluid. This method is suitable

for valves with low zeta values but higher than 0,1 by determining pressure loss, with respect to fluid flow rate and specific gravity, and

for valves with equal inlet and outlet nominal size.

Industrial process control valves are excluded from this European Standard.

NOTE 1 For zeta values above 6, the pressure loss coefficient inaccuracy is higher than the pressure loss caused by the test tubes. It becomes the same configuration of tests as in EN 60534-2-3.

NOTE 2 If using air as test fluid, other standards e.g. EN 60534-2-3 and ISO 6358 should be referred to.

Industriearmaturen - Messung des Strömungswiderstandes mit Wasser als Prüfmedium

Diese Europäische Norm legt ein Verfahren zur Bestimmung der Koeffizienten für Druckverlust und Durch-fluss¬menge von Armaturen fest, wobei Wasser als Prüfmedium verwendet wird. Dieses Ver¬fahren ist geeignet

- für Armaturen mit niedrigen -Werten, jedoch über 0,1, bei Bestimmung des Druckverlustes in Abhängig-keit vom Durchfluss und vom spezifischen Gewicht des Prüfmediums sowie

- für Armaturen mit gleichen Nennweiten auf der Ein- und Austrittsseite.

Industriestellgeräte fallen nicht in den Anwendungsbereich dieser Europäischen Norm.

ANMERKUNG 1 Bei Armaturen mit 6 ist die Messunsicherheit des Druckverlustkoeffizienten höher als der durch die Prüfrohre verursachte Druck¬verlust. Dabei entspricht die Prüfkonfiguration EN 60534-2-3.

ANMERKUNG 2 Bei Verwendung von Luft als Prüfmedium sollten andere Normen in Bezug genommen werden, z. B. EN 60534 2-3 und ISO 6358.

Robinetterie industrielle - Essai de résistance à l'écoulement utilisant l'eau comme fluide d'essai

La présente Norme européenne spécifie une méthode de détermination du coefficient de perte de charge et

du coefficient de débit du fluide d’un appareil de robinetterie en utilisant l'eau comme fluide d'essai. Cette

méthode est applicable

- aux appareils de robinetterie à faible coefficient de perte de charge zeta, mais plus grand que 0,1 par

détermination de la perte de charge, en fonction du débit et de la densité du fluide, et

- aux appareils de robinetterie dont les diamètres nominaux d'entrée et de sortie sont identiques.

Les robinets de régulation de procédés industriels sont exclus de la présente Norme européenne.

NOTE 1 Pour les valeurs de zêta supérieures à 6, l'imprécision du coefficient de perte de charge est supérieure à la

perte de charge provoquée par les tubes d'essai. Il en résulte la même configuration d'essai que celle de l'EN 60534-2-3.

NOTE 2 Si l'air est utilisé comme fluide d'essai, il convient que d'autres normes telles que l'EN 60534-2-3 et l'ISO 6358

soient mentionnées.

Industrijski ventili - Preskušanje pretočne upornosti z vodo kot preskusnim medijem

Ta evropski standard določa metodo za ugotavljanje koeficienta izgube tlaka za ventile in koeficienta pretoka tekočine z vodo vode kot preskusno tekočino. Ta metoda je ustrezna za ventile z nizkimi vrednostmi zeta, vendar višjimi od 0,1, tako da se določi izguba tlaka, ob upoštevanju stopnje pretoka tekočine in specifične težnosti, ter za ventile z enako nazivno dovodno in odvodno velikostjo. Ta evropski standard ne zajema regulacijskih ventilov za industrijske procese.

General Information

- Status

- Published

- Publication Date

- 17-Jan-2012

- Withdrawal Date

- 30-Jul-2012

- Technical Committee

- CEN/TC 69 - Industrial valves

- Drafting Committee

- CEN/TC 69/WG 1 - Basic standards

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 20-Jun-2023

- Completion Date

- 09-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 09-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

prEN 15116 - Ventilation in buildings - Chilled beams - Testing and rating of active chilled beams - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN ISO 21787:2006 - Industrial valves - Globe valves of thermoplastics materials (ISO 21787:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Referred By

EN ISO 16139:2006 - Industrial valves - Gate valves of thermoplastics materials (ISO 16139:2006) - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 1267:2012 - Industrial valves: Test of flow resistance using water as test fluid is a CEN European Standard that specifies a laboratory method to determine valve pressure loss coefficient (ζ, zeta) and flow coefficients (Kv and Cv) using water as the test fluid. The method is intended for valves with low zeta values (but > 0.1) and for valves with equal inlet and outlet nominal size. Industrial process control valves are excluded. The document describes test facility layout, test procedures, calculation methods and uncertainty evaluation required to produce reproducible flow-resistance data for valve selection and hydraulic design.

Key topics and technical requirements

- Scope and applicability: Suitable for valves with low ζ > 0.1 and equal inlet/outlet DN; excludes industrial process control valves. For ζ > 6, testing aligns with EN 60534-2-3.

- Test facility: Layout requirements including test tube lengths (L1 & L3 ≥ 10·D; L2 & L4 ≥ 2·D), straightening options, and arrangement for straight, angle and multiport valves.

- Test tubes and sizes: Specifications for steel and copper test tube dimensions (DN ranges) and requirements for straightness, end preparation and internal cleanliness; inner diameter must be reported for low-ζ valves.

- Pressure tappings and instrumentation: Number and placement of pressure taps, tap diameters and tolerances, connection tube sizing, upstream/downstream tapping points and differential pressure measurement devices.

- Test procedure and conditions: Permissible measurement fluctuations, steady and non‑steady condition limits, accounting for pressure loss in test tubes, and recommended measurement practice.

- Calculations and outputs: Determination of valve pressure loss (ζ), flow coefficients Kv and Cv, and reporting format (test report requirements).

- Uncertainty analysis: Annexes cover uncertainty propagation, Type A/B evaluation, sensitivity coefficients and calculation of total measurement uncertainty (Annex D and C).

- Flow phenomena: Informative annexes on cavitation, flashing and other flow regimes that can influence results.

Practical applications and users

- Valve manufacturers - characterise valves for datasheets and quality control.

- Independent test laboratories - perform standardized flow-resistance testing and certify Kv/Cv and ζ values.

- System designers / HVAC / plumbing / fire protection engineers - use Kv/Cv and ζ to size piping and predict pressure losses.

- Specification writers / procurement - compare valve hydraulic performance across products.

- Research and development - test effects of geometry changes on flow resistance.

Practical benefits include consistent, repeatable hydraulic data for energy-efficient system design, accurate pressure-loss budgeting and clearer vendor comparisons.

Related standards and notes

- For air/gas testing, refer to EN 60534-2-3 and ISO 6358.

- For high ζ (>6) conditions, measurement configurations align with EN 60534-2-3.

- Normative references in EN 1267:2012 include EN 736 (terminology), EN 1057 (copper tubes), EN 24006 and ISO references used for measurement conventions.

Keywords: EN 1267:2012, industrial valves, flow resistance test, water test fluid, Kv, Cv, zeta, pressure loss coefficient, valve testing, CEN.

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 1267:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Industrial valves - Test of flow resistance using water as test fluid". This standard covers: This European Standard specifies a method for determining valve pressure loss coefficient and fluid flow coefficient using water as test fluid. This method is suitable for valves with low zeta values but higher than 0,1 by determining pressure loss, with respect to fluid flow rate and specific gravity, and for valves with equal inlet and outlet nominal size. Industrial process control valves are excluded from this European Standard. NOTE 1 For zeta values above 6, the pressure loss coefficient inaccuracy is higher than the pressure loss caused by the test tubes. It becomes the same configuration of tests as in EN 60534-2-3. NOTE 2 If using air as test fluid, other standards e.g. EN 60534-2-3 and ISO 6358 should be referred to.

This European Standard specifies a method for determining valve pressure loss coefficient and fluid flow coefficient using water as test fluid. This method is suitable for valves with low zeta values but higher than 0,1 by determining pressure loss, with respect to fluid flow rate and specific gravity, and for valves with equal inlet and outlet nominal size. Industrial process control valves are excluded from this European Standard. NOTE 1 For zeta values above 6, the pressure loss coefficient inaccuracy is higher than the pressure loss caused by the test tubes. It becomes the same configuration of tests as in EN 60534-2-3. NOTE 2 If using air as test fluid, other standards e.g. EN 60534-2-3 and ISO 6358 should be referred to.

EN 1267:2012 is classified under the following ICS (International Classification for Standards) categories: 23.060.01 - Valves in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 1267:2012 has the following relationships with other standards: It is inter standard links to EN 1267:1999, ISO 7194:2008, EN 1057:2006+A1:2010, EN 736-3:2008, EN 736-1:1995, EN ISO 6708:1995, EN 24006:1993, prEN 15116, EN 14267:2004, EN 13175:2019+A1:2020, EN ISO 21787:2006, EN 12514:2020, EN ISO 16139:2006, EN 14812:2005+A1:2007, EN 13175:2014. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 1267:2012 is associated with the following European legislation: EU Directives/Regulations: 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 1267:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.SUHVNXVQLPPHGLMHPIndustriearmaturen - Messung des Strömungswiderstandes mit Wasser als PrüfmediumRobinetterie industrielle - Essai de résistance à l'écoulement utilisant l'eau comme fluide d'essaiIndustrial valves - Test of flow resistance using water as test fluid23.060.01Ventili na splošnoValves in generalICS:Ta slovenski standard je istoveten z:EN 1267:2012SIST EN 1267:2012en,fr,de01-marec-2012SIST EN 1267:2012SLOVENSKI

STANDARDSIST EN 1267:20001DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 1267

January 2012 ICS 23.060.01 Supersedes EN 1267:1999English Version

Industrial valves - Test of flow resistance using water as test fluid

Robinetterie industrielle - Essai de résistance à l'écoulement utilisant l'eau comme fluide d'essai

Industriearmaturen - Messung des Strömungswiderstandes mit Wasser als Prüfmedium This European Standard was approved by CEN on 26 November 2011.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 1267:2012: ESIST EN 1267:2012

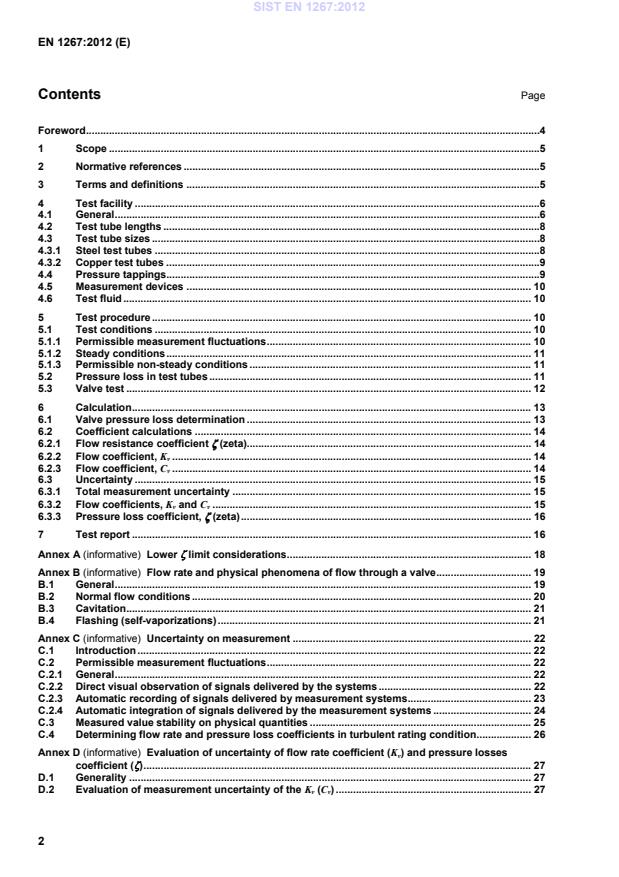

Lower ζζζζ limit considerations . 18Annex B (informative)

Flow rate and physical phenomena of flow through a valve . 19B.1 General . 19B.2 Normal flow conditions . 20B.3 Cavitation . 21B.4 Flashing (self-vaporizations) . 21Annex C (informative)

Uncertainty on measurement . 22C.1 Introduction . 22C.2 Permissible measurement fluctuations . 22C.2.1 General . 22C.2.2 Direct visual observation of signals delivered by the systems . 22C.2.3 Automatic recording of signals delivered by measurement systems . 23C.2.4 Automatic integration of signals delivered by the measurement systems . 24C.3 Measured value stability on physical quantities . 25C.4 Determining flow rate and pressure loss coefficients in turbulent rating condition . 26Annex D (informative)

Evaluation of uncertainty of flow rate coefficient (Kv) and pressure losses coefficient (ζζζζ) . 27D.1 Generality . 27D.2 Evaluation of measurement uncertainty of the Kv (Cv) . 27SIST EN 1267:2012

Kv or Cv [EN 736-3:2008, 3.4.1] SIST EN 1267:2012

[EN 736-3:2008, 3.4.5] 3.3 fluctuations low period modifications of the measured value of a physical quantity around its mean value during the measurement reading time 3.4 nominal diameter DN [EN ISO 6708:1995, 2.1] 3.5 stability stability, or the permanent rating conditions, which is reached, when the variations or value changes for these same physical quantities are low enough between a given reading and the next one 3.6 types of valves [EN 736-1:1995] 3.7 uncertainty [EN 24006:1993, 5.26] 4 Test facility 4.1 General A basic flow test facility is shown in Figure 1. The position of components outside the frame may be determined by the laboratory. For angle valves (Figure 1 b)), the tested valve and the tube section (L3 length) may be laid either vertically or horizontally. For multi-way valves, additional test tubes of the same type shall be used, in the same conditions. SIST EN 1267:2012

NOTE L1 and L3 ≥ 10 D and L2 and L4 ≥ 2 D. a) Straight valves

b) Angle or multiport valves Key 1 water supply 6 upstream pressure measuring device 2 flow meter 7 valve under test 3 temperature measurement 8 downstream pressure tapping point 4 regulating valve 9 regulating valve 5 upstream pressure tapping point 10 differential pressure measuring device Figure 1 — Test installation SIST EN 1267:2012

Nominal size of valve DN Nominal size of tube mm Thread size Gauge length mm 8 13,5 × 2,3 ¼ 11,0 10 17,2 × 2,3 ê 11,5 15 21,3 × 2,6 ½ 15,0 20 26,9 × 2,6 ¾ 16,5 25 33,7 × 3,2 1 19,0 32 42,4 × 3,2 1 ¼ 21,5 40 48,3 × 3,2 1 ½ 21,5 50 60,3 × 3,6 2 25,5 65 76,1 × 3,6 2 ½ 30,0 80 88,9 × 4,0 3 33,0 100 114,3 × 4,5 4 39,0 125 139,7 × 5,0 5 43,5 150 165,1 × 5,0 6 43,5 200 219,1 × 3,6

250 273,0 × 4,0

300 323,9 × 4,5

350 355,6 × 5,0

400 406,4 × 5,0

450 457,0 × 5,0

500 508,0 × 5,6

600 610,0 × 6,3

NOTE The nominal dimensions of DN 8 to DN 150 are in accordance with ISO 65, medium series and ISO 7598. The nominal dimensions of DN 200 to DN 600 are in accordance with ISO 4200, series C and EN ISO 1127.

Dimensions and tolerances shall be in accordance with EN 1057. Test tubes shall be straight. Their ends shall be cut square and deburred. Their internal surfaces shall be cleaned and free from obstructions visible to the naked eye. Inner diameters are determined by the valve manufacturer unless otherwise specified in a valve, product or application standard. For valves with low ζ coefficient, the results obtained are affected by the test tube inner diameter. Therefore, the actual test tube inner diameter shall be mentioned (see Clause 7 b)). NOTE When new test tubes are made, it is recommended to make them in accordance with Table 1 and Table 2. 4.4 Pressure tappings The number of pressure taps is determined by the laboratory. At each pressure measurement section, there can be one, two or four tabs or a slot, provided that eccentricity is controlled. There should be four measurement taps for sizes greater than DN 300. Pressure tap diameters shall comply with Table 3 and length shall be at least twice the diameter. The measurement tap hole on test tube internal surface is sharp-edged and free from burrs. The measurement tape hole centreline cuts the axis of the test tube. The pressure tap hole centreline is square to axis with a maximum tolerance of 5°. The inner diameter of connection tubes between taps and pressure measurement devices shall be at least twice the pressure tap hole diameter. To avoid dirt accumulation, no tap shall be located at measurement section bottom. Table 3 — Pressure tap hole diameter DN

Minimum mm Maximum mm < 20 1,5 2 20 to 50 2 3 > 50 3 5

4 ± 17 0,1 ≤ ζ ≤ 1 ± 26

Table 5 — Flow rate and pressure fluctuations Quantity Symbol Fluctuations % Flow rate eq ± 6 Upstream pressure ep ± 6

NOTE More information about accuracy is given in Annex C. SIST EN 1267:2012

Test conditions are referred to as steady if the mean values of all measured values are time-independent. Practically, test conditions may be considered as steady if the variations of each value observed at the test operating point for at least 10 s, do not exceed 1,2 % (difference between larger and smaller values read for a quantity versus mean value). If this condition is met and the fluctuations are lower than the limit values in 5.1.1, one single measurement shall be recorded for a given operating point.

5.1.3 Permissible non-steady conditions When test conditions are not steady, the following procedure shall apply. At each tested operating point, repetitive readings of the measured quantities shall be performed at random time intervals exceeding 10 s. At least three series of measurement acquisitions shall be performed for each operating point. The percentage difference between the largest and the smallest value for each measurement shall not exceed the percentage indicated in Table 6. This leads to an uncertainty in accordance with 6.3.1. Table 6 — Difference between the largest and smallest values Number of measurement series Permissible difference to mean value % 3 1,8 5 3,5 7 4,5 9 5,8 13 5,9 > 30 6,0

The arithmetic mean of all measurements shall be taken as measured value in the scope of the test. If excessive variations cannot be avoided, the uncertainty may be calculated by statistic analysis. 5.2 Pressure loss in test tubes In order to eliminate the pressure loss of the test tubes between the upstream and downstream pressure taps from the characteristic for the tested valve, the pressure loss associated with flow rate from that tube portion may be determined as follows. For each test tube nominal dimension, connect the tubes concentrically to each other without gap between ends in the test section indicated in Figure 1. Provide a suitable water flow rate in the test facility to eliminate any entrapped air pockets. Record a series of associated flow rate and pressure loss values in the same operating flow rate range used for the valve test. Determine the relationship between test tube flow rate and pressure loss. Test this relationship again periodically, notably if the internal surface condition of the tubes has changed significantly.

For valves with capillarity- or compression-type ends, the tubes used shall be mounted in thrust abatement in the valve body.

For flanged valves, connection shall be aligned without offset between the test facility flange face and the tube on which it is secured, and the fluid path shall not be obstructed by the gaskets. Provide a water flow rate so that all air is purged off the facility. The test can be performed differently according to the valve type, the scope and the specifications of the applicable product standard or of the application standard, as follows: a) determining the pressure loss for a given flow rate; b) determining the pressure loss in a range of flow rate values; c) determining the flow rate for a given pressure loss; d) determining the flow rate in a range of pressure loss values; e) determining one or more coefficients measured under different flows, in turbulent flow conditions. NOTE More information on turbulent flow and vaporisation conditions is given in Annex B. When a valve is tested to determine its flow coefficient in turbulent conditions:

measurements shall be performed for at least three different flow rate values;

the minimum flow rate value shall be determined so that the Reynolds number always exceeds 4 × 104; the maximum flow rate value shall be greater than the upper value of the operating range specified by the manufacturer. If this limit cannot be reached by the test facility, the test laboratory shall establish that the maximum attainable flow rate value of its facility is satisfactory to obtain results within accuracy compatible to this European Standard;

an intermediate flow rate value between maximum and minimum shall be determined. SIST EN 1267:2012

If the difference exceeds this tolerance, it can be due to vaporisation. Therefore, the test shall be repeated with a higher upstream pressure value. If the difference is within tolerance, the flow coefficient in turbulent flow conditions is the average between the three calculated flow coefficient values. Vaporisation shall be avoided unless in contradiction with the product standard or the application standard.

For each test, the pressure loss in the test tubes shall be subtracted from the total measured pressure loss.

Table 7 — Engaged thread length Thread dimension, ISO 7-1 ¼ ê ½ ¾ 1 1¼ 1½ 2 2½ 3 4 5 6 Engaged thread length a mm 10,0 10,5 14,0 15,5 18,0 20,5 20,5 24,5 28,5 31,5 37,5 42,0 42,0 Tolerance mm ± 1 ± 1 ± 1 ± 1 ± 1 ± 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...