EN 13659:2004

(Main)Shutters - Performance requirements including safety

Shutters - Performance requirements including safety

This European Standard specifies the performance requirements which shutters shall fulfil when fitted within a building. It deals also with the significant hazards for construction, transport, installation, operation and maintenance of the shutters (see list of significant machine hazards in annex C).

It applies to all shutters as well as similar products whatever their use and nature of the materials used, as follows :

- external Venetian blind, roller shutter, wing shutter, Venetian shutter, flat-closing concertina shutter, concertina shutter or sliding panel shutter, with or without a system of projection.

These products can be operated manually with or without compensating spring, or by means of electric motors (power operated products).

This document is not applicable to shutters which are manufactured before the date of application of this document by CEN.

Abschlüsse außen - Leistungs- und Sicherheitsanforderungen

Diese Europäische Norm legt die Leistungsanforderungen fest, die an einem Gebäude befestigte Abschlüsse erfüllen müssen. Die Norm behandelt auch signifikante Gefährdungen für Konstruktion, Transport, Einbau, Betrieb und Wartung der Abschlüsse (siehe Liste der signifikanten Gefährdungen im Anhang C).

Die Norm gilt wie folgt für alle Abschlüsse und ähnliche Produkte, unabhängig von ihrem Gebrauch und der Art der verwendeten Werkstoffe:

- Außenjalousie, Rollladen, Drehladen, Faltladen ungeführt, Faltladen geführt (flach geschlossen), Faltladen geführt (Akkordeon), oder Schiebeladen, mit oder ohne Überstand (Überlappung).

Diese Produkte können manuell bedient werden, mit oder ohne Ausgleichfedern, oder mit Elektromotoren (kraftbetätigte Produkte).

Dieses Dokument gilt nicht für Abschlüsse, die vor dem Ausgabedatum dieses Dokumentes hergestellt wurden.

Fermetures pour baies libres équipées de fenêtres - Exigences de performance y compris la sécurité

La présente Norme européenne spécifie les exigences de performance que doivent remplir les fermetures équipant les bâtiments. Elle traite également des risques significatifs liés aux machines relatifs aux opérations de fabrication, transport, installation, utilisation et de maintenance des fermetures (voir la liste des phénomènes dangereux significatifs en Annexe C).

Elle s'applique à toutes les fermetures dont la liste est donnée ci-après, ainsi qu'aux produits similaires, quelles que soient leur conception et la nature des matériaux utilisés et définis dans la norme EN 12216 :

store vénitien extérieur, volet roulant, volet battant, persienne, persienne coulissante, jalousie accordéon ou volet coulissant, projetables ou non projetables.

Ces produits peuvent être manoeuvrés manuellement avec ou sans ressort de compensation ou au moyen de moteurs électriques (produits motorisés).

Le présent document n’est pas applicable aux fermetures fabriquées avant la date de mise en application de ce document par le CEN.

Polkna - Zahtevane lastnosti, vključno z varnostjo

General Information

- Status

- Withdrawn

- Publication Date

- 08-Jun-2004

- Withdrawal Date

- 30-Sep-2008

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 3 - Blinds and shutters

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 01-Oct-2008

- Completion Date

- 01-Oct-2008

- Directive

- 89/106/EEC - Construction products

- Directive

- 98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Referred By

EN 1932:2001 - External blinds and shutters - Resistance to wind loads - Method of testing - Effective Date

- 28-Jan-2026

- Referred By

EN 12833:2001 - Skylight and conservatory roller shutters - Resistance to snow load - Test method - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 22-Dec-2008

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13659:2004 is a standard published by the European Committee for Standardization (CEN). Its full title is "Shutters - Performance requirements including safety". This standard covers: This European Standard specifies the performance requirements which shutters shall fulfil when fitted within a building. It deals also with the significant hazards for construction, transport, installation, operation and maintenance of the shutters (see list of significant machine hazards in annex C). It applies to all shutters as well as similar products whatever their use and nature of the materials used, as follows : - external Venetian blind, roller shutter, wing shutter, Venetian shutter, flat-closing concertina shutter, concertina shutter or sliding panel shutter, with or without a system of projection. These products can be operated manually with or without compensating spring, or by means of electric motors (power operated products). This document is not applicable to shutters which are manufactured before the date of application of this document by CEN.

This European Standard specifies the performance requirements which shutters shall fulfil when fitted within a building. It deals also with the significant hazards for construction, transport, installation, operation and maintenance of the shutters (see list of significant machine hazards in annex C). It applies to all shutters as well as similar products whatever their use and nature of the materials used, as follows : - external Venetian blind, roller shutter, wing shutter, Venetian shutter, flat-closing concertina shutter, concertina shutter or sliding panel shutter, with or without a system of projection. These products can be operated manually with or without compensating spring, or by means of electric motors (power operated products). This document is not applicable to shutters which are manufactured before the date of application of this document by CEN.

EN 13659:2004 is classified under the following ICS (International Classification for Standards) categories: 91.060.50 - Doors and windows. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13659:2004 has the following relationships with other standards: It is inter standard links to EN 13659:2004+A1:2008, EN 1932:2001, EN 12833:2001, EN 12045:2000, EN 13330:2002, EN 14201:2004, EN 13659:2004/prA1. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13659:2004 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC, 98/37/EC; Standardization Mandates: M/079, M/101. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13659:2004 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Shutters - Performance requirements including safetyFermetures pour baies libres équipées de fenetres - Exigences de performance y compris la sécuritéAbschlüsse außen - Leistungs- und Sicherheitsanforderungen91.060.50Vrata in oknaDoors and windowsICS:SIST EN 13659:2004enTa slovenski standard je istoveten z:EN 13659:200401-september-2004SIST EN 13659:2004SLOVENSKI

STANDARD

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 13659June 2004ICS 91.060.50English versionShutters - Performance requirements including safetyFermetures pour baies libres équipées de fenêtres -Exigences de performance y compris la sécuritéAbschlüsse außen - Leistungs- undSicherheitsanforderungenThis European Standard was approved by CEN on 2 March 2004.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia,Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2004 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 13659:2004: E

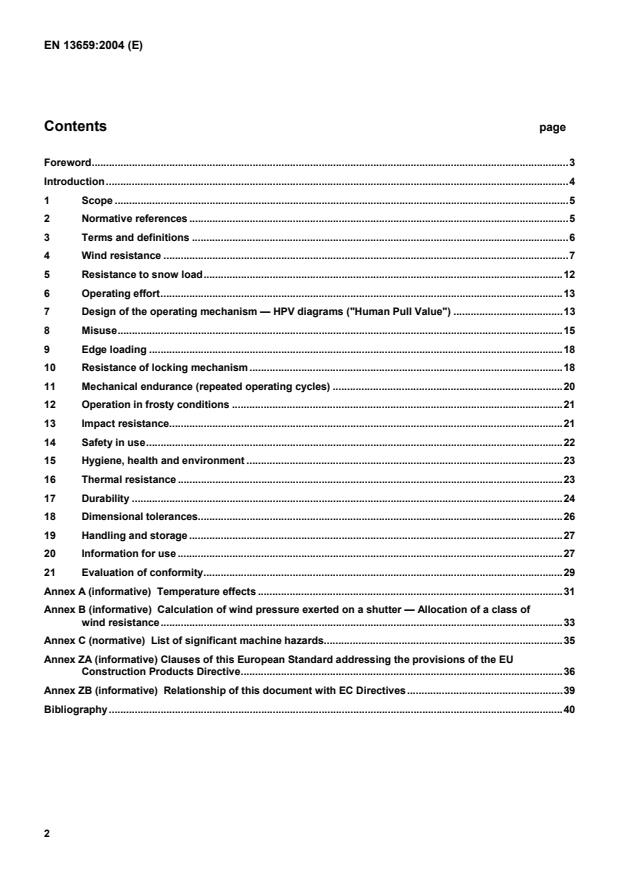

2 Contents

page Foreword.3 Introduction.4 1 Scope.5 2 Normative references.5 3 Terms and definitions.6 4 Wind resistance.7 5 Resistance to snow load.12 6 Operating effort.13 7 Design of the operating mechanism — HPV diagrams ("Human Pull Value").13 8 Misuse.15 9 Edge loading.18 10 Resistance of locking mechanism.18 11 Mechanical endurance (repeated operating cycles).20 12 Operation in frosty conditions.21 13 Impact resistance.21 14 Safety in use.22 15 Hygiene, health and environment.23 16 Thermal resistance.23 17 Durability.24 18 Dimensional tolerances.26 19 Handling and storage.27 20 Information for use.27 21 Evaluation of conformity.29 Annex A (informative)

Temperature effects.31 Annex B (informative)

Calculation of wind pressure exerted on a shutter — Allocation of a class of wind resistance.33 Annex C (normative)

List of significant machine hazards.35 Annex ZA (informative) Clauses of this European Standard addressing the provisions of the EU Construction Products Directive.36 Annex ZB (informative)

Relationship of this document with EC Directives.39 Bibliography.40

This standard specifies the requirements for shutters, the levels of performance and the associated classes where applicable.

It is completed by test standards as well as by the standards referring to specific performance requirements.

No existing European Standard is superseded.

Annexes A and B are informative.

Annex C is normative.

This document includes a Bibliography.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

4 Introduction

The performances given in this European Standard which illustrate suitability for use, are required for every type of shutter (intrinsic performances). Other performances are only required as a complement (specific performances) and result in specific products. Some of them are described in European Standards (e.g. EN 1522, EN 1523, ENV 1627, ENV 1628, ENV 1629, ENV 1630, EN 13123-1, EN 13124-1, EN 13123-2 and EN 13124-2). Others are described in prEN 14500 and prEN14501 in the process of preparation and deal with important subjects such as thermal comfort, i.e.: - Solar factor; - Shading factor; - Direct solar transmittance; - Secondary heat transfer factor; - Solar radiation reduction factor. and visual comfort, i.e.: - Light control; - Night privacy; - Visual contact with the outside; - Glare control; - Rendering of colours.

or with the airborne sound insulation brought by shutters (see prEN 14759).

NOTE Health and Safety regulations require that the workplace receives as much natural light as is reasonably practical (see EU Directive 89/654/EEC) and protection of operators working with VDV screens against glare control and reflected light (see EU Directive 87/391/EEC).

The list of these documents is given in the Bibliography.

With the aim of clarifying the intentions of the standard and avoiding doubts when reading it, following assumptions were made related to power operated products while producing it:

— Negotiations shall occur between the manufacturer and the purchaser concerning particular conditions for use and places for use such as for nursery schools or for buildings for disabled people which need specific risk analysis;

— The risk analysis carried out in this standard and the corresponding significant hazards listed in annex C suppose a normal use or normally predictable use e.g. which excludes deliberate and conscious risks taken by the user (see Interpretative Document “Safety in use” of EU Construction Products Directive).

This European Standard specifies the performance requirements which shutters shall fulfil when fitted to a building. It deals also with the significant hazards for construction, transport, installation, operation and maintenance of the shutters (see list of significant machine hazards in annex C).

It applies to all shutters as well as similar products whatever their use and nature of the materials used, as follows:

— external Venetian blind, roller shutter, wing shutter, Venetian shutter, flat-closing concertina shutter, concertina shutter or sliding panel shutter, with or without a system of projection.

These products can be operated manually with or without compensating spring, or by means of electric motors (power operated products).

This document is not applicable to shutters which are manufactured before the date of application of this document by CEN.

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These normative references are cited at the appropriate places in the text, and the publications are listed hereafter. For dated references, subsequent amendments to or revisions of any of these publications apply to this European Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the publication referred to applies (including amendments).

EN ISO 12100-2:2003, Safety of machinery — Basic concepts, general principles for design — Part 2: Technical principles (ISO 12100-2:2003). EN 1050:1996, Safety of machinery - Principles for risk assessment. EN 1070:1998, Safety of machinery - Terminology. EN 1670, Building hardware - Corrosion resistance - Requirement and test methods. EN 1932, External blinds and shutters - Resistance to wind loads - Method of testing. EN 12045, Shutters and blinds power operated - Safety in use - Measurement of the transmitted force. EN 12194, Shutters, external and internal blinds - Misuse - Test methods. EN 12216:2002, Shutters, external blinds, internal blinds — Terminology, glossary and definitions. EN 12833, Skylight and conservatory roller shutters - Resistance to snow load - Test method. EN 12835, Airtight shutters - Air permeability test. EN 13125, Shutters and blinds - Additional thermal resistance - Allocation of a class of air permeability to a product. EN 13245-1:2004, Plastics - Unplasticized poly(vinyl chloride) (PVC-U) profiles for building applications – Part 1: Designation of light coloured profiles. EN 13330, Shutters - Hard body impact — Test method. EN 13527, Shutters and blinds – Measurement of operating force — Test methods. EN 14201, Blinds and shutters - Resistance to repeated operations (mechanical endurance) - Methods of testing. EN 60335-1, Household and similar electrical

appliances - Safety - Part 1: General

requirements (IEC 60335-1:2001, modified)

6 EN 60335-2-97,Safety of household and similar electrical appliances - Part 2-97: Particular requirements for drives for rolling shutters, awnings, blinds and similar equipment (IEC 60335-2-97:1998, modified). EN 61310-1, Safety of machinery – Indication, marking and actuation – Part 1: Requirements for visual, auditory and tactile signals (IEC 61310-1:1995). EN ISO 10077-1, Thermal performance of windows, doors and shutters -Calculation of thermal transmittance - Part 1: Simplified method (ISO 10077-1:2000). ISO 9227, Corrosion tests in artificial atmospheres – Salt spray tests.

3 Terms and definitions

For the purposes of this European Standard, the terms and definitions given in EN 1070:1998 and EN 12216:2002 and the following apply.

3.1 intrinsic performance overall performances of the shutter regardless of its application as opposed to specific performance

3.2 specific performance performance which may be additional and complementary to the intrinsic performances and refers to a specific product (for example, acoustic, thermic, burglary resistance, etc.)

3.3 curtain that part of the product which is set in motion by the operating mechanism, and ensures its function

3.4 extension/retraction movement of the curtain resulting in an increase/decrease the surface area covered

3.5 opening/closing terms used to describe the increase in light (opening) or reduction of light (closing) in an extended position for products with slats or slats which can be tilted or adjusted

NOTE The common parlance uses "open" for retraction and "closed" for extension.

3.6 rough operation sharp action on the operating mechanism or directly on the curtain, resulting in excessive speed at the beginning and a sudden stop at the end

NOTE Rough operation is only possible if the moving part has significant inertia (mass and speed).

3.7 forced operation excessive force exerted on the operating mechanism or directly on the curtain with the aim of causing movement in spite of resistance to the travel of the curtain

3.8 reversed operation extension or retraction of the curtain occurring in the opposite direction to that intended without use of abnormal force

3.9 winch handle operating mechanism consisting of a reel rotated by an operation handle which allows accumulation of a cord, cable, or chain

3.10 gear with crank handle operating mechanism consisting of a gear attached to an axle, a drive shaft, a universal joint, a rotated rod and a crank handle

3.11 one direction movement of the operating mechanism operating mechanism operated by a single cord, belt, etc., extension / retraction being effected by relying on gravity or the potential energy stored up during retraction / extension, respectively

3.12 endless movement of the operating mechanism operating mechanism operated by a loop, movement in one direction extends the curtain (or tilts the laths), and in the reverse retracts the curtain (or tilts the laths) in the opposite direction

3.13 monocommand same mechanism which achieves both opening/closing and extension/retraction

3.14 vertical loading/racking downward force applied to the panel edge of a wing shutter

3.15 determination of performance means of verification of the performance relating to the corresponding requirement

4 Wind resistance

4.1 General

The wind resistance of a shutter is assumed by its ability to withstand to specified loads, simulating the action of wind in positive or negative pressure. Wind resistance is specified through classes defined by threshold values of nominal pressure p and safety pressure γγγγ x p with

γγγγ = 1,5

a) Nominal wind pressure p

Represents the wind pressure applied to the shutter for which the shutter shall not sustain deformation or deterioration which is detrimental to its correct operation.

b) Safety wind pressure 1,5 p

Represents the wind pressure applied to the shutter for which no deterioration which may be dangerous for the persons shall be observed: breakage, coming out from the fixing or locking devices. Safety wind pressure 1,5 p corresponds to a net pressure (difference of the pressures on each surface taking due account of their signs) calculated according to annex B with a wind velocity having a mean return period of 20 years (annual probability of exceedence of 0,05).

NOTE Nominal wind pressure corresponds approximately to a wind having a mean return period of 3 years.

4.2 Determination

The determination shall be in accordance with the test methods specified in EN 1932.

8 4.3 Performance requirement

4.3.1 General

As a function of the type of shutter, the performance criteria specified in Tables 2, 3 and 4 shall be achieved having applied the test loads FN and FS as specified in Table 1.

Table 1 — Test loads

Non projecting curtain Projecting curtain FN = ββββ x p x L x H

FS = γγγγ x FN , with γγγγ = 1,5 FN = 2ββββ x p x L x H

FS = γγγγ x FN , with γγγγ = 1,5

where:

L, H is the width and height of shutter as specified in EN 1932 p

is the threshold value of wind test pressure in N/m2corresponding to the class of resistance considered (see 4.4) ββββ

is the coefficient of passage of effect of loads distributed to those of the test loads with: ββββ = 1, in the case of roller shutter, wing shutter, venetian shutter, sliding concertina shutter, concertina shutter, sliding panel shutter (see Table 2) ββββ = 0,2, in the case of external venetian blind (see Table 3) γγγγ is the conversion coefficient between nominal and safety loads, with γγγγ = 1,5.

The classification as given in Table 5 is only obtained after the safety level is achieved.

4.3.2 Performance of the curtain

ROLLER SHUTTER, WING SHUTTER, VENETIAN SHUTTER, FLAT-CLOSING CONCERTINA SHUTTER, CONCERTINA SHUTTER, SLIDING PANEL SHUTTER

The curtain, in the extended non projecting position, is uniformly loaded according to the sequences described in Table 2:

— either in the horizontal position under the effect of spread loads reproducing uniform pressure; — or in the vertical position to test under pneumatic pressure.

LOAD :

FN = ββββ x p x L x H or FN = 2xββββ x p x L x H PERFORMANCE CRITERIA

with ββββ = 1 Appearance Operation Safety

Nominal direct load FN

Applied on the external side of curtain

Inverse nominal load FN

Applied on the internal side of the curtain

no visible deterioration of the curtain, fixing locking device and guiding

manual operating effort maintained wjthin the class

___

Direct and inverse safety loads

FS = 1,5 x FN

and - FS = 1,5 x - FN

Applied on the external side (direct safety load) then on the internal side of the curtain (inverse safety load)

____

____

no breakage

the curtain shall not come out of its fixings or locking device

EXTERNAL VENETIAN BLIND

The loading shall be applied on the external venetian blind in the vertical position by using a rigid rail, according to the sequences described in Table 3.

10 Table 3 — External venetian blind — Performance criteria

LOAD :

FN = ββββ x p x L x H PERFORMANCE CRITERIA

(ββββ = 0,20) Appearance Operation Safety

1 2

Nominal direct and inverse loads FN and -FN Applied on the external side of curtain (nominal direct load) then on the internal side (nominal inverse load)

residual deflection of laths < 5‰ L

-----

Direct and inverse safety loads FS = 1,5 x FN and -FS = 1,5 x -FN Applied on the external side of curtain

(direct safety load) then on the internal side (inverse safety load)

-----

-----

no breakage

no exit from guide rail

NOTE The coefficient ββββ = 0,20 is a global coefficient of adjustment to test results under assigned air speeds.

4.3.3 Performance of the projection mechanism (projecting products)

ROLLER SHUTTER, VENETIAN SHUTTER, FLAT-CLOSING CONCERTINA SHUTTER, CONCERTINA SHUTTER

The loading FS being applied at mid-height of the curtain, the projection mechanism shall comply with the conditions given in Table 4.

— Performance of the projection mechanism (projecting product)

LOAD :

FS = 1,5 x FN REQUIREMENT CRITERIA

(FN = 2 ×××× ββββ ×××× p ×××× L ×××× H, ββββ = 1) Appearance Operation Safety

Curtain extended and projected

Direct safety load FS (towards interior)

___

___

the projection system shall

stay locked

no breakage

Curtain extended and projected Inverse safety load - FS (towards exterior)

___

___

the projection system shall

stay locked

no breakage

Curtain extended but not projected Inverse safety load -FS (towards exterior)

___

___

the projection system shall

stay locked

no breakage

4.4 Classes of wind resistance

The classes of wind resistance are given by the threshold test pressures specified in Table 5.

Table 5 — Classes of wind resistance

Classes 0 1 2 3 4 5 6 Nominal test pressure p (N/m²) < 50 50 70 100 170 270 400 Safety test pressure 1,5 p (N/m²) < 75 75 100 150 250 400 600

NOTE Class 0 corresponds to either performance not required or not declared or a product that does not fulfil the requirements of class 1.

12 5 Resistance to snow load

5.1 General

Only applicable to roller shutters for skylight and conservatory inclined less than 60° from the horizontal.

Under the weight of snow, the shutter fitted to the window shall not:

a) sustain deformation or deterioration which is detrimental to its correct operation; b) exit from its guide rails.

Two forms of resistance are envisaged:

1) the shutter itself resists the snow pressure; 2) the shutter resists the snow pressure together with the mechanical association with the glazing, at a distance d defined by the manufacturer.

This second form of resistance is allowed only if:

— the shutter accepts a level of deformation causing it to lean against the glazing under the snow loading; and — the distance between shutter and glazing is not modified by the opening of the window.

NOTE An attempt to open the window, when the shutter is loaded with snow, should not endanger the user.

5.2 Determination

The determination shall be in accordance with the test method specified in EN 12833.

5.3 Performance requirement

The shutter resists to the snow pressure p, maximum snow pressure specified by the manufacturer, if the following conditions are fulfilled:

under nominal pressure pN, after test, the operating effort shall be maintained within the limit of the initial class; under safety load pS = fS x p with fS =1,5, the shutter shall not exit from the guide rails or sustain breakage.

5.4 Expression of the results

1) the shutter itself resists the snow pressure:

maximum snow pressure : p expressed in N/m²; form of resistance : shutter alone; shutters of the same range which are narrower and have no greater surface area than the product tested shall be deemed to be capable of resisting at least the same snow pressure as the product tested.

2) the shutter resists the snow pressure with the mechanical association with the glazing:

maximum snow pressure : p expressed in N/m²; form of resistance: shutter in association with a glazing which withstands pressure p and located at the maximum distance d from the shutter;

5.5 Classes of snow resistance

No classes are attributed for snow resistance. For each dimension, the manufacturer shall precise the maximum snow pressure the shutter can sustain, by itself or in mechanical association with a closed window.

6 Operating effort

6.1 General

Does not apply for power operated products.

The effort Fc necessary to set the curtain in motion in retraction / extension and tilting the laths, in addition to the projection of the curtain is a function of the type of operation.

6.2 Determination The determination shall be in accordance with the test methods specified in EN 13527.

6.3 Performance requirement and operational effort classes

Operational effort FC shall not exceed the values in Table 6.

Table 6 — Maximum values of FC for operating effort

Fc (N) TYPES OF OPERATION Class 1

Class 2

Crank or winch handle

a,c, lever 30 15 Belt, cord or chain a,b,c, 90 50 Rod operation

vertical plane 90 50 or hand

horizontal or sloping plane 50 30 Spring compensated roller shutters can reach 1,5 Fc for locking in the fully extended position. A shutter belongs to class 2 if both the operations of moving the curtain, tilting the laths and projecting the curtain are class 2. Otherwise the shutter is class 1. a Operation mechanism shall also fulfil the requirement in clause 7. b One direction movement or endless movement of the operating mechanism. c Monocommand.

7 Design of the operating mechanism — HPV diagrams ("Human Pull Value")

7.1 General

Geometrical characteristics of operating mechanisms taking into account the comfort of the operation.

14 7.2 Performances requirements

Gear operation

Gear with crank or winch handle shall have: - a handle R of length less or equal to 0,20 m (R ≤ 0,20 m); - a reduction ratio r of the gear less than 1:10 (average or mean reduction ratio when, for the same gear, several reductions exist).

NOTE A reduction ratio of 1:10 means it is necessary to make ten turns of the cranks to achieve one rotation of the roller tube or axle.

Belt, cord or chain operation

Operation mechanisms shall have minimal dimensions as given in the HPV diagrams (see Figures 1 and 2).

7.3 Diagrams HPV

dHPV (mm) Apparent cord diameter for HPV for n cords with diameter d

d is the diameter of a single cord

Key

Acceptable 2

Not acceptable 3

Operating effort Figure 1 — Diagram HPV for cord or chain operation

n dHPV z 1 1d zz 2 1,5 d z zz 3 2 d zz zz 4 2,4 d zz zzz 5 2,7 d z zz zzz 6 3 d 4 8 1.5 2 25 5090FC(N) 1 3

Key

Acceptable 2

Not acceptable 3

Operating effort

Figure 2 — Diagram HPV for belt operation

8 Misuse

8.1 Curtain and slats - General

8.1.1 General requirement

Under the action of abnormal but foreseeable use (misuse), the shutter shall not become misshapen or damaged to the extent that:

a) the damage impairs its correct operation; b) the damage which leads to a deterioration in appearance as defined in Tables 2 and 3.

Misuse operations are related to the displacement of the curtain, the tilting of the laths and, for projected products, to the projection of the curtain.

8.1.2 Displacement of the curtain

— Rough operation

Rough operation occurs during extension and retraction.

— Forced operation

Forced operation occurs in the direction of extension and retraction, the curtain being either stopped or blocked in extended or retracted position, or blocked in an intermediate position. Figure 3 illustrates the six possibilities of forced operations.

a)

b)

c)

Key 1 Direction of extension 2 Direction of retraction 3 Obstruction a) Curtain fully extended b) Curtain fully retracted c) Curtain in intermediate position, obstructed during extension and/or retraction

Figure 3 — Illustration of the six possibilities of forced operation

— Reversed operation

Reversed operations are only applicable to roller shutters or to products using a rolling mechanism for extension or retraction.

For these products, operation in situation a1 or b2 illustrated in Figure 3 is a reversed operation when the movement in the opposite direction is possible with an effort less than the limit of the class of operation. If the movement is not possible, it is a forced operation.

Reversed operation occurs on extension with the curtain fully extended and on retraction with the curtain fully retracted.

8.1.3 Tilting of laths

— Rough operation

Rough operation is not possible, the conditions defining its occurrence are not likely to occur (no excessive speed, no inertia of laths).

— Forced operation

Forced operation occurs in both closed positions which are the result of tilting laths in both directions from the open position.

— Reversed operation

Does not exist.

8.1.4 Projection of the curtain

— Rough operation

Rough operation occurs from the fully projected position, after unlocking of projecting arms at which point, the curtain is left free.

Forced operation occurs at the end of projection, if effort is continued.

— Reversed operation

Not applicable.

8.2 Determination

The determination shall be in accordance with the test methods specified in EN 12194.

8.3 Performance requirement

On completion of each of the tests, using rough, forced and reversed operations, with the values given in Table 7:

— The following flaws in appearance shall not be evident: no permanent distortion of the curtain, fixing or locking devices, residual deflection of laths ≤ 5‰ L, where L is the length of the slat, in the case of external venetian blinds;

— and, for manual operation, the value of the operating effort shall be maintained within the limit of the initial class (see Table 6).

Certain products are not designed to withstand obstruction of the curtain in situations defined in a2, b1, c1 and c2 illustrated in Figure 3. They will not be subjected to the corresponding tests if the technical instructions of the manufacturer have a warning for the user of the risk of damage when the curtain is obstructed in these situations.

The manufacturer shall ensure his installation instructions emphasise that the operating procedures shall be provided to the end user.

For projecting shutters, if the product cannot be extended or retracted when in the projecting position, the manufacturer shall provide a warning.

18 Table 7 — Misuse forces values relative to the type of operation

Effort of misuse operation Misuse operation Force (N) Torque (Nm)

PB = 2 FC not applicable a rough Movement of curtain PF = 180 CF = 60 x R projection of curtain tilting the laths PF = 100 CF = 30 x R forced b c PI ≤ FC CI ≤ FC x R reversed FC = value of operating effort of the class obtained P = exerted misuse force

C = exerted misuse torque B= rough, F = forced, I = reversed R = maximum length of crank handle described in the technical instructions of the manufacturer with R ≤ 0,20m a Operation by gear is never rough. b If the operating mechanism is equipped with system which limits the force or the torque (see clause 12), values of PF and CF are those given by these systems. c For power operated operations, the effort to be applied is the one produced by the motor.

NOTE There are no performance classes.

9 Edge loading

9.1 General

Only wing shutters are concerned.

Behaviour of the shutter under the action of vertical effort Pel of 500 N, applied to the edge of the leaf.

9.2 Determination

The determination shall be in accordance with the test methods specified in EN 12194.

9.3 Performance requirement

After unloading, the remaining displacement of the extremity of the leaf shall be less than 5 mm/m of width of leaf.

10 Resistance of locking mechanism

10.1 General

When equipped with a specific locking mechanism (as bolt, sash-bolt, self closing device or espagnolette with latch locked with a key) holding the curtain fastened or locked in closed position the shutter in the fully extended position shall not be able to be opened from the exterior by intruders without tools.

The mechanisms which hold the curtain in the extended position are not considered as specific locking mechanisms except if they are stated as such by the manufacturer in his technical instructions.

10.2 Determination

Check whether locking mechanism can be disconnected or not from the outside and if not, exert an effort of 250 N, in the test conditions defined in the following flowchart.

10.3 Performance requirement

The shutter in the fully extended position shall not be able to be opened from the exterior by intruders without tools.

The shutter shall not allow an intruder to pass through (0,40 m x 0,40 m opening).

Performance not achieved Exert 250 N to allow entryof a hand Performance not achievedPerformance achievedCurtain with locking mechanism option yes no Locking mechanism dismountable no yes Accessible opening

≤ 0,40 m x 0,40 m yes no Not concerned Gap ≤ 12 mm

yes no Exert 250 N to allow entry Performance fulfilled

11 Mechanical endurance (repeated operating cycles)

11.1 General

Ability of the shutter to withstand a number of operating cycles corresponding to a given usage:

— the curtain: one cycle corresponds to a complete operation of curtain extension and retraction including the rest times; — the laths (external venetian blind, roller and wing shutters with tilting laths): one tilt cycle is defined as a complete movement of the pivoting mechanism, moving the laths from one extreme position to the other and then back again.

11.2 Determination

The determination shall be in accordance with the test methods specified in EN 14201.

11.3 Performance requirement

11.3.1 General

After carrying out the cycles relating to the appropriate class, the following requirements shall be fulfilled.

11.3.2 Manual operation

— The operating effort value shall be maintained within the limit of the initial class; — Wear of the constituent material of the laths of the curtain: the wall of the lath shall not be perforated as a result of abrasion; — Operating mechanisms shall not sustain significant damage.

11.3.3 Power operated products

* Variation of the speed under load

The ratio 100121×ΤΤ−Τ shall be less or equal to 20 %.

where :

T1 is the time taken for full retraction of the curtain, measured at the beginning of the endurance test, after five cycles of functioning

T2 is the time taken for full retraction of the curtain measured at the end of the endurance test

* Accuracy of the positions of the limit stops

The variation of the fully retracted and fully extended positions, measured in the two rotation directions and expressed as an angle in relation to the initial value, shall remain in the range of values given in Table 8:

Table 8 — Power operated products — Accuracy of the positions of the limit stops

Motorization type Limit stops drift

Class 1 Class 2 Tubular ± 15° ± 5° Square ±10° ± 3°

* Characteristics of the mechanical brake

— Stopping the movement of the curtain shall not lead to an angular displacement more than 20°.

— the displacement of the curtain, after applying an overload of 15 % of the weight of the curtain, shall not exceed 5 mm, the measurement from an intermediate position carried out after 12 h.

NOTE A mechanical brake is a brake applied mechanically by stored energy (spring force) until released with an external sustained electric power supply under the control of the operator or automatically.

* Grease and oil traces There shall be no visible traces of grease or oil.

* Wear of the constituent material of the laths of the curtain:

The wall of the lath shall not be perforated as a result of abrasion.

11.4 Classes of endurance

Table 9 gives the endurance cycles corresponding to the three endurance classes specified.

Table 9 – Classes of endurance

Number of cycles Class 1 Class 2 Class 3 Extension/retraction 3 000 7 000 10 000 Tilting 6 000 14 000 20 000

NOTE Class 2 can correspond to 10 years with 2 cycles per day.

12 Operation in frosty conditions

The technical instructions of the manufacturer shall state whether or not the product can be operated in frosty conditions (in case of formation of ice) and if not, the product shall have a warning: "The operation in frosty conditions may damage the shutter".

13 Impact resistance

13.1 General

Behaviour of the shutter under the action of hard body impact.

13.2 Determination

The determination shall be in accordance with the test methods specified in EN 13330.

13.3 Performance requirement

Under the action of the hard body D 0,5, steel ball of 0,5 kg and a drop Z of 0,45 m, the shutter shall not sustain deteriorations:

— which are detrimental to its correct operation ; for manual operation the operating effort shall be maintained within the limit of the initial class;

— which lead to unacceptable appearance defects (local indentations and cracks); the average diameter of indents shall not be greater than 20 mm.

22 14 Safety in use

14.1 General

The significant machine hazards dealt with are listed in annex C.

14.2 Protection against potentially harmful components

14.2.1 General

Contact between the user and the product and its parts shall not cause injury.

14.2.2 Determination

The requirements in 14.2.3 shall be fulfilled.

14.2.3 Safety requirement

Components likely to come into contact with passers-by and users, shall not present any sharp or projecting edges, likely to cause injury. Sharp and projecting edges of any moving parts of the shutter structure likely to be located at a height lower than 2,50 m above floor or any permanent access level, shall be rounded with a minimum radius of 0,5 mm.

14.3 Power operated shutters – Injurious contact in operation

14.3.1 General

Crushing hazards shall be eliminated or reduced.

14.3.2 Determination

The requirements in 14.3.3, shall be fulfilled, and where appropriate, in accordance with the test methods specified in EN 12045.

14.3.3 Safety requirement

The requirement is met if, at least, one of the following conditions is present:

a) In the crushing area, the transmitted force on the obstacle is less than 150 N and speed of extension of curtain is less than 0,2 m/s, and, in the case of wing shutter with two leaves or more, a minimum gap of 0,10 m is maintained between the leaves in the area of extension (see Figure 4).

Figure 4 — Gap between the panels at the end of extension

b) Shutters with accumulating or retractable laths conform to the accumulation condition as defined in EN 12045 and the average speed of extension of curtain in the last 0,40 m shall be less than 0,2 m/s.

c) The shutter has a hold-to-run control and the switch is incorporated in the product or installed in such a way that it allows the control in the direct view of the movement of the curtain. In that last case, it shall be mentioned in the installation instructions.

d) The crushing area is found at a distance Z more or equal to 2,50 m from the floor or from any other permanent access level.

e) The shutter is equipped with a safety device which:

— either prevents contact in the crushing area (guards)

— or limits the transmitted force (static operation force) to a value lower than 150 N and allows removal of the obstacle either by reversing the movement of the curtain or by stopping it. With the last solution, it shall be possible to lift up the curtain with a force less than 25 N.

In the case of roller shutter fitted to a roof window, the drive shall stop the movement of the curtain, and within

5 s, start to reverse automatically. During this period, the maximum operating force shall not exceed 250 N for more than 2 s, and the average force calculated over the period of 5 s, shall not exceed 150 N.

Guards designed to protect from the mobile elements of transmission shall be fixed in such a way that they can only be dismounted with the use of a tool.

Roller shutters with venting position shall not allow the introduction of a finger between slats. This condition is satisfied if a 5 mm diameter rod cannot be introduced.

14.4 Electric hazards

The electric drives shall conform to EN 60335-1 and EN 60335-2-97.

15 Hygiene, health and environment

15.1 General

Under the action of external environmental conditions, the materials and components used in the fabrication of the shutter, the design of the shutter itself, shall not encourage the development of micro-organisms.

15.2 Determination

There is no test relating to this requirement.

15.3 Performance requirement

Materials in products shall not release any dangerous substances in excess of the maximum levels specified in the European material Standards and any national regulations. For more information, consult the Construction web site on EUROPA (CREATE, accessed through http://europa.eu.int/comm/enterprise/construction/internal/dangsub/dangmain.htm).

16 Thermal resistance

16.1 General

The installation of a shutter, in the extended and closed position, in front of a window produces an additional thermal resistance ∆R expressed in m²K/W.

24 16.2 Determination

The determination shall be in accordance with the method of calculation as specified in EN ISO 10077-1.

16.3 Performance requirement

The allocation of the class of thermal resistance to a shutter is given as a function of air permeability as specified in EN 13125 and measured as specified in EN 12835 for tight shutters for which only an air permeability test can prove it (class 5 shutters).

17 Durability

17.1 General

Ability of constituent materials of the product to fulfil the following requirements during an economically reasonable service life: — colour fastness; — no degradation of aspect; — resistance to breakage; — resistance to corrosion; — dimensional stability.

NOTE Temperature effects are dealt with in annex A.

Table 10 states the requirements asked for the different materials used.

Table 10 — Durability requirements for materials

Requirements material colour aspect resistance corrosion dimensional stability Rigid plastic „ „ „

„ Metal … …

„

Wood … „

„ Only the requirements described by a „ are covered by this standard. The requirements with a … will be the subject of further developments.

Selected criteria are linked to the test methods described in 17.2, 17.3 and 17.4. They specify the minimum quality of characteristics to be fulfilled by the materials.

17.2 Rigid plastic materials

The minimum characteristics of suitability for use of unplasticized polyvinyl chloride (PVC-U) profiles shall be as specified in Table 11, in reference to EN 13245-1.

Group Properties Designation Comments 1 Material identification PVC-U

2 Intended use E

3 Material properties - laths for roller shutter - other profiles

080,29 077,23

Profile properties - e ≤ 1,5 mm - e > 1,5 mm

PM, 3, (23, 10) PM, 2, (-10, 10) e = thickness of the wall of the profile PM: linear mass stated by the profile manufacturer (-10, 10): impact resistance test with the striker of 1000 g carried out at -10°C and an impact energy of 10 J 5 Ageing properties -light colours -other colours

A4 or A6 or A8 N, 8, 20 or N, 12, 25 Or N, 16, 28

A: artificial exposure

N, 8, 20 : 2 years natural exposure with a mean of 4 GJ/m2 and a mean temperature of the warmest month of 20 °C EXAMPLE

20 °C is a climate type Berlin, 25 °C is a climate type Bandol (south of France), 28 °C is a climate type Sevilla). Light colours are defined by L* ≥ 82 ; -2, 5 ≤ a* ≤ 5 ; -5 ≤ b* ≤ 15.

17.3

Metals

Requirements and classes for resistance to corrosion shall be in accordance with EN 1670, except as follows:

The salt spray test according ISO 9227 shall be carried out: — either on the different profiles and components used in the shutter, not assembled; — or on a complete small scale sample of shutter (minimum size 7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...